Professional Documents

Culture Documents

Case Cx210b Cx290b Diagnostic

Case Cx210b Cx290b Diagnostic

Uploaded by

bruceCopyright:

Available Formats

You might also like

- New Holland b110 b115 en Service Manual 12n17446Document20 pagesNew Holland b110 b115 en Service Manual 12n17446james100% (60)

- Hanix h15b 2 h15b Plus 2 Service Manual Sept 09Document10 pagesHanix h15b 2 h15b Plus 2 Service Manual Sept 09vickie100% (50)

- New Holland Serie t6000 Operator ManualDocument20 pagesNew Holland Serie t6000 Operator Manualbruce100% (64)

- Case Crawler Excavator Cx130 Cx160 Operators ManualDocument20 pagesCase Crawler Excavator Cx130 Cx160 Operators Manualirma100% (55)

- JCB Backhoe Loader JCB 3cx 4cx 5cx Service ManualDocument22 pagesJCB Backhoe Loader JCB 3cx 4cx 5cx Service Manualianclements260586qfi100% (126)

- Sumitomo MaintenenceDocument317 pagesSumitomo MaintenenceMg Roy100% (39)

- Caterpillar Cx31 Transmission Shop ManualDocument2 pagesCaterpillar Cx31 Transmission Shop Manualnicholas98% (64)

- Komatsu Hydraulic Excavator Pc228 Us 3 Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc228 Us 3 Shop Manualhelen100% (57)

- JLG g10 43a Telehandler Parts ManualDocument20 pagesJLG g10 43a Telehandler Parts Manualmelvin98% (59)

- Hitachi Zx140w 3 Wheeled Excavatir Technical Manual Operational PrincipleDocument20 pagesHitachi Zx140w 3 Wheeled Excavatir Technical Manual Operational Principlenora100% (60)

- Komatsu pc25 1 pc30 7 pc40 7 pc45 1 Shop Manual Sebm020s0707Document20 pagesKomatsu pc25 1 pc30 7 pc40 7 pc45 1 Shop Manual Sebm020s0707jimmie100% (42)

- Komatsu Hydraulic Excavator Pc290lc 290nlc 7k Operation Maintenance ManualDocument20 pagesKomatsu Hydraulic Excavator Pc290lc 290nlc 7k Operation Maintenance Manualhattie100% (50)

- Manual NASH CL 200-2000 PDFDocument39 pagesManual NASH CL 200-2000 PDFGabriel VejarNo ratings yet

- 2954 2570 05 - XR (H, V) S 336-396 CD S3A APP - XR (H, V) S 700-830 CD6 T3 APP - ENDocument112 pages2954 2570 05 - XR (H, V) S 336-396 CD S3A APP - XR (H, V) S 700-830 CD6 T3 APP - ENMiguel Angel100% (1)

- Diagrama Hidraulico D9TDocument2 pagesDiagrama Hidraulico D9TCristian Valencia100% (1)

- Hitachi Ex200 210 5 Excavator Parts CatalogDocument20 pagesHitachi Ex200 210 5 Excavator Parts Catalogwilliam100% (61)

- Terex Gyro 4518 Parts ManualDocument10 pagesTerex Gyro 4518 Parts Manualwilliam100% (65)

- Doosan Wheel Loader Dl350 Shop Manual K1046897eDocument20 pagesDoosan Wheel Loader Dl350 Shop Manual K1046897echarlyn97% (58)

- Case Cx210 230 240 Crawler Excavator Shop ManualDocument20 pagesCase Cx210 230 240 Crawler Excavator Shop Manualrobert100% (55)

- Doosan Engine Dl08 Shop ManualDocument10 pagesDoosan Engine Dl08 Shop Manualrichard100% (58)

- Case Cx290 Crawler Excavator Shop ManualDocument20 pagesCase Cx290 Crawler Excavator Shop Manualkelly100% (55)

- Komatsu Pc25 1 Pc30 7 Pc40 7 Pc45 1 Operation Maintenance Manual Seam006600Document20 pagesKomatsu Pc25 1 Pc30 7 Pc40 7 Pc45 1 Operation Maintenance Manual Seam006600chad100% (54)

- Kubota Engine z402 B Aixam 1 Parts ManualDocument5 pagesKubota Engine z402 B Aixam 1 Parts Manualyvette100% (64)

- Case Crawler Excavator Cx145csr Operators ManualDocument20 pagesCase Crawler Excavator Cx145csr Operators Manuallucile100% (56)

- Case Hydraulic Excavators Poclan 988p C Shop ManualDocument20 pagesCase Hydraulic Excavators Poclan 988p C Shop Manualjanice100% (54)

- Kato Crane KR 45 051 77100041 KR 45 Ss500 Hydraulic Wiring DiagramDocument22 pagesKato Crane KR 45 051 77100041 KR 45 Ss500 Hydraulic Wiring Diagramrebeccathompsondds120800pkq100% (124)

- Komatsu Hydraulic Excavator Pc130 6 Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc130 6 Shop ManualRobert98% (60)

- Kobelco Sk220 V Sk220lc V Shop Manual S5lq0008e GBDocument20 pagesKobelco Sk220 V Sk220lc V Shop Manual S5lq0008e GBTimothy100% (58)

- Komatsu Wa470 6 Shop ManualDocument20 pagesKomatsu Wa470 6 Shop Manualbetty100% (66)

- Komatsu Pc200 7 Shop Manual 1Document20 pagesKomatsu Pc200 7 Shop Manual 1james100% (55)

- Komatsu Pw150es 6k Operation Maintenance ManualDocument20 pagesKomatsu Pw150es 6k Operation Maintenance ManualDorcas100% (54)

- Hitachi Zaxis Zx110 Equipment Components PartsDocument20 pagesHitachi Zaxis Zx110 Equipment Components Partsamanda100% (51)

- Kobelco Crawler Crane Ck850 2f Cke700 1f Cke800 1f Shop Manual S5gg00005ze04Document20 pagesKobelco Crawler Crane Ck850 2f Cke700 1f Cke800 1f Shop Manual S5gg00005ze04louis100% (49)

- Hitachi Zaxis 140w 170w 190w 210w 220w 3 Electrical Circuit Diagram 1Document2 pagesHitachi Zaxis 140w 170w 190w 210w 220w 3 Electrical Circuit Diagram 1gertrude100% (45)

- Doosan Wheel Loader Dk250 3 Shop ManualDocument20 pagesDoosan Wheel Loader Dk250 3 Shop Manualdonald100% (53)

- Tadano Faun Tf90g 4 Spare Parts ListDocument20 pagesTadano Faun Tf90g 4 Spare Parts Listwilliam100% (54)

- Case Cx240b Crawler Excavator Shop ManualDocument20 pagesCase Cx240b Crawler Excavator Shop Manualphyliss100% (55)

- Case Crawler Excavator 9050b Operators ManualDocument10 pagesCase Crawler Excavator 9050b Operators Manualpatrice100% (59)

- Komatsu Hydraulic Excavator Pc850 8e0 Pc850se Shop ManualDocument10 pagesKomatsu Hydraulic Excavator Pc850 8e0 Pc850se Shop Manualelsa100% (49)

- Komatsu Hydraulic Excavator Pc200lc 210lc 220lc 250lc 6le Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc200lc 210lc 220lc 250lc 6le Shop Manualdavid98% (60)

- Doosan Dx190w Shop ManualDocument20 pagesDoosan Dx190w Shop Manualcarol98% (60)

- Hitachi Ex120 130 5 Excavator Parts CatalogDocument20 pagesHitachi Ex120 130 5 Excavator Parts CatalogStephen100% (58)

- John Deree 750c 850c Crawler Dozer Operator ManualDocument20 pagesJohn Deree 750c 850c Crawler Dozer Operator Manualmanuel100% (53)

- Komatsu Pc200 5 Shop ManualDocument20 pagesKomatsu Pc200 5 Shop Manualeric100% (63)

- Volvo l120f SchematicsDocument10 pagesVolvo l120f Schematicsclyde100% (65)

- Hitachi Zaxis 200 225us 225usr 240 270 3 Technical Manual TroubleshootingDocument20 pagesHitachi Zaxis 200 225us 225usr 240 270 3 Technical Manual Troubleshootingleon100% (50)

- Hitachi Zx200 Workshop ManualDocument20 pagesHitachi Zx200 Workshop Manualjoseph100% (63)

- Doosan Wheel Loader Dl160 Shop Manual K1040197eDocument20 pagesDoosan Wheel Loader Dl160 Shop Manual K1040197emary98% (54)

- Komatsu Hydraulic Excavator Pc290lc 290nlc 6k Operation Maintenance ManualDocument20 pagesKomatsu Hydraulic Excavator Pc290lc 290nlc 6k Operation Maintenance Manualnancy100% (57)

- Komatsu 95 3 Series Engine MotorDocument20 pagesKomatsu 95 3 Series Engine Motorjohnathan100% (61)

- Hino Truck 2005 2010 Quick Reference GuideDocument7 pagesHino Truck 2005 2010 Quick Reference Guideashley100% (52)

- Komatsu Crane Lw250 5 Shop Manual Sebm008905Document20 pagesKomatsu Crane Lw250 5 Shop Manual Sebm008905eddie100% (48)

- Doosan Solar 225lc V Shop ManualDocument20 pagesDoosan Solar 225lc V Shop ManualJeffrey100% (60)

- Doosan Wheel Loader Dl400 Shop Manual K1010635eDocument20 pagesDoosan Wheel Loader Dl400 Shop Manual K1010635erhonda100% (54)

- Caterpillar 246c 256c 262c 272c Skid Steer Loader Electrical SystemDocument2 pagesCaterpillar 246c 256c 262c 272c Skid Steer Loader Electrical Systemedward100% (54)

- Ammann Av12 2 Av16 2 Av20 2 Av16 2k InstructionDocument5 pagesAmmann Av12 2 Av16 2 Av20 2 Av16 2k InstructionBo98% (59)

- Hitachi Zaxis 200 240 270 3 Class Training Text Operational PrincipleDocument20 pagesHitachi Zaxis 200 240 270 3 Class Training Text Operational Principledavid100% (51)

- Padlede Lm100xiDocument7 pagesPadlede Lm100xig8rw47vdggNo ratings yet

- Technical Specification: Operating Manual Universal Temperature Controller UTC-1131,2131 & 4131Document4 pagesTechnical Specification: Operating Manual Universal Temperature Controller UTC-1131,2131 & 4131VIRALNo ratings yet

- Portable Rife Crane UnitDocument10 pagesPortable Rife Crane Unitmuhammadnaggar100% (1)

- Rohan Prehab TemplateDocument5 pagesRohan Prehab TemplateDeepak PartekiNo ratings yet

- SP 01 - SmartTorquePump - 2018 09 03Document4 pagesSP 01 - SmartTorquePump - 2018 09 03arpv8081No ratings yet

- T-Touch Ii User's Manual: AcknowledgementsDocument12 pagesT-Touch Ii User's Manual: AcknowledgementshafiziNo ratings yet

- 2258-6 Flow Detection ManualDocument8 pages2258-6 Flow Detection ManualGustavo Gonzalez ToledoNo ratings yet

- VDRLDocument4 pagesVDRLfarazhussainkhanNo ratings yet

- Pressure Reducing Function - Series K1 10: HYDROBLOC SystemDocument2 pagesPressure Reducing Function - Series K1 10: HYDROBLOC SystemDanny Guarderas RNo ratings yet

- Deluge Valve Accessroies TdsDocument6 pagesDeluge Valve Accessroies TdsHarshit GautamNo ratings yet

- Silverson Brochure US 2022Document60 pagesSilverson Brochure US 2022kellyteamoNo ratings yet

- Specifications of Hunter PGP-ADJ SprinklerDocument20 pagesSpecifications of Hunter PGP-ADJ Sprinklerhassan4ur5759No ratings yet

- ML7999A Universal Parallel-Positioning Actuator: FeaturesDocument8 pagesML7999A Universal Parallel-Positioning Actuator: Featuresfrank torresNo ratings yet

- I08-028-000J-TS092 - 0 V-Ball Control ValvesDocument7 pagesI08-028-000J-TS092 - 0 V-Ball Control ValvesCristian RománNo ratings yet

- Aircon Technician Sample ContractDocument2 pagesAircon Technician Sample ContractBoy Ice PickNo ratings yet

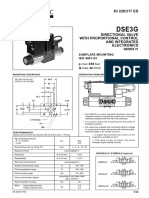

- Dse3G: Series 31 Subplate Mounting ISO 4401-03 P MaxDocument10 pagesDse3G: Series 31 Subplate Mounting ISO 4401-03 P MaxIbrahim HassaanNo ratings yet

- JCB PresentationDocument22 pagesJCB Presentationsatyajeet750% (4)

- GEM Series - Fire Fighting Booster Sets in Egypt, Technical Catalog Part 1Document114 pagesGEM Series - Fire Fighting Booster Sets in Egypt, Technical Catalog Part 1Rheoserve Industrial SolutionsNo ratings yet

- Mazda VBDocument4 pagesMazda VBrigogarzaNo ratings yet

- 1903 9349 95 - P20Document46 pages1903 9349 95 - P20Er Ravinder SinghNo ratings yet

- Catálogo Pead PDFDocument96 pagesCatálogo Pead PDFElieuton MayerNo ratings yet

- Excess Flow Valves - General InformationDocument7 pagesExcess Flow Valves - General Informationtranhonghakd5533No ratings yet

- Finished Plan: CloseDocument89 pagesFinished Plan: CloseHuy HùynhNo ratings yet

- ValvesDocument138 pagesValvesRODOLFONo ratings yet

- Guide To Design and Selection of Check Valves PDFDocument18 pagesGuide To Design and Selection of Check Valves PDFNareshNo ratings yet

- Transient - Chapter 10 - 2E - Split Level Control and Setting LimitDocument12 pagesTransient - Chapter 10 - 2E - Split Level Control and Setting LimitQuynh NguyenNo ratings yet

- Paw Friwa PDFDocument2 pagesPaw Friwa PDFGoheimNo ratings yet

- 34 Samss 611Document8 pages34 Samss 611shrikantbelekarNo ratings yet

- GC GOW MAC Series-5900 - 1019 ManualDocument38 pagesGC GOW MAC Series-5900 - 1019 ManualbashirNo ratings yet

- OxyChem Caustic HandbookDocument64 pagesOxyChem Caustic HandbookAnonymous Kr13NEBNo ratings yet

- BDF 35S Freefall Davit Manual (RV.1)Document46 pagesBDF 35S Freefall Davit Manual (RV.1)Cleverson Schmidt100% (4)

- Manage Your Steam With Greater Safety, Reliability and EfficiencyDocument28 pagesManage Your Steam With Greater Safety, Reliability and EfficiencyMohammad FouladiNo ratings yet

- Nami Tech Co.,Ltd.: Provision Ref. PlantDocument9 pagesNami Tech Co.,Ltd.: Provision Ref. PlantTamNo ratings yet

Case Cx210b Cx290b Diagnostic

Case Cx210b Cx290b Diagnostic

Uploaded by

bruceOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Cx210b Cx290b Diagnostic

Case Cx210b Cx290b Diagnostic

Uploaded by

bruceCopyright:

Available Formats

Case Cx210b Cx290b Diagnostic

CX210B

Full download: to CX290B

http://manualplace.com/download/case-cx210b-cx290b-diagnostic/ 4 - DIAGNOSTIC

SERVICE SUPPORT

KEY ON

antithief turned ON

antithief turned OFF

Enter

model setting is incompleted

model setting is completed

MODEL SETTING press 5 times for one touch idle SW

+

all reset 3 sec.

+

10 sec.

completed model sett

1 sec.

past 3sec

+ press down braker SW or crusher SW 3 sec.

flow volume reset

Press a second during displays

CASE logo +

10 sec.

1 sec. 3 sec.

+ +

3 sec.

+

SERVICE

ENGINE SERVICE

Desplays Engine S/N, Q and QR.

DIAG RESET

10 sec.

or

HR RESET

+

10 sec.

or

CFG RESET

or

+

10 sec.

Escaping by

KEY OFF

Monthyon training centre 02/2007 4-1

This is the cut pages sample. Download all 51 page(s) at: ManualPlace.com

4 - DIAGNOSTIC CX210B to CX290B

a) Operation for shifting to service support screen

1. If both the travel high-speed switch and the horn volume select switch on the switch panel are held

down for 3 seconds, the display switches to the service support screen.

2. If both the high-speed travel switch and the horn volume select switch on the switch panel are held

down again for 1 second, the display returns to the normal screen.

Normal screen Service support screen

Hold down for CHK MAI N 1 P1 024.6 MPa

3 seconds Eng 1800 min -1 P2 013.7 MPa

Power 0350 mA N1 02.56 MPa

Hold down for Flow 0120 mA N2 00.93 MPa

1 second

b) Service support screen switching operation

B C

1 2 3

D

CHK MAI N 1 P1 000.0 MPa

Eng 0000 min-1 P2 000.0 MPa

Power 0000 mA N1 00.00 MPa

Flow 0000 mA N2 00.00 MPa

A Mode select switch 1 Mode (switching with high speed travel switch A)

B Section select switch 2 Section (switching with horn volume select switch B)

C Page (-) 3 Page (switching: forward with light switch D and back with washer

D Page (+) switch C)

[Mode] [Section] [Page]

CHK MAIN (1 - 10)

MNT (1 - 3)

H/W-A (1 - 8)

H/W-B (1 - 8)

H/W-M (1)

DIAG ALL (1 - 16)

HR MAIN (1 - 14)

ENG (1 - 12)

CFG MAIN (1 - 3)

CAL MAIN (1)

4-2 Monthyon training centre 02/2007

CX210B to CX290B 4 - DIAGNOSTIC

Screen Display List

1. CHK (status display) Screen List

In CHK mode, in addition to the machine status (milli-amp, oil pressures, temperatures, etc.), it is possible

to check sensor and switch input/output states, as well as the angle, load ratio and work radius, etc. at the

applied machine (liftcrane application machine, lifting magnet machine).

Section

Select switch

Page (-)

Page (+)

1 Section 2 Page

NOTE: From the CHK mode screen, if the wiper switch and the light switch are held down for 3

seconds, the display shifts to the model selection screen.

A) MAIN

1) Engine and pump

Eng : Engine speed

CHK MAI N 1 P1 000.0 MPa Power Actual milli-amp for horsepower control

:

proportional valve

Eng 0000 min -1 P2 000.0 MPa

Flow Actual milli-amp for flow control

:

Power 0000 mA N1 00.00 MPa proportional valve

Flow 0000 N2 00.00 P1 : Pump1 Discharge pressure

mA MPa

P2 : Pump2 Discharge pressure

N1 : Pump1 Negative control pressure

N2 : Pump2 Negative control pressure

2) Temperature and pressure

Coolnt : Radiator coolant temperature

CHK MA I N 2 Baro 0000 h Pa HydOil : Hydraulic oil temperature

Coolnt 0000 EngOil 0000 FuelT : Fuel temperature

˚C k Pa

Baro : Barometric pressure

HydOil 0000 ˚C BstT 0000 ˚C EngOil : Engine oil pressure

FuelT 0000 ˚C Air 0000 ˚C BstT : Boost temperature

Air : Suction air temperature

3) Load and boost

Eng : Engine speed

CHK MA I N 3 P1 000.0 MPa Load : Load ratio

Power Actual milli-amp for horsepower control

Eng 0000 min-1 P2 000.0 MPa :

proportional valve

Load 0000 % BstT 0000 ˚C P1 : Pump 1 Discharge pressure

P2 : Pump 2 Discharge pressure

Power 0000 mA BstP 0000 kPa

BstT : Boost temperature

BstP : Boost pressure

Monthyon training centre 02/2007 4-3

4 - DIAGNOSTIC CX210B to CX290B

4) Load and milli-amp for horsepower control proportional valve

Eng : Engine speed

CHK MAI N 4 P1 000.0 MPa Load : Load ratio

Eng 0000 min -1 P2 000.0 Power Actual milli-amp for horsepower control

MPa :

proportional valve

Load 0000 % N1 00.00 MPa P1 : Pump 1 Discharge pressure

Power 0000 mA N2 00.00 MPa P2 : Pump 2 Discharge pressure

N1 : Pump 1 Negative control pressure

N2 : Pump 2 Negative control pressure

5) Target and actual milli-amp for horsepower control proportional valve

Eng : Engine speed

CHK MAIN 5 -4- Load : Load ratio

Power Actual milli-amp for horsepower control

Eng 0000 min-1 tEng 0000 min -1 :

proportional valve

Load 0000 % ThVol 0000 % -4- : *

Power 0000 tPower 0000 tEng : Target engine speed

mA mA

ThVol : Throtle volume degree of opening

tPower Target milli-amp for horsepower control

:

proportional valve

6) Target and actual milli-amp for flow control proportional valve

Eng : Engine speed

CHK MAIN 6 P1 000.0 MPa Power Actual milli-amp for horsepower control

:

Eng 0000 min -1 N1 00.00 MPa proportional valve

Flow Actual milli-amp for flow control

Power 0000 mA Swg 00.00 MPa :

proportional valve

Flow 0000 mA tFlow 0000 mA P1 : Pump 1 Discharge pressure

N1 : Pump 1 Negative control pressure

Swg : Swing pilot pressure

tFlow Target milli-amp for flow control

:

proportional valve

7) Target and actual milli-amp for hydraulic fan proportional valve

Eng : Engine speed

CHK MAIN 7 HydOil 0000 ˚C Coolnt : Radiator coolant temperature

-1 Fan : Actual milli-amp for hydraulic fan

Eng 0000 min FuelT 0000 ˚C proportional valve

Coolnt 0000 ˚C BstT 000 ˚C HydOil : Hydraulic oil temperature

FuelT : Fuel temperature

Fan 0000 mA tFan 000 mA

BstT : Boost temperature

tFan : Target milli-amp for hydraulic fan

proportional valve

8) Pilot pressure

P1 : Pump1 Discharge pressure

C HK MAI N 8 Upr 00.00 MPa P2 : Pump2 Discharge pressure

Cyl(B) : Boom bottom pressure

P1 000.0 MPa Swg 00.00 MPa

Upr : Upper pilot pressure

P2 000.0 MPa Trv 00.00 MPa Swg : Swing pilot pressure

Cyl(B) 000.0 MPa AmCls 00.00 MPa Trv : Travel pilot pressure

AmCls : Arm-in pilot pressure

4-4 Monthyon training centre 02/2007

Case Cx210b Cx290b Diagnostic

CX210B

Full download: to CX290B

http://manualplace.com/download/case-cx210b-cx290b-diagnostic/ 4 - DIAGNOSTIC

9) Hydraulic circuits; Input/ouput and pressure

P1 : Pump1 Discharge pressure

CHK MA I N 9 P1 000.0 MPa P2 : Pump2 Discharge pressure

In P2 000.0 N1 : Pump1 Negative control pressure

MPa

N2 : Pump2 Negative control pressure

Out1 N1 00.00 MPa

Out2 N2 00.00 MPa

Hydraulic circuit input /output state ( = OFF, = ON )

In Out1 Out2

1 5 9

2 6 10

3 7 11

4 8 12

1 Pressure sensor; Arm in 7 Solenoid; Boost

2 Pressure sensor; Travel 8 Solenoid; Swing brake

3 Pressure sensor; Swing 9 Relay; Travel alarm

4 Pressure sensor; Upper 10 Solenoid; Fan reverse (large machine only)

5 Solenoid; Free swing / beacon 11 Solenoid; Option line switchover

6 Solenoid; Travel high-speed switchover 12 Solenoid; Power save

10)Electrical circuits; Input/ouput

Eng : Engine speed

CHK MA I N 10 Eng 0000 min -1 Coolnt : Radiator coolant temperature

Batt : Battery voltage

In Coolnt 0000 ˚c

FuelLv : Fuel sensor

Out1 Batt 0000 V

Out2 FuelLv 0000 %

Electrical circuit input /output state ( = OFF, = ON )

In Out1 Out2

*

1

*

4

*7

2 5 8

3 6 9

1 Switch; Anti-theft protection 6 Glow signal

2 Battery charge 7 Engine stop due to trouble

3 Switch; Key 8 Low idle restriction due to trouble

4 A/C coolant temprerature transmission Restriction on milli-amp for horsepower control

9

5 Relay; Feed pump automatic stop proportional valve due to trouble

Monthyon training centre 02/2007 4-5

This is the cut pages sample. Download all 51 page(s) at: ManualPlace.com

You might also like

- New Holland b110 b115 en Service Manual 12n17446Document20 pagesNew Holland b110 b115 en Service Manual 12n17446james100% (60)

- Hanix h15b 2 h15b Plus 2 Service Manual Sept 09Document10 pagesHanix h15b 2 h15b Plus 2 Service Manual Sept 09vickie100% (50)

- New Holland Serie t6000 Operator ManualDocument20 pagesNew Holland Serie t6000 Operator Manualbruce100% (64)

- Case Crawler Excavator Cx130 Cx160 Operators ManualDocument20 pagesCase Crawler Excavator Cx130 Cx160 Operators Manualirma100% (55)

- JCB Backhoe Loader JCB 3cx 4cx 5cx Service ManualDocument22 pagesJCB Backhoe Loader JCB 3cx 4cx 5cx Service Manualianclements260586qfi100% (126)

- Sumitomo MaintenenceDocument317 pagesSumitomo MaintenenceMg Roy100% (39)

- Caterpillar Cx31 Transmission Shop ManualDocument2 pagesCaterpillar Cx31 Transmission Shop Manualnicholas98% (64)

- Komatsu Hydraulic Excavator Pc228 Us 3 Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc228 Us 3 Shop Manualhelen100% (57)

- JLG g10 43a Telehandler Parts ManualDocument20 pagesJLG g10 43a Telehandler Parts Manualmelvin98% (59)

- Hitachi Zx140w 3 Wheeled Excavatir Technical Manual Operational PrincipleDocument20 pagesHitachi Zx140w 3 Wheeled Excavatir Technical Manual Operational Principlenora100% (60)

- Komatsu pc25 1 pc30 7 pc40 7 pc45 1 Shop Manual Sebm020s0707Document20 pagesKomatsu pc25 1 pc30 7 pc40 7 pc45 1 Shop Manual Sebm020s0707jimmie100% (42)

- Komatsu Hydraulic Excavator Pc290lc 290nlc 7k Operation Maintenance ManualDocument20 pagesKomatsu Hydraulic Excavator Pc290lc 290nlc 7k Operation Maintenance Manualhattie100% (50)

- Manual NASH CL 200-2000 PDFDocument39 pagesManual NASH CL 200-2000 PDFGabriel VejarNo ratings yet

- 2954 2570 05 - XR (H, V) S 336-396 CD S3A APP - XR (H, V) S 700-830 CD6 T3 APP - ENDocument112 pages2954 2570 05 - XR (H, V) S 336-396 CD S3A APP - XR (H, V) S 700-830 CD6 T3 APP - ENMiguel Angel100% (1)

- Diagrama Hidraulico D9TDocument2 pagesDiagrama Hidraulico D9TCristian Valencia100% (1)

- Hitachi Ex200 210 5 Excavator Parts CatalogDocument20 pagesHitachi Ex200 210 5 Excavator Parts Catalogwilliam100% (61)

- Terex Gyro 4518 Parts ManualDocument10 pagesTerex Gyro 4518 Parts Manualwilliam100% (65)

- Doosan Wheel Loader Dl350 Shop Manual K1046897eDocument20 pagesDoosan Wheel Loader Dl350 Shop Manual K1046897echarlyn97% (58)

- Case Cx210 230 240 Crawler Excavator Shop ManualDocument20 pagesCase Cx210 230 240 Crawler Excavator Shop Manualrobert100% (55)

- Doosan Engine Dl08 Shop ManualDocument10 pagesDoosan Engine Dl08 Shop Manualrichard100% (58)

- Case Cx290 Crawler Excavator Shop ManualDocument20 pagesCase Cx290 Crawler Excavator Shop Manualkelly100% (55)

- Komatsu Pc25 1 Pc30 7 Pc40 7 Pc45 1 Operation Maintenance Manual Seam006600Document20 pagesKomatsu Pc25 1 Pc30 7 Pc40 7 Pc45 1 Operation Maintenance Manual Seam006600chad100% (54)

- Kubota Engine z402 B Aixam 1 Parts ManualDocument5 pagesKubota Engine z402 B Aixam 1 Parts Manualyvette100% (64)

- Case Crawler Excavator Cx145csr Operators ManualDocument20 pagesCase Crawler Excavator Cx145csr Operators Manuallucile100% (56)

- Case Hydraulic Excavators Poclan 988p C Shop ManualDocument20 pagesCase Hydraulic Excavators Poclan 988p C Shop Manualjanice100% (54)

- Kato Crane KR 45 051 77100041 KR 45 Ss500 Hydraulic Wiring DiagramDocument22 pagesKato Crane KR 45 051 77100041 KR 45 Ss500 Hydraulic Wiring Diagramrebeccathompsondds120800pkq100% (124)

- Komatsu Hydraulic Excavator Pc130 6 Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc130 6 Shop ManualRobert98% (60)

- Kobelco Sk220 V Sk220lc V Shop Manual S5lq0008e GBDocument20 pagesKobelco Sk220 V Sk220lc V Shop Manual S5lq0008e GBTimothy100% (58)

- Komatsu Wa470 6 Shop ManualDocument20 pagesKomatsu Wa470 6 Shop Manualbetty100% (66)

- Komatsu Pc200 7 Shop Manual 1Document20 pagesKomatsu Pc200 7 Shop Manual 1james100% (55)

- Komatsu Pw150es 6k Operation Maintenance ManualDocument20 pagesKomatsu Pw150es 6k Operation Maintenance ManualDorcas100% (54)

- Hitachi Zaxis Zx110 Equipment Components PartsDocument20 pagesHitachi Zaxis Zx110 Equipment Components Partsamanda100% (51)

- Kobelco Crawler Crane Ck850 2f Cke700 1f Cke800 1f Shop Manual S5gg00005ze04Document20 pagesKobelco Crawler Crane Ck850 2f Cke700 1f Cke800 1f Shop Manual S5gg00005ze04louis100% (49)

- Hitachi Zaxis 140w 170w 190w 210w 220w 3 Electrical Circuit Diagram 1Document2 pagesHitachi Zaxis 140w 170w 190w 210w 220w 3 Electrical Circuit Diagram 1gertrude100% (45)

- Doosan Wheel Loader Dk250 3 Shop ManualDocument20 pagesDoosan Wheel Loader Dk250 3 Shop Manualdonald100% (53)

- Tadano Faun Tf90g 4 Spare Parts ListDocument20 pagesTadano Faun Tf90g 4 Spare Parts Listwilliam100% (54)

- Case Cx240b Crawler Excavator Shop ManualDocument20 pagesCase Cx240b Crawler Excavator Shop Manualphyliss100% (55)

- Case Crawler Excavator 9050b Operators ManualDocument10 pagesCase Crawler Excavator 9050b Operators Manualpatrice100% (59)

- Komatsu Hydraulic Excavator Pc850 8e0 Pc850se Shop ManualDocument10 pagesKomatsu Hydraulic Excavator Pc850 8e0 Pc850se Shop Manualelsa100% (49)

- Komatsu Hydraulic Excavator Pc200lc 210lc 220lc 250lc 6le Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc200lc 210lc 220lc 250lc 6le Shop Manualdavid98% (60)

- Doosan Dx190w Shop ManualDocument20 pagesDoosan Dx190w Shop Manualcarol98% (60)

- Hitachi Ex120 130 5 Excavator Parts CatalogDocument20 pagesHitachi Ex120 130 5 Excavator Parts CatalogStephen100% (58)

- John Deree 750c 850c Crawler Dozer Operator ManualDocument20 pagesJohn Deree 750c 850c Crawler Dozer Operator Manualmanuel100% (53)

- Komatsu Pc200 5 Shop ManualDocument20 pagesKomatsu Pc200 5 Shop Manualeric100% (63)

- Volvo l120f SchematicsDocument10 pagesVolvo l120f Schematicsclyde100% (65)

- Hitachi Zaxis 200 225us 225usr 240 270 3 Technical Manual TroubleshootingDocument20 pagesHitachi Zaxis 200 225us 225usr 240 270 3 Technical Manual Troubleshootingleon100% (50)

- Hitachi Zx200 Workshop ManualDocument20 pagesHitachi Zx200 Workshop Manualjoseph100% (63)

- Doosan Wheel Loader Dl160 Shop Manual K1040197eDocument20 pagesDoosan Wheel Loader Dl160 Shop Manual K1040197emary98% (54)

- Komatsu Hydraulic Excavator Pc290lc 290nlc 6k Operation Maintenance ManualDocument20 pagesKomatsu Hydraulic Excavator Pc290lc 290nlc 6k Operation Maintenance Manualnancy100% (57)

- Komatsu 95 3 Series Engine MotorDocument20 pagesKomatsu 95 3 Series Engine Motorjohnathan100% (61)

- Hino Truck 2005 2010 Quick Reference GuideDocument7 pagesHino Truck 2005 2010 Quick Reference Guideashley100% (52)

- Komatsu Crane Lw250 5 Shop Manual Sebm008905Document20 pagesKomatsu Crane Lw250 5 Shop Manual Sebm008905eddie100% (48)

- Doosan Solar 225lc V Shop ManualDocument20 pagesDoosan Solar 225lc V Shop ManualJeffrey100% (60)

- Doosan Wheel Loader Dl400 Shop Manual K1010635eDocument20 pagesDoosan Wheel Loader Dl400 Shop Manual K1010635erhonda100% (54)

- Caterpillar 246c 256c 262c 272c Skid Steer Loader Electrical SystemDocument2 pagesCaterpillar 246c 256c 262c 272c Skid Steer Loader Electrical Systemedward100% (54)

- Ammann Av12 2 Av16 2 Av20 2 Av16 2k InstructionDocument5 pagesAmmann Av12 2 Av16 2 Av20 2 Av16 2k InstructionBo98% (59)

- Hitachi Zaxis 200 240 270 3 Class Training Text Operational PrincipleDocument20 pagesHitachi Zaxis 200 240 270 3 Class Training Text Operational Principledavid100% (51)

- Padlede Lm100xiDocument7 pagesPadlede Lm100xig8rw47vdggNo ratings yet

- Technical Specification: Operating Manual Universal Temperature Controller UTC-1131,2131 & 4131Document4 pagesTechnical Specification: Operating Manual Universal Temperature Controller UTC-1131,2131 & 4131VIRALNo ratings yet

- Portable Rife Crane UnitDocument10 pagesPortable Rife Crane Unitmuhammadnaggar100% (1)

- Rohan Prehab TemplateDocument5 pagesRohan Prehab TemplateDeepak PartekiNo ratings yet

- SP 01 - SmartTorquePump - 2018 09 03Document4 pagesSP 01 - SmartTorquePump - 2018 09 03arpv8081No ratings yet

- T-Touch Ii User's Manual: AcknowledgementsDocument12 pagesT-Touch Ii User's Manual: AcknowledgementshafiziNo ratings yet

- 2258-6 Flow Detection ManualDocument8 pages2258-6 Flow Detection ManualGustavo Gonzalez ToledoNo ratings yet

- VDRLDocument4 pagesVDRLfarazhussainkhanNo ratings yet

- Pressure Reducing Function - Series K1 10: HYDROBLOC SystemDocument2 pagesPressure Reducing Function - Series K1 10: HYDROBLOC SystemDanny Guarderas RNo ratings yet

- Deluge Valve Accessroies TdsDocument6 pagesDeluge Valve Accessroies TdsHarshit GautamNo ratings yet

- Silverson Brochure US 2022Document60 pagesSilverson Brochure US 2022kellyteamoNo ratings yet

- Specifications of Hunter PGP-ADJ SprinklerDocument20 pagesSpecifications of Hunter PGP-ADJ Sprinklerhassan4ur5759No ratings yet

- ML7999A Universal Parallel-Positioning Actuator: FeaturesDocument8 pagesML7999A Universal Parallel-Positioning Actuator: Featuresfrank torresNo ratings yet

- I08-028-000J-TS092 - 0 V-Ball Control ValvesDocument7 pagesI08-028-000J-TS092 - 0 V-Ball Control ValvesCristian RománNo ratings yet

- Aircon Technician Sample ContractDocument2 pagesAircon Technician Sample ContractBoy Ice PickNo ratings yet

- Dse3G: Series 31 Subplate Mounting ISO 4401-03 P MaxDocument10 pagesDse3G: Series 31 Subplate Mounting ISO 4401-03 P MaxIbrahim HassaanNo ratings yet

- JCB PresentationDocument22 pagesJCB Presentationsatyajeet750% (4)

- GEM Series - Fire Fighting Booster Sets in Egypt, Technical Catalog Part 1Document114 pagesGEM Series - Fire Fighting Booster Sets in Egypt, Technical Catalog Part 1Rheoserve Industrial SolutionsNo ratings yet

- Mazda VBDocument4 pagesMazda VBrigogarzaNo ratings yet

- 1903 9349 95 - P20Document46 pages1903 9349 95 - P20Er Ravinder SinghNo ratings yet

- Catálogo Pead PDFDocument96 pagesCatálogo Pead PDFElieuton MayerNo ratings yet

- Excess Flow Valves - General InformationDocument7 pagesExcess Flow Valves - General Informationtranhonghakd5533No ratings yet

- Finished Plan: CloseDocument89 pagesFinished Plan: CloseHuy HùynhNo ratings yet

- ValvesDocument138 pagesValvesRODOLFONo ratings yet

- Guide To Design and Selection of Check Valves PDFDocument18 pagesGuide To Design and Selection of Check Valves PDFNareshNo ratings yet

- Transient - Chapter 10 - 2E - Split Level Control and Setting LimitDocument12 pagesTransient - Chapter 10 - 2E - Split Level Control and Setting LimitQuynh NguyenNo ratings yet

- Paw Friwa PDFDocument2 pagesPaw Friwa PDFGoheimNo ratings yet

- 34 Samss 611Document8 pages34 Samss 611shrikantbelekarNo ratings yet

- GC GOW MAC Series-5900 - 1019 ManualDocument38 pagesGC GOW MAC Series-5900 - 1019 ManualbashirNo ratings yet

- OxyChem Caustic HandbookDocument64 pagesOxyChem Caustic HandbookAnonymous Kr13NEBNo ratings yet

- BDF 35S Freefall Davit Manual (RV.1)Document46 pagesBDF 35S Freefall Davit Manual (RV.1)Cleverson Schmidt100% (4)

- Manage Your Steam With Greater Safety, Reliability and EfficiencyDocument28 pagesManage Your Steam With Greater Safety, Reliability and EfficiencyMohammad FouladiNo ratings yet

- Nami Tech Co.,Ltd.: Provision Ref. PlantDocument9 pagesNami Tech Co.,Ltd.: Provision Ref. PlantTamNo ratings yet