Professional Documents

Culture Documents

CRJ-00 and 00-Fire Protection

CRJ-00 and 00-Fire Protection

Uploaded by

Bwana SrbinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CRJ-00 and 00-Fire Protection

CRJ-00 and 00-Fire Protection

Uploaded by

Bwana SrbinCopyright:

Available Formats

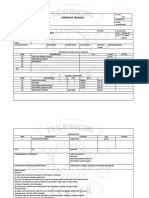

Vol.

1 10--00--1

FIRE PROTECTION

Table of Contents REV 3, May 03/05

CHAPTER 10 --- FIRE PROTECTION

Page

TABLE OF CONTENTS 10--00--1

Table of Contents 10--00--1

INTRODUCTION 10--10--1

Introduction 10--10--1

FIRE DETECTION AND EXTINGUISHING (FIDEEX) 10--20--1

Fire Detection and Extinguishing (FIDEEX) 10--20--1

Engine 10--20--1

APU 10--20--7

Cargo Compartment 10--20--12

Testing 10--20--15

System Circuit Breakers 10--20--17

LAVATORY 10--30--1

Lavatory Fire Protection 10--30--1

Detection 10--30--1

Extinguishing 10--30--3

System Circuit Breakers 10--30--4

MAIN LANDING GEAR OVERHEAT DETECTION 10--40--1

Main Landing Gear Overheat Detection 10--40--1

System Circuit Breakers 10--40--4

LIST OF ILLUSTRATIONS

INTRODUCTION

Figure 10--10--1 FIDEEX System Block Diagram 10--10--2

FIRE DETECTION AND EXTINGUISHING (FIDEEX)

Figure 10--20--1 Engine Fire Detection Block Schematic 10--20--2

Figure 10--20--2 Engine Fire Push Buttons 10--20--3

Figure 10--20--3 Engine Fire Extinguishing -- Schematic 10--20--4

Figure 10--20--4 Engine Fire EICAS Indications 10--20--5

Figure 10--20--5 APU Fire Detection Block Schematic 10--20--8

Figure 10--20--6 APU Fire Pushbuttons 10--20--9

Figure 10--20--7 APU Fire Extinguishing -- Schematic 10--20--10

Figure 10--20--8 APU Fire EICAS Indications 10--20--11

Figure 10--20--9 Cargo Firex 10--20--14

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--00--2

FIRE PROTECTION

REV 3, May 03/05

Table of Contents

Figure 10--20--10 Fire Detection and Extinguishing -- Testing 10--20--16

LAVATORY

Figure 10--30--1 Smoke Detector 10--30--2

Figure 10--30--2 Smoke Setector EICAS Indications 10--30--3

Figure 10--30--3 Lavatory Waste Compartment Extinguisher 10--30--4

MAIN LANDING GEAR OVERHEAT DETECTION

Figure 10--40--1 Landing Gear Control Panel 10--40--1

Figure 10--40--2 Landing Gear EICAS Messages 10--40--2

Figure 10--40--3 MLG Overheat Indication and Test 10--40--3

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--10--1

FIRE PROTECTION

Introduction Sep 09/02

1. INTRODUCTION

Fire protection consists of a fire detection and extinguishing (FIDEEX) system for detecting

and extinguish a fire in the engine nacelles, the auxiliary power unit (APU) compartment and

the forward and aft cargo compartments. An independent system is provided for fire

detection and protection in the lavatories. A detection system is also provided for the main

landing gear wheel wells.

Indications to alert the crew to fire, smoke and overheat conditions as well as fire protection

system health are provided by the EICAS displays and panel lights.

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--10--2

FIRE PROTECTION

Sep 09/02

Introduction

BOTTLE 2

ENGINE FIREX LH ENG

ARMED

FIRE

BOTTLE 2 PUSH TO

PUSH

RIGHT ENGINE DISCH

DETECTION LOOPS

LEFT ENGINE ENGINE FIREX BOTTLE 1 RH ENG

DETECTION LOOPS BOTTLE 1

ARMED FIRE

PUSH TO PUSH

DISCH

APU FIREX

BOTTLE

APU

APU FIRE

DETECTION LOOPS PUSH

CARGO HRD

FORWARD CARGO FIREX BOTTLE

BOTTLE

SMOKE DETECTOR #1 FIDEEX ARMED

CONTROL CARGO LRD PUSH TO

UNIT FIREX BOTTLE

DISCH

FORWARD CARGO

SMOKE DETECTOR #2

CARGO FIREX

FWD

FORWARD CARGO

SMOKE DETECTOR #3 CARGO

SMOKE

PUSH

AFT CARGO AFT

BOTTLE

ARMED

PUSH TO

SMOKE DETECTOR #1 DISCH

CARGO

SMOKE

PUSH

AFT CARGO

SMOKE DETECTOR #2

LAVATORY WASTE

FIRE EXTINGUISHER

LAMP

LAVATORY DCU DRIVER

SMOKE DETECTOR UNIT

RIGHT MLG

DETECTION LOOP OVERHEAT

IDG 1 DISC

IDG 2 DISC

DETECTION

LEFT MLG UNIT

DETECTION LOOP

FIDEEX System Block Diagram

Figure 10---10---1

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--1

FIRE PROTECTION

Fire Detection and Extinguishing (FIDEEX) REV 3, May 03/05

1. FIRE DETECTION AND EXTINGUISHING (FIDEEX)

The fire detection and extinguishing system (FIDEEX) interfaces with the engines, APU and

cargo compartment fire protection systems. The FIDEEX uses the interfacing to provide fire

detection, smoke detection, fire extinguishing and system indication. The L/R ENG FIRE

PUSH and the 1/2 BOTTLE ARMED PUSH TO DISCH switchlights on the glareshield are

used by the crew to supply control inputs to the FIDEEX system.

A. Engine

Detection

Engine fire detection is provided by dual heat sensitive detection loops arranged in

parallel around the engine combustion section and exhaust pipe. Each loop is

connected to the FIDEEX and is monitored continuously for fire or overheat conditions.

In normal operation, both detection loops must detect a fire or overheat condition

before a fire warning alarm is issued. If a short or open circuit fault is detected in one

loop, the FIDEEX control unit will automatically switch to single loop detection and

signal the EICAS to display a L/R FIRE FAIL caution message on the EICAS primary

page.

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--2

FIRE PROTECTION

REV 3, May 03/05

Fire Detection and Extinguishing (FIDEEX)

LEFT ENGINE

ELEMENT 1 ELEMENT 2 ELEMENT 3 ELEMENT 4 ELEMENT 1 ELEMENT 2 ELEMENT 3 ELEMENT 4

LOOP A LOOP B

CHIME

L/R ENG FIRE

CHIME

(WARNING MSG) CHIME

CBP-- 1 FIRE SYS FAULT

CB1--N2 (STATUS)

FIRE

DET B L (R) FIRE FAIL

CB1--N1 FIREBELL

FIRE (CAUTION)

DET A

DCU LH ENG

28 VDC BATT BUS FIRE SYS OK FIRE

(ADVISORY) PUSH

EICAS DISPLAY FIRE

WARN PILOT

FIRE RH ENG

FIRE

FIDEEX CONTROL UNIT FAIL PUSH

PILOT--

LOOP DETECTION INITIATED COPILOT

A LOGIC TEST

GLARESHIELD

LOOP

B

CHANNEL A

LOOP DETECTION

A LOGIC

LOOP

B

CHANNEL B

TEST

FIRE DETECTION/

FIREX MONITOR PANEL

LOOP A LOOP B

ELEMENT 1 ELEMENT 2 ELEMENT 3 ELEMENT 4 ELEMENT 1 ELEMENT 2 ELEMENT 3 ELEMENT 4

RIGHT ENGINE

Engine Fire Detection --- Block Schematic

Figure 10---20---1

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--3

FIRE PROTECTION

Fire Detection and Extinguishing (FIDEEX) REV 3, May 03/05

Extinguishing

The engine fire extinguishing system provides a means to extinguish fires in the left and

right engines. The system consists of two FIREX bottles, located in the aft equipment

compartment, a low pressure switch, a bottle pressure gauge and discharge lines. The

bottles contain Halon and are pressurized to 600 psi. Each bottle has two firing

cartridges (squibs) to permit discharge of the fire extinguishing agent into either engine

nacelle. The pressure switches are connected to the FIDEEX, and if the bottle

pressure decrease to a preset point, an ENG BTL 1 (2) LO caution message will be

displayed on the EICAS primary page.

LH and RH ENG FIRE PUSH

Used to arm left or right squibs of both bottles. Closes engine fuel,

bleed air and hydraulic shut--off valves.

LH and RH ENG FIRE PUSH (red) light indicates that a fire is

detected in respective engine.

BOTTLE 1 and 2 ARMED PUSH TO DISCH

Left Glareshield Right Glareshield

Used to discharge one bottle.

BOTTLE 1 or 2 ARMED PUSH TO DISCH (green)

light indicates respective squib is armed and

bottle is charged.

Fire Detection and Extinguishing (FIDEEX) --- Engine Push Buttons

Figure 10---20---2

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--4

FIRE PROTECTION

REV 3, May 03/05

Fire Detection and Extinguishing (FIDEEX)

NO. 1 AFT EQUIPMENT BAY NO. 2

ENGINE ENGINE

FIREX FIREX

BOTTLE BOTTLE

ZONE A ZONE A

LH ENGINE RH ENGINE

CBP--1 LEFT GLARESHIELD PANEL

EICAS DISPLAY

CB1--R2

FIREX A

CB1--R3 L ENG SQUIB

FIREX B

DC EMERGENCY BUS BOT 1 L ENG

SQUIB FAIL

RIGHT GLARESHIELD PANEL BOT 1 R ENG

SQUIB FAIL

FROM BOT 1 LO PRESS

ENGINE FIRE

DETECTION

SYSTEM

DCUs

LEFT & RIGHT ENGINE

BRIDGEWIRE MONITOR B

(MONITORS FOR OPEN

LH ENG CIRCUITS) CHANNEL A

FUEL SOV

LEFT & RIGHT ENGINE

BRIDGEWIRE MONITOR A

(MONITORS FOR OPEN

CIRCUITS)

BOTTLE 1 ENGINE BOTTLE 1 CHANNEL B

LOW MONITOR

PRESSURE (MONITORS FOR BOTTLE

SWITCH LOW PRESSURE)

L GENERATOR

LEFT ENGINE SHUTDOWN

SIGNALS (SHUTS OFF LEFT HYD SOV

GENERATOR, HYDRAULIC

NOTE SOV, BLEED AIR) LEFT BLEED AIR

Left engine shown,

right engine the same. FIDEEX CONTROL UNIT

Engine Fire Extinguishing --- Schematic

Figure 10---20---3

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--5

FIRE PROTECTION

Fire Detection and Extinguishing (FIDEEX) REV 3, May 03/05

L or R ENG FIRE warning (red)

Indicates that a fire exists in the

left or right engine.

FIREBELL

L or R ENG SQB caution (amber)

Indicates that left or right squibs of

both bottles have failed or have fired.

L or R FIRE FAIL caution (amber)

Indicates a failure of the respective

engine detection system.

ENG BTL 1 or 2 LO caution (amber)

Indicates that respective bottle has

discharged.

Primary Page

L ENG SQB

R ENG SQB

L or R ENG SQB status (white)

Indicates that one left or right squib

has failed or has fired.

Status Page

Fire Detection and Extinguishing (FIDEEX) --- EICAS Indications <1001>

Figure 10---20---4

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--6

FIRE PROTECTION

REV 3, May 03/05

Fire Detection and Extinguishing (FIDEEX)

ENGINE FIRE EXTINGUISHING

GLARESHIELD INDICATIONS

EVENT

(Left engine fire

procedure is

described, the right RESULT LH BOTTLE 1 BOTTLE 2

engine fire procedure ENG ARMED ARMED MASTER

is similar) FIRE PUSH TO PUSH TO WARNING

PUSH DISCH DISCH

1 Fire condition occurs -- Firebell sounds.

in the left engine fire -- MASTER WARNING and LH

zone. ON OUT OUT ON

FIRE PUSH switchlights

come on.

2 MASTER WARNING -- Firebell is silenced.

switchlight is pressed -- MASTER WARNING

in. ON OUT OUT OUT

switchlight goes out and the

system is reset.

3 Left thrust lever is set -- LH ENG FIRE PUSH

to the SHUTOFF switchlight remains on. ON OUT OUT OUT

position.

4 LH ENG FIRE PUSH -- BOTTLE 1 ARMED PUSH

switchlight is pressed TO DISCH switchlight com-

in. es on.

-- BOTTLE 2 ARMED PUSH

TO DISCH switchlight com-

es on.

ON ON ON OUT

-- Left squibs of bottles 1 and 2

are armed.

-- Left engine fuel SOV closes.

-- Left bleed air SOV closes.

-- Left hydraulic SOV closes.

5 BOTTLE 1 ARMED -- Left squib on bottle 1 fires.

PUSH TO DISCH -- FIREX agent from bottle 1

switchlight is pressed ON ON ON OUT

discharges into left power

in. plant nacelle.

6 Bottle 1 fully -- The pressure switch on

discharges. bottle 1 opens as pressure

drops below the set point. ON OUT ON OUT

-- ENG BTL 1 LO is displayed

on the EICAS.

7 Fire condition in left -- LH ENG FIRE PUSH

ON OUT ON OUT

engine persists. switchlight remains on.

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--7

FIRE PROTECTION

Fire Detection and Extinguishing (FIDEEX) REV 3, May 03/05

ENGINE FIRE EXTINGUISHING

8 BOTTLE 2 ARMED -- Left squib on bottle 2 fires.

PUSH TO DISCH -- FIREX agent from bottle 2

switchlight is pressed ON OUT ON OUT

discharges into left engine

in. nacelle.

9 Bottle 2 fully -- The pressure switch on

discharges. bottle 2 opens as pressure

drops below the set point. OUT OUT OUT OUT

-- ENG BTL 2 LO is displayed

on EICAS.

B. APU

Detection

The APU fire detection system is used to detect a fire or overheat condition in the APU

enclosure. The detection system consists of dual heat sensitive detection loops

arranged in parallel around the APU and the forward APU firewall and above the two

APU compartment doors. Each loop is connected to the FIDEEX and is monitored

continuously for fire or overheat conditions. In normal operation, both detection loops

must detect a fire or overheat condition before a fire warning alarm is issued. If a short

or open circuit fault is detected in one loop, the FIDEEX control unit will automatically

switch to single loop detection and signal the EICAS to display a APU FIRE FAIL

caution message on the EICAS primary page.

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--8

FIRE PROTECTION

REV 3, May 03/05

Fire Detection and Extinguishing (FIDEEX)

APU ENCLOSURE

ELEMENT 1 ELEMENT 2 ELEMENT 3 ELEMENT 4

LOOP A

ELEMENT 1 ELEMENT 2 ELEMENT 3 ELEMENT 4

LOOP B

APU FIRE

(WARNING MSG) CHIME

CHIME

CBP-- 1 FIRE SYS FAULT CHIME

CB1--N2 (STATUS)

FIRE

DET B L (R) FIRE FAIL

CB1--N1

FIRE (CAUTION)

DET A

28 VDC BATT BUS FIRE SYS OK

(ADVISORY) FIREBELL

DCU

EICAS DISPLAY

FIRE

WARN APU

FIRE

PUSH

FIRE

FAIL COPILOT

FIDEEX CONTROL UNIT

PILOT-- COPILOT’S

LOOP DETECTION INITIATED GLARESHIELD

A LOGIC TEST PANEL

LOOP

B CHANNEL A

LOOP DETECTION

A LOGIC

LOOP

B CHANNEL B

TEST

FIRE DETECTION/

FIREX MONITOR PANEL

APU Fire Detection --- Block Schematic

Figure 10---20---5

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--9

FIRE PROTECTION

Fire Detection and Extinguishing (FIDEEX) REV 3, May 03/05

Extinguishing

The APU fire extinguishing system provides a means to extinguish fires in the APU

enclosure. The system consists of a single FIREX bottle, located in the aft equipment

compartment, a low pressure switch, a bottle pressure gauge and discharge lines. The

bottle contain Halon and is pressurized to 600 psi. The bottle has a single firing

cartridge (squib) to permit discharge of the fire extinguishing agent into APU enclosure.

The pressure switch is connected to the FIDEEX, and if the bottle pressure decreases

to a preset point, an APU BTL LO caution message will be displayed on the EICAS

primary page.

APU FIRE PUSH

Used to arm APU bottle squib.

Closes APU bleed air load control

valve and turns off the APU fuel pump.

APU FIRE PUSH (red) light

indicates that a fire is detected

in the APU compartment.

BOTTLE

ARMED

PUSH TO BOTTLE ARMED PUSH TO DISCH

DISCH Used to discharge APU bottle.

BOTTLE ARMED PUSH TO DISCH

Right Glareshield (green) light indicates the squib

is armed and the bottle is charged.

Fire Detection and Extinguishing (FIDEEX) --- APU Pushbuttons

Figure 10---20---6

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--10

FIRE PROTECTION

REV 3, May 03/05

Fire Detection and Extinguishing (FIDEEX)

APU FIRE

CARTRIDGE BOTTLE

CBP--1 RIGHT GLARESHIELD PANEL

CB1--R2

FIREX A A

CB1--R3

FIREX B B

DC EMERGENCY BUS

FROM

APU FIRE

DETECTION

SYSTEM

EICAS DISPLAY

APU SQUIB

(CAUTION)

FIDEEX CONTROL UNIT APU BOTTLE LO

(CAUTION)

AUTOMATIC APU AUTOMATIC APU

BOTTLE ARM & BOTTLE ARM &

DISCHARGE A DISCHARGE B

DCUs

MONITOR B (MONITORS

FOR OPEN CIRCUIT)

CHANNEL A

MONITOR A (MONITORS

FOR OPEN CIRCUIT)

APU BOTTLE

LOW MONITORS FOR BOTTLE

PRESSURE LOW PRESSURE

SWITCH

WOW CIRCUIT A/C ON CHANNEL B

PSEU GROUND DETERMINES

WOW AUTO EXTINGUISHING

WHEN A/C IS ON THE GND

APU ECU

APU SHUTDOWN SIGNAL APU POWER

AUTO SHUTDOWN

APU FUEL SOV

APU Fire Extinguishing --- Schematic

Figure 10---20---7

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--11

FIRE PROTECTION

Fire Detection and Extinguishing (FIDEEX) REV 3, May 03/05

APU FIRE warning (red)

Indicates that a fire exists in the

APU compartment.

APU FIRE FIREBELL

APU SQB

APU FIRE FAIL

APU BTL LO

APU SQB caution (amber)

Indicates that the APU bottle

squib has failed or has fired.

APU FIRE FAIL caution (amber)

Indicates a failure of the APU

detection system.

APU BTL LO caution (amber)

Indicates that APU bottle has

discharged.

Primary Page

Fire Detection and Extinguishing (FIDEEX) --- APU EICAS Indications <1001>

Figure 10---20---8

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--12

FIRE PROTECTION

REV 3, May 03/05

Fire Detection and Extinguishing (FIDEEX)

APU FIRE EXTINGUISHING

GLARESHIELD INDICATIONS

BOTTLE

EVENT RESULT MASTER

APU FIRE ARMED

WARN-

PUSH PUSH TO

ING

DISCH

1 Fire condition occurs in -- Firebell sounds.

APU fire zone. -- MASTER WARNING and APU

FIRE PUSH lights come on.

-- Emergency shut down is

ON OUT ON

automatically initiated.

If airplane is on the ground:

-- APU bottle automatically

discharges after 5 seconds.

2 MASTER WARNING is -- Firebell is silenced.

pressed in. -- MASTER WARNING light goes ON OUT OUT

out and system is reset.

3 APU FIRE PUSH is -- BOTTLE ARMED PUSH TO

pressed in. DISCH light comes on.

-- APU squibs are armed. ON ON OUT

-- APU fuel SOV closes.

-- APU bleed air LCV closes.

4 BOTTLE ARMED PUSH -- APU squib fires.

TO DISCH is pressed in. -- FIREX agent discharges into ON ON OUT

APU compartment.

5 APU bottle fully -- Pressure switch on bottle

discharges. opens as pressure drops below

set level. OUT OUT OUT

-- APU BTL LO is displayed on

EICAS.

C. Cargo Compartment

The cargo smoke detection system provides smoke detection in the forward and aft

cargo compartments using optical type smoke detectors. Three detectors are located

in the ceiling of the forward cargo compartment and two in the ceiling of the aft cargo

compartment. All the smoke detector are protected from damage by a steel cage.

Each detector is capable of producing an alarm within an established time frame and

smoke concentration level. The detectors are positioned to avoid false alarms with

overlapping coverage to guard against the failure of one detector.

The FIDEEX control unit monitors the cargo bay smoke detectors. Normally, two

detectors must detect smoke to issue a cargo compartment smoke warning. If there is

only one serviceable detector within a compartment, the FIDEEX will automatically

switch to single smoke detector operation. In the event of a detector fault, a signal will

be sent by the FIDEEX control unit to the to the EICAS to display a FIRE SYS FAULT

caution message on the EICAS primary page.

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--13

FIRE PROTECTION

Fire Detection and Extinguishing (FIDEEX) REV 3, May 03/05

NOTE

Operation of mobile transceivers in close proximity to the

smoke detectors may cause a false alarm.

Fire suppression for the forward and aft cargo compartments is provided by a high rate

discharge FIREX bottle and a low rate discharge FIREX bottle. Both bottles are located

inside the right belly fairing, aft of the main landing gear, and are pressurized to 360 psi

with Halon. Each bottle has a forward and aft compartment firing cartridge (squib), used

to discharge the extinguishing agent into either compartment. Each bottle has a low

pressure switch and a pressure gauge. Both bottles discharge simultaneously. The

high rate discharge bottle is designed to quickly deliver extinguishing agent into the

cargo compartment for initial fire suppression. The low rate discharge bottle discharges

slowly, maintaining a flow of extinguishing agent into the cargo compartment (over a 60

minute period) to prevent reignition and allow for aircraft diversion. The pressure

switches are connected to the FIDEEX, and if either bottle pressure decrease to a

preset point, an CARGO BTL LO caution message will be displayed on the EICAS

primary page.

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--14

FIRE PROTECTION

REV 3, May 03/05

Fire Detection and Extinguishing (FIDEEX)

CARGO FIREX

FWD

CARGO

SMOKE

PUSH

BOTTLE

AFT ARMED

PUSH TO

DISCH

CARGO

SMOKE

PUSH

Cargo Firex Panel

Center Pedestal

FWD and AFT CARGO SMOKE PUSH BOTTLE ARMED PUSH TO DISCH

Used to arm the forward or aft squibs of both Used to discharge both cargo bottles.

cargo bottles. AFT CARGO SMOKE PUSH BOTTLE ARMED PUSH TO DISCH

closes the air--conditioning shut--off valve and (green) light indicates respective squibs

turns the heater off. are armed and bottles are charged.

CARGO SMOKE PUSH (red) light

indicates that a smoke condition is

detected in respective cargo compartment.

SMOKE AFT or FWD CARGO warning (red)

Indicates that a smoke condition exists in the

forward or aft cargo compartment.

SMOKE AFT CARGO

SMOKE FWD CARGO

AFT CARGO SQB 1

AFT CARGO SQB 2 SMOKE

FWD CARGO SQB 1

FWD CARGO SQB 2

AFT CARGO DET

FWD CARGO DET AFT or FWD CARGO SQB 1 or 2 caution (amber)

CARGO BTL LO

Indicates that the forward or aft cargo bottle squib 1

or 2 has failed or has fired.

AFT or FWD CARGO DET caution (amber)

Indicates a failure of the forward or aft cargo

detection system.

CARGO BTL LO caution (amber)

Indicates that one or both cargo bottle(s) have

discharged.

Primary Page

Fire Detection and Extinguishing (FIDEEX) --- Cargo Firex <1001>

Figure 10---20---9

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--15

FIRE PROTECTION

Fire Detection and Extinguishing (FIDEEX) REV 3, May 03/05

CARGO COMPARTMENT FIRE EXTINGUISHING

INDICATIONS

EVENT BOTTLE

RESULT CARGO MASTER

(Aft described; ARMED

SMOKE WARN-

forward similar) PUSH TO

PUSH ING

DISCH

1 Fire condition occurs in -- “Smoke” aural is annunciated.

aft cargo compartment. -- MASTER WARNING and AFT ON OUT ON

CARGO SMOKE PUSH lights

come on.

2 MASTER WARNING is -- MASTER WARNING light goes

ON OUT OUT

pressed in. out and system is reset.

3 AFT SMOKE CARGO -- BOTTLE ARMED PUSH TO

PUSH is pressed in. DISCH light comes on.

-- Aft squibs of both bottles are

armed.

ON ON OUT

For aft cargo compartment:

-- Cargo bay heater shuts off.

-- Cargo air-conditioning shut-off

valve closes.

4 BOTTLE ARMED PUSH -- Aft squibs of both bottles fire.

TO DISCH is pressed in. -- FIREX agent discharges into ON ON OUT

aft cargo compartment.

5 One bottle fully -- Pressure switch on one bottle

discharges. opens as pressure drops below

set level.

-- CARGO BTL LO is displayed

OUT OUT OUT

on EICAS.

-- Remaining bottle continues to

discharge for a minimum of 60

minutes.

D. Testing

Testing is initiated using the TEST switch located on the Fire Detection / FIREX Monitor

Panel, on the overhead panel. Test results are provided on the EICAS displays. The

FIDEEX control unit monitors the fire protection systems by automatically performing

periodic checks.

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--16

FIRE PROTECTION

REV 3, May 03/05

Fire Detection and Extinguishing (FIDEEX)

Fire Detection/FIREX Monitor Panel

Overhead Panel

FIRE SYS FAULT caution (amber)

Indicates loss of all ARINC communication

FIRE SYS FAULT

to the FIDEEX system.

FIRE SYS OK

FIRE SYS FAULT

Primary Page

FIRE SYS OK advisory (green)

Indicates that FIDEEX system has been tested

and is operational.

FIRE SYS FAULT status (white) Status Page

Indicates a loss of redundancy in the

FIDEEX system.

Fire Detection and Extinguishing (FIDEEX) --- Testing <1001>

Figure 10---20---10

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--17

FIRE PROTECTION

Fire Detection and Extinguishing (FIDEEX) REV 3, May 03/05

E. System Circuit Breakers

SYSTEM SUB--SYSTEM CB NAME BUS BAR CB CB NOTES

PANEL LOCATION

CARGO

M8

Cargo Smoke SMOKE DET A

Detection CARGO BATTERY M9

SMOKE DET B BUS

FIDEEX FIRE DET A 1 N1

Fire Detection

FIRE DET B N2

Fire FIREX A DC R2

Extinguishing FIREX B EMERGENCY R3

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--20--18

FIRE PROTECTION

REV 3, May 03/05

Fire Detection and Extinguishing (FIDEEX)

THIS PAGE INTENTIONALLY LEFT BLANK

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--30--1

FIRE PROTECTION

Lavatory REV 3, May 03/05

1. LAVATORY FIRE PROTECTION

Lavatory fire detection and protection for each lavatory consists of a ceiling mounted smoke

detector and a waste compartment fire extinguisher. <2202>

A. Detection

A smoke detector, in each lavatory, monitors for the presence of smoke. When the

smoke density exceeds a preset level, the detector sounds an aural alarm and a

SMOKE FWD (AFT) LAV warning message is displayed on the EICAS primary page.

The lavatory smoke detector is not connected to or monitored by the FIDEEX control

unit. <2202>

The smoke detectors can be tested by pressing the test button on the detector. During

the test, an aural alarm sounds in the lavatory, the red alarm light on the detector

comes on and a SMOKE FWD (AFT) LAV warning message is displayed on EICAS

primary page. The system is reset by pressing the interrupt button on the detector.

<2202>

NOTE

Operation of mobile transceivers in close proximity to the

smoke detectors may cause a false alarm.

Alarm Light (red) Power Light (green)

Comes on with the Comes on to indicate Interrupt Pushbutton

aural alarm to indicate that the unit is powered. Used to reset smoke detector.

that a smoke condition

exists in the lavatory.

Test Pushbutton

Used to test smoke detector.

When pressed in:

Aural alarm comes on.

Alarm light comes on.

EICAS warning message

is displayed.

700 and 2000 Hz tone

Smoke Detector

Lavatory Ceiling

Smoke Detector

Figure 10---30---1

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--30--2

FIRE PROTECTION

REV 3, May 03/05

Lavatory

SMOKE AFT LAV

SMOKE FWD LAV

SMOKE AFT or FWD LAV warning (red)

Indicates that a smoke condition

exists in the lavatory.

Primary Page

Smoke Detector EICAS Indications <1001,2202>

Figure 10---30---2

B. Extinguishing

Fire extinguishing in the lavatory waste paper towel container is done automatically.

The system consists of a disposable extinguisher bottle and a dual discharge nozzle.

The bottle is mounted near the waste container with the nozzles extending into the

waste container. The end of each discharge nozzle is sealed with a heat sensitive

capsule which, when subjected to heat, melts to release the extinguishing agent into

the waste container.

A temperature sensor installed on the inside of the waste compartment door is used to

provide evidence that high temperature has occurred in the waste compartment and

that the extinguisher bottle may have discharged. The sensor is a heat sensitive strip

with a temperature scale that turns black when the temperature in the compartment

exceeds 160_F (71_C).

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--30--3

FIRE PROTECTION

Lavatory REV 3, May 03/05

WASTE COMPARTMENT

FIRE EXTINGUISHER

LAVATORY

A TEMPERATURE

SENSOR

Lavatory Waste Compartment Extinguisher

Figure 10---30---3

C. System Circuit Breakers

SYSTEM SUB--SYSTEM CB NAME BUS BAR CB CB NOTES

PANEL LOCATION

Smoke LAV SMOKE

Lavatory DC BUS 1 1 D9

Detection DET

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--30--4

FIRE PROTECTION

Sep 09/02

Lavatory

THIS PAGE IS INTENTIONALLY LEFT BLANK

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--40--1

FIRE PROTECTION

Main Landing Gear Overheat Detection REV 3, May 03/05

1. MAIN LANDING GEAR OVERHEAT DETECTION

The main landing gear overheat detection system provides indication of overheat conditions

in the main landing gear wheel wells that can be caused by overheated brakes or brake

fires. The system consists of two overheat detection loops and an overheat detection unit.

The detection loops are installed around the top inner surface of each main wheel bin and

are connected in series to the detection unit.

The overheat detection unit is located under the copilots side console. The unit continuously

monitors the loops for overtemperature conditions and system faults. If an overheat

condition is detected by the unit, in either wheel bin, a signal is sent to display a MLG BAY

OVHT warning message on the EICAS primary page. If a system fault is detected by the

unit, a signal is sent to display a MLG OVHT FAIL caution message on the EICAS primary

page.

The warning of an overheat condition, alerts the pilot to immediately lower the landing gear

to reduce the landing gear temperature. The warning message will persist until the

temperature in the wheel bin returns to normal limits.

The main landing gear overheat detection system may be tested, from the landing gear

control panel, by simulating an overheat condition or a system fault condition. The EICAS

will display the applicable warning or caution message during the test.

BTMS OVHT HORN

WARN RESET

MUTED LDG GEAR

UP

DN

ANTI SKID

ARMED

DN LCK

OFF REL

MLG BAY OVHT TEST

OVHT WARN FAIL

MLG BAY OVHT

Used to simulate an

overheat condition in the OVHT TEST WARN FAIL

main landing gear bay. Landing Gear Control Panel Used to simulate a failure in

MLG BAY OVHT warning Center Pedestal the main landing gear bay

message comes on. overheat detection system.

MLG OVHT FAIL caution

message comes on.

Landing Gear Control Panel

Figure 10---40---1

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--40--2

FIRE PROTECTION

Sep 09/02

Main Landing Gear Overheat Detection

MLG BAY OVHT warning (red)

Indicates that an overheat condition

MLG BAY OVHT exists in one or both of the main

MLG OVHT FAIL landing gear bays.

GEAR BAY

OVERHEAT

MLG OVHT FAIL caution (amber)

Indicates that a fault exists in the

main landing gear bay overheat

detection system.

Primary Page

Landing Gear EICAS Messages <1001>

Figure 10---40---2

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--40--3

FIRE PROTECTION

Main Landing Gear Overheat Detection Sep 09/02

28 VDC

BATTERY BUS

GEAR BAY OVERHEAT

MLG BAY OVHT OVERHEAT DETECTION UNIT

DETECTION

CB2--N9

OVERHEAT 10 ms

DETECTOR DELAY

DCU’S

SHORT

CIRCUIT

DETECTOR INHIBIT

OVERHEAT

TEST

RESISTOR

EICAS DISPLAY

MLG BAY OVHT (RED)

RIGHT TEMP LEFT TEMP OVHT

SENSOR SENSOR

MLG BAY FAIL (AMBER)

WARN

FAIL

MLG BAY

OVHT TEST

PANEL

MLG Overheat Indication and Test

Figure 10---40---3

Flight Crew Operating Manual

CSP C--013--067

Vol. 1 10--40--4

FIRE PROTECTION

Sep 09/02

Main Landing Gear Overheat Detection

A. System Circuit Breakers

SYSTEM SUB--SYSTEM CB NAME BUS BAR CB CB NOTES

PANEL LOCATION

Main Landing Overheat MLG BAY BATTERY

2 N9

Gear Detection OVHT DET BUS

Flight Crew Operating Manual

CSP C--013--067

You might also like

- TM 10-1670-295-23&P Sling Kits & Cargo Nets 2Document99 pagesTM 10-1670-295-23&P Sling Kits & Cargo Nets 2Juan Carlos Romero SusunagaNo ratings yet

- Croma UputstvoDocument258 pagesCroma UputstvoBwana Srbin100% (1)

- 737 Systems SchematicsDocument31 pages737 Systems SchematicsKhurram Naseem100% (5)

- Anti IcingDocument17 pagesAnti IcingSubash DhakalNo ratings yet

- JCB380 Parts Manual PDFDocument254 pagesJCB380 Parts Manual PDFSRINIVASA RAO MARTURI100% (1)

- ITAcademy Zavrsni Rad - Neradovic IvanDocument40 pagesITAcademy Zavrsni Rad - Neradovic IvanBwana SrbinNo ratings yet

- Tracking and Dynamic Balancing of Rotor BladesDocument6 pagesTracking and Dynamic Balancing of Rotor Bladesfitasmounir100% (1)

- B 757 General Familiarisation in MaintenanceDocument167 pagesB 757 General Familiarisation in MaintenanceManish Mishra100% (8)

- Air Travel VocabularyDocument6 pagesAir Travel VocabularyLorenzo Martinez ValenzuelaNo ratings yet

- Thales CATSDocument2 pagesThales CATSPark SungNo ratings yet

- CRJ Study Guide PDFDocument32 pagesCRJ Study Guide PDFsdn35252No ratings yet

- Bombardier CRJ 00-Emergency EquipmentDocument36 pagesBombardier CRJ 00-Emergency Equipmentjuan carlos balderas silvaNo ratings yet

- Emergency ShutingdownDocument11 pagesEmergency ShutingdownOsama OmayerNo ratings yet

- HF011000 Co0c3 GD08001Document40 pagesHF011000 Co0c3 GD08001proincyrNo ratings yet

- Marc and Jenssen Industrial CorporationDocument8 pagesMarc and Jenssen Industrial CorporationAdrian Bien SaturnoNo ratings yet

- Global Express XRS-Aural and Visual WarningsDocument60 pagesGlobal Express XRS-Aural and Visual Warningscharle grantNo ratings yet

- Storage Tank Gas Breathing For Purge Gas SizingDocument3 pagesStorage Tank Gas Breathing For Purge Gas SizingguhadebasisNo ratings yet

- Gas Reception Terminal InformationDocument7 pagesGas Reception Terminal InformationkhadijaNo ratings yet

- Estimate by CarloDocument36 pagesEstimate by CarloCarlo DungcaNo ratings yet

- Yanmar Motor 4TNV84T Dsa3Document36 pagesYanmar Motor 4TNV84T Dsa3Lilly NovilloNo ratings yet

- 82F1097-001-EQP-DTS-1515199-00-00 Lifting Pump DatasheetDocument2 pages82F1097-001-EQP-DTS-1515199-00-00 Lifting Pump DatasheetHamza ISSAOUINo ratings yet

- 3TNV84T GKMDocument29 pages3TNV84T GKMpecasplh02No ratings yet

- Chapter 8 - Environmental Control System: REV 3, May 03/05Document40 pagesChapter 8 - Environmental Control System: REV 3, May 03/05julian marinNo ratings yet

- CHW2204 00 EL CAL 7303 RevA Electrical Load ListDocument4 pagesCHW2204 00 EL CAL 7303 RevA Electrical Load ListphongtttNo ratings yet

- Bombardier CRJ 00-Aural Visual Indicating and RecordingDocument44 pagesBombardier CRJ 00-Aural Visual Indicating and RecordingDiego FreireNo ratings yet

- Yanmar 4tnv84t Gge Engine Parts CatalogDocument4 pagesYanmar 4tnv84t Gge Engine Parts Catalogmark100% (66)

- Orden de Trabajo O2Document10 pagesOrden de Trabajo O2JUAN DAVID TORRES TELLEZNo ratings yet

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Document6 pagesAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanNo ratings yet

- CCF 009 Yearly Vessel Inspection ReportDocument14 pagesCCF 009 Yearly Vessel Inspection Reporttharindu hasarangaNo ratings yet

- Water Drain Valves - Inspection/Check: Reference DesignationDocument2 pagesWater Drain Valves - Inspection/Check: Reference DesignationAle FernandezNo ratings yet

- Telephone Unit SpecsDocument10 pagesTelephone Unit SpecsChristianNo ratings yet

- Illustrated Parts Catalogue: Ps-28 Cruiser / Sportcruiser / PipersportDocument486 pagesIllustrated Parts Catalogue: Ps-28 Cruiser / Sportcruiser / PipersportCristhian342No ratings yet

- G3516C GZZ00273Document4 pagesG3516C GZZ00273ronaldNo ratings yet

- Invent A RioDocument35 pagesInvent A RioDheyvid Josue Quispe GavinoNo ratings yet

- Cleaning of Pitot Probe Drain HolesDocument7 pagesCleaning of Pitot Probe Drain HolesSuman BajracharyaNo ratings yet

- Asme VT-1Document22 pagesAsme VT-1raul carvajal rozasNo ratings yet

- Og P-1 FeederDocument7 pagesOg P-1 Feederjalaj bisenNo ratings yet

- Parts Catalog: 0CR10-M56600ENDocument25 pagesParts Catalog: 0CR10-M56600ENEdward De La CruzNo ratings yet

- Hindalco Details PDFDocument264 pagesHindalco Details PDFSiddhant SatpathyNo ratings yet

- Calculos Locatario - Ro3Document17 pagesCalculos Locatario - Ro3augmorelopezNo ratings yet

- As 365 N3 Mmel PDFDocument50 pagesAs 365 N3 Mmel PDFhariadymarpaung0% (1)

- Annexure V - Project TimelineDocument1 pageAnnexure V - Project TimelineShawaiz Ali MeharNo ratings yet

- Yanpet MM21-U/O K-7701 Compressor O/H RFQ No# 5500392869: TOTAL (Excluding VAT)Document2 pagesYanpet MM21-U/O K-7701 Compressor O/H RFQ No# 5500392869: TOTAL (Excluding VAT)faisal khanNo ratings yet

- Emergency Equipment: CL 605 Flight Crew Operating Manual PSP 605 6Document18 pagesEmergency Equipment: CL 605 Flight Crew Operating Manual PSP 605 6viola beckNo ratings yet

- Parts Catalog: 0CD50-M05530ENDocument28 pagesParts Catalog: 0CD50-M05530ENVladis0710100% (1)

- Pa-28 (Manual Ingles) PARTE 6Document5 pagesPa-28 (Manual Ingles) PARTE 6pepeNo ratings yet

- 2TNV70 KBRCDocument24 pages2TNV70 KBRCMahmoud Mohamed M. GeprilNo ratings yet

- FAA 2020 0199 0002 - Attachment - 2Document42 pagesFAA 2020 0199 0002 - Attachment - 2Sabri ÇifçibaşıNo ratings yet

- Gas Detector InstallationDocument11 pagesGas Detector InstallationOmar TocmoNo ratings yet

- WM 08Document88 pagesWM 08chrideerNo ratings yet

- Eg5010 0 1Document4 pagesEg5010 0 1Victor SanchezNo ratings yet

- STACKSDocument16 pagesSTACKSjkhan_724384No ratings yet

- ffloo - & : C Ae Ergy E G Eer Nggro PT N N E Ectr C E Constructi N Co., TDDocument4 pagesffloo - & : C Ae Ergy E G Eer Nggro PT N N E Ectr C E Constructi N Co., TDasyerfernandezNo ratings yet

- Sender Cost Cneters PRSL Admn Finc Profit Center Cost Center Description PERSONNEL ADMINISTARTION FINANCE 1100 1200Document10 pagesSender Cost Cneters PRSL Admn Finc Profit Center Cost Center Description PERSONNEL ADMINISTARTION FINANCE 1100 1200Anil SinghNo ratings yet

- 3TNV88-BPYBT (New Holland)Document24 pages3TNV88-BPYBT (New Holland)pecasplh02No ratings yet

- @A318/A319/A320/A321: Chapter 35 - OxygenDocument50 pages@A318/A319/A320/A321: Chapter 35 - OxygenhengwahchungNo ratings yet

- Cfts-Exep-Ins-Lst-00000-05 - R01 - Alarm and Trip SettingsDocument2 pagesCfts-Exep-Ins-Lst-00000-05 - R01 - Alarm and Trip SettingsKenneth EmbeleNo ratings yet

- ETD1000 Instruction ManualDocument28 pagesETD1000 Instruction ManualrgunasekaranNo ratings yet

- 3TNV70-XHBT - 0CD10-M91301 - enDocument22 pages3TNV70-XHBT - 0CD10-M91301 - enjavier muñoz100% (1)

- A320-214 - Yom 2014 (Sale)Document6 pagesA320-214 - Yom 2014 (Sale)Francisco SoFuentesNo ratings yet

- Cleaning of Contact Points and Wiring HarnessesDocument3 pagesCleaning of Contact Points and Wiring HarnessesRafa Montes MOralesNo ratings yet

- TM-10-8415-209-10 - Operator's Manual For Individual Chemical Protective ClothingDocument133 pagesTM-10-8415-209-10 - Operator's Manual For Individual Chemical Protective ClothingLIVE3ORDIENo ratings yet

- 4jh5e Parts ManualDocument54 pages4jh5e Parts ManualKALILNo ratings yet

- Bombardier CRJ 00-Environmental Control SystemDocument42 pagesBombardier CRJ 00-Environmental Control SystemVincent GuignotNo ratings yet

- (Final DWG) Ms Sophie Ecs-900bx1 Rev.0 230330 OwnerDocument157 pages(Final DWG) Ms Sophie Ecs-900bx1 Rev.0 230330 Ownerzabiyaka175No ratings yet

- Hoja de Cálculo en TABLERO DE COMPUTODocument19 pagesHoja de Cálculo en TABLERO DE COMPUTOaugmorelopezNo ratings yet

- ClaimDocument5 pagesClaimZewduErkyhunNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- The Big Secret - The Only Serb Raid Into AlbaniaDocument3 pagesThe Big Secret - The Only Serb Raid Into AlbaniaBwana Srbin100% (1)

- Autobiography of Nikola Tesla: Chapter 1, My Early LifeDocument20 pagesAutobiography of Nikola Tesla: Chapter 1, My Early LifeBwana SrbinNo ratings yet

- Biber Crep Letva 3/5 CM Ventilaciona Letva 3/5 CM Ter Hartija Daska 2.4 CM Rog 16 CM Termoizolacija 15 CM Gipsana PloDocument1 pageBiber Crep Letva 3/5 CM Ventilaciona Letva 3/5 CM Ter Hartija Daska 2.4 CM Rog 16 CM Termoizolacija 15 CM Gipsana PloBwana SrbinNo ratings yet

- A4 Print 3Document1 pageA4 Print 3Bwana SrbinNo ratings yet

- Imm 0008 EgenDocument2 pagesImm 0008 EgenBwana SrbinNo ratings yet

- Operation Guide 3377: Getting AcquaintedDocument3 pagesOperation Guide 3377: Getting AcquaintedBwana SrbinNo ratings yet

- Description Price Buy Description Price BuyDocument2 pagesDescription Price Buy Description Price BuyBwana SrbinNo ratings yet

- Product Name Units Sold +/-% Decrease FlagDocument11 pagesProduct Name Units Sold +/-% Decrease FlagBwana SrbinNo ratings yet

- Oc 505d 7avefDocument1 pageOc 505d 7avefBwana SrbinNo ratings yet

- Kokošinjac 2233332Document4 pagesKokošinjac 2233332Bwana SrbinNo ratings yet

- A3c Electrical Flight Control System B1Document1 pageA3c Electrical Flight Control System B1kpilNo ratings yet

- Lgts Ad 2.1 Aerodrome Location Indicator and Name Lgts - Thessaloniki/ MakedoniaDocument17 pagesLgts Ad 2.1 Aerodrome Location Indicator and Name Lgts - Thessaloniki/ MakedoniasamNo ratings yet

- Ufc 3 600 01-Fire Prot EngrDocument158 pagesUfc 3 600 01-Fire Prot EngrcarlcrowNo ratings yet

- AFMC AlmanacDocument44 pagesAFMC AlmanacPrinses1234567No ratings yet

- Trafi EASA - Cabin Crew DutiesDocument6 pagesTrafi EASA - Cabin Crew DutiesRichard Thodé JrNo ratings yet

- 9HQDL LH Ob Aft Flap DisbondDocument5 pages9HQDL LH Ob Aft Flap DisbondWisePipeNo ratings yet

- Final Report: AIB/AAI/CAS.103 Transport Safety Investigation Bureau Ministry of Transport Singapore 12 June 2018Document23 pagesFinal Report: AIB/AAI/CAS.103 Transport Safety Investigation Bureau Ministry of Transport Singapore 12 June 2018Mos DetNo ratings yet

- Army Aviation Digest - Jul 1969Document68 pagesArmy Aviation Digest - Jul 1969Aviation/Space History Library100% (2)

- Loading & Buckling of StrutsDocument40 pagesLoading & Buckling of StrutsDeepesh MeenaNo ratings yet

- Flight Briefing Package: Release #1Document10 pagesFlight Briefing Package: Release #1Matcha MatchuNo ratings yet

- Contoh Soal TOEFLDocument6 pagesContoh Soal TOEFLRizky Permatawati100% (1)

- ESL Conversation Questions - Airplanes (I-TESL-J)Document2 pagesESL Conversation Questions - Airplanes (I-TESL-J)Juan Báez RebolloNo ratings yet

- DYNAPAR - Quick ReferenceDocument12 pagesDYNAPAR - Quick ReferenceGualaNo ratings yet

- 12-22-56-600-001-A - Lubrication of The Cockpit Sliding Window TracksDocument3 pages12-22-56-600-001-A - Lubrication of The Cockpit Sliding Window TracksAndre SanarNo ratings yet

- EPMA-Final - HIP - Brochure - Introduction To PM HIP TechnologyDocument30 pagesEPMA-Final - HIP - Brochure - Introduction To PM HIP TechnologygillougillouNo ratings yet

- Helix 360Document2 pagesHelix 360Tom SteinhauerNo ratings yet

- Socorro Squadron History - Vol IDocument25 pagesSocorro Squadron History - Vol ICAP History LibraryNo ratings yet

- Citycraft: BOEING 727-200Document13 pagesCitycraft: BOEING 727-200arthur von zuben0% (1)

- GpsDocument27 pagesGpsPrajwal RaoNo ratings yet

- Caap 215 1 2 AnnexcDocument8 pagesCaap 215 1 2 AnnexcHuseyin UZUNNo ratings yet

- Directory of Oil N Gas Supporting IndustriesDocument57 pagesDirectory of Oil N Gas Supporting IndustriesVinodh KumarNo ratings yet

- DGCA PaperDocument24 pagesDGCA PaperHardik Tank0% (1)

- Calibration of AnemometerDocument4 pagesCalibration of AnemometerAhmet ŞenNo ratings yet

- Shippers Declaration Dangerous Goods Form and InstructionsDocument4 pagesShippers Declaration Dangerous Goods Form and InstructionsMd SalimNo ratings yet