Professional Documents

Culture Documents

Fkur Bio Flex Bio Based Biodegradable Multifaceted

Fkur Bio Flex Bio Based Biodegradable Multifaceted

Uploaded by

Shruti Singh0 ratings0% found this document useful (0 votes)

7 views10 pagesOriginal Title

fkur-bio-flex-bio-based-biodegradable-multifaceted

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views10 pagesFkur Bio Flex Bio Based Biodegradable Multifaceted

Fkur Bio Flex Bio Based Biodegradable Multifaceted

Uploaded by

Shruti SinghCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 10

Bio-Flex®

biobased – biodegradable – multifaceted

Bio-Flex®

for home compostable films

The home compostable Bio-Flex® grades are suitable for the production of low

gauge films which will biodegrade completely in garden compost at low, variable

temperatures. All grades have been certified ”OK Compost HOME“ by the

independent testing institute TÜV Austria. Films made from home compostable

Bio-Flex® grades have outstanding mechanical properties and moisture resist-

ance. The range of possible applications includes multi-purpose bags, as well as

bags for fruit and vegetable packaging, mulching films and other packaging.

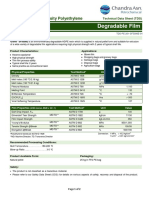

Type Minimum Tear resistance Spencer impact Optics

Biobased (MD/TD) test

Carbon Content

Bio-Flex® [%] [N/mm] [N/mm]

ASTM D 1922 ASTM D 3420

F 1801 10 b

85/35 570 translucent

F 1804 43 a

170/60 550 translucent

F 1814 44 a

215/120 340 translucent

FX 1821 10 b

100/180 240 opaque

FX 1824 43 a

140/300 160 opaque

a

BCC measured according to ISO 16620. BCC calculated.

b

Bio-Flex® for industrial compostable

film applications

The key feature of the flexible Bio-Flex® film grades is the certified compostability.

Independent institutes confirm that Bio-Flex® passes the strict testing criteria of

the EN 13432 standard and is ultimately converted into water, CO2 and biomass

in industrial composting facilities, just as organic waste. The main applications are

low gauge bags, magazine envelopes, mulch films and food packaging.

Type Minimum Biobased Tear resistance Spencer impact Optics

Carbon Content (MD/TD) test

Bio-Flex® [%] [N/mm] [N/mm]

ASTM D 1922 ASTM D 3420

F 1100 <10 b

85/35 570 translucent

F 2110 28 c

11/30 680 translucent

FX 1120 50 c

12.5/73 240 opaque

FX 1130 10 b

110/110 420 opaque

FX 1137 10 b

95/150 260 opaque

b

BCC calculated. c BCC measured according to ASTM D6866.

Bio-Flex® for thermoforming

applications

Standard bioplastics are often limited due to their low temperature resistance,

so that certain applications cannot be realized. The thermoformable Bio-Flex®

grades are characterized by excellent heat resistance and can be processed on

conventional cast film systems. The subsequent thermoforming process can be

done both inline and offline. All Bio-Flex® thermoforming grades are both

biobased and biodegradable.

Type Minimum Tensile Notched Vicat A

Biobased strength impact strength

Carbon Content (Charpy)

Bio-Flex® [%] [N/mm] [kJ/m²] [ °C]

ISO 527 ISO 179/1 eA ISO 306

F 6611 70b 47 7.2 130*

F 6711 70b 44 14 n.a.

S 5630 WH 60b 32 3 105

S 7711 75 b

49 5.2 112

*

Dependent upon process parameters. b BCC calculated.

Bio-Flex® for injection moulding

The injection molding Bio-Flex® grades are characterized by a balance of rigidity

and toughness. Products made from Bio-Flex® have a pleasant surface touch with

a natural shiny color. The main application areas include gardening and landscap-

ing, toys and high-quality cosmetics. But even complex technical parts or thin-

walled packaging can be realized with Bio-Flex®.

Type Minimum Tensile Notched Vicat A MFR

Biobased strength impact (190 °C/

Carbon Content strength 2.16 kg)

(Charpy)

Bio-Flex® [%] [N/mm] [kJ/m²] [ °C] [g/10 min]

ISO 527 ISO 179/1 eA ISO 306 ISO 1133

F 6513 70b 46 7.6 130* 7 – 12

F 6514 70b 43 4 60 17 – 22

F 9533 WH 85b 50 2.6 63 22 – 28

S 5630 WH 60b 32 3 105 7 – 10

S 7514 75b 47 3.5 112 25 – 30

*

Dependent upon process parameters. BCC calculated.

b

Bio-Flex® are sophisticated and

innovative resins that comprise renewability,

biodegradability and compostability.

Their natural source is e.g. corn, sugar cane

or castor oil. Bio-Flex® resins are suitable for

numerous flexible applications and

can be converted using a wide variety of

processing methods.

Bio-Flex® resins are drop-in,

ready-to-use compounds.

FKuR –

The Bioplastic Specialist

As a full service provider FKuR

will give you all the necessary technical support

and marketing advice to enable you to process

and sell your products successfully.

We will be happy to assist you in selecting the material

that will best meet your requirements or provide you with a

tailor-made formulation.

Get in touch with us to find the perfect solution for your application.

FKuR Kunststoff GmbH

Siemensring 79 | 47877 Willich

Phone: +49 2154 9251- 0 | Fax: - 51

E-Mail: info@fkur.com

Visit www.fkur.com for more information.

You might also like

- Hi Solid PolyurethaneDocument4 pagesHi Solid PolyurethaneafvasquezNo ratings yet

- Dobeckot EH-411 & 505CDocument2 pagesDobeckot EH-411 & 505CDeependraNo ratings yet

- Adhesives For WoodDocument500 pagesAdhesives For WoodJoão Victor WorkNo ratings yet

- TD Bio-Flex F 1801 enDocument2 pagesTD Bio-Flex F 1801 enJosiola MariledoNo ratings yet

- Riblene FC 30Document2 pagesRiblene FC 30Josevi Jiménez MerinoNo ratings yet

- Ecovio F2332: Biodegradable Compound For Compostable Fi LMDocument3 pagesEcovio F2332: Biodegradable Compound For Compostable Fi LMFelipeBohorquezNo ratings yet

- 511 Borstar fb1370 BorougeDocument3 pages511 Borstar fb1370 Borougewebhareggebru06No ratings yet

- Sikafloor 264 PDS (CE)Document7 pagesSikafloor 264 PDS (CE)AymanNo ratings yet

- Ecovio F23B1: Biodegradable Polyester For Compostable FilmDocument3 pagesEcovio F23B1: Biodegradable Polyester For Compostable FilmSiddharthBhasneyNo ratings yet

- Borstar® FB2310: PolyethyleneDocument3 pagesBorstar® FB2310: Polyethylene李万福No ratings yet

- BP115 SilidorDocument2 pagesBP115 SilidorNuri YucelNo ratings yet

- Sikafloor®-169: Product Data SheetDocument4 pagesSikafloor®-169: Product Data SheetMohammed AwfNo ratings yet

- TD Bio-Flex F 1814 enDocument2 pagesTD Bio-Flex F 1814 enShruti SinghNo ratings yet

- Protective & Marine Coatings: General Polymers 3552WDocument2 pagesProtective & Marine Coatings: General Polymers 3552WGustavo SánchezNo ratings yet

- 2-Part PUR Highly Elastic, Crack-Bridging Coating: Product DescriptionDocument7 pages2-Part PUR Highly Elastic, Crack-Bridging Coating: Product Descriptionbeck.26No ratings yet

- KAJO-BIO-Longlife Grease LZR 2: Product InformationDocument2 pagesKAJO-BIO-Longlife Grease LZR 2: Product InformationMassimiliano VolaNo ratings yet

- Special Characteristics:: Innoplus Ll7410DDocument1 pageSpecial Characteristics:: Innoplus Ll7410Dductoan32No ratings yet

- Sikaflex Pro 3 I CureDocument5 pagesSikaflex Pro 3 I Curemuhammad aliNo ratings yet

- FlexprufDocument2 pagesFlexprufEGO AnimationNo ratings yet

- Sikafloor®-263 SLDocument6 pagesSikafloor®-263 SLHalit Baris SertbakanNo ratings yet

- Sikafloor 264Document10 pagesSikafloor 264khanhNo ratings yet

- Technical Data Sheet Baltoflake EcolifeDocument5 pagesTechnical Data Sheet Baltoflake EcolifeAkram AlhaddadNo ratings yet

- 1-Technical Data Sheet Baltoflake Ecolife (750 Μm)Document5 pages1-Technical Data Sheet Baltoflake Ecolife (750 Μm)Akram AlhaddadNo ratings yet

- FB2230 PDS Reg - Europe en V15 PDS Eur 25548 10047661Document4 pagesFB2230 PDS Reg - Europe en V15 PDS Eur 25548 10047661李万福No ratings yet

- Typical Physical Properties:: Property Unit Value Test MethodDocument4 pagesTypical Physical Properties:: Property Unit Value Test Methodmohamad mostafaviNo ratings yet

- Elastocoat C 6335-101Document4 pagesElastocoat C 6335-101Cristina AndronescuNo ratings yet

- Symbol Card Eco 100Document2 pagesSymbol Card Eco 100nita.kurniaNo ratings yet

- Jotamastic 80: Technical Data SheetDocument14 pagesJotamastic 80: Technical Data SheetCv RONATAMA GUSLHANNo ratings yet

- Sikafloor®-264: Product Data SheetDocument5 pagesSikafloor®-264: Product Data SheetEaswar KumarNo ratings yet

- TDS Pe 201 Sf5008eDocument2 pagesTDS Pe 201 Sf5008eOktaviandri SaputraNo ratings yet

- Jotamastic 80.TDS - EngDocument5 pagesJotamastic 80.TDS - EngchepurthiNo ratings yet

- Sika PDS - E - Sikafloor - 359 N (V1)Document4 pagesSika PDS - E - Sikafloor - 359 N (V1)Joh SongthamNo ratings yet

- Technical Data Sheet ADFLEX F 500Document2 pagesTechnical Data Sheet ADFLEX F 500leftpowtaNo ratings yet

- Sikafloor - Decor: 5-Part Epoxy Self-Smoothing and Broadcast SystemDocument6 pagesSikafloor - Decor: 5-Part Epoxy Self-Smoothing and Broadcast SystemAmNo ratings yet

- Ecovio M2351Document3 pagesEcovio M2351ssczusNo ratings yet

- Fosroc Polyurea WH 200Document4 pagesFosroc Polyurea WH 200AdityaVikramVermaNo ratings yet

- Ecovio F2224: Biodegradable Polyester For Compostable Film and Blow Molding ApplicationsDocument4 pagesEcovio F2224: Biodegradable Polyester For Compostable Film and Blow Molding ApplicationsSiddharthBhasneyNo ratings yet

- Sikafloor®-2540 WDocument5 pagesSikafloor®-2540 WJérémie LacombeNo ratings yet

- Invercote GDocument2 pagesInvercote Gmohamed fayedNo ratings yet

- Sikafloor®-2540 W: Product Data SheetDocument5 pagesSikafloor®-2540 W: Product Data SheetAndreiBindeaNo ratings yet

- Jotamastic 80: Technical Data SheetDocument5 pagesJotamastic 80: Technical Data SheetSafinahNo ratings yet

- Jotamastic 87 GFDocument5 pagesJotamastic 87 GFBiju_PottayilNo ratings yet

- BPC Handrails, Caged Ladder & Structural 2010Document23 pagesBPC Handrails, Caged Ladder & Structural 2010sofyanshahNo ratings yet

- PPG PMC Steelguard 651 Dop Apr2021 Emea enDocument5 pagesPPG PMC Steelguard 651 Dop Apr2021 Emea enJ. Jorge Maquieira GonzalezNo ratings yet

- Polibrid 705: Technical DataDocument2 pagesPolibrid 705: Technical DataSky MoonNo ratings yet

- Sikaflex® PRO-3: Product Data SheetDocument4 pagesSikaflex® PRO-3: Product Data SheetLovely BoutikNo ratings yet

- Sikafloor 359 NDocument4 pagesSikafloor 359 NYOSAFAT YUDHA GUNTORONo ratings yet

- 2K-PU Flooring, Flexible, Self-Leveling, Solvent-Free, 50-65-75 Shore A (V 44409 - 0)Document2 pages2K-PU Flooring, Flexible, Self-Leveling, Solvent-Free, 50-65-75 Shore A (V 44409 - 0)Oswaldo Manuel Ramirez Marin0% (1)

- EASTMAN DOUBLE X Negative Film Datasheet US 180924 ENDocument2 pagesEASTMAN DOUBLE X Negative Film Datasheet US 180924 ENtonyNo ratings yet

- Jotamastic 80 Technical Data SheetDocument6 pagesJotamastic 80 Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Sikaflex®-Construction (AP) : One-Part Polyurethane Elastic Adhesive /sealantDocument4 pagesSikaflex®-Construction (AP) : One-Part Polyurethane Elastic Adhesive /sealantJoeNo ratings yet

- Corro-Coat PE Series 50: Technical Data SheetDocument3 pagesCorro-Coat PE Series 50: Technical Data SheetBiju_PottayilNo ratings yet

- Technical Data Sheet - RIBLENE - FL 34 F - ITDocument2 pagesTechnical Data Sheet - RIBLENE - FL 34 F - ITEmanuele GizziNo ratings yet

- Sikaflex® PRO-3: Product Data SheetDocument4 pagesSikaflex® PRO-3: Product Data Sheetislam mohamedNo ratings yet

- 18 - Sikafloor - 264 - SGDocument6 pages18 - Sikafloor - 264 - SGPaul ManiquisNo ratings yet

- CIKOjoint Plyflex 1200Document3 pagesCIKOjoint Plyflex 1200Vaittianathan MahavapillaiNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Automotive Paints and CoatingsFrom EverandAutomotive Paints and CoatingsHans-Joachim StreitbergerNo ratings yet

- Membrane Technology: in the Chemical IndustryFrom EverandMembrane Technology: in the Chemical IndustrySuzana Pereira NunesNo ratings yet

- Us7084310 PG PDFDocument9 pagesUs7084310 PG PDFmeimeiNo ratings yet

- PFD FileDocument44 pagesPFD FilerahulkhakhriyaNo ratings yet

- P11-13 Isomerisms Functional Groups and ReactionDocument62 pagesP11-13 Isomerisms Functional Groups and ReactionNing CahNo ratings yet

- Nutrition and Human HealthDocument339 pagesNutrition and Human HealthOmar CianitoNo ratings yet

- STEREOISOMERISMDocument11 pagesSTEREOISOMERISMSuresh KumarNo ratings yet

- Hexose Monophosphate (HMP) ShuntDocument45 pagesHexose Monophosphate (HMP) ShuntMaryam HallajNo ratings yet

- Water Supply and Treatment Engineering - 18CV46 - Notes-Module-2Document39 pagesWater Supply and Treatment Engineering - 18CV46 - Notes-Module-2Laxmi MahanteshNo ratings yet

- C) MSDS Curing Agent (03rd Coat)Document9 pagesC) MSDS Curing Agent (03rd Coat)MACOYNo ratings yet

- Haloalkanes and HaloarenesDocument7 pagesHaloalkanes and HaloarenesHarish DharavathNo ratings yet

- 8 Boron FamilyDocument129 pages8 Boron FamilyArdra MuraliNo ratings yet

- ადამიანის ფიზიოლოგია 1Document377 pagesადამიანის ფიზიოლოგია 1giorgi borcvaZeNo ratings yet

- Alfa Laval Webinar - 3mcpd and Ge Mitigation - PresentationDocument42 pagesAlfa Laval Webinar - 3mcpd and Ge Mitigation - PresentationImam DarmantoNo ratings yet

- Anammox: Sustainable Nitrogen RemovalDocument4 pagesAnammox: Sustainable Nitrogen RemovalLuqmanNo ratings yet

- About The Dyes: Dyes For Cellulose FibersDocument4 pagesAbout The Dyes: Dyes For Cellulose FibersmanqabatNo ratings yet

- Summ Test 3 G9 ScienceDocument1 pageSumm Test 3 G9 ScienceAlexa RodriguezNo ratings yet

- Itrc Pfas-1 092020Document386 pagesItrc Pfas-1 092020Hiếu NhưNo ratings yet

- Amines WorksheetDocument5 pagesAmines WorksheetMeenakshi Saji0% (1)

- Science of The Total Environment: ReviewDocument17 pagesScience of The Total Environment: ReviewMs dhoniNo ratings yet

- Atp and Coupled Reaction ProcessesDocument5 pagesAtp and Coupled Reaction ProcessesJohn Carlo G. NolascoNo ratings yet

- XII Chemistry 2023 (Complete Notes) - 1Document201 pagesXII Chemistry 2023 (Complete Notes) - 1anzalabdullatif2004No ratings yet

- DT-3000 SDS 090115Document8 pagesDT-3000 SDS 090115Alejandro VescovoNo ratings yet

- Shyamoli Textile Engineering CollegeDocument15 pagesShyamoli Textile Engineering CollegeMehzabeen ShahidyNo ratings yet

- Water Pollution: Causes and Prevention: October 2020Document9 pagesWater Pollution: Causes and Prevention: October 2020ASHISH SINGH BHADOURIYANo ratings yet

- Oils Fats and Waxes NotesDocument3 pagesOils Fats and Waxes NotesArianne BatallonesNo ratings yet

- PRAC 2 Chapter 1 3 RevisedDocument25 pagesPRAC 2 Chapter 1 3 Revisededdiedocot1031No ratings yet

- Eudragit Expert OpinionDocument19 pagesEudragit Expert OpinionHarish GundaNo ratings yet

- LGHH Chemical Product Catalog V1Document4 pagesLGHH Chemical Product Catalog V1Akmal CoinNo ratings yet

- ASTM D-974 Standard Test Method For Acid and Base Number by Color-Indicator TitrationDocument7 pagesASTM D-974 Standard Test Method For Acid and Base Number by Color-Indicator TitrationGabriela EhlertNo ratings yet

- Agriculture Waste MangementDocument31 pagesAgriculture Waste MangementDaniaNo ratings yet