Professional Documents

Culture Documents

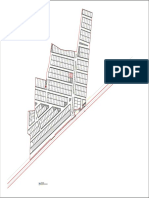

Layout Current Drg-Model

Layout Current Drg-Model

Uploaded by

Muzzammil ShaikhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Layout Current Drg-Model

Layout Current Drg-Model

Uploaded by

Muzzammil ShaikhCopyright:

Available Formats

60.

65 [199']

77.11 [253']

LEGEND

6.0

6.0

80

]

1"

9'-

[1

50 K LTR

36

82

18 18 6.3

5.

0 5

9.80 [32'-2"]

m.

DM

Sq

HR LR

H3522

4

GAS BANK

LATHE M/C

DRILLING V MILLING H MILLING H MILLING INDUCTION 1

19

5

5

FURNACE

LAEUN CINUNMNATI MILWAUKE BRIDGEPORT 4 9

3

BANNING

PRESS

TRIM

M/C NO-47 M/C NO-48 M/C NO-49 M/C NO-51 LOADER

HAMMER

LASCO

1

SCALE 1 : 500

3

OP

PROPOSED SHOTBLASTING 3

PROPOSED HT EXPANSION AREA

HAMMER

BANNING

EXPANSION AREA 2

5

H MILLING H MILLING H MILLING

5

DRILLING

6

GRINDING

]

ELLIOTT ELLIOTT

2

22

M/C NO-001 1

4"

M/C NO-54 M/C NO-53 M/C NO-52

1 2

PRESS

7'-

TRIM

2

1

[16

PRESS

TRIM

10

HAMMER

FIRST-AID BOX

6

NKH

3

DRILLING

DRILLING

.00

M/C-07

M/C-04

M/C NO-13

M/C NO-59

M/C NO-62

5.8

M/C NO-58

PRAKASH

DRILLING

DRILLING

DRILLING

DRILLING

RABOMA

4

M/C NO-111

DM

GRINDING

ETP

51

FURNACE

STOCK

29

10

6.0 INDUCTION 2

2

GRINDING 13 HR LR

1

2

7

LOADER

M/C NO -110

12 1

PRESS

TRIM

HI LIFE

OP 7

PRESS

TRIM

M/C NO -65

1 2 1

2

DRILLING

HAMMER

10

HAMMER

BANNING

MASSY

2

QUENCH TANK PIT

3

49

FIRST-AID BOX

TANK

OIL

AREA

2

CRAWFORD

M/C NO -123

DM

LATHE 121

LATHE 120

BERTHIFZ

TEMPERING FURNACE

WATER

QUENCH

TANK

VTL

(OIL)

TANK

AREA STATEMENT H3521

INDUCTION

HR LR

HARDENING FURNACE

STOCK AREA

LOADER

PROPOSED FORGING

HARDENING

6 1

AREA = 26435 Sq. Meter 2.1

SHEARING

MACHINE

OP

MAINTAENCE 20.2 Roller EXPANSION AREA

AREA = 284544 Sq.Ft. 2.3

4.4 2

QUENCH

TANK

WARNER CNC 5.0

5.4

AREA = 2 Hect. 64.35 Are AREA TO STORE FURNITURE

TEMPERING

2.4

1.8

AREA = 1070 sqft PROPOSED TOOL ROOM AREA

AREA = 6.53 Acre. 15.2

& DIE SHOP

EXISTING SHOT BLASTING

& GRAINDING AREA

AREA = 6 Acre. 21.28 Gunte HEAT TREATMENT

CONTROL

PANEL

FOR PUPJOINT PROCESSING

10.2

(PAINTING , MAKEUP , HYDROTEST)

INSPECTION

AREA = 2307 sqft HARD AREA SH

MILLING M/c

LATHE M/c

LATHE M/c

OT

REWORK

BLA

AREA

FINAL

M/c.

MILLING

STI

DOOR

DIE

MA NG

CH

INE

MPI

17

OFFICE

1

HARDNESS TESTING

HARD SOFT

AREA AREA

ALL DIMN ARE IN MTR

BENCH GRINDER

5.7

All Dimension are in Ft

3.0

38

AREA

PACKING AREA 108 Sqm.

39.0

EXIT DOOR 2

2.8

CUTTING MACHINE

CUTTING

2.0 1.5

CNC

0.8

3500

GANG WAY

INPUT

3

CUTTING

MPI 1

INSP TABLE

7

MARKING

SS BASKET

1.9

CUTTING

CUTTING SHOP -2

TABLE 3.0

CUTTING

21 Sqm.

15

SHED NO. 5

CUTTING

INPUT

MPI 2

INSP TABLE

09

CUTTING

MARKING

SS BASKET

15.8

15.8

2

CUTTING

CUTTING MACHINE

INPUT

CUTTING

MPI 3

INSP TABLE

MARKING

SS BASKET

EXIT DOOR

WAITING FOR PHOSPHATING

OFFICE &

5']

LAB FINAL INSPECTION INPUT

SS BASKET

SS BASKET

SS BASKET

SS BASKET

SS BASKET

[70

Inspection

CEMICAL

CUTTING SHOP LAYOUT STORAGE Room

ALL DIMN ARE IN MTR

2

.87

1.5

3.5

7.6

5.6

214

1.8

CNC 31

14.3

LOADING

8.7

108.50 [356']

PAINTING

OUTSIDE

BOOTH

CNC 20

UN-LOADING

CNC 24

FLASHOFF

ZONE 1

CNC 39

CNC 32

LA COOLER

DRIVE UNIT

PP

CUTTING SHOP 1

PROD.

WATER

DEPT.

IN DOOR

G

FIX

AUTO OIL

BOOTH

CNC 19

SPRAY

I.R. OVEN 1

TU AREA

M/C

5

18

SHED NO. 8

R

1

ER

1

AC INWARD CNC 21

17.8

K CNC 41

5

NC AREA

CNC 33

06

COOLING ZONE 2

2

1

COOLING

ZONE 1

AREA= 125.50 Sqm.

CNC 18

PAINTING

BOOTH

BAND

MATERIAL CNC 50

CNC 40

18.4

CONTROL PANEL

INPROCESS CNC 34

17.39

VTL

CHIP CONVEYOR

PT 80

FLASHOFF

ZONE 2

5

1

I.R. OVEN 2

CNC 46

1

1

COOLANT TANK

5

CNC 49

34

DOOSAN CNC 42

CNC Shop

PRINTING

INKJET

CNC m/c Shop CNC 35

CNC

TEXT

2

CUTTING CUTTING

0.27 Non Tubular Tubular

TABLE

CNC 13

0.92

ZONE 3

0.29 NEW HMC

FLASHOFF

CNC 30 CNC 48

CUTTING CUTTING

0.75 0.92

CNC

Hwacheon

CNC 38

0.75

TABLE

CNC 14

CNC 47

Vehicle Weighbridge

CNC 02

CNC 37

3.71

Hyundai 4 Hyundai 3

CNC CNC 52

PROTEC

CNC 15

FOR TUBULAR PRODUCT

PROPESED F.G. AREA

CNC 36

10.6

Raw Material Yard Hyundai 2 Hyundai 1 CNC 45

35895 X 19700

Hwacheon

AREA TO STORE FURNITURE

18.50Sqm.

CNC

55

15 15

STORAGE RACK

STORAGE RACK

STORAGE RACK

STORAGE RACK

Spinner Spinner

DIE

23.71

14.2 14.2 10.2

GANG WAY

GANG WAY

VMC

AREA = 1235 sqft

18

Spinner

24.3

EDM

60 Sqm.

KITAMURA

AREA= 690 Sqm.

DOOSAN

VMC

DEBURING AREA

5.0

VMC SABRI

5.95

FINAL INSPECTION AREA 6.7

VMC BFW

10.7

8.55

9.7

15 Sqm.

6.50

ELECTRIC PANNEL

BORD

RFD AREA

3.10

DOOR ROOM

10.1

TRIMOS

1.7

m.

AREA=49 Sq

40

6.9

4.5

AREA= 366.45 Sqm.

Recreation Area

Security

Cabin 92

Gat no 10

6.8

89'-2"]

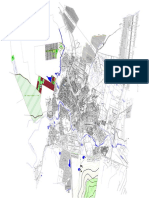

210.07 [6 NOTE ; AS PER TOWN PLANING

TURBO VENTS

FOR VENTILLATION.

TURBO VENTS

FOR VENTILLATION.

INDICATE ROAD MAP 0

3.2

REV. DETAILS OF MODIFICATION NIMSE NIKAM NIKAM 10.05.2017

ALL DIMN ARE IN MTR

2.0

Designed by Checked by Approved by Date

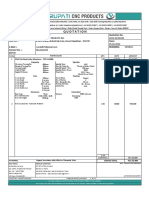

SANKALP ENGINEERING & SERVICES PVT. LTD.

8.1

Gat No. 1093/1, & 1093/2 Chakan-Shikrapur Road, CUST NAME :-

5.5

6.0000

0.4500

Karandi, Tal. Shirur, Pune 412 208. CUST. DWG. NO. :-

W

MURRUM MURRUM

G.LVL

TITLE PART No.:-

FILLING FILLING

0.5

Drawing No - Layout 003

40.0

FACTORY LAYOUT

SAP No :-

You might also like

- Roberto Cacciapaglia: Poco Più LentoDocument5 pagesRoberto Cacciapaglia: Poco Più LentoAsh100% (3)

- Work HoldingDocument5 pagesWork HoldingBalvinder Uday BudaniaNo ratings yet

- WHOLEDocument1 pageWHOLEPia LagmanNo ratings yet

- Perfil de Conjunto A-A: Esquema de LocalizaciónDocument1 pagePerfil de Conjunto A-A: Esquema de Localizaciónborrosan80No ratings yet

- Lotes - GuillermoDocument1 pageLotes - GuillermoKlismann ParedesNo ratings yet

- Gambar Titik Penyiram TanamanDocument1 pageGambar Titik Penyiram Tanamanregi destawanNo ratings yet

- Row - 6 M Row - 6 MDocument1 pageRow - 6 M Row - 6 MBahagianti RossyNo ratings yet

- Alto Qosqo: Plano Topográfico ESC: 1/1250Document1 pageAlto Qosqo: Plano Topográfico ESC: 1/1250JunanNo ratings yet

- Conjunto Habitacional-CroquisDocument1 pageConjunto Habitacional-CroquisGoretti GonzálezNo ratings yet

- Plano ReplanteoDocument1 pagePlano ReplanteoMejia Andia SixtoNo ratings yet

- Set Out For JP5-2024.01.24Document1 pageSet Out For JP5-2024.01.24Sze Wong HoNo ratings yet

- Plano General FFP2022Document1 pagePlano General FFP2022nelson gutierrez galloNo ratings yet

- Drawing1 Layout1Document1 pageDrawing1 Layout1Joel Bermudez TuerosNo ratings yet

- Raisina Estate Layout PlanDocument1 pageRaisina Estate Layout PlanRohit ChhabraNo ratings yet

- Timbaubinha: Lot. Vereador Eliezer Barbosa de AraujoDocument1 pageTimbaubinha: Lot. Vereador Eliezer Barbosa de AraujoJackes DouglasNo ratings yet

- Prancha 02 Ambulatório e PoliclínicaDocument1 pagePrancha 02 Ambulatório e PoliclínicajosevitordinizzNo ratings yet

- STCT-ILV-SHC-PL-AD03-REV24-AD3-4 cd1Document1 pageSTCT-ILV-SHC-PL-AD03-REV24-AD3-4 cd1Giancarlo Manrique VillarrealNo ratings yet

- Curvas PDFDocument1 pageCurvas PDFRicardo Alexis Castro ChavezNo ratings yet

- Planta Primer Tramo ESC.1/100: Pasaje ErmitaDocument1 pagePlanta Primer Tramo ESC.1/100: Pasaje ErmitamvalegaNo ratings yet

- Eh LoloDocument1 pageEh LoloPrince vang-sy PambouNo ratings yet

- Plano de Ubicación CarabaylloDocument1 pagePlano de Ubicación CarabaylloelizabethNo ratings yet

- Panel 13Document1 pagePanel 13suboor222No ratings yet

- Son TerraDocument1 pageSon TerraGerman ChaconNo ratings yet

- Plan Excvaciones Localizadas 20.08.2020Document1 pagePlan Excvaciones Localizadas 20.08.2020carol madeleine de souzaNo ratings yet

- IBMD - MKD Layout 02.12.2019 PDFDocument1 pageIBMD - MKD Layout 02.12.2019 PDFManoj DasNo ratings yet

- Sweet Cherub: ©2010 Stitchx Cross Stitch Designs All Rights ReservedDocument16 pagesSweet Cherub: ©2010 Stitchx Cross Stitch Designs All Rights Reservedgenie1970100% (1)

- F-212 Ad08 PDFDocument13 pagesF-212 Ad08 PDFVictor JimenezNo ratings yet

- Mexico Site Devt Plan A1Document1 pageMexico Site Devt Plan A1Bray CastroNo ratings yet

- Twilight Seashore: Masao AichiDocument4 pagesTwilight Seashore: Masao AichiLauraNo ratings yet

- TMIB - T6 - GT1 - PL - 000 - 2001 - 01 07: Croquis de LocalizaciónDocument9 pagesTMIB - T6 - GT1 - PL - 000 - 2001 - 01 07: Croquis de LocalizaciónENRIQUE CASTAÑEDANo ratings yet

- Sector 8 - Lotes PMDocument1 pageSector 8 - Lotes PMalexlandivarvelaNo ratings yet

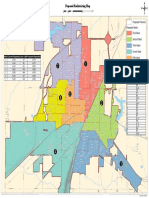

- Proposed Ward Changes For GalesburgDocument1 pageProposed Ward Changes For Galesburgregister-mailNo ratings yet

- Planos 13Document1 pagePlanos 13AndresCamargoNo ratings yet

- Diseño A.A CartagenaDocument1 pageDiseño A.A CartagenawcanizaresruizsenaNo ratings yet

- Guias Mecanicas DepartamentoDocument1 pageGuias Mecanicas Departamentochristian.foxNo ratings yet

- 19038-001 Implantations Ind02Document1 page19038-001 Implantations Ind02Virane DantonNo ratings yet

- Hallelujah F MajorDocument1 pageHallelujah F Majormoja linaNo ratings yet

- Pekerjaan Spillway 09 September 2021-Layout1Document1 pagePekerjaan Spillway 09 September 2021-Layout1Terancam sarjanaNo ratings yet

- Projeto de Arborização - r0Document1 pageProjeto de Arborização - r0Robson Calleia Kalil HoneimNo ratings yet

- Concerto No.3 Adagio - Alessandro MarcelloDocument2 pagesConcerto No.3 Adagio - Alessandro Marcellojfmb brancoNo ratings yet

- Hvac Snagov Iz E3.1 CDocument1 pageHvac Snagov Iz E3.1 CIancului OPMNo ratings yet

- 26 de Octubre Villa VictoriaDocument1 page26 de Octubre Villa VictoriaRaquel Ayra CastilloNo ratings yet

- Municipalidad Distrital de Santiago de Pischa: LeyendaDocument1 pageMunicipalidad Distrital de Santiago de Pischa: LeyendaMadhuri AnghelyNo ratings yet

- CD Garbanza RicksDocument10 pagesCD Garbanza RicksRicks Sanchez KensNo ratings yet

- 141 Plano Solo CurvasDocument1 page141 Plano Solo CurvasCarlos AquiñoNo ratings yet

- Pelimp.+Pengr.+Gor - Sil.+ B. Sadap Km. 4+706 BANG. SADAP (B.Kb.14) Km. 4+499 (B.Kb.15)Document1 pagePelimp.+Pengr.+Gor - Sil.+ B. Sadap Km. 4+706 BANG. SADAP (B.Kb.14) Km. 4+499 (B.Kb.15)iwansNo ratings yet

- Captacion Chupa-CERCO PDocument1 pageCaptacion Chupa-CERCO PNobel Noel SejjeNo ratings yet

- Elevation 12Document2 pagesElevation 12vigilanzapNo ratings yet

- Puente El Fierro Plantas Cortes - LevantamientoDocument1 pagePuente El Fierro Plantas Cortes - LevantamientoAxEl oJeDa 4CNo ratings yet

- Rajiv Gandhi Nagar MapDocument1 pageRajiv Gandhi Nagar MapRekha DeviNo ratings yet

- 3.detalles SegundoDocument1 page3.detalles SegundoZhariitha Koketizhima Nieto RodriguezNo ratings yet

- Plano de Señalizacion Tramo 1-2p. SeñalizacionDocument1 pagePlano de Señalizacion Tramo 1-2p. SeñalizacionLesmes Saddan Flores EstebanNo ratings yet

- Alc Juliorincon V2-Planta Areas AferentesDocument1 pageAlc Juliorincon V2-Planta Areas AferentesCesar Augusto Granados CamargoNo ratings yet

- Tmpe 1 A2 Hid Pla Odl 0021 E04Document1 pageTmpe 1 A2 Hid Pla Odl 0021 E04Philip J FrayNo ratings yet

- Plano de Planta: PC 0+110.225 PT 0+068.775Document1 pagePlano de Planta: PC 0+110.225 PT 0+068.775Wilson Ever Irigoin BustamanteNo ratings yet

- Alambradas de Horizonte PDFDocument6 pagesAlambradas de Horizonte PDFEduardito De Villa CrespoNo ratings yet

- Gilberto Santa Rosa - Perdoname (Karaoplay - Com) 2Document20 pagesGilberto Santa Rosa - Perdoname (Karaoplay - Com) 2zeus33No ratings yet

- Alambradas de HorizonteDocument6 pagesAlambradas de HorizonteDiego SuarezNo ratings yet

- Roosevelt Field Merch Plan - Updated 3.24.22Document3 pagesRoosevelt Field Merch Plan - Updated 3.24.22R. Arief Ferdiansyah PrajaNo ratings yet

- r0 - Design - Nncs Del Deh Lvup CH 105+450 1x12x4Document47 pagesr0 - Design - Nncs Del Deh Lvup CH 105+450 1x12x4Muzzammil ShaikhNo ratings yet

- SBCC DS Nh927a D211 189+428 PC DWG 101Document1 pageSBCC DS Nh927a D211 189+428 PC DWG 101Muzzammil ShaikhNo ratings yet

- R2-SKP-MJB 76+923 Dt.13.05.2023Document9 pagesR2-SKP-MJB 76+923 Dt.13.05.2023Muzzammil ShaikhNo ratings yet

- Letter No-1021Document1 pageLetter No-1021Muzzammil ShaikhNo ratings yet

- Chain Link Fencing - R0Document1 pageChain Link Fencing - R0Muzzammil ShaikhNo ratings yet

- Super Structure of Solid Slab of Span 14MDocument2 pagesSuper Structure of Solid Slab of Span 14MMuzzammil ShaikhNo ratings yet

- Design of Soild Slab 1x14x0.65Document21 pagesDesign of Soild Slab 1x14x0.65Muzzammil ShaikhNo ratings yet

- GAD & SUPER STRUCTURE - VUP - Ch. 67+430 - DWGDocument16 pagesGAD & SUPER STRUCTURE - VUP - Ch. 67+430 - DWGMuzzammil ShaikhNo ratings yet

- Design of Structural Steel Pipe RacksDocument12 pagesDesign of Structural Steel Pipe RacksMuzzammil ShaikhNo ratings yet

- Comment Sheet-Seldoh To Pavnar-PCC - Ret - Wall - 1.5 To 6m-27!7!21Document2 pagesComment Sheet-Seldoh To Pavnar-PCC - Ret - Wall - 1.5 To 6m-27!7!21Muzzammil ShaikhNo ratings yet

- Comment Sheet-MNB - Ch-42+385 1x15x3.5m-19-7-22Document2 pagesComment Sheet-MNB - Ch-42+385 1x15x3.5m-19-7-22Muzzammil ShaikhNo ratings yet

- Comment Sheet-MNB - Ch-49+842 1x10x2m-19-7-22Document2 pagesComment Sheet-MNB - Ch-49+842 1x10x2m-19-7-22Muzzammil ShaikhNo ratings yet

- Comment Sheet-MNB - Ch-41+498 1x10x4m-19-7-22Document2 pagesComment Sheet-MNB - Ch-41+498 1x10x4m-19-7-22Muzzammil ShaikhNo ratings yet

- Lab OrientationDocument15 pagesLab OrientationAarush GuptaNo ratings yet

- Ch-4 LatheDocument98 pagesCh-4 LathePARESHNo ratings yet

- Polygon Turning CNC LatheDocument9 pagesPolygon Turning CNC Lathe223ABDULTEF faresNo ratings yet

- Introduction To Machine Tool, Machine Tool ClassificationsDocument33 pagesIntroduction To Machine Tool, Machine Tool ClassificationsDeepan Raj100% (1)

- Manual de Torno ChinoDocument50 pagesManual de Torno Chinonestor100% (2)

- General e 16063bsDocument6 pagesGeneral e 16063bscoronaqcNo ratings yet

- F 14 133Document639 pagesF 14 133Rafael Díaz duarteNo ratings yet

- CNC Programming BasicsDocument24 pagesCNC Programming BasicsprinilNo ratings yet

- Machine Shop 1Document11 pagesMachine Shop 1Ozen AnchetaNo ratings yet

- Machining ProcessDocument23 pagesMachining ProcessAshish KatariaNo ratings yet

- Precision: We Can You CanDocument16 pagesPrecision: We Can You CanNasr Eldin AlyNo ratings yet

- CNC Exercises For The FANUC Programming Key MTS TeachWare Teacher VersionDocument175 pagesCNC Exercises For The FANUC Programming Key MTS TeachWare Teacher Versiontranviet25No ratings yet

- Document From RDocument26 pagesDocument From RRahul SehgalNo ratings yet

- Modulos y Servos FanucDocument14 pagesModulos y Servos FanucIrving LopezNo ratings yet

- Workpiece Tool Clamping NANNDocument4 pagesWorkpiece Tool Clamping NANNyraju88No ratings yet

- Little Machine Shop CatalogDocument128 pagesLittle Machine Shop CatalogPercy J. Mistry100% (1)

- Burnerd Collet SpecsDocument2 pagesBurnerd Collet SpecsRonza129No ratings yet

- Milling Machine DMDocument6 pagesMilling Machine DMShreya SNo ratings yet

- Milling Machine PPT - 002010301098Document13 pagesMilling Machine PPT - 002010301098দেবার্ঘ্য চক্রবর্তীNo ratings yet

- Tirupati CNC)Document1 pageTirupati CNC)Amit GuptaNo ratings yet

- Introduction Machine ToolsDocument28 pagesIntroduction Machine ToolsMobassher Al HasanNo ratings yet

- PengenalanDocument3 pagesPengenalanAin Syamimi KhairuddinNo ratings yet

- Lathe ComponentsDocument13 pagesLathe Componentsdhanushkachathuranga2021No ratings yet

- CNC ProgrammingDocument20 pagesCNC ProgrammingMansingh YadavNo ratings yet

- Lathe MachineDocument27 pagesLathe MachineRAGHVENDRA SINGHNo ratings yet

- Machine Shop ActivitiesDocument6 pagesMachine Shop ActivitiesCllyan ReyesNo ratings yet

- Common G-Codes For CNC MachinesDocument7 pagesCommon G-Codes For CNC Machinesvijay nayakNo ratings yet

- Catalogo 14 PDFDocument258 pagesCatalogo 14 PDFJuan Manuel VizosoNo ratings yet

- Cnccuttingtools 140314063757 Phpapp01Document26 pagesCnccuttingtools 140314063757 Phpapp01Taha BardanwalaNo ratings yet