Professional Documents

Culture Documents

Catálogo

Catálogo

Uploaded by

Leandro Gomes100%(1)100% found this document useful (1 vote)

33 views15 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

100%(1)100% found this document useful (1 vote)

33 views15 pagesCatálogo

Catálogo

Uploaded by

Leandro GomesCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 15

ALLWEILER

Series NISM

Volute Casing Centrifugal Pumps PN 16 of Inline Design

with lateral Feet

Series NISM

With serial standard motors

‘Application

For handling fresh water, sea water, condensate, oils, brines,

lyes etc. The tluids pumped must not contain any abrasive par

ticles nor chemically attack the construction materials of the

pumps,

Main Fields of Application

In shipbuilding: as general service and fire pump, bilge, ballast

and cooling-water pump, as drinking and sea-water sanitary

‘pump as well as circulating pump for heating systems,

Inall industrial branches: for general water supply as well asin

heating, cooling and circulation systems.

Design Description

The characteristic feature ofthis pump is the design of the con-

nection pump shaft - motor shaft allowing the employment of

‘serial standard motors with alocating-type bearing and normal

shaft end.

‘Any and all screw connections are by means of hexagonal

Screws and hexagonal nuts so as to ensure their proper un-

screwing even with several coats of paint (shipbuilding)

‘The requirements of DIN 31 001 ,Protection against acciden-

tal contact” are met.

‘Type and Series Construction

Single-stage, single-fiow volute casing centrifugal pump.

Series assembly according to the unit assembly system,

Volute casing of intine design. Nominal capacities according to

DIN 24 255.

Series NISM 2/32-200, 2/40-250 and 2/50-250 are two'stage,

but their outer dimensions correspond to the respective single

stage sizes. Owing to the two-stage design, relatively small

delivery flows are achieved with great delivery heads, good

efficiencies and low NPSH values,

These pumps can be mounted in any position. For safety pur-

poses, the arrangement with motor downwards” is not admis~

sible.

Attention: The pump denomination gives the standard nominal

diameter on the delivery side according to DIN 24 255, as this,

diameter, in connection with the impeller diameter, i also a

Characteristic of he hydraulic capacity of the pump.

‘The actual nominal widths on the suction and delivery sides of

sizes having a shaft diameter of 30 mm, are identical. The nomi

ral wiath on the delivery side is greater by one nominal width

teach than as per DIN 24 255 (e.g. NISM 32-160 with DN,/ONg =

440 mm). The actual nominal widths on the suction and delivery

sides of sizes having a shatt diameter of 40 mm, are greater by

fone nominal width each than as per DIN 24255 (e.g. NISM

80-250 with DN, = 125 mm and DNg = 100 mm),

For sizes with shat diameter 30 mm or 40 mm, please reter to

table .Combination of Components,” page 3.

Branch Position, Flanges

Suction and delivery branches arranged opposed in ane line,

Flanges: up to ON 160 as per DIN 2533

DN 200 and above as per DIN 2532

Shaft Sealing

Single-stage pump sizes by uncooled stuffing box with internal

Sealing. Packing rings of Teflon-impregnated white asbestos

yarn of the diaplex-type of braiding,

‘Single and two-stage pump sizes by uncooled, maintenance-

{ree mechanical seal ot the unbalanced type of construction,

Material design:

Rotary sealing Hard carton

Stationary seal ring Oxide ceramics

O-rings Viton ©

Metal parts Stainless steot

Bearing/Lubrication

‘By means of the grease-tubricated grooved ball bearings incor

porated in the motor as per DIN 625.

Upper Temperature @ and Pressure Limits,

Apply to all material designs,

‘Admissible temperature of fluid pumped with

stutfing box uncooled 125°

‘mechanical seal uncooled 140°C

‘Admissible internal pump pressure

for sizes with shaft diameter 20 mm with

stuffing box 16 bar

unbalanced mechanical seal iar

Admissible internal pump pressure for sizes,

‘with shaft diameter 40 mm 10bar

[Admissible admission pressure Admision pressure pus max

Dismantling of Driving Unit

When dismanting the driving unit, the volute casing may

remain in the piping.

The drving unit comprises all pump components except for the

volute easing

ALLWEILER Series NISM

Combination of Components The following table shows the possible voltages and starting

The table on page 3 shows the combination possiblities of varieties as a function of the motor performance

‘components of all NISM sizes.

‘A material advantage is the fact that independently of the Motor Voltage and starting variety

size, the motor capacity and motor design, with the single- a 220 380

Stage sizes, only one casing cover per shaft diameter Is jean

required for the shaft sealing with stuffing box and only one (ie i eave

‘casing cover for the shaft sealing with mechanical sea — -

up t022 5 x =aa=

Connections -

‘The following connections are always provided abowe22 | — 2 x x

[At Filing or contro! pressure tap for automatic breather Grr Gan dae phases acu on ark waalanle

_ NISM pumps with single-ph * 3 avalab

DB Seepage drain Motor Design

€3 Venting AM three-phase motors on all NISM centrifugal pumps are

E4 Venting with automatic breather ‘equipped witha ocating-type bearing. Also, only such motors

MiM2_ Pressure gauge may be attached

Drive Some sizes (different depending upon the manufacturer) have

Surface-cooled three-phase squirrel-cage induction motors, the lecatingstype bearing as a serial equipment.

IMVI type of construction, enclosure IP 44/IP 54 according to as : ae

EC Standard, class 8 insulation, capacities and main dimen- Automatic Breather A 25 A

sions according to DIN 42677, For details, please refer to the back page of this brochure,

Materials Material

Denomination Part-No. wa. wie wie

Volute casing 102.12 G-CuAITON! @a-25 ea-25

Casing cove 161.26/161.28 G-CUAITON: Gc-25 Ga-25

Casing cover 16131 G-CUAITON: GG-25 Ga-25

Casing cover s615/161.23 G-CuAl 10Ni GG-25 GG-25

Stub shaft 02204 4.4401/1.7139 1.4401/1.7139 1.4401/1.7139

Impeller 230.1 G-CuAltONi G-CUALTONI GG-20

Impeller 1st stage 2302 G-CuAl tONi G-CUAI1ONI GG-20

Impeller 2nd stage 2303 G-CuAI TON G-CuAl 10Ni @a-20

Diffuser a4 G-CUAITON: G-CuAlTONi Ga-20

Stage casing 108.1 G-CUAITONI GG-25 GG-25

Motor bracket 347.4 eo-25 GG-25 Ga-25

Gland 4521 G-CuAl10Ni @G-25 Gc-25

Split ring © 5021/5022 GCiGz-Cusn12 GcIGz-Cusn12 GciGZ-Cusa12

Intermediate ring 508.1 G-CuAItONi 6-25 Ge-25

Spacer tube 525.1 Gc-Cusni2 Ga-25 Ga-25

‘Serews and nuts coming into contact, stainless steel stainless steel stainless st

with the fluid to be pumped

© On pump side (in contact with fluid) 1.441, on motor side 1.7139. Split rings at extra charge.

‘Abbreviation System of a NISM Pump,

NISM 92 - 200 / 160 USD W3 98 / 300

Series

ine J Standard nominal width on delivery sida according to DIN 24255:

sizeo-{ ominaimpetordameter ne

Shatt sealing

Material design:

‘Stub shatt bore diameter for fastening on motor shatt end.

Outside motor-bracket or intarmediate-ring diameter or flange size of electric motor

@ Witn the two-stage sizes, the stage number, together with an oblique stroke, is placed before

the nominal width of the delivery branch, e.g, NISM 2/32-200)

Motor performance given in the abbreviation

{ ‘oor partormance Josslors] ss [vs[22

[ite peromence avanin ine atiovanen [os [a7 [nt wes [rs] ufos a [ae [a0 [ar [os [os [75] 99 [v0

2 VM seressa4

ALLWEILER Series NISM

‘Table Combination of Components

‘The table below shows the combination possibilties of structural parts and components of the NISM sizes

fume | Oi Teoniaton

| Aish oth Vous poe] weir [otuse] Sage | re laing crt Base | ump | Substot | Wor bnce | imemeaae

stacy ai oe pate | base | fra

sealing ist | 2nd ‘ing |Stufting| Me- ‘Allocation to the sizes depends upan spe

‘ee stage | sage J | er] eae motor perfomance and at dsign

| se ee sit

a0 ee

| |. ria

wa 2 | ose

2 Py

32-200 - 1 a 1 i‘ - = 2 | ‘30-200

0-160 3 a | a

a we

40-200 i: . ‘ 30-282

w19 3 1

5

2140-250 - - ace a : Aaa - 30-3872 ‘sa-300

wm} afe|s - |

50-200 ce ae - - 1 1 ae a

5 1 |

5-250 e wousn |

I eis |at | reea ae ea leg | soo

afe i. ws |

ew | ra

nn | |

fe | oe 70.00

aes on amma

| rm25050

on

cutee mans

© efefe}-]-etedada]a] oa | oso

|” sp 2035050

; [ets os 2a 25080

| om mse

v[@| I 04s assis

Within a vertical column, identical parts with identical numbers are interchangeable.

ALLWEILER Series NISM

Performance graph 20 30 4060 ad 100 alUSgpni 200 300 uso «acon to

1% 20 ~=30 40 <60~—~8D +100 Qligpmi 200 300 «00 600 700400

so

4

30

20

"

tal

10

8

6

5

‘

3

: I

ae ao 80D «BO 100 rgyyy 200-300 400

Performance graph 29 30 4060 100 a (USgpm! 200 soo «01000 2000 3000

2900 t/min es

730 60 “100 Align) 200 woo 6001000 000

160 7

PaO

100

300

80

“0 200

ol 4

0 vm

20 100

a

20

6

40

10

eae tt 20 «606 D100 yg 200 300-0000

For exact performance data, please refer to the individual characteristics

For a greater range of performances, please refer to Series NIMJNAM.

wu sores

ALLWEILER Series NISM

Performance graph 20 = 304060 100 700 Q1USgpm]_ 6001000 2000

1750 11min

mn 0 100 700 QUgpel 600 ——«1000 800

“0

0

30

2»

6 an » 0 0 100 ginny 200 © 300500

Performance graph 7 «30-4600 TUSgpmj 200 300 400 6001000 200 3000

3500 17min

2% 3 60 6 80 T0OAligemi 200 300 (00 600 000 000 2000

160

r

<2

100

0

60

tm

0

2»

»

See 30 6 OO Ginny 200 © 300 400100

For exact performance data, please refer to the individual characteristics.

For a greater range of performances, please refer to Series NIMINAM.

ww sereisae 8

ALLWEILER

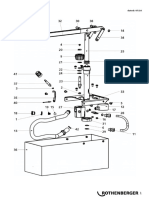

Sectional drawing for single-stage sizes

with shaft 30 mr

‘Series NISM

{2"160, 92° 200: 40-160, 40-200, 40-250, 50-160, 50-200, 60-250, 65-160, 65-200, 80-160)

a.

/ Ye

£3 && a

Shatt sealing: uncooled, unbalanced mechanical seal, internal flushing

Abbreviation: USD

Design with split ring V2

(extra charge)

3 et 08

Jeon)

Se

‘Stuffing box with i

[U1B with single-stage sizes only

Design with intermediate

fing for sizes

40-250 and 50-250

ALLWEILER Series NISM

Sectional drawing for two-stage sizes enomination

wth shaft dlameter 30 mn en

. y Volute casing 02.12

(2132-200, 2140-250, 2150-250) — 1a

Casing cover e128

Casing cover 161.28

Casing cover tert

Casing cover te133

Dituser wa

Stub shat nos

impetier 2301

Impeller tet stage 2302

£ | = Impeller 2ndstage 280.8

Impaiier iststage 2308

H Impeller ndstage 2308

ie impale 2a a

Gasket #002

Gasket i008

Sint washer an

/ Sint washer ae

/ Joint washer a3

Soe ate ae

| : Joint washer ais

: aia

ita

wun ey ae oan Retainer ring asa

per nin ne Packing ang aett

ing: uncooled unbalanced mechanical se Mechanical seal 470;

Sra seal epee tushng ne Techanca sel Eiaionayseaiong 481

eviation ating

ee ee Spitrng 5022

Intermeciat ring 03.1

Threaded rng Stat

Spacer tube S261

Wash ee

Blind rivet 5er

Venting serew era

Guard pate 281

Nipotejont 05

sir nos sus a0 Flange motor 01.1

33 ewagonalserew 801.2

Hexagonal screw 801.8

\ \ Hexagonal screw

4 (Gove tatorm) 201.19

Stud vot, 02

= Stud bolt soa8

Threaded pin soas

Socket mead cap screw 314 14

: Threaded plus 3171

Impotier 2nd stage Casing cover design with Threaded plug 8172

Fastening with tweades Sizes 2/40-250 and 2/50-250 Threaded plug 8173

fing ease of material, Threaded plug sire

designs Hesagona at mt

7 fexagonal nut

WS ang Wis Hexagonal nut e208

Cre 8022

Spring washer sea

Key sao

Rating pate ort

Connections

‘Al Filing or control pressure tap

for automatic breather

81 Drainage

D8 Seepage drain

£3 Venting

4 Venting with automatic

breather

M1 Pressure gauge

M2_ Pressure gauss

weseressee 001 7

ALLWEILER Series NISM

‘Sectional drawing for sizes with shatt diameter 40 mm Denomination Part No

(85-260, 0200, 80-250, 100-200, 100250, 125-250) Jouning een

Volute casing 102.11

Casing cover 1615

Casing cover ret23

Pump toot 1821

Stub shaft 2204

impeler 2301

Motor bracket Bart

4002

ana

Joint washer an

Joint washer ang

Joint washer ana

Joint washer ans

Oving 4123

Giang 4521

Retainer ring 4581

Packing ring sett

Mechanical seat 4701

Stationary sealing = 478.1

Salting 5021

Spit ring 5022

intermediate ring 5099

Space tube 5251

Alsi , Washer 5541

io- | Bind rivet 5671

rae 7 Net Venting screw er2

} 1 iS Guard plate 6351

‘| \ \ Nippie joint i365

- ] Ny Flange motor aor

} | Base plate e021

| tl Hexagonal screw sort

> Hexagonal screw 201.14

{ ial Hexagonal screw 901.19

{| cr Hexagonal screw 901.21

van sony 201 axa at sas) aa! 7065 | 9x72 Stud bot 802.4

31 Stud bot 902.11

sor2t 1615 e701 sa0r 9381 81 e002 an? Forcing screw 908 1

Socket head cap screw 914.14

eee ee Socket head cap screw 914.32

9 mochanial sea rntrna Mushing Threaded plug airs

Abbreviation: U3D ‘Threaded plug 9172

Threaded plug ara

Treaded plug aire

Hexagonal nut 9201

Hexagonal nut 9202

Hexagonal nut 9209

Hexagonal nut 920.12

Spring washer 903

Key 9401

Rating plat ona

Connections

on [At Filing or contol pressure tap

for automatic breather

81 Drainage

Design with spit ring V2 Fastening of the pump ee

(ext charge) foot to he base plate BG Soopage

E4 Venting with automatic

Dreather

Mi Pressure gauge

Ma

eg ee

Sra eszy 9202 ent

vwiza ans 206 one sey

Stutting box with internal sealing U1B.

8 wasererse 1002

ALLWEILER

Series NISM

Unit dimensions Sizes with shaft diameter 30 mm

4

Motors without ex-protection

.

anges aco wo BIN 2588

Bhs esa

oe} of] «| o feel

wo] 10] 18 [to] |

so tes | 25 | t2s| is | ¢

| tas | 20 | tas ie | &

0 | 200 | 22 | 120) 19 |

100 | 220| 2 | te0| 18 | 8

Comectons

Fiing] Ora Sanp-] venting | Presi

tae | ase ane

aan

Seneca: ec a son rom ar|er|os|es|e«| mi] ue

ee —

Pump size] Ranges Pump Feet tor screws | Exension

dimension

DMN] a) ft [mi m{o;eajmymimim| s x

BIG _| | a0 LST 300] 180] 50°] 40"| 270] 320] Teo] B10] —wTe | —ToR

32-200

EO! a0 | «0 | 97 200| 190] s0 | 40 |270| 320] 160| 210] mie | 102

40-160 | 50] 50 108 210] 200] 50] 40 [270 [320 | 160| 210] we | vos | 210 |

20-200 | 50] 50.1105] 5, ¢ssgnql 220] 208] 50/| 40 | 270|820| 200] 250| Mie [toa | 210]

40-250 ‘depending

OBE 20 | 50 | 105] depending | a40| 225] so | 20 |o10| 360] 200|250/ wie | 95 250

30-160 | 665 [ ira] meter, [Zao] a70| w0-| «0 | 970] 320 veo] a1 wie | vor | a9

30-200 [ 65 [65 [i148] “3K [aaol 295 | 50-| 40 [290] 340] 200| 250] Mie [vos | 280

50-280

28 os | 0s 265| 245| 50 | 50 | e80| 400] 200| 250| mie | as 290

@5-160 | 80. | 80 370 | 230] $0 | 6 [980] 380] 300 | 260] we [08 | 370

165-200 60] 80 275| 235| 50 | 50 [350 | 400 |200|250| M16 | 102 | 290

‘20-160 | 100 100 275] 245[ 50 | 50 |350| 400|200| 250] we _[ 102_| 200

ALLWEILER

Series NISM

Unit dimensions Sizes with shaft diameter 40 mm

1p oN 00 and above ace to DIN 2502

Na No.of

ons] © | | * | & {noi}

‘a0 | 200| 22 | 160/18 | @

100 | 220 24 | t80| 18 | 8

125| 250 | 25 | 210| 18 | 8

150 | 285 | 26 | 240| 22 | 8

200 | 340 | 26 | 205| 22 | 8

Connections

Fiting [Orain-] Seep-] Venting Pressure

age | “age gauge |

rain Automatic

Dreather

ar{a:|os| es | ee | wi | mz

esaleselese| cin | cia [ev2|ese

When using special marine motors, it

pending upon the enclosures, different

must be noted that de-

t performances are allo-

ated to the individual sizes, The main dimensionsare changed

srecmng e accordingly In case of order binding tables of motor cimen-

mans inn wou cormimant Sions are to be transmitted to Us

Pump size | Flanges Pump Feet |

|

ON,|ONs| @ | fm | he b m|mifm}m| > [er] | a fns|m| mls |

{55-250 [700] 60 |2701267/ 3551350] —pimensione [600/440] <60] 470) BO | 22"1 296) 600] 540] 400) 350]M20

= 1 jeperd upon j

9-200 [25] 100|210] 261|360) 350] °fre'size” [600] 440) 480| 410) a0 | 22 | 296] 600] 540] 400] s90|M20

orth

109-209 | 150) 128] 210|261 280! 50] intermediate | g9|440| 480] 410) 0 | 22 | 296| 600] 640| 400, 290|M20)

125-250 |200|150|270] 287 | 40] 360 00] 420| 480/416) 80 | 22 1296/60] S40) 200) 350)M20)

10

ALLWEILER

Possible driving motors and allocation to pump sizes,

The motor dime

Exact data depend on the motor make

ions as indicated are approximate values.

When using special marine motors, it must be noted that

different performances are

The main dimensions are

‘changed accordingly. In case of order, binding tables of motor

‘dimensions are to be transmitted to us.

‘Series NISM

Pump sizes with shaft diameter

wna a sepoaratsimaeanmen | dou a aan

wes, Mesa ved 3/8] 8]2]8]8]e 2/e)e)2\2]9]2\ gigi |g lel

shaft/motor intermediate e sloioig Blsiolaigid/ala

fe ww [PHN | soo | sae OBA] sue | see ae epee || 88h #88 §|8)8) 8/8/22) 8)8 8) 8\ sig)

0.55 e |

: Si. si-| | ./ i]

|. .| | | |.

T22 ee eeoee eevee e e

Pa Salalah is

eel | SECOOSOOOOOOsOEC

ion

aeawo | san | oom | waco | soae | sxozsoz0| 0 wo |

} 160M W 260 185, 446 . ° eevee

— iol 7 7

as la

| | |. =| |. : :

200 30 55/400 40-55 280.300.50 400 363 316 631 50, - 3 e

2258 37 60/450, 40-60 280.350.80 | 450 399, 337, 651 80 - 5 e

90, 22 | 24/200 | 30-2412 | 30-200 7 7 = 200 178 130 265 - 13 | + |e] | le

voor | 3 200 | 140 | 202 t lee) fe °

ee ee Pe 1s d

wees aesoo | aoe | osm | sumo | soso | anozsoze| aco | smo | aes | om | mo | a0

5 i.

sxe | 1

ou 2 Laan [aa [am [an [ee noone | eo [ose [cae [ce [ oe s[lslsls1-[s{[s[s{s/s[s[e[6[ 1s

> Slee ele

PT ee ee or slels[s|els

can lie conse | vase [sooasoso| wees [cass [am [re [0 sslslslele

a ee eee eS 1 J

coma 7 sis

are sre | oe lisseeaes | es lee cae fe :

M567 £15085 © Contained in abbrevition ona

1"

2

ALLWEILER Series NISM

we serersae 13

ALLWEILER Series NISM

Size with shatt diameter 30

The A 25 As employed for the automatic venting of pump and

suction line. It operates with a pressure-dependent control

system.

‘Owing to a pressure-controlled shut-off vaive in the suction

line, the device can also be used in plantsin which excess pres

sure is temporarily incurred

Function description:

‘By way of the venting line, suction branch Q2 of the automatic,

breather is connected with connection £4 of the pump. The :

compressed air required for the venting process is supplied to os

the ejector at connection Qt po

Inorder to avoid any dry operation of the pump, the electric cir

‘cuit arrangement (not included in the normal scope of supply)

must be such that the pumps switched on only after the entire ns

suction system has been vented, o

‘As soon as a delivery pressure has been built up and the preset, size

pressure limit reached, the automatic breather is switched off

by the pressure switch, Theimpulseis transmitted by way of the 755

‘control pressure line coupling connection At at the pump with

connection Q4 at the pressure switch ssa

‘The delivery pressure dropping below the preset pressure limit, a

the automatic breather is switched on again. Bae

‘According to the respective operating conditions, the pressure 108

Switch should be adjusted s0 as to switch the automatic

breather off at approx. 80 % of the lowest delivery pressure,

switching it on again at approx. 30 %.

Required control voltage 220 V, 50 Hz or 60 H2; power con-

sumption during starting 21 VA.inoperation 12VA;enclosurelP assy) 3g. ay os) uy sa

56.

Materials, a eee

Lower nozzle: Plastic

Upper nozzle: Plastic

Inlet nozzle: G-Cuzn 18Si4

Pipes ©: cu

Soring nto const win ne Ni pron axes

st of components for the mounting-type automatic breather

‘A25A, Series NISM:

Denomination Part No.

Joint washer 41131

Joint washer 411.32

Joint washer 411.33

Joint washer 411.38

Joint washer 411.35

Reinforcing sieeve 8321 me

Reinforcing sleeve 5322

Reinforcing sieeve 5323

Reinforcing sleeve 5324

‘Automatic breather ers Motor bracket size Dimension

Pipe 7105

Pipe 7108 Ga a Gles eae te |neD

Mount 7324 e

Straight union 735.4 ea

Straight union 7355 30-250 365

Straight union 7358

Threaded pipe angle 7652 30-300 430 | 155 | 85

Reducing socket 769.1 f

Hexagonal screw 901.20 30-350 =

‘Stud Bolt 90210 30-400 }

—

ALLWEILER Series NISM

‘Automatic Breather A 25 A Sizes with shatt diameter 40

4

mss

Pesesel] feta 3

7A

| | _ns7

mo oo

Denomination

Joint washer antat

‘Joint washer 41132

‘Joint washer ai134

Reinforcing sleeve 5321

Reinforcing sleeve 5324

Reinforcing sleeve 532.5

Reinforcing sleeve 5326

‘Automatic breather 675.1

Pipe 7105

Pipe T1068

Mount 732.1

Straight union 7386

Straight union 1357

Threaded pipe angie 7953

Threaded pipe angle 7654

Hexagonal screw 901.20

sus go.2s sazr 5226 Hexagonal screw 901.25

vm se7 ers04 18

ALLWEILER ean i

sun

ALLWEILER AG 9)

wer neato

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2210 InteractiveBrochure MPGDocument60 pages2210 InteractiveBrochure MPGLeandro GomesNo ratings yet

- Bill of Material: Product Number DescriptionDocument1 pageBill of Material: Product Number DescriptionLeandro GomesNo ratings yet

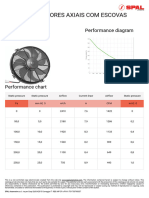

- Ventiladores Axiais Com Escovas: VA34-BP70/LL-66A Performance DiagramDocument3 pagesVentiladores Axiais Com Escovas: VA34-BP70/LL-66A Performance DiagramLeandro GomesNo ratings yet

- LZS RT4A4L24 Datasheet enDocument4 pagesLZS RT4A4L24 Datasheet enLeandro GomesNo ratings yet

- CatalogoDocument5 pagesCatalogoLeandro GomesNo ratings yet

- CatalogoDocument3 pagesCatalogoLeandro GomesNo ratings yet

- EC300 Clutch Engine Control SystemDocument2 pagesEC300 Clutch Engine Control SystemLeandro GomesNo ratings yet

- Product Specifications: VickersDocument1 pageProduct Specifications: VickersLeandro GomesNo ratings yet

- Prüfpumpe TP 25 EN 0716Document2 pagesPrüfpumpe TP 25 EN 0716Leandro GomesNo ratings yet

- GPS01 1027723 Halostar 24 VDocument2 pagesGPS01 1027723 Halostar 24 VLeandro GomesNo ratings yet

- Pro 728442Document4 pagesPro 728442Leandro GomesNo ratings yet

- CatalogoDocument12 pagesCatalogoLeandro GomesNo ratings yet

- ThinkPad L14 Gen 2 Intel 20X20062BODocument2 pagesThinkPad L14 Gen 2 Intel 20X20062BOLeandro GomesNo ratings yet

- GPS01 1027721 Halostar StarliteDocument5 pagesGPS01 1027721 Halostar StarliteLeandro GomesNo ratings yet

- DanelecConnect BrochureDocument8 pagesDanelecConnect BrochureLeandro GomesNo ratings yet

- Ficha TecnicaDocument1 pageFicha TecnicaLeandro GomesNo ratings yet

- SW 800Document12 pagesSW 800Leandro GomesNo ratings yet

- Product Specifications: VickersDocument1 pageProduct Specifications: VickersLeandro GomesNo ratings yet

- DesenhoDocument2 pagesDesenhoLeandro GomesNo ratings yet

- Ficha TecnicaDocument3 pagesFicha TecnicaLeandro GomesNo ratings yet

- Eixo Tecon RSDocument1 pageEixo Tecon RSLeandro GomesNo ratings yet

- Danfoss Pressure Transmitter MBS 33 000 - 40000 Bar 000 - 580151 Psi 060G3019Document3 pagesDanfoss Pressure Transmitter MBS 33 000 - 40000 Bar 000 - 580151 Psi 060G3019Leandro GomesNo ratings yet

- Eao 10-2J13.1065 - Single-LEDDocument2 pagesEao 10-2J13.1065 - Single-LEDLeandro GomesNo ratings yet