Professional Documents

Culture Documents

Mpe 750 Turbo Marine

Mpe 750 Turbo Marine

Uploaded by

TRCopyright:

Available Formats

You might also like

- 2007-2012 Yamaha Big Bear 400 Repair Manual Yfm400Document388 pages2007-2012 Yamaha Big Bear 400 Repair Manual Yfm400Miles Tetlock50% (2)

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- Motor DB58TIS PDFDocument198 pagesMotor DB58TIS PDFRonaldi motter76% (17)

- John Deere 10-5-12 5l Diesel Engine Technical ManualDocument20 pagesJohn Deere 10-5-12 5l Diesel Engine Technical Manualhilda98% (55)

- Service Manual VM D700222Document314 pagesService Manual VM D700222Yohao Cahuana Durand100% (5)

- Daewoo Doosan DB58 Diesel Engine Service Repair ManualDocument20 pagesDaewoo Doosan DB58 Diesel Engine Service Repair ManualRyan Darilag67% (3)

- Harvtm 2122Document662 pagesHarvtm 2122Александр100% (5)

- Liner Reachstacker C4130Document374 pagesLiner Reachstacker C4130JONHHY NGUYEN DANG100% (1)

- 3784A KXX K4J K4M Clio Motor ManualDocument32 pages3784A KXX K4J K4M Clio Motor ManualDavid NebainNo ratings yet

- Operating Instruction Gear Box AFM04,05,06Document20 pagesOperating Instruction Gear Box AFM04,05,06Bang Ochim100% (1)

- HRD k3v k5v Series Parts DiagramsDocument12 pagesHRD k3v k5v Series Parts Diagramsيحيى بن يحيىNo ratings yet

- Eletronic Engines Support 7 3 0 Global GuideDocument524 pagesEletronic Engines Support 7 3 0 Global Guidemayphatbaoson_512242100% (1)

- Operator Manual: DGBB, DGBC, Dgca, DGCB, DGCC, Dgda, DGDB, DGDK, Dgea, Dgfa, DGFB, DGFCDocument67 pagesOperator Manual: DGBB, DGBC, Dgca, DGCB, DGCC, Dgda, DGDB, DGDK, Dgea, Dgfa, DGFB, DGFCLuis Batlle Aguilera100% (2)

- Handbook On General Maintenance Schedule For 8 Wheeler Diesel Hydraulic Tower WagonDocument66 pagesHandbook On General Maintenance Schedule For 8 Wheeler Diesel Hydraulic Tower WagonSahithya VigneshNo ratings yet

- 125Cc RL - Tag: Assembly Instructions & User ManualDocument49 pages125Cc RL - Tag: Assembly Instructions & User ManualjpsdsdsdsdsddNo ratings yet

- Index: R1040 Maintenance ManualDocument48 pagesIndex: R1040 Maintenance ManualZayne BatistaNo ratings yet

- Booklet On Traction Motor and Gear Box of Train SetDocument41 pagesBooklet On Traction Motor and Gear Box of Train SetDeepak AsokanNo ratings yet

- Ee 483 TCDocument49 pagesEe 483 TCmnvijaybabuNo ratings yet

- Appendix I JD Service ManualDocument20 pagesAppendix I JD Service ManualJoao Silva50% (2)

- Engine Fundamental PDFDocument16 pagesEngine Fundamental PDFmohamed hamedNo ratings yet

- S63-5-2013 G Series 1-3.5t IC Forklift Operation and Maintenance ManualDocument125 pagesS63-5-2013 G Series 1-3.5t IC Forklift Operation and Maintenance ManualJohn fredy cuervoNo ratings yet

- Maintenance Handbook For Traction Motor TAO-659 PDFDocument45 pagesMaintenance Handbook For Traction Motor TAO-659 PDFsumitNo ratings yet

- 3512 Construction & Majors RepairesDocument114 pages3512 Construction & Majors RepairesNoureddine Adj100% (1)

- PDFDocument450 pagesPDFazis fauzan100% (1)

- Specifications: 2008 Ford Edge SE 2008 Ford Edge SEDocument6 pagesSpecifications: 2008 Ford Edge SE 2008 Ford Edge SECarlos VelázquezNo ratings yet

- Installation Procedure: SMCS - 4050,4351Document3 pagesInstallation Procedure: SMCS - 4050,4351Enso E Rosales FNo ratings yet

- John Deere 4 5l 6 8l Diesel Engines Workshop ManualDocument20 pagesJohn Deere 4 5l 6 8l Diesel Engines Workshop Manualpaulette98% (44)

- CTM100 PDFDocument452 pagesCTM100 PDFJosé David Barrios PadrónNo ratings yet

- 3500 PDFDocument54 pages3500 PDFmuftah76100% (1)

- U - D700-754E UK - Service-Ed - 5 - 07-2011 PDFDocument299 pagesU - D700-754E UK - Service-Ed - 5 - 07-2011 PDFAlex Varas100% (3)

- Operation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsDocument38 pagesOperation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsangelvhNo ratings yet

- Manual Motor de Pistones Radiales CA Bosch RexrothDocument64 pagesManual Motor de Pistones Radiales CA Bosch RexrothOlegNo ratings yet

- Diesel Generator Service Manual: OPEN TYPE: DHY6000LE / DHY6000LE-3 Soundproof Type: Dhy6000Se / Dhy6000Se-3Document57 pagesDiesel Generator Service Manual: OPEN TYPE: DHY6000LE / DHY6000LE-3 Soundproof Type: Dhy6000Se / Dhy6000Se-3Nestor LopezNo ratings yet

- Manuel de Réparation 3 Tonnes 2Document155 pagesManuel de Réparation 3 Tonnes 2Faouzi Zorgati100% (1)

- Operating Instructions: Diesel Engine 12V2000M91 16V2000M91Document169 pagesOperating Instructions: Diesel Engine 12V2000M91 16V2000M91Bruna Rahd100% (1)

- 4200 Wet Sump Engine OverhaulDocument136 pages4200 Wet Sump Engine OverhaulGONZALO AMATNo ratings yet

- 18-Dynasys Servicemanual Revs 2Document32 pages18-Dynasys Servicemanual Revs 2SouthUnion DieselNo ratings yet

- Operating Instruction - Motores DieselDocument254 pagesOperating Instruction - Motores DieselAlbertoNo ratings yet

- SERV1847 - TXT3 - EngineDocument65 pagesSERV1847 - TXT3 - Enginefrezgi birhanu100% (3)

- Manual IK +C13370 PDFDocument23 pagesManual IK +C13370 PDFsergioNo ratings yet

- Service - Manual - CLASSIC 500 - 350 PDFDocument229 pagesService - Manual - CLASSIC 500 - 350 PDFsandystays100% (1)

- Operating Instructions: Diesel Engine 16 V 4000 Rx3 XDocument163 pagesOperating Instructions: Diesel Engine 16 V 4000 Rx3 Xcosty_transNo ratings yet

- Technical Service Bulletin: ModelDocument3 pagesTechnical Service Bulletin: Modelkilofome05No ratings yet

- 317 Training Manual 0704Document219 pages317 Training Manual 0704mliugong100% (4)

- Tonkaflo Pumps SS Series Installation, Operation, and Maintenance ManualDocument40 pagesTonkaflo Pumps SS Series Installation, Operation, and Maintenance ManualSmith Jonhatan Moya CarbajalNo ratings yet

- 336 02 GB 0312Document310 pages336 02 GB 0312Nguyen Sy100% (1)

- Maintenance Handbook On Traction Motor Cooling Blower & Its Motor PDFDocument55 pagesMaintenance Handbook On Traction Motor Cooling Blower & Its Motor PDFsupriya rakshitNo ratings yet

- 4wheel ElectricDocument76 pages4wheel ElectricJohn PavalNo ratings yet

- Esp. Bomba Do MotorDocument3 pagesEsp. Bomba Do MotorflavioNo ratings yet

- Operating Instructions: Diesel Engine 16V4000R43xDocument177 pagesOperating Instructions: Diesel Engine 16V4000R43xEng M ElseaidyNo ratings yet

- 336 03 GB 0611Document266 pages336 03 GB 0611Tahar BenacherineNo ratings yet

- MS150048 04e 20V4000M93Document200 pagesMS150048 04e 20V4000M93Giang DoNo ratings yet

- 317 GB 0009Document192 pages317 GB 0009kashif AliNo ratings yet

- Clarke LC2A Lombardini Engines For Fire PumpDocument18 pagesClarke LC2A Lombardini Engines For Fire PumpPutraNo ratings yet

- cummins 45m WUV 90kw应发完工资料(20170526)Document39 pagescummins 45m WUV 90kw应发完工资料(20170526)Saran RSNo ratings yet

- Eletronic Engines Support 7 5 0 Global GuideDocument551 pagesEletronic Engines Support 7 5 0 Global Guidemauricio olayaNo ratings yet

- Operating Instructions 395 SeriesDocument190 pagesOperating Instructions 395 Seriesjamal molana0% (1)

- Crankshaft - InstallDocument5 pagesCrankshaft - InstallalonsoNo ratings yet

- Manual de Servicio KSB WKDocument46 pagesManual de Servicio KSB WKHeriberto MendozaNo ratings yet

- Operating Instructions: Diesel Engine 12V2000M91 16V2000M91Document169 pagesOperating Instructions: Diesel Engine 12V2000M91 16V2000M91Jason McLaughlinNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Study On The Adavnce Technology Used in Bs6 Engines: Visvesvaraya Technological UniversityDocument11 pagesStudy On The Adavnce Technology Used in Bs6 Engines: Visvesvaraya Technological UniversityVishal GNo ratings yet

- Lubrication SystemDocument6 pagesLubrication SystemAbdulrahman AliNo ratings yet

- Kirloskar: Diesel Generating Sets KG125W / KG125WSDocument4 pagesKirloskar: Diesel Generating Sets KG125W / KG125WSnam phạmNo ratings yet

- VHP F3521gsi 7008 0102Document2 pagesVHP F3521gsi 7008 0102jairoNo ratings yet

- 12M Fe-Slf - J2 - AmtDocument62 pages12M Fe-Slf - J2 - AmtD. Nanda KishoreNo ratings yet

- 25-Service Manual Fuel Supply System Diesel Engines ASB, ASE, BNG, BVN & BMCDocument83 pages25-Service Manual Fuel Supply System Diesel Engines ASB, ASE, BNG, BVN & BMCDamir SasaNo ratings yet

- Almera: GI MA EM EM LC EC FE CL - 5Mt CL - 6Mt MT - 5Mt MT - 6Mt AT AX SU BR ST RS BT HA ATC SC EL IDXDocument1 pageAlmera: GI MA EM EM LC EC FE CL - 5Mt CL - 6Mt MT - 5Mt MT - 6Mt AT AX SU BR ST RS BT HA ATC SC EL IDXAlex RonNo ratings yet

- Fuel Filter Housing ExplanationDocument3 pagesFuel Filter Housing ExplanationMrAlbert2009No ratings yet

- Chemistry Grade 7 - Answer KeyDocument3 pagesChemistry Grade 7 - Answer KeyAnam MahmoodNo ratings yet

- Generator Faults, Causes, Effect and ProtectionDocument8 pagesGenerator Faults, Causes, Effect and ProtectionSk The Alternator100% (1)

- L6 Introduction To Cycle Analysis Second Law of Thermodynamics 6 Hrs. To Be Distributed - NewDocument25 pagesL6 Introduction To Cycle Analysis Second Law of Thermodynamics 6 Hrs. To Be Distributed - NewJohn Paul AbanNo ratings yet

- Thermal EngineeringDocument6 pagesThermal Engineeringtarek ali ahmedNo ratings yet

- Caterpillar Common RailDocument2 pagesCaterpillar Common RailErick AlarconNo ratings yet

- Features:: 1250kVA, Open Type, 4012-46TWG2A, PI734A, 3phase, AMFDocument7 pagesFeatures:: 1250kVA, Open Type, 4012-46TWG2A, PI734A, 3phase, AMFhelmy muktiNo ratings yet

- 10 11 035 ErrorList Liebherr V1.0Document17 pages10 11 035 ErrorList Liebherr V1.0Martin ZaehNo ratings yet

- TDI Injection and Glow Plug System 2.0LDocument79 pagesTDI Injection and Glow Plug System 2.0LFailCucNo ratings yet

- FME Remedial AssignmentDocument2 pagesFME Remedial AssignmentHann yaay daddyNo ratings yet

- Ocs-Mv01 Miss Bee Inventory and Equipment ListDocument13 pagesOcs-Mv01 Miss Bee Inventory and Equipment ListferdinandusNo ratings yet

- Fuel, Coolant and Oil FlowDocument7 pagesFuel, Coolant and Oil Flowshaken56No ratings yet

- Mvl3e 62KL NP2Document33 pagesMvl3e 62KL NP2Phil100% (1)

- Volvo Penta d13-800Document108 pagesVolvo Penta d13-800Maxim VasilevskiyNo ratings yet

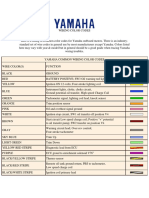

- Yamaha Color CodesDocument2 pagesYamaha Color CodesMohd essa100% (2)

- Manuel Volvo B17 B19 B21 B23 1975-85Document108 pagesManuel Volvo B17 B19 B21 B23 1975-85monodNo ratings yet

- Technical Information: For V1505Document27 pagesTechnical Information: For V1505hendra100% (1)

- BOSCH Filter Catalogue A4!21!09-20Document29 pagesBOSCH Filter Catalogue A4!21!09-20Jayesh PatelNo ratings yet

- Pumps: (Sample Problems)Document11 pagesPumps: (Sample Problems)JAYNo ratings yet

- Illustrate Your Answers With NEAT Sketches Wherever NecessaryDocument4 pagesIllustrate Your Answers With NEAT Sketches Wherever Necessarya c s KumarNo ratings yet

Mpe 750 Turbo Marine

Mpe 750 Turbo Marine

Uploaded by

TROriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mpe 750 Turbo Marine

Mpe 750 Turbo Marine

Uploaded by

TRCopyright:

Available Formats

Installation Guide

MPE 750 Turbo Marine

Closed Loop

MPE 750 Turbo Marine - Closed Loop

This Installation Guide is valid for the following engine variants:

• 103666_I2 749 MAR TC-100 DS V4 2007 3.1

• 103730_I2 749 MAR TC-143 DS V1 2007 3.1

103666_EHB_Rev1.0_080215

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

Table of contents

1 Mechanical Installation 1

1.1 Engine lift 2

1.2 Engine fixation and decoupling 3

1.3 Power Take Off (PTO) 4

1.4 Throttle cable 5

2 Alignment engine to drive train 6

3 Fuel system 7

4 Cooling water 10

4.1 Supply sea water 12

4.2 Flush system 13

4.3 Boat tow 14

5 Exhaust system 15

6 Electric 17

6.1 Engine monitoring 18

6.2 Schema engine wire harness 19

6.3 Schema boat harness 20

6.4 Required connectors for boat harness 21

7 First run and brake in of engine 22

8 Maintenance 24

9 Serial release 25

10 Specification for fuel, oil and coolant 26

11 Basic dimensions 27

12 Reference addresses 28

13 Appendix 29

103666_EHB_Rev1.0_080215

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

1 Mechanical Installation

The following section describes the handling of the engine during installation and the assembly into the boat.

In general a clearance of 50 mm between engine and boat hull is required.

Vent openings of an area of 9000 m² is needed to give the engine enough air to operate.

103666_EBH_Rev1.0_080215 Page 1

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

1.1 Engine lift

The engine has two lift eyes (1) at the cylinder head. Only use these eyes to raise the engine.

103666_EBH_Rev1.0_080215 Page 2

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

1.2 Engine fixation and decoupling

The engine mounts are specific for marine applications, a decoupling to the boat is necessary. The picture

shows the placement and proposed engine bearings (1) of the marine engine.

Pos. Part No Description QTY

1 100527 engine mount D62 H30 M12 4

2 102535 engine bracket front 1

3 100119 engine bracket rear 1

103666_EBH_Rev1.0_080215 Page 3

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

1.3 Power Take Off (PTO)

The connection to the drive train is by a thread M24x2 on the PTO of the engine

103666_EBH_Rev1.0_080215 Page 4

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

1.4 Throttle cable

The engine has a mechanical throttle body which has to be activated by a marine throttle cable. The travel

of 70 mm is designed to meet the function throttle levers like the Teleflex JBS system.

maximum possible

position of bowden cable

The Teleflex JBS system is designated for jet boats and is available e.g. at Allpa Marine Equipment, part

number CH2300

103666_EBH_Rev1.0_080215 Page 5

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

2 Alignment Engine to Drive Train

The alignment of the engine to the drive train has to be in following limits

Radial alignment: max. 0.8 mm [ 0.03 inch ]

Angular alignment: max. 0.5°

To check and adjust the alignment between the engine and the Weber Automotive Jet Propulsion System a

Weber Automotive alignment tool was designed. This tool is using a laser to get the engine with drive system

set up properly. The use of this tool is described in the installation manual of the Weber Jet Propulsion

System.

To adjust the alingnment engine shims (1) are available at Weber Automotive

Part No Description Thickness

103708 engine shim 0,5 mm

103707 engine shim 1,0 mm

103666_EBH_Rev1.0_080215 Page 6

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

3 Fuel System

The fuel pump (1) has to deliver 120 liters per hour at a pressure of 4.5 bar. A possible

pump and filter configuration is shown in the following picture. To ensure a safe and

adequate fuel delivery a minimum inner diameter of 8 mm is required for fuel hoses and

fittings. This includes fittings on the gas tank including gas pick up in the tank.

1) fuel pump from gastank

2) main filter

3) pre filter

to engine

1 2

Fuel filters (2) (3) have to be used to be avoid damages on the fuel pump and malfunction of the fuel

injectors:

Prefilter (3):

• 105 μm

• e.g. Pierburg 4.000.30.80.0

Mainfilter (2):

• 15 μm, filtergrade 95%

• e.g. Mann&Hummel WK512

103666_EBH_Rev1.0_080215 Page 7

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

3 Fuel System

b a

The fuel rails fittings ars designed conform to

SAE J2044. The use of quick connectors (1) (2) is

strictly recommended.

(a) Fuel Feed Line from Fuel Pump: Fitting SAE

J2044 diameter 7,89 mm for quick connector

(b) Fuel Return Line to tank: Fitting SAE J2044

diameter 7,89 mm for quick connectors

2

3

fuelrail

fuel tank

fuel pump

120liter/hour at 4.5bar

Pos. Order No Description Specification Manufacturer

1 104227 quick connector 7,89x90° Weber

2 104228 quick connector 7,89x180° Weber

3 103450 fuel filter, pressure side Mann & Hummel WK512

4 103397 fuel filter, intake side Pierburg 4.000.30.80.0

103666_EBH_Rev1.0_080215 Page 8

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

3 Fuel System

The engine and the fuel components including recommended fuel

filters and stainless steel fuel quick connectors are conform to:

• USCG: Boatbilder handbook Subpart J - Fuel Systems:

Title 33 CFR Sections 183.501-183.590

• DIN EN ISO 10088 - Pemanently installed fuel systems and

fixed fuel tanks

Consult the specifications for gas tanks, fuel pump and fuel line

installation of USCG Boatbilders handbook and the Directive 94/25/EG

last amended by 2003/44/EG

103666_EBH_Rev1.0_080215 Page 9

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

4 Cooling Water

The engine itself has no water pump to feed the open loop of the cooling system. In a combination with a jet

pump the sea water for cooling is delivered by the jet pump propulsion system. By using different propulsion

systems a water pump has to be integrated into the drive train.

The tube for the sea water supply has to be mounted to the fitting at the charge air cooler

103666_I2 749 MAR TC-100 DS V4 2007 3.1

(1) Fitting at charge air cooler for sea water

supply. Inner diameter of tube: 19mm

The water / water cooler has a fitting to drain

the water out of the open loop. This drainage

can be implemented into the sea water supply

tube.

water / water cooler

drainage

tube from jetpump

103666_EBH_Rev1.0_080215 Page 10

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

4 Cooling Water

103730_I2 749 MAR TC-143 DS V1 2007 3.1

(2) Fitting at charge air cooler for sea water

supply . Inner diameter of tube: 19mm

The water / water cooler has a fitting to drain

the water out of the open loop. This drainage

can be implemented into the sea water supply

tube.

water / water cooler

drainage

tube from jetpump

103666_EBH_Rev1.0_080215 Page 11

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

4.1 Supply Sea Water

The delivery of sea water of the open loop cooling circuit has to meet the specification listed in the table.

Engine: 98 - 105 kW Engine: 49 - 76 kW

engine speed Fresh water pressure Waterflow Fresh water pressure Waterflow

HO cooling system HO system SO cooling system SO system

(at pump outlet Line) (at pump outlet Line)

[ rpm] [ bar ] [ l/min ] [ bar ] [ l/min ]

1500 0.25 13.40 0.18 11.00

2000 0.26 17.50 0.22 12.20

2500 0.38 21.40 0.20 13.00

3000 0.58 26.20 0.25 15.00

3500 0.77 32.00 0.35 19.00

4000 0.98 36.70 0.51 24.00

4500 1.22 40.70 0.69 29.50

5000 1.49 47.20 0.92 35.00

5500 1.85 54.60 1.19 41.00

6000 2.20 61.60 1.53 46.50

6500 2.62 67.80 1.84 53.00

7000 3.00 71.70 2.20 59.00

7500 3.39 74.00 2.51 63.50

103666_EBH_Rev1.0_080215 Page 12

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

4.2 Flush System

Especially for the use of the boat in salt water a

flush system to rinse the open loop cooling circuit is

recommended. Therefore a flush system has to be

implemented by the boat builder. The following picture

shows an example how to implement this kind of

system.

Jetpump

The engine has a wet exhaust system. This means sea water is injected into the exhaust out of the open loop

cooling circuit. Due to this water injection the exhaust temperature and also noise is reduced. This water is

pressed out of the exhaust system by the exhaust pressure of the engine. If the engine does not run there is

no mechanism to drain the exhaust system.

Flush procedure:

• Connect the Flush kit

• Start the engine and operate only in idle. Do not accelerate

• Ensure the water supply within 30 seconds

• Flush the open loop cooling circuit for one minute minimum

• Stop water supply

• Stop engine within 30 seconds

• Remove the flush kit

Never flush without a running engine otherwise there is

a high risk to fill the engine with water

The engine may only be operated at idle speed for

ATTENTION maximum of 30 seconds without flush water

103666_EBH_Rev1.0_080215 Page 13

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

4.3 Boat tow

In combination with a jet propulsion system there is a risk to fill the engine with water by towing the boat.

The engine has a wet exhaust system. This means sea water is injected into the exhaust out of the open loop

cooling circuit. Due to this water injection the exhaust temperature and also noise is reduced. This water is

pressed out of the exhaust system by the exhaust pressure / stream of the engine. If the engine does not run

there is no mechanism to drain the exhaust system.

By towing the boat the jet pump system delivers sea water to the engine even without running engine. This

means water will be injected into the exhaust system. When the exhaust system is fully filled with water it will

fill the engine with water.

Don’t tow the boat with a high speed. If a high

tow speed is necessary the water feed tube

between jet pump and engine has to be closed

ATTENTION by a clamping device or a closure valve has to

be installed.

103666_EBH_Rev1.0_080215 Page 14

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

5 Exhaust System

The exhaust system of the spark ignition

marine engine is water cooled. A part of

the sea water is injected into the manifold

to reduce the exhaust temperature and

the noise in the system. This injected

water will leave the boat through the

exhaust system (1). 1

The rest of the sea water leaves the

engine through a fitting (2) at the bottom

of the exhaust manifold. This water has to

be drained out of the boat.

103666_EBH_Rev1.0_080215 Page 15

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

5 Exhaust System

Engine exhaust manifold and muffler can be connected by a rubber tube, e.g. Marine exhaust tube by VETUS.

The muffler should have a volume of approximately 17 Liter and the back pressure of the whole exhaust

system has to be: max. 200 mbar - 143 hp

max. 180 mbar - 104 hp

To avoid a filling of the exhaust system e.g. by the stern wave or during boat slip, the layout should look like

shown in the following picture

103666_EBH_Rev1.0_080215 Page 16

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

6 Electric

The engine will be delivered including an engine wire harness and Engine ECU. All necessary connectors for

the vehicle wire hardness are listed in section 6.4. Also diameters of the wires in the vehicle harness have to

match the diameters of the engine harness.

103666_EBH_Rev1.0_080215 Page 17

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

6.1 Electric

The engine can give out following output / informations:

• MIL (Malfunktion Indicator Light): Will be activated when engine performance is limited

• Engine overtemperature lamp: Is activated when engine temperature exceed the limit

• Oil pressure lamp

• Engine speed signal

• Engine up to 98 kW: 2 pulses/rev

• Engine 105 kW: 6 pulses/rev

The wireing for the oil pressure lamp is not included in the engine wire

harness and has to be implemented in the boat harness.

The EMS / engine package includes sensors and control strategies for:

• Raw water supply: temperature sensor in exhaust manifold

• Altitude: air pressure sensor

• Temperature: air and coolant temperature

• RPM: Crank sensor

• Start: Phase sensor for cylinder 1 detection

• Turbo System: pressure sensor for boost control

• Oil System: oil pressure switch to warning lamp

• Emissions / Performance: closed loop lamda control

Specification

Malfunktion Indicator Light (MIL) max. 10 Watt

engine overtemperature lamp max. 10 Watt

oil pressure lamp max. 10 Watt

Engine up to 98 kW: 2 pulses/rev

engine speed signal

Engine 105 kW: 6 pulses/rev

battery capacity 12 V / 10 Ah

starter solenoid 600 A steady state

internal generator with regulator Idle: 150 Watt > 3000rpm: Watt max. 340 Watt

103666_EBH_Rev1.0_080215 Page 18

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

6.2 Schema engine wire harness

103666_EBH_Rev1.0_080215 Page 19

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

6.3 Schema boat wire harness

103666_EBH_Rev1.0_080215 Page 20

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

6.4 Required connectors for boat harness

Following table shows the connector parts needed fort he boat wire harness:

Connector to the engine wire harness (Engine / Chassis 1):

Description Manufacturer Series Part Number Quantity

Connector

Housing 10 Delphi / Packard Metri Pack 150 12065425 1

Cavities Female

Terminal Position

Delphi / Packard Metri Pack 150 12124264 1

Assurance 10

Female Terminals Delphi / Packard Metri Pack 150 12048074 8

cable seals Delphi / Packard Metri Pack 150 12048087 8

cavity plug Delphi / Packard Metri Pack 150 12059168 2

Connector starter relay:

Description Manufacturer Series Part Number Quantity

Connector

Delphi / Packard Metri Pack 150 12162195 1

Assembly 2F

Female Terminals Delphi / Packard Metri Pack 150 12124075 2

All components for the connectors can be purchased at:

www. powerandsignal.com

103666_EBH_Rev1.0_080215 Page 21

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

7 First engine run and brake in

After the engine installation is finished a first run with the boat out of the water is recommended. Therefor use

the flush system to avoid any damage of the engine due to overheat. The use of the flush system is described

in section 4.2.

Engine is delivered filled with engine oil by the factory

ATTENTION

Procedure:

Check at first the connection to the drive train. Therefore disconnect the ignition coils to avoid a starting of the

engine. Crank the engine by using the starter, do not crank longer than 10 seconds and repeat as needed.

Check the drive train for abnormal behaviour (e.g. mechanical noise). Reconnect the ignition coils

1) Remove cable harness on the ignition coils (1).

2) Loosen the cable harness on the cable holders (2).

3) Remove the cable harness on the injection valves (3).

103666_EBH_Rev1.0_080215 Page 22

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

7 First engine run and brake in

• Prime the fuel system: Activate the fuel pump by turning on the key switch (not in start position).

• Connect the flush system as described in section 4.2

• Start engine. Do not accelerate. The engine may only be operated at idle speed for a maximum of 30

seconds without sea water

• Ensure the water supply within 30 seconds

• Check if the water out of the outer cooling loop is leaving the boat.

• Check if the injected water is leaving the exhaust

• Stop water supply

• Check oil level as described on the hang tang on the oil tank

• Check coolant level (1) of the inner cooling loop

Coolant level below the MIN marking can cause damage

to the engine due to overheating.

Coolant level below the MAX marking should be avoided

ATTENTION to prevent environmental damage

103666_EBH_Rev1.0_080215 Page 23

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

8 Maintenance

Following table shows the maintenance intervals for the marine engine.

At end of season

1st

mainte-

nance Maintenance interval

Procedure

h 1) h 1)

see page

Activity

after 25 every 50 every 100

Motor oil and oil

Change 14 ■ 2) ■ 2) ■

filter

Coolant Change 20 ■ every 4 years 4)

Check /

23 ■

clean

Spark plugs

Change 23 ■ 3)

Check /

Valve play 26 ■ 3) ■ 3)

set

Fuel filter Change 32 ■ 3)

1)

h = hours of operation

2)

or at least once a year if the hours of operation specified above are not reached before

that.

3)

or at least every two years if the hours of operation specified above are not reached

before that.

4)

Valid for engine manufacturer’s fill. Please note the instructions provided by coolant

manufacturer, when using other coolants.

For detailed maintenance informations please consult the service handbook.

This handbook can be downloaded in the service section at:

www.weber-motor.com

103666_EBH_Rev1.0_080215 Page 24

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

9 Engine Serial Release

The engine installation and function has to be released by Weber Automotive before warranty will cover the

product. Therefore two ways are possible:

• Installation check by Weber Automotive, this service will be quoted on a time

travel and mateial basis

• Installation by customer: the customer has to provide evidence of the engine

installation and function

Both ways will be documented in a release document by Weber Automotive.

103666_EBH_Rev1.0_080215 Page 25

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

10 Specification for fuel, oil and coolant

Fuel:

Fuel quality Unleaded gasoline according to DIN 51607 („super

unleaded“), with an octane rating of at least 95 ROZ

[RON] or 85 MOZ [MON]

Oil:

Recommendiation: 15W 50 completely synthetic, API SH, JASO MA

Alternative 0W 50

Fill quantity Initial filling 4.2 liters [4.4 qt (US)]

Oil change with filter 3.3 - 3.5 liters

[3.5 - 3.7 qt (US)]

Coolant:

Coolant additive: Coolant additive based on ethylene glycolsilicate and

nitrite-free. Suitable for aluminium engines.

Anti-freeze mixture 50% water + 50% coolant additive

Fill quantity 3.3 liters [3.5 qt (US)]

Approved coolant additives BASF Glysantin G30

Chevron Havoline Extended Life Coolant XTC+B

Valvoline Zerex G30

Manufacturer´s fill provides frost protection up to -37°C [-34.6°F]

Recommended minimum frost protection up to -30°C [-22°F]

103666_EBH_Rev1.0_080215 Page 26

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

11 Basic dimensions [mm]

Please contact Weber Automotive for detailed drawings or CAD models.

547

424

117,5

214 332 52,5

720

609

140° 140°

295 400

103666_EBH_Rev1.0_080215 Page 27

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

12 Reference Adresses

Throttle cable: RCS: Remote Control Systems GmbH

www.r-c-s-online.de

Contact Mr. Frank Schneider

Frank.Schneider@r-c-s-online.de

Helm Throttle Level: Teleflex

www.teleflexmorse.com

Allpa Marine Equipment

www.allpa.nl

www.allpa.de

www.allpa.eu

Exhaust Tube: Vetus

Allpa Marine Equipment

www.allpa.nl

www.allpa.de

www.allpa.eu

Engine Monitoring: VDO Marine

www.vdo-marine.com

Contact Mr. Joachim Smolka

smolka@kienzle.de

Connector: Power&Signal Group

www.powerandsignal.com

103666_EBH_Rev1.0_080215 Page 28

Downloaded from www.Manualslib.com manuals search engine

Installation Guide

MPE 750 Turbo Marine

Closed Loop

103666_EBH_Rev1.0_080215 Page 29

Downloaded from www.Manualslib.com manuals search engine

You might also like

- 2007-2012 Yamaha Big Bear 400 Repair Manual Yfm400Document388 pages2007-2012 Yamaha Big Bear 400 Repair Manual Yfm400Miles Tetlock50% (2)

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- Motor DB58TIS PDFDocument198 pagesMotor DB58TIS PDFRonaldi motter76% (17)

- John Deere 10-5-12 5l Diesel Engine Technical ManualDocument20 pagesJohn Deere 10-5-12 5l Diesel Engine Technical Manualhilda98% (55)

- Service Manual VM D700222Document314 pagesService Manual VM D700222Yohao Cahuana Durand100% (5)

- Daewoo Doosan DB58 Diesel Engine Service Repair ManualDocument20 pagesDaewoo Doosan DB58 Diesel Engine Service Repair ManualRyan Darilag67% (3)

- Harvtm 2122Document662 pagesHarvtm 2122Александр100% (5)

- Liner Reachstacker C4130Document374 pagesLiner Reachstacker C4130JONHHY NGUYEN DANG100% (1)

- 3784A KXX K4J K4M Clio Motor ManualDocument32 pages3784A KXX K4J K4M Clio Motor ManualDavid NebainNo ratings yet

- Operating Instruction Gear Box AFM04,05,06Document20 pagesOperating Instruction Gear Box AFM04,05,06Bang Ochim100% (1)

- HRD k3v k5v Series Parts DiagramsDocument12 pagesHRD k3v k5v Series Parts Diagramsيحيى بن يحيىNo ratings yet

- Eletronic Engines Support 7 3 0 Global GuideDocument524 pagesEletronic Engines Support 7 3 0 Global Guidemayphatbaoson_512242100% (1)

- Operator Manual: DGBB, DGBC, Dgca, DGCB, DGCC, Dgda, DGDB, DGDK, Dgea, Dgfa, DGFB, DGFCDocument67 pagesOperator Manual: DGBB, DGBC, Dgca, DGCB, DGCC, Dgda, DGDB, DGDK, Dgea, Dgfa, DGFB, DGFCLuis Batlle Aguilera100% (2)

- Handbook On General Maintenance Schedule For 8 Wheeler Diesel Hydraulic Tower WagonDocument66 pagesHandbook On General Maintenance Schedule For 8 Wheeler Diesel Hydraulic Tower WagonSahithya VigneshNo ratings yet

- 125Cc RL - Tag: Assembly Instructions & User ManualDocument49 pages125Cc RL - Tag: Assembly Instructions & User ManualjpsdsdsdsdsddNo ratings yet

- Index: R1040 Maintenance ManualDocument48 pagesIndex: R1040 Maintenance ManualZayne BatistaNo ratings yet

- Booklet On Traction Motor and Gear Box of Train SetDocument41 pagesBooklet On Traction Motor and Gear Box of Train SetDeepak AsokanNo ratings yet

- Ee 483 TCDocument49 pagesEe 483 TCmnvijaybabuNo ratings yet

- Appendix I JD Service ManualDocument20 pagesAppendix I JD Service ManualJoao Silva50% (2)

- Engine Fundamental PDFDocument16 pagesEngine Fundamental PDFmohamed hamedNo ratings yet

- S63-5-2013 G Series 1-3.5t IC Forklift Operation and Maintenance ManualDocument125 pagesS63-5-2013 G Series 1-3.5t IC Forklift Operation and Maintenance ManualJohn fredy cuervoNo ratings yet

- Maintenance Handbook For Traction Motor TAO-659 PDFDocument45 pagesMaintenance Handbook For Traction Motor TAO-659 PDFsumitNo ratings yet

- 3512 Construction & Majors RepairesDocument114 pages3512 Construction & Majors RepairesNoureddine Adj100% (1)

- PDFDocument450 pagesPDFazis fauzan100% (1)

- Specifications: 2008 Ford Edge SE 2008 Ford Edge SEDocument6 pagesSpecifications: 2008 Ford Edge SE 2008 Ford Edge SECarlos VelázquezNo ratings yet

- Installation Procedure: SMCS - 4050,4351Document3 pagesInstallation Procedure: SMCS - 4050,4351Enso E Rosales FNo ratings yet

- John Deere 4 5l 6 8l Diesel Engines Workshop ManualDocument20 pagesJohn Deere 4 5l 6 8l Diesel Engines Workshop Manualpaulette98% (44)

- CTM100 PDFDocument452 pagesCTM100 PDFJosé David Barrios PadrónNo ratings yet

- 3500 PDFDocument54 pages3500 PDFmuftah76100% (1)

- U - D700-754E UK - Service-Ed - 5 - 07-2011 PDFDocument299 pagesU - D700-754E UK - Service-Ed - 5 - 07-2011 PDFAlex Varas100% (3)

- Operation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsDocument38 pagesOperation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsangelvhNo ratings yet

- Manual Motor de Pistones Radiales CA Bosch RexrothDocument64 pagesManual Motor de Pistones Radiales CA Bosch RexrothOlegNo ratings yet

- Diesel Generator Service Manual: OPEN TYPE: DHY6000LE / DHY6000LE-3 Soundproof Type: Dhy6000Se / Dhy6000Se-3Document57 pagesDiesel Generator Service Manual: OPEN TYPE: DHY6000LE / DHY6000LE-3 Soundproof Type: Dhy6000Se / Dhy6000Se-3Nestor LopezNo ratings yet

- Manuel de Réparation 3 Tonnes 2Document155 pagesManuel de Réparation 3 Tonnes 2Faouzi Zorgati100% (1)

- Operating Instructions: Diesel Engine 12V2000M91 16V2000M91Document169 pagesOperating Instructions: Diesel Engine 12V2000M91 16V2000M91Bruna Rahd100% (1)

- 4200 Wet Sump Engine OverhaulDocument136 pages4200 Wet Sump Engine OverhaulGONZALO AMATNo ratings yet

- 18-Dynasys Servicemanual Revs 2Document32 pages18-Dynasys Servicemanual Revs 2SouthUnion DieselNo ratings yet

- Operating Instruction - Motores DieselDocument254 pagesOperating Instruction - Motores DieselAlbertoNo ratings yet

- SERV1847 - TXT3 - EngineDocument65 pagesSERV1847 - TXT3 - Enginefrezgi birhanu100% (3)

- Manual IK +C13370 PDFDocument23 pagesManual IK +C13370 PDFsergioNo ratings yet

- Service - Manual - CLASSIC 500 - 350 PDFDocument229 pagesService - Manual - CLASSIC 500 - 350 PDFsandystays100% (1)

- Operating Instructions: Diesel Engine 16 V 4000 Rx3 XDocument163 pagesOperating Instructions: Diesel Engine 16 V 4000 Rx3 Xcosty_transNo ratings yet

- Technical Service Bulletin: ModelDocument3 pagesTechnical Service Bulletin: Modelkilofome05No ratings yet

- 317 Training Manual 0704Document219 pages317 Training Manual 0704mliugong100% (4)

- Tonkaflo Pumps SS Series Installation, Operation, and Maintenance ManualDocument40 pagesTonkaflo Pumps SS Series Installation, Operation, and Maintenance ManualSmith Jonhatan Moya CarbajalNo ratings yet

- 336 02 GB 0312Document310 pages336 02 GB 0312Nguyen Sy100% (1)

- Maintenance Handbook On Traction Motor Cooling Blower & Its Motor PDFDocument55 pagesMaintenance Handbook On Traction Motor Cooling Blower & Its Motor PDFsupriya rakshitNo ratings yet

- 4wheel ElectricDocument76 pages4wheel ElectricJohn PavalNo ratings yet

- Esp. Bomba Do MotorDocument3 pagesEsp. Bomba Do MotorflavioNo ratings yet

- Operating Instructions: Diesel Engine 16V4000R43xDocument177 pagesOperating Instructions: Diesel Engine 16V4000R43xEng M ElseaidyNo ratings yet

- 336 03 GB 0611Document266 pages336 03 GB 0611Tahar BenacherineNo ratings yet

- MS150048 04e 20V4000M93Document200 pagesMS150048 04e 20V4000M93Giang DoNo ratings yet

- 317 GB 0009Document192 pages317 GB 0009kashif AliNo ratings yet

- Clarke LC2A Lombardini Engines For Fire PumpDocument18 pagesClarke LC2A Lombardini Engines For Fire PumpPutraNo ratings yet

- cummins 45m WUV 90kw应发完工资料(20170526)Document39 pagescummins 45m WUV 90kw应发完工资料(20170526)Saran RSNo ratings yet

- Eletronic Engines Support 7 5 0 Global GuideDocument551 pagesEletronic Engines Support 7 5 0 Global Guidemauricio olayaNo ratings yet

- Operating Instructions 395 SeriesDocument190 pagesOperating Instructions 395 Seriesjamal molana0% (1)

- Crankshaft - InstallDocument5 pagesCrankshaft - InstallalonsoNo ratings yet

- Manual de Servicio KSB WKDocument46 pagesManual de Servicio KSB WKHeriberto MendozaNo ratings yet

- Operating Instructions: Diesel Engine 12V2000M91 16V2000M91Document169 pagesOperating Instructions: Diesel Engine 12V2000M91 16V2000M91Jason McLaughlinNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Study On The Adavnce Technology Used in Bs6 Engines: Visvesvaraya Technological UniversityDocument11 pagesStudy On The Adavnce Technology Used in Bs6 Engines: Visvesvaraya Technological UniversityVishal GNo ratings yet

- Lubrication SystemDocument6 pagesLubrication SystemAbdulrahman AliNo ratings yet

- Kirloskar: Diesel Generating Sets KG125W / KG125WSDocument4 pagesKirloskar: Diesel Generating Sets KG125W / KG125WSnam phạmNo ratings yet

- VHP F3521gsi 7008 0102Document2 pagesVHP F3521gsi 7008 0102jairoNo ratings yet

- 12M Fe-Slf - J2 - AmtDocument62 pages12M Fe-Slf - J2 - AmtD. Nanda KishoreNo ratings yet

- 25-Service Manual Fuel Supply System Diesel Engines ASB, ASE, BNG, BVN & BMCDocument83 pages25-Service Manual Fuel Supply System Diesel Engines ASB, ASE, BNG, BVN & BMCDamir SasaNo ratings yet

- Almera: GI MA EM EM LC EC FE CL - 5Mt CL - 6Mt MT - 5Mt MT - 6Mt AT AX SU BR ST RS BT HA ATC SC EL IDXDocument1 pageAlmera: GI MA EM EM LC EC FE CL - 5Mt CL - 6Mt MT - 5Mt MT - 6Mt AT AX SU BR ST RS BT HA ATC SC EL IDXAlex RonNo ratings yet

- Fuel Filter Housing ExplanationDocument3 pagesFuel Filter Housing ExplanationMrAlbert2009No ratings yet

- Chemistry Grade 7 - Answer KeyDocument3 pagesChemistry Grade 7 - Answer KeyAnam MahmoodNo ratings yet

- Generator Faults, Causes, Effect and ProtectionDocument8 pagesGenerator Faults, Causes, Effect and ProtectionSk The Alternator100% (1)

- L6 Introduction To Cycle Analysis Second Law of Thermodynamics 6 Hrs. To Be Distributed - NewDocument25 pagesL6 Introduction To Cycle Analysis Second Law of Thermodynamics 6 Hrs. To Be Distributed - NewJohn Paul AbanNo ratings yet

- Thermal EngineeringDocument6 pagesThermal Engineeringtarek ali ahmedNo ratings yet

- Caterpillar Common RailDocument2 pagesCaterpillar Common RailErick AlarconNo ratings yet

- Features:: 1250kVA, Open Type, 4012-46TWG2A, PI734A, 3phase, AMFDocument7 pagesFeatures:: 1250kVA, Open Type, 4012-46TWG2A, PI734A, 3phase, AMFhelmy muktiNo ratings yet

- 10 11 035 ErrorList Liebherr V1.0Document17 pages10 11 035 ErrorList Liebherr V1.0Martin ZaehNo ratings yet

- TDI Injection and Glow Plug System 2.0LDocument79 pagesTDI Injection and Glow Plug System 2.0LFailCucNo ratings yet

- FME Remedial AssignmentDocument2 pagesFME Remedial AssignmentHann yaay daddyNo ratings yet

- Ocs-Mv01 Miss Bee Inventory and Equipment ListDocument13 pagesOcs-Mv01 Miss Bee Inventory and Equipment ListferdinandusNo ratings yet

- Fuel, Coolant and Oil FlowDocument7 pagesFuel, Coolant and Oil Flowshaken56No ratings yet

- Mvl3e 62KL NP2Document33 pagesMvl3e 62KL NP2Phil100% (1)

- Volvo Penta d13-800Document108 pagesVolvo Penta d13-800Maxim VasilevskiyNo ratings yet

- Yamaha Color CodesDocument2 pagesYamaha Color CodesMohd essa100% (2)

- Manuel Volvo B17 B19 B21 B23 1975-85Document108 pagesManuel Volvo B17 B19 B21 B23 1975-85monodNo ratings yet

- Technical Information: For V1505Document27 pagesTechnical Information: For V1505hendra100% (1)

- BOSCH Filter Catalogue A4!21!09-20Document29 pagesBOSCH Filter Catalogue A4!21!09-20Jayesh PatelNo ratings yet

- Pumps: (Sample Problems)Document11 pagesPumps: (Sample Problems)JAYNo ratings yet

- Illustrate Your Answers With NEAT Sketches Wherever NecessaryDocument4 pagesIllustrate Your Answers With NEAT Sketches Wherever Necessarya c s KumarNo ratings yet