Professional Documents

Culture Documents

Rod Handler RH 714 CHA

Rod Handler RH 714 CHA

Uploaded by

João GuardadoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rod Handler RH 714 CHA

Rod Handler RH 714 CHA

Uploaded by

João GuardadoCopyright:

Available Formats

C 35710-- 1 en 1001 / MAH 1 (14)

ROD HANDLER RH 714

CHA

ROD HANDLER RH 714

CHA

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

2 (14) C 35710-- 1 en 1001 / MAH

ROD HANDLER RH 714

CHA

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35710-- 1 en 1001 / MAH 3 (14)

ROD HANDLER RH 714

CHA

CONTENTS

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1. Type identifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. MAIN COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5. OPERATING PRINCIPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1. Taking rod to drilling centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2. Taking rod to cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6. HYDRAULICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1. Hydraulic components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2. Hydraulic circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.3. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7. MECHANICAL FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.1. Adjusting Pito retainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.2. Adjusting rod handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8. MAINTENANCE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.1. Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.2. Periodic maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.3. Grease nipples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

4 (14) C 35710-- 1 en 1001 / MAH

ROD HANDLER RH 714

CHA

1. GENERAL

These instructions describe the structure, operating principle and adjustments of the RH

714 rod handler.

Tamrock Service is always ready to offer advice and help in all service problems.

2. SAFETY INSTRUCTIONS

Maintenance and adjustments are only allowed to persons who have

received specific training on the device in question. Read the system

adjustment instructions before starting adjustment work.

WARNING

OBSERVE ABSOLUTE CLEANLINESS WHEN DISASSEMBLING AND

ASSEMBLING HYDRAULIC EQUIPMENT.

Blow all parts clean with compressed air and wipe them using a

CAUTION

CLEAN, non-- fluffy cloth before assembling.

Pressurized hydraulic hoses must not be touched by hand. The hoses

may have unnoticeable needle holes that let out high-- pressure oil

sprays that may penetrate the skin.

WARNING

Beware of moving machine parts. Do the service and repair work only

with the rig stopped. Make also sure that the rig cannot be accidentally

started during maintenance or repair work.

WARNING

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35710-- 1 en 1001 / MAH 5 (14)

ROD HANDLER RH 714

CHA

3. TECHNICAL DATA

3.1. Type identifier

RH 714

Rod

Handler

Rock drill serie

Rod length max 14’

3.2. Technical data

Number of rods 6 pcs in cassette + 1 in rock drill

Rod length 10, 12 or 14 feed

Rod size 1 1/2”, 1 3/4” and 2’’ (5+1 MF) (*)

Weight (excl. rods) 270 kg

All cassette functions are electrically controlled.

The upper end rod handler has three alternative mounting positions:

-- The upper position is for sleeved 14’ rods, whereby the upper gripper jaw grips the

sleeve.

-- The middle position is for 14’ MF rods and 12’ sleeved rods.

-- The lower position is for 12’ MF rods and 10’ sleeved rods.

-- With 12’ and 14’ MF rods, the upper gripper grips the rod.

-- With sleeved rods, the upper jaw grips the sleeve.

(*) The cassette can be used with 1 1/2“, 1 3/4” or 2” rods provided that the flange at the

end of the lifting cylinder, and the jaw pieces of the Pito retainer and the handlers are

changed.

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

6 (14) C 35710-- 1 en 1001 / MAH

ROD HANDLER RH 714

CHA

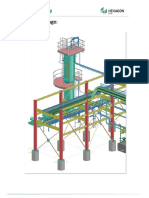

4. MAIN COMPONENTS

1. Rod handler, upper end (The upper end rod handler has three alternative

mounting positions.) (1*)

2. Rod handler, lower end

D The rod handlers perform:

-- rod transfers to drilling centre or to cassette, and

-- gripping of rod with jaws and rod storing into cassette.

3. Lower support

D The rods rest against the lower support in the cassette.

4. Rod gripping cylinder

D The cylinder presses the gripper jaws around the rod.

5. Gripper transfer cylinder

D The cylinder moves the rods in gripper jaws to drilling centre or to cassette.

6. Top cover

D The top cover prevents the rods from falling out of the cassette during tramming

or transport.

7. Rod feed cylinder

D The cylinder keeps the rods in a position where rod handling can take place.

8. Slide gate

D Prevents rods from rolling out and falling from the cassette.

9. Valve block

D The valves control the rod handler, Pito retainer, and movable suction head.

10. Flow divider valve

D The valve divides the oil flow so that both grippers (upper and lower end) move

simultaneously to drilling centre or to cassette.

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35710-- 1 en 1001 / MAH 7 (14)

ROD HANDLER RH 714

CHA

6

8 5 4

1

1*

1*

7

9

9

10

2

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

8 (14) C 35710-- 1 en 1001 / MAH

ROD HANDLER RH 714

CHA

5. OPERATING PRINCIPLE

5.1. Taking rod to drilling centre

When a rod is added, the gripper jaw (1) presses the shut--out plate (2) so that the rod can

move over the shut--out plate with the gripper to the drilling centre.

When the gripper is in the drilling centre, the rods in the cassette are retained behind the

shut--out plate (2) and under the surface (3), preventing the rods from falling out.

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35710-- 1 en 1001 / MAH 9 (14)

ROD HANDLER RH 714

CHA

5.2. Taking rod to cassette

When disassembling is started, the inclined edge (4) of the gripper body first presses the

rods downwards in the cassette, and then under the shut--out plate (2) surface.

When a rod is taken from the drilling centre to the cassette, the gripper jaw and the rod

together push the shut--out plate (2) and the rods (5) in the cassette downwards, making

room for the rod coming from the drilling centre.

When the jaws open, the shut--off plate (2) closes, preventing the rods from escaping from

the cassette.

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

10 (14) C 35710-- 1 en 1001 / MAH

ROD HANDLER RH 714

CHA

6. HYDRAULICS

6.1. Hydraulic components

100.Rod handler control valve bank; the valve bank is used to control the rod handler

movements

101. Control valve for gripper transfer cylinders

103. Control valve for upper gripper jaw

105. Control valve for lower gripper jaw

210. Rod feed cylinders

213. Cylinder of the upper gripper jaw

214. Cylinder of the lower gripper jaw

215. Gripper transfer cylinder

216. Gripper transfer cylinder

300. Valve block

301. Pressure reducing valve for rod lifting cylinders

400. Pilot operated control valve for the rod feed cylinders; directs the oil from the rod

feed cylinders into the receiver when the rods are taken in or out from the cassette.

500. Shuttle valve

701. Gear pump

704. Gear pump

800. Cylinder lock–up valves, 3 pcs

801. Cylinder one--way restrictors, 3 pcs

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35710-- 1 en 1001 / MAH 11 (14)

ROD HANDLER RH 714

CHA

6.2. Hydraulic circuit diagram

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

12 (14) C 35710-- 1 en 1001 / MAH

ROD HANDLER RH 714

CHA

6.3. Operation

The rod handler is controlled by the levers on the front control panel. They affect the

directional valves of the rod handler valve bank (100). The oil coming from the hydraulic

pump (704) through the valves will go to the cylinders (210, 213 – 216). The rod handler

valve bank (100) is mounted into the front control panel. The rod handler includes also the

following components: the valve block (800) mounted on the side of the feed beam, the

valve block (300) mounted into the front control panel including pressure reducing valve

(301), pilot operated control valve (400) and a shuttle valve (500).

The valve bank (100) consists of six (6) direct controlled valves (101 – 106). Valves (101),

(103) and (105) will control the rod handling functions. Control valve (101)directs the oil

flow to the gripper transfer cylinders, moving the rod from cassette to the drilling center

and from the drilling center to the cassette. The control valve (105) operates the jaw of the

lower gripper (open/closed) and the control valve (103) opens and closes the jaw of the

upper gripper.

All the cylinders, except the lift cylinder for Pito and rod lifting, operated by the control

valves, are equipped with lock--up valves (800) and adjustable one--way restrictors (801).

The lock–up valve (207) will ensure that the pressure will remaining in the cylinder while

the valve spool is in the middle position. The suitable cylinder speed can be adjusted by

the adjustable one--way restrictor (801) by restricting the oil flow into the cylinder. Therod

gripper transfer cylinders (215, 216) and rod feed cylinders (210) are provided with an

additional flow divider (900) which purpose is to distribute an equal oil flow to both

cylinders in both directions.

When the rod string is being disassembled and a rod is taken to the cassette, the pilot

operated control valve (400) will change the position and direct the rod feeding cylinders

(210) return oil back to the tank. This will reduce the force to push and pull the rod in and

out from the cassette. When the rod is in the cassette and the control lever is released, the

pilot operated control valve (400) will change the position and the pressure will enter

through the pressure reducing valve (301) to the piston side of cylinders (210) and

tightens the rods into the cassette. The set value of the pressure reducing valve (301) is

30–40 bar.

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35710-- 1 en 1001 / MAH 13 (14)

ROD HANDLER RH 714

CHA

7. MECHANICAL FUNCTIONS

7.1. Adjusting Pito retainer

D Loosen the bolts between the feed and the Pito retainer.

D Mount a shank to the rock drill and an extension sleeve to the Pito retainer jaws.

D Drive the shank into the sleeve by using the rock drill.

D Tighten the bolts, and run the rock drill to the upper position.

7.2. Adjusting rod handler

D Move a rod with the gripper transfer cylinders between the extension sleeve and

the rock drill shank.

D Loosen the bolts (1) between the rod handlers and the feed.

D Loosen the locking nuts of the adjusting screws (2, 3, 4).

D Centralize the rod to the drilling centre using the adjusting screws (2, 3). Lock the

adjustment.

D Move the rod back to the cassette, and adjust the screw (4) so that the rod is far

enough in the cassette (behind the slide gate) and that the gripper jaw pushes the

rod against the inclined surface of the gripper. Lock the adjustments. (If the gripper

goes too deep into the cassette the gripper will not squeeze the rod against the

corner and when the rod is moved to the drilling center the alignment is off).

D Test all the movements.

2 4

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

14 (14) C 35710-- 1 en 1001 / MAH

ROD HANDLER RH 714

CHA

8. MAINTENANCE INSTRUCTIONS

8.1. Tools

No special tools required.

8.2. Periodic maintenance

Each shift:

-- Check possible oil leaks.

-- Tighten all loosened nuts and screws.

-- Lubricate the sliding body (1) grease nipples (4 pcs).

Once a week:

-- Wash the rod handler.

-- Lubricate all grease nipples.

-- Check the condition of the gripper and Pito jaws.

8.3. Grease nipples

In both rod handlers (upper and lower end):

1. Sliding body 2 pcs

2. Gripper jaw cylinder 2 pcs

3. Gripper transfer cylinder 2 pcs

3 2

E 2001 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

You might also like

- John Deere 7610, 7710, 7810 Tractor Operation & Test Manual - TM2030Document2,797 pagesJohn Deere 7610, 7710, 7810 Tractor Operation & Test Manual - TM2030João Guardado75% (4)

- 98180-01930 - Parts Catalogue MG330 - Oct.'92Document269 pages98180-01930 - Parts Catalogue MG330 - Oct.'92João Guardado100% (2)

- Timberjack 1110CDocument278 pagesTimberjack 1110CMMM-MMM100% (3)

- CN35 Owners HandbookDocument27 pagesCN35 Owners HandbookmcguinesNo ratings yet

- Operator and Maintenance Manual: TimberjackDocument225 pagesOperator and Maintenance Manual: TimberjackАлександр100% (3)

- J-1175 ENGLISH Operation Manual: Finlay Hydrascreen Finlay Hydrascreens (Omagh) LTDDocument178 pagesJ-1175 ENGLISH Operation Manual: Finlay Hydrascreen Finlay Hydrascreens (Omagh) LTDcuenta1100% (2)

- 622C Operator ManualDocument90 pages622C Operator ManualPathitoVeraVeraNo ratings yet

- Dp1500i Maintenance ManualDocument62 pagesDp1500i Maintenance ManualLewis Nemananga100% (2)

- Operator's Manual: Through The RockDocument90 pagesOperator's Manual: Through The RockJesus Fco Garcia Perez100% (1)

- Hydraulic Rock Drill HL 800 T Lifting Instructions: Incorrect CorrectDocument88 pagesHydraulic Rock Drill HL 800 T Lifting Instructions: Incorrect Correctcristian100% (3)

- AP 240 enDocument6 pagesAP 240 enJoão GuardadoNo ratings yet

- Tamrock Cha-700Document11 pagesTamrock Cha-700Jesus Fco Garcia PerezNo ratings yet

- Operating Manual Lubrication Device - 8175-9001-032Document14 pagesOperating Manual Lubrication Device - 8175-9001-032Michael Toledo100% (1)

- Empacadora Al Vacio - VS95TS - GB - SN02921-2945 PDFDocument512 pagesEmpacadora Al Vacio - VS95TS - GB - SN02921-2945 PDFDaniel castrillon75% (8)

- 616 Operator ManualDocument102 pages616 Operator ManualPathitoVeraVeraNo ratings yet

- Manual Servicio TMP4100Document54 pagesManual Servicio TMP4100Anonymous CvXiivV100% (1)

- Jackaroo 4JX1 Engine Manual 2014 Ver 2.2Document65 pagesJackaroo 4JX1 Engine Manual 2014 Ver 2.2João Guardado100% (4)

- HM 300Document1,056 pagesHM 300João Guardado100% (4)

- Joints in Steel Construction - Simple Connections - Part 11 PDFDocument4 pagesJoints in Steel Construction - Simple Connections - Part 11 PDFkakem61No ratings yet

- Rod Handler RH 714: Ranger, ScoutDocument20 pagesRod Handler RH 714: Ranger, ScoutcristianNo ratings yet

- DustDocument18 pagesDustdefiunikasungtiNo ratings yet

- Chain Feed CF 145 H + RH 714 Maintenance Instruction: C 31360 - 4 en 0904 / JT 1Document22 pagesChain Feed CF 145 H + RH 714 Maintenance Instruction: C 31360 - 4 en 0904 / JT 1cristianNo ratings yet

- Maintenance AND Lubrication Manual: Drill Carrier TC 6Document234 pagesMaintenance AND Lubrication Manual: Drill Carrier TC 6wezito moraisNo ratings yet

- Rod Changer-1Document21 pagesRod Changer-1Mitchelle GonouyaNo ratings yet

- CylinderDocument25 pagesCylinderthomazNo ratings yet

- Maintenance ManualDocument58 pagesMaintenance ManualIgnacio Alejandro Jose Helo Varela100% (1)

- General Safety InstructionsDocument30 pagesGeneral Safety InstructionsrolandNo ratings yet

- 1500 MaintenanceDocument66 pages1500 Maintenanceliliana06macarenaNo ratings yet

- Taking A New Rig Into Use: 4.2.1. Check Fuel Level and Oil Levels With The Rig in Horizontal Position 3 - . - .Document3 pagesTaking A New Rig Into Use: 4.2.1. Check Fuel Level and Oil Levels With The Rig in Horizontal Position 3 - . - .rolandNo ratings yet

- SLU 1/2/3 Operation and Maintenance: B 63250 - 8 en 1102 / JAS 1Document11 pagesSLU 1/2/3 Operation and Maintenance: B 63250 - 8 en 1102 / JAS 1Gabo Luna MorenoNo ratings yet

- Manual de Manutenção-Ing1Document13 pagesManual de Manutenção-Ing1João GuardadoNo ratings yet

- Manual de Manutenção-Ing2Document11 pagesManual de Manutenção-Ing2João GuardadoNo ratings yet

- OperatorsManual PartsList Chipper CH160Document48 pagesOperatorsManual PartsList Chipper CH160Павел ХромовNo ratings yet

- 9103604R45 tz35 GB From SNAQ-875Document54 pages9103604R45 tz35 GB From SNAQ-875Felipe RivasNo ratings yet

- Articulated Boom Lift Model Ta50RtDocument65 pagesArticulated Boom Lift Model Ta50RtLicínio DâmasoNo ratings yet

- Rock DrillDocument72 pagesRock Drilljosue100% (3)

- MP 2Document134 pagesMP 2cpmailing10No ratings yet

- Instruction Manual Viscotester 6 L/R Viscotester 7 L/R: Thermo Haake Thermo Haake (Usa) Rheo S.A. (France)Document31 pagesInstruction Manual Viscotester 6 L/R Viscotester 7 L/R: Thermo Haake Thermo Haake (Usa) Rheo S.A. (France)overcomeboyNo ratings yet

- Kioti Daedong PX7520, PX9020, PX9520, PX1002, PX1052 Tractors Service Manual 04-2015Document19 pagesKioti Daedong PX7520, PX9020, PX9520, PX1002, PX1052 Tractors Service Manual 04-2015LisakolyNo ratings yet

- 798 Operation English 011203-02Document122 pages798 Operation English 011203-02eaglego00100% (1)

- Uen R 62710001Document274 pagesUen R 62710001Jhon Montenegro100% (1)

- CylinderDocument30 pagesCylinderDanilo CabreraNo ratings yet

- FeedDocument10 pagesFeedDanilo CabreraNo ratings yet

- For Trained Technical Personnel: Extra - X MK5 XtenderDocument44 pagesFor Trained Technical Personnel: Extra - X MK5 XtenderARMANDOROSASNo ratings yet

- Feeder Protection Relay: Instruction ManualDocument108 pagesFeeder Protection Relay: Instruction Manualesilva2021No ratings yet

- FEED. Alimentacion Del CilindroDocument31 pagesFEED. Alimentacion Del CilindroAlexandra chata monsalve momsalveNo ratings yet

- Rockdrill HL650Document74 pagesRockdrill HL650Luis Josue100% (1)

- Forming Tool DN16 - DN20 - DN26 - DN32 Operator Manual: 850 1011I.2 - ENGDocument36 pagesForming Tool DN16 - DN20 - DN26 - DN32 Operator Manual: 850 1011I.2 - ENGzinebNo ratings yet

- Tideland Signal Corp.Document93 pagesTideland Signal Corp.agsan.algabh2718No ratings yet

- HY85 (160 - 180) MG: User ManualDocument85 pagesHY85 (160 - 180) MG: User Manualrendi setiawanNo ratings yet

- TM 205Document74 pagesTM 205Carlos Gabriel EstergaardNo ratings yet

- TMX1000ADocument74 pagesTMX1000AcuongNo ratings yet

- Owners Manual 2018Document49 pagesOwners Manual 2018Marv-Vic SantosNo ratings yet

- TR-2-C Beginning Sections-1999 PDFDocument50 pagesTR-2-C Beginning Sections-1999 PDFArmandoOlivaresNo ratings yet

- 4018 DSK Multi Skid Operation Maintenance Manual Issue 5Document55 pages4018 DSK Multi Skid Operation Maintenance Manual Issue 5Mostafa ElhamadyNo ratings yet

- Service Manual: Pedal 1 Pedal 2Document29 pagesService Manual: Pedal 1 Pedal 2Victor DumitrascuNo ratings yet

- 65002-0001 Terex Ta33Document59 pages65002-0001 Terex Ta33reman partsNo ratings yet

- Manual TZ100-TZ600 REV.5-MITCHELL PDFDocument44 pagesManual TZ100-TZ600 REV.5-MITCHELL PDFBrian KomivesNo ratings yet

- HYDRAULICSDocument133 pagesHYDRAULICSdendeng RusaNo ratings yet

- Forming Tool DN16 - DN20 - DN26 - DN32 Installation Manual: 850 1010I.2 - ENGDocument22 pagesForming Tool DN16 - DN20 - DN26 - DN32 Installation Manual: 850 1010I.2 - ENGzinebNo ratings yet

- Sme35390a 3 FR8062 8122 8252Document286 pagesSme35390a 3 FR8062 8122 8252宋翔No ratings yet

- Terex Ta 50 e Oprat0rDocument61 pagesTerex Ta 50 e Oprat0rzeljkoNo ratings yet

- Pneumatic Steel Strapping Tool Model A3hDocument19 pagesPneumatic Steel Strapping Tool Model A3hjulioantoniocervantesnoriegaNo ratings yet

- Manuale Pitney Piegatrice NuovaDF800 - 900serviceDocument84 pagesManuale Pitney Piegatrice NuovaDF800 - 900servicegiuseppe mocciaNo ratings yet

- Custom Molding of Thermoset Elastomers: A Comprehensive Approach to Materials, Mold Design, and ProcessingFrom EverandCustom Molding of Thermoset Elastomers: A Comprehensive Approach to Materials, Mold Design, and ProcessingNo ratings yet

- Flushing Control Automatics: Operation and MaintenanceDocument8 pagesFlushing Control Automatics: Operation and MaintenanceJoão GuardadoNo ratings yet

- Instruções de Elevação para Perfurador de Rocha: HE 122 / HE 119 39 KG HE 300 89 KG HL 300 94 KG HL 300 S 92 KGDocument64 pagesInstruções de Elevação para Perfurador de Rocha: HE 122 / HE 119 39 KG HE 300 89 KG HL 300 94 KG HL 300 S 92 KGJoão Guardado100% (1)

- Feedback About Technical Documents: Tampere PlantDocument5 pagesFeedback About Technical Documents: Tampere PlantJoão GuardadoNo ratings yet

- Manual de Manutenção-Ing2Document11 pagesManual de Manutenção-Ing2João GuardadoNo ratings yet

- C Frontal 950G (A52) PDFDocument28 pagesC Frontal 950G (A52) PDFPercy Ponce100% (1)

- SM E215B ENDocument332 pagesSM E215B ENJoão Guardado100% (4)

- Pilot 53in Sbach 342 ManualDocument23 pagesPilot 53in Sbach 342 ManualAlvaro ReyesNo ratings yet

- Massey Ferguson 4260 TRACTORS ( - K37009) Service Parts Catalogue Manual (Part Number 819919)Document17 pagesMassey Ferguson 4260 TRACTORS ( - K37009) Service Parts Catalogue Manual (Part Number 819919)bvk2980022100% (1)

- Manual de Partes Airsource 185 OpmDocument151 pagesManual de Partes Airsource 185 Opmreluma100% (1)

- Actuator MANDocument30 pagesActuator MANsinamicsNo ratings yet

- Washing Machine: Service ManualDocument44 pagesWashing Machine: Service ManualmiltoncgNo ratings yet

- Lemonade Stand Project Diagram RevDocument6 pagesLemonade Stand Project Diagram Revmel ChiffonNo ratings yet

- Braime: Whirligig Heavy DutyDocument2 pagesBraime: Whirligig Heavy Dutyhamid hoorshadNo ratings yet

- Instruction Manual: Flow Pad Size12 Without GrateDocument20 pagesInstruction Manual: Flow Pad Size12 Without GrateBata ZivanovicNo ratings yet

- Dsaud0032801 PDFDocument29 pagesDsaud0032801 PDFsujanto widjajaNo ratings yet

- Kettle Type Reboiler KE301 - OutDocument55 pagesKettle Type Reboiler KE301 - OutYogeshbhau MandgeNo ratings yet

- Weaving Loom Parts Catalogue Vamatex SpareDocument73 pagesWeaving Loom Parts Catalogue Vamatex SpareMASEREKA JOELNo ratings yet

- Ezlimo CatalogDocument76 pagesEzlimo CatalogTran Tuan AnhNo ratings yet

- Ension Embers: Chinmoy KolayDocument28 pagesEnsion Embers: Chinmoy KolayAreeb AhmadNo ratings yet

- Fx1100b-E Fx1100b-E MJ-FX1100B'06Document0 pagesFx1100b-E Fx1100b-E MJ-FX1100B'06Ray Cepeda MenaNo ratings yet

- Installation Instructions: Parts List Cassette Player: P/N 08A53-S5A-100 CD Player: P/N 08A53-S5D-100Document8 pagesInstallation Instructions: Parts List Cassette Player: P/N 08A53-S5A-100 CD Player: P/N 08A53-S5D-100Luis AguirreNo ratings yet

- WP001Document37 pagesWP001jfl2096No ratings yet

- Revised PMPDocument40 pagesRevised PMPMico CañeteNo ratings yet

- D 5421 - 00 PDFDocument5 pagesD 5421 - 00 PDFlitalomp05No ratings yet

- Furnace 320725 753installDocument4 pagesFurnace 320725 753installbece13No ratings yet

- Lifting Eye Bolts (Rotating) : Technical InformationsDocument3 pagesLifting Eye Bolts (Rotating) : Technical InformationsBruno Thiago DamascenoNo ratings yet

- Z-45/25 Z-45/25J DC and Bi-Energy: Serial Number RangeDocument160 pagesZ-45/25 Z-45/25J DC and Bi-Energy: Serial Number RangeСвятослав ВороновNo ratings yet

- 1 Tonne, Quick Lift, Folding Engine Crane: Instructions ForDocument6 pages1 Tonne, Quick Lift, Folding Engine Crane: Instructions ForAnwar MohamedNo ratings yet

- Alba Light Shear SP LIST For C 32-42 LDocument16 pagesAlba Light Shear SP LIST For C 32-42 LdrmassterNo ratings yet

- Bucyrus: Technical ManualDocument5 pagesBucyrus: Technical ManualBrian CareelNo ratings yet

- Bird FeederDocument4 pagesBird FeederJayme LealNo ratings yet

- 01MU005BDocument60 pages01MU005BJonson Kiran DcostaNo ratings yet

- Heavy Hex Structural Bolts - ASTM A325M: Metric Series - DimensionsDocument2 pagesHeavy Hex Structural Bolts - ASTM A325M: Metric Series - Dimensionskptl6185No ratings yet

- Coefficients of FrictionDocument7 pagesCoefficients of Frictionswordprinces100% (1)