Professional Documents

Culture Documents

L1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 EN

L1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 EN

Uploaded by

kamals55Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 EN

L1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 EN

Uploaded by

kamals55Copyright:

Available Formats

Avesta 309 AC/DC

Covered electrode, high-alloyed, austenitic stainless, special applications

Classifications

EN ISO 3581-A AWS A5.4 / SFA-5.4

E Z 23 12 R E309-17

Characteristics and typical fields of application

Rutile coated high-carbon electrode of E Z 23 12 R / E309-17 type for welding heat resistant steels such as 1.4833 / 309S. Suitable for

high temperature applications with service temperatures up to 1000ºC. The resistance to intergranular corrosion is somewhat limited

due to the high carbon content. Can also be used for dissimilar welding between stainless and mild or low-alloyed steels and surfacing

on unalloyed steels. Designed for first class weld seems and easy handling on AC or DC. The resulting all-weld metal microstructure is

austenite with approximately 10 – 15% ferrite.

Base materials

Primarily used for welding of high temperature steels such as 1.4833 / 309S, but may also be used for surfacing unalloyed steel, dissimi-

lar welding of stainless steel to unalloyed steel, and welding of cladded material.

Typical analysis

C Si Mn Cr Ni FN

wt.-% 0.055 0.8 1.1 24.3 13.3 14

Mechanical properties of all-weld metal - typical values (min. values)

Condition Yield strength Rp0.2 Tensile strength Rm Elongation A (L0=5d0) Impact energy ISO-V Hardness

KV J

MPa MPa % 20°C HB

u 450 (≥ 320) 570 (≥ 550) 35 (≥ 25) 50 210

u untreated, as-welded

Operating data

Polarity DC+ / AC Dimension mm Current A

Electrode 309-17 2.5 × 300 50 – 80

identification 3.2 × 350 80 – 120

4.0 × 350 100 – 160

Suggested heat input is max. 2.0 kJ/mm, interpass temperature max. 150ºC.

Metal recovery approximately 115%.

Redrying needed: 350ºC, min. 2 h.

Post-weld heat treatment generally not needed. For contructions that include low-alloyed steels in mixed joints, stress-relieving may be

advisable. Always consult the parent material supplier to ensure that the correct heat treatment is carried out.

Approvals

CE

All information provided is based upon careful investigation and intensive research. 1 / 1 05/2021

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

You might also like

- AI I 4145 Allo Teel (UN G41450) : Topics CoveredDocument3 pagesAI I 4145 Allo Teel (UN G41450) : Topics CoveredUmerNo ratings yet

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- Böhler Fox Skwa: Classifi CationsDocument1 pageBöhler Fox Skwa: Classifi CationsBranko FerenčakNo ratings yet

- Boehler 2507 P100 Rutile E2594 16 Covered ElectrodeDocument1 pageBoehler 2507 P100 Rutile E2594 16 Covered ElectrodekapsarcNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- 18042016000000T - Thermanit X - Solid WireDocument2 pages18042016000000T - Thermanit X - Solid WireMadhusudan YeoleNo ratings yet

- T Thermanit GEW 316L-17 Se en 5Document1 pageT Thermanit GEW 316L-17 Se en 5PubcrawlNo ratings yet

- L1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Document1 pageL1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Dimitris NikouNo ratings yet

- Thermanit 308 Mo 1SE3A00G 3407112 ENDocument1 pageThermanit 308 Mo 1SE3A00G 3407112 ENbrayanNo ratings yet

- L1 12981 en Thermanit 25 22 H 2SDBA01E 3205884 EN 1612524259 SmallDocument1 pageL1 12981 en Thermanit 25 22 H 2SDBA01E 3205884 EN 1612524259 Smallkamals55No ratings yet

- Böhler Fox Skwam: Classifi CationsDocument1 pageBöhler Fox Skwam: Classifi CationsBranko FerenčakNo ratings yet

- Utp 630Document1 pageUtp 630brayanNo ratings yet

- Bohler Fox S 308L-16Document1 pageBohler Fox S 308L-16HAKANNo ratings yet

- L1 7723 en BOEHLER FOX FF 2SF7A05E 3383108 ENDocument1 pageL1 7723 en BOEHLER FOX FF 2SF7A05E 3383108 ENkamals55No ratings yet

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocument1 pageB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- Böhler Fox Dcms KB: Classifi CationsDocument1 pageBöhler Fox Dcms KB: Classifi CationsBranko FerenčakNo ratings yet

- Thermanit P23Document1 pageThermanit P23Branko FerenčakNo ratings yet

- Acfrogb5xupx1uiu51q4qpegob11kinx4cpthkjuzsxe Qrny8qp19zkiaaqlrzp5mtx7fqalib7js6hirn5qet1v1 Jzc9t4e1g1 Ywrk Xx3fgo44x6qxwaembbcmDocument1 pageAcfrogb5xupx1uiu51q4qpegob11kinx4cpthkjuzsxe Qrny8qp19zkiaaqlrzp5mtx7fqalib7js6hirn5qet1v1 Jzc9t4e1g1 Ywrk Xx3fgo44x6qxwaembbcmdodoNo ratings yet

- Utp 068 HHDocument1 pageUtp 068 HHRoberto_PrrNo ratings yet

- E309LDocument1 pageE309Lashishkumaragrawal.rs.mec20No ratings yet

- 05042016000000A - Avesta 904L - CeDocument1 page05042016000000A - Avesta 904L - CeJorge Uribe RochaNo ratings yet

- Thermanit P24Document1 pageThermanit P24Branko FerenčakNo ratings yet

- Thermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicDocument1 pageThermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicbrayanNo ratings yet

- Böhler Fox CM 2 KB: Classifi CationsDocument1 pageBöhler Fox CM 2 KB: Classifi CationsBranko FerenčakNo ratings yet

- Supranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageSupranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- 02112015000000B - Boehler FOX E 347 H - CeDocument1 page02112015000000B - Boehler FOX E 347 H - CeUnir Welds CoatingsNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- Utp 63Document1 pageUtp 63brayanNo ratings yet

- 02112015000000B - Boehler FOX EASN 25 M - CeDocument1 page02112015000000B - Boehler FOX EASN 25 M - CeABNo ratings yet

- 02112015000000B - Boehler FOX DCMS Ti - CeDocument1 page02112015000000B - Boehler FOX DCMS Ti - CeparbinaNo ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- 04042016000000A Avesta 2205 Covered ElectrodesDocument1 page04042016000000A Avesta 2205 Covered Electrodesmeckup123No ratings yet

- Citorail OerlikonDocument1 pageCitorail OerlikonGiancarlo BlandinoNo ratings yet

- Avesta 316L-SKRDocument1 pageAvesta 316L-SKRIuliu HurducaciNo ratings yet

- 03112015000000B - Boehler FOX SUM - CeDocument1 page03112015000000B - Boehler FOX SUM - Cekapster KannourNo ratings yet

- Böhler Fox CN 29/9-A: DescriptionDocument1 pageBöhler Fox CN 29/9-A: DescriptionKadir Koray BozyelNo ratings yet

- مكونات نقط اللحام شامل بنط اللحامDocument2 pagesمكونات نقط اللحام شامل بنط اللحامdaha333No ratings yet

- 01112015000000B - Boehler FOX CEL - CeDocument1 page01112015000000B - Boehler FOX CEL - Cekapster KannourNo ratings yet

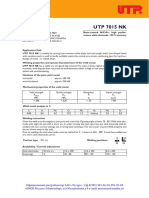

- Utp 7015Document1 pageUtp 7015cesarlopezpolysiusNo ratings yet

- Supranox Rs 347: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageSupranox Rs 347: MMA Electrodes Stainless and Heat Resistant SteelsGogo PNo ratings yet

- Datasheet BOHLER AWS E7018-1 Stick ElectrodeDocument1 pageDatasheet BOHLER AWS E7018-1 Stick ElectrodeArhamNo ratings yet

- Boehler FOX CN 25 9 CuT - CeDocument1 pageBoehler FOX CN 25 9 CuT - CeNiranjan Fakirchand YadavNo ratings yet

- Katalog BelerDocument1 pageKatalog BelerСтефан АнтонићNo ratings yet

- T - Thermanit 22 - 09 - de - en - 5Document1 pageT - Thermanit 22 - 09 - de - en - 5brayanNo ratings yet

- B Boehler-Fox-Cel Se en v1Document1 pageB Boehler-Fox-Cel Se en v1tacosanchezbrayanNo ratings yet

- B Boehler-Fox-Cel Se en v1Document1 pageB Boehler-Fox-Cel Se en v1tacosanchezbrayanNo ratings yet

- B Boehler-Fox-Cel Se en v1Document1 pageB Boehler-Fox-Cel Se en v1tacosanchezbrayanNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Avesta 2205 AC DCDocument1 pageAvesta 2205 AC DCpipedown456No ratings yet

- T - Thermanit 25 - 09 CuT - de - en - 5Document1 pageT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINo ratings yet

- Utp 34 NDocument1 pageUtp 34 NbrayanNo ratings yet

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Document3 pagesAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouNo ratings yet

- 04042016000000A - Avesta 307-Si - Solid WireDocument1 page04042016000000A - Avesta 307-Si - Solid WireDaniel GuerreroNo ratings yet

- Fox - FFDocument1 pageFox - FFGustavo NietoNo ratings yet

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- Basinox 318: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageBasinox 318: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- Avesta: Welding Wire TIGDocument1 pageAvesta: Welding Wire TIGErenBaşaraNo ratings yet

- L1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1Document1 pageL1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1cristian popescuNo ratings yet

- L1 26159 en SOUDOTAPE 310MM 7SD9A01C 3204822 ENDocument1 pageL1 26159 en SOUDOTAPE 310MM 7SD9A01C 3204822 ENkamals55No ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Process Analysis 202021 R1Document39 pagesProcess Analysis 202021 R1kamals55No ratings yet

- Bohler Fox S EV 50-1Document1 pageBohler Fox S EV 50-1kamals55No ratings yet

- Brochure Sugar IndustryDocument2 pagesBrochure Sugar Industrykamals55No ratings yet

- Bohler Fox N CM 2 KBDocument1 pageBohler Fox N CM 2 KBkamals55No ratings yet

- Lect 1 1610799804379Document42 pagesLect 1 1610799804379kamals55No ratings yet

- Cement Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler MetalsDocument2 pagesCement Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler Metalskamals55No ratings yet

- UTP For Chemical IndustryDocument12 pagesUTP For Chemical Industrykamals55No ratings yet

- POV Total Quality Management An Early Adopter of The ISO Process Approach 1634453099052Document8 pagesPOV Total Quality Management An Early Adopter of The ISO Process Approach 1634453099052kamals55No ratings yet

- UTP For OffshoreDocument16 pagesUTP For Offshorekamals55No ratings yet

- 2021 PJM L 11 1632919789873Document47 pages2021 PJM L 11 1632919789873kamals55No ratings yet

- UTP Raiilways BrochureDocument8 pagesUTP Raiilways Brochurekamals55No ratings yet

- Strips and Fluxes For Electroslag and Submerged Arc Welding: Tailor-Made Protectivity™Document38 pagesStrips and Fluxes For Electroslag and Submerged Arc Welding: Tailor-Made Protectivity™kamals55No ratings yet

- Reference Cement HolcimDocument11 pagesReference Cement Holcimkamals55No ratings yet

- Railways Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler MetalsDocument2 pagesRailways Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler Metalskamals55No ratings yet

- UTP For LNG PDFDocument5 pagesUTP For LNG PDFkamals55No ratings yet

- Steelworks Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler MetalsDocument2 pagesSteelworks Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler Metalskamals55No ratings yet

- Facility Location & Layout (F)Document15 pagesFacility Location & Layout (F)kamals55No ratings yet

- Tubes and Pipes Potable Water SanitationDocument3 pagesTubes and Pipes Potable Water Sanitationkamals55No ratings yet

- The New Böhler Welding Dry System For Stick ElectrodesDocument4 pagesThe New Böhler Welding Dry System For Stick Electrodeskamals55No ratings yet

- B Bã-Hler Nibas 70 20-Fd Fcaw 02Document1 pageB Bã-Hler Nibas 70 20-Fd Fcaw 02kamals55No ratings yet

- Weldingguide ENG PDFDocument518 pagesWeldingguide ENG PDFkamals55No ratings yet

- UTP Welding Guide 2009 GB PDFDocument487 pagesUTP Welding Guide 2009 GB PDFkamals55No ratings yet

- Summary Epri Workshop 2017Document3 pagesSummary Epri Workshop 2017arissaNo ratings yet

- Henthorne1974 oDocument8 pagesHenthorne1974 oMohamed RamadanNo ratings yet

- Utp 7015 NKDocument1 pageUtp 7015 NKsergey.pu4kaNo ratings yet

- STOODYDocument40 pagesSTOODYandreasNo ratings yet

- EN380 Homework #7 SolutionDocument6 pagesEN380 Homework #7 SolutionMafer ReyesNo ratings yet

- Effect of PWHT Temperature and Time On Hardness and Microstructure of 410nimo Weld MetalDocument7 pagesEffect of PWHT Temperature and Time On Hardness and Microstructure of 410nimo Weld MetalDNH RND - VijaykumarNo ratings yet

- ECS 3-10-1 - 2 - 800871cdDocument14 pagesECS 3-10-1 - 2 - 800871cdFlorin Daniel AnghelNo ratings yet

- Astm A320mDocument4 pagesAstm A320mSHYAM SINGHNo ratings yet

- Mild Steel Is The Most Commonly Used SteelDocument2 pagesMild Steel Is The Most Commonly Used SteelPeter HenryNo ratings yet

- An Experimental Comparative Review - PK NanavatiDocument9 pagesAn Experimental Comparative Review - PK NanavatiPurvesh NanavatiNo ratings yet

- Calorised Pipes Petrochemical W-UpDocument6 pagesCalorised Pipes Petrochemical W-UpSunil Gupta100% (1)

- Grade 500 SteelDocument3 pagesGrade 500 SteelNathan LakaNo ratings yet

- A Hot Cracking On Dissimilar Metal Weld Between A106GrB and A312 TP316L With Buttering ERNiCr-3Document16 pagesA Hot Cracking On Dissimilar Metal Weld Between A106GrB and A312 TP316L With Buttering ERNiCr-3kamal touilebNo ratings yet

- BPT Cobined Brochur 03 01 2023 Print FileDocument12 pagesBPT Cobined Brochur 03 01 2023 Print FileTrilok PrabhakaranNo ratings yet

- Question 11 To 20Document37 pagesQuestion 11 To 20Ehsan KhanNo ratings yet

- MEM Question BankDocument5 pagesMEM Question Bankronakgandhi401No ratings yet

- New Insert Enter Into Market: SeriesDocument1 pageNew Insert Enter Into Market: SeriesJanaka ChathurangaNo ratings yet

- Part 2 - Materials and Manufacturing ElementsDocument101 pagesPart 2 - Materials and Manufacturing ElementsREYNALD MILONo ratings yet

- Welding Defect: Major CausesDocument9 pagesWelding Defect: Major CausesCarlos BustamanteNo ratings yet

- Datasheet 1505 01 ENDocument2 pagesDatasheet 1505 01 ENDaniela Alejandra Chaparro DiazNo ratings yet

- 2019 - DatasheetsQuard500 UK LRDocument2 pages2019 - DatasheetsQuard500 UK LRGabriel CamargoNo ratings yet

- Intro To AluminumDocument51 pagesIntro To AluminumAzmi NdtNo ratings yet

- Flange Manufacturing ProcessDocument1 pageFlange Manufacturing ProcessAlaaNo ratings yet

- Metallurgy and ArchaeologyDocument7 pagesMetallurgy and ArchaeologySidharthNo ratings yet

- Worksheet On Metal - Student PDFDocument6 pagesWorksheet On Metal - Student PDFv4djbgykkmNo ratings yet

- Material Used in Ship BuildingDocument13 pagesMaterial Used in Ship BuildingAnshuman SharmaNo ratings yet

- RUKO Hole Saws CMSDocument15 pagesRUKO Hole Saws CMSjoaomachadoNo ratings yet

- Bhushan SteelDocument46 pagesBhushan SteelVidhan SrivastavaNo ratings yet

- LKM Stell ChartDocument1 pageLKM Stell Chartagus miptahNo ratings yet