Professional Documents

Culture Documents

Global Pulley Specification - QF

Global Pulley Specification - QF

Uploaded by

rrobles011Copyright:

Available Formats

You might also like

- Dow Polyurethanes Flexible FoamsDocument480 pagesDow Polyurethanes Flexible FoamsPk Keller92% (12)

- Molarity, Molality, Normality, and Mass Percent Worksheet II Answer Key 11-12 PDFDocument3 pagesMolarity, Molality, Normality, and Mass Percent Worksheet II Answer Key 11-12 PDFGerald KamulanjeNo ratings yet

- Tub Mill Fist Piece & Inprocess Inspection ReportDocument1 pageTub Mill Fist Piece & Inprocess Inspection ReportZeeshan PathanNo ratings yet

- MT-I NotesDocument79 pagesMT-I NotesPrakhar AggarwalNo ratings yet

- Temp 2Document3 pagesTemp 2dasdsaNo ratings yet

- Master Mto Sheet-Unit 1Document541 pagesMaster Mto Sheet-Unit 1shreearihantamolsNo ratings yet

- Chart W Line Ontop1275 PDFDocument1 pageChart W Line Ontop1275 PDFKamel HocineNo ratings yet

- PDB241-GTR Series - 24 MM Guitar Potentiometer: FeaturesDocument2 pagesPDB241-GTR Series - 24 MM Guitar Potentiometer: FeaturesTiago Santa RosaNo ratings yet

- Chart W Line Ontop320-1 PDFDocument1 pageChart W Line Ontop320-1 PDFMiri HasanovNo ratings yet

- TOPS 7oz Choco Butts 18s 2x3x3Document1 pageTOPS 7oz Choco Butts 18s 2x3x3Casandra MontesNo ratings yet

- Flexitallic Spiralwound CgiDocument1 pageFlexitallic Spiralwound CgiDiego Martínez FernándezNo ratings yet

- Victaulic Vic-Flange Adapters Styles 741 and 743: 1.0 Product DescriptionDocument14 pagesVictaulic Vic-Flange Adapters Styles 741 and 743: 1.0 Product Descriptiongabriel_127971761No ratings yet

- 460V Heat Recovery: Simultaneous Heating and Cooling From A Single SystemDocument1 page460V Heat Recovery: Simultaneous Heating and Cooling From A Single SystemJosephRusselVizmanosNo ratings yet

- BASEDocument3 pagesBASEalexlo999chipNo ratings yet

- Umc 1500duoDocument4 pagesUmc 1500duoadul jangsawangNo ratings yet

- Alternator: SpecificationsDocument4 pagesAlternator: SpecificationsjogremaurNo ratings yet

- Simple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)Document5 pagesSimple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)Bißék ŚílwàlNo ratings yet

- Ventilinsel HF04: Profile Trimming Unit Application ControllerDocument1 pageVentilinsel HF04: Profile Trimming Unit Application ControllerRogério Ferreira de SouzaNo ratings yet

- Origin Equipment Tag Number Equipment Description Category: Insurace Capital Spares Consumables Equip Purch Order NumberDocument23 pagesOrigin Equipment Tag Number Equipment Description Category: Insurace Capital Spares Consumables Equip Purch Order NumberMarudavanan SomasundaramNo ratings yet

- 19 TWA TN Koma-Tsudakoma-23.0-finalDocument2 pages19 TWA TN Koma-Tsudakoma-23.0-finalDong BuiNo ratings yet

- 133 T - Pot Ptfe-Free-R0-GadDocument1 page133 T - Pot Ptfe-Free-R0-Gadankit19200No ratings yet

- Origin Equipment Tag Number Equipment Description Category: Insurace Capital Spares Consumables Equip Purch Order NumberDocument38 pagesOrigin Equipment Tag Number Equipment Description Category: Insurace Capital Spares Consumables Equip Purch Order NumberMarudavanan SomasundaramNo ratings yet

- ARBURG ALLROUNDER 170S TD 525600 en GBDocument6 pagesARBURG ALLROUNDER 170S TD 525600 en GBIsmail ElisNo ratings yet

- 19 Producto PDF Pastera BobcatDocument2 pages19 Producto PDF Pastera Bobcatraul_beronNo ratings yet

- KR - SCAC (R410A - 50,60Hz) - Saudi - CO - MFL67986317 - 0CSL0-03B (Mar.2020) - IDU Duct - SpecDocument2 pagesKR - SCAC (R410A - 50,60Hz) - Saudi - CO - MFL67986317 - 0CSL0-03B (Mar.2020) - IDU Duct - SpecNikolaNo ratings yet

- Flat Ribbon Fibre Optic Patch CableDocument2 pagesFlat Ribbon Fibre Optic Patch CableAmir SalahNo ratings yet

- Ape Diesel D125 D180 Manual 20100402Document30 pagesApe Diesel D125 D180 Manual 20100402Binh le ThanhNo ratings yet

- 4tnv88 Bdsa BroDocument1 page4tnv88 Bdsa BroKevin HarrisNo ratings yet

- Manual de Instalação Samsung FJM Duto SlimDocument16 pagesManual de Instalação Samsung FJM Duto SlimRobson FreitasNo ratings yet

- General Product Catalog Low Res Part43Document1 pageGeneral Product Catalog Low Res Part43JosephRusselVizmanosNo ratings yet

- Fluid Power Metric Catalogue 2018 720 WebDocument4 pagesFluid Power Metric Catalogue 2018 720 WebMarcio RibeiroNo ratings yet

- N X y P ƩM ƩM ƩX Ʃy: Pile FoundationDocument5 pagesN X y P ƩM ƩM ƩX Ʃy: Pile FoundationAnkush KumarNo ratings yet

- 2009manual ST-2TDocument12 pages2009manual ST-2TJean Michel BattailNo ratings yet

- 460V Heat Pump: A Complete, Engineered Heating and Cooling SolutionDocument1 page460V Heat Pump: A Complete, Engineered Heating and Cooling SolutionJosephRusselVizmanosNo ratings yet

- Finglow N7Document2 pagesFinglow N7RobinReyndersNo ratings yet

- TATA Blue BookDocument201 pagesTATA Blue BookmrswcecivilNo ratings yet

- Big Kaiser2019 PDFDocument624 pagesBig Kaiser2019 PDFGoto SamNo ratings yet

- Big Kaiser High Performance Tooling Solutions 2018-2019Document624 pagesBig Kaiser High Performance Tooling Solutions 2018-2019DEANo ratings yet

- AASHTO Bridge Design (Girder + Deck)Document82 pagesAASHTO Bridge Design (Girder + Deck)Samjang CastillejosNo ratings yet

- S355 To Hardox 450Document1 pageS355 To Hardox 450Bien NguyenDuyNo ratings yet

- 25 90mm Metal Screen Filter 1 NosDocument2 pages25 90mm Metal Screen Filter 1 NosMilinda DiasNo ratings yet

- L370 L370-M L370-W L370-MW L470 L470-M: SpecificationsDocument1 pageL370 L370-M L370-W L370-MW L470 L470-M: SpecificationsDumbo_balenoNo ratings yet

- Diamondspark S 55 HP: Seamless Basic Cored Wire With Interesting Potential To Increase Submerged Arc Welding ProductivityDocument2 pagesDiamondspark S 55 HP: Seamless Basic Cored Wire With Interesting Potential To Increase Submerged Arc Welding ProductivityRMNo ratings yet

- Makita HR2230Document2 pagesMakita HR2230adinugrohoNo ratings yet

- Siat SK2 - S26 13549Document2 pagesSiat SK2 - S26 13549ataraxia57No ratings yet

- PF FitDocument2 pagesPF Fitadninfirdaus95No ratings yet

- Datasheet UH CC 5 24Document1 pageDatasheet UH CC 5 24R MdzaNo ratings yet

- BLANKING VAM TOP ® HC 7in. 26lb-ft API DriftDocument1 pageBLANKING VAM TOP ® HC 7in. 26lb-ft API DriftbmwoooooNo ratings yet

- Vessel Analytical Calculation For:: InputsDocument2 pagesVessel Analytical Calculation For:: InputsmakamahamisuNo ratings yet

- Transformer Equipment AllbroDocument48 pagesTransformer Equipment AllbrorafeeqNo ratings yet

- 3362 - 1/4 Square Trimpot Trimming Potentiometer: FeaturesDocument3 pages3362 - 1/4 Square Trimpot Trimming Potentiometer: FeaturesPhan Ngọc DuyNo ratings yet

- Valores de Correcion Del Factor de Velocidad de Las Grasas LubricantesDocument8 pagesValores de Correcion Del Factor de Velocidad de Las Grasas LubricantesLeonardo CardosoNo ratings yet

- Quotation Scheme Jstomi: Equiptech (PVT.) LTDDocument4 pagesQuotation Scheme Jstomi: Equiptech (PVT.) LTDvasiliy vasilievichNo ratings yet

- Rittal - The SystemDocument17 pagesRittal - The SystemrabloNo ratings yet

- Barden - 107Document1 pageBarden - 107Linh LạiNo ratings yet

- BAU1SLX27 - ΤσιμουχαDocument2 pagesBAU1SLX27 - ΤσιμουχαDiam BkNo ratings yet

- Ducted Type: Air Conditioner WibxmDocument2 pagesDucted Type: Air Conditioner WibxmMarco QuitoNo ratings yet

- Widxm-36sva2 PDFDocument2 pagesWidxm-36sva2 PDFMarco Quito0% (1)

- One Tough Animal One Tough Animal: Brushcat Rotary Cutter AttachmentDocument2 pagesOne Tough Animal One Tough Animal: Brushcat Rotary Cutter AttachmentJhon jaider Álvarez BarbozaNo ratings yet

- TOPS 7oz Choco Butts 18s 2x3x4Document1 pageTOPS 7oz Choco Butts 18s 2x3x4Casandra MontesNo ratings yet

- Screenshot 2023-11-16 at 3.45.42 PMDocument20 pagesScreenshot 2023-11-16 at 3.45.42 PMrajeevbhardwaj20No ratings yet

- M3 Catalogo ENGDocument84 pagesM3 Catalogo ENGJose GonzalezNo ratings yet

- Speed Changers, Drives & Gears World Summary: Market Values & Financials by CountryFrom EverandSpeed Changers, Drives & Gears World Summary: Market Values & Financials by CountryNo ratings yet

- Engine, Turbine & Power Transmission Equipment World Summary: Market Values & Financials by CountryFrom EverandEngine, Turbine & Power Transmission Equipment World Summary: Market Values & Financials by CountryNo ratings yet

- BDocument1 pageBrrobles011No ratings yet

- OT1GN01 - Bearing Dimensional Interchange Chart - 0622 (W)Document2 pagesOT1GN01 - Bearing Dimensional Interchange Chart - 0622 (W)rrobles011No ratings yet

- EM3665T InfoPacket 5HP 1750RPMDocument10 pagesEM3665T InfoPacket 5HP 1750RPMrrobles011No ratings yet

- 8.2 Dodge Extreme Duty Ball BearingsDocument11 pages8.2 Dodge Extreme Duty Ball Bearingsrrobles011No ratings yet

- WP0351Dodge Torque-Arm Family Screw Conveyor Driveshafts - EDocument7 pagesWP0351Dodge Torque-Arm Family Screw Conveyor Driveshafts - Errobles011No ratings yet

- 8.3 Dodge Washdown Ball BearingsDocument16 pages8.3 Dodge Washdown Ball Bearingsrrobles011No ratings yet

- Data Sheet QF 2-12-Premium-100 0.75HP With 3Document3 pagesData Sheet QF 2-12-Premium-100 0.75HP With 3rrobles011No ratings yet

- Para-Flex Couplings: Includes ATEX Certified Couplings Instruction ManualDocument4 pagesPara-Flex Couplings: Includes ATEX Certified Couplings Instruction Manualrrobles011No ratings yet

- 2022 - Smart Sensor X MechanicalProducts - 9AKK107592Document16 pages2022 - Smart Sensor X MechanicalProducts - 9AKK107592rrobles011No ratings yet

- Selection Guide TAII Vs TXT, Browing, Falk, Sumitomo - MXDocument17 pagesSelection Guide TAII Vs TXT, Browing, Falk, Sumitomo - MXrrobles011No ratings yet

- 2009 - Sales Training Cement - InternationalDocument32 pages2009 - Sales Training Cement - Internationalrrobles011No ratings yet

- Gear Basics: Torque, HP, Efficiency & Service FactorDocument15 pagesGear Basics: Torque, HP, Efficiency & Service Factorrrobles011No ratings yet

- 2.0 TXT-SCXT 11Document30 pages2.0 TXT-SCXT 11rrobles011No ratings yet

- 8.4 Spherical Roller BearingsDocument68 pages8.4 Spherical Roller Bearingsrrobles011No ratings yet

- 3 - Conveyor - Components - Mexico IPTSDocument24 pages3 - Conveyor - Components - Mexico IPTSrrobles011No ratings yet

- BRG Isn BR3010 - 0709 - WebDocument8 pagesBRG Isn BR3010 - 0709 - Webrrobles011No ratings yet

- 7.0 PT ComponentsDocument52 pages7.0 PT Componentsrrobles011No ratings yet

- 1.1 Conveyor PulleysDocument34 pages1.1 Conveyor Pulleysrrobles011No ratings yet

- Catalogo Juntas Proco 230-232Document12 pagesCatalogo Juntas Proco 230-232rrobles011No ratings yet

- Tigear - 2 Gearing: Engineering CatalogDocument292 pagesTigear - 2 Gearing: Engineering Catalogrrobles011No ratings yet

- 8-MagnaGear4-3-08-Metric - CompDocument26 pages8-MagnaGear4-3-08-Metric - Comprrobles011No ratings yet

- 3GBA082320 ASC 3gba082320 AscDocument3 pages3GBA082320 ASC 3gba082320 Ascrrobles011No ratings yet

- It Tigear2Document2 pagesIt Tigear2rrobles011No ratings yet

- Emerging Material and Processes IEEE Paper NewDocument4 pagesEmerging Material and Processes IEEE Paper NewpriyanjanaNo ratings yet

- E406Document4 pagesE406diego100% (1)

- Primetals TechnologiesDocument2 pagesPrimetals TechnologiesJulioCesarLunaIbañezNo ratings yet

- Galenical PreperationDocument35 pagesGalenical PreperationAhmed ImranNo ratings yet

- Metal Matrix Composites: I. Kostikov A N D KilinDocument16 pagesMetal Matrix Composites: I. Kostikov A N D Kilinsupriyo1970No ratings yet

- Active Municipal Solid Waste Landfills in TexasDocument7 pagesActive Municipal Solid Waste Landfills in TexasPaul BowerNo ratings yet

- Katalog SimonDocument5 pagesKatalog SimonRiyadi tNo ratings yet

- Soil ClassificationDocument21 pagesSoil ClassificationGabby ChebetNo ratings yet

- Rock Baby RockDocument31 pagesRock Baby RockMarcbien EnocillasNo ratings yet

- Turco 4316: Heat Scale Conditioning CompoundDocument2 pagesTurco 4316: Heat Scale Conditioning CompoundMuhammad Ejaz QureshiNo ratings yet

- Rcc95 Continuous Beams (Tables)Document8 pagesRcc95 Continuous Beams (Tables)Steve JsobNo ratings yet

- Styrene Monomer: Storage & Handling Safety GuideDocument17 pagesStyrene Monomer: Storage & Handling Safety GuideRonak MotaNo ratings yet

- Spiral-Wound-Gaskets ASME B16 20 2012 Spiral Wound Gaskets For ASME B16.5 FlangesDocument6 pagesSpiral-Wound-Gaskets ASME B16 20 2012 Spiral Wound Gaskets For ASME B16.5 FlangesAntonio CardosoNo ratings yet

- DTM985 MDSDocument3 pagesDTM985 MDSSahanNo ratings yet

- Hsslive Xi Chem Pyq Ans 2. EletrochemistryDocument12 pagesHsslive Xi Chem Pyq Ans 2. EletrochemistryPritika RajendranNo ratings yet

- Behaviour of Al6061-T6 Alloy at Different Temperatures and Strain-Rates - Experimental Characterization and Material Modelling M. Scapin & A. ManesDocument34 pagesBehaviour of Al6061-T6 Alloy at Different Temperatures and Strain-Rates - Experimental Characterization and Material Modelling M. Scapin & A. Manestaylor.collins291100% (10)

- Eni Grease LCX 2-220 PDFDocument2 pagesEni Grease LCX 2-220 PDFranjanguptNo ratings yet

- PP GF30 - Hostacom PC072-3 NaturaleDocument3 pagesPP GF30 - Hostacom PC072-3 NaturalearmandoNo ratings yet

- How Do PH Meters WorkDocument11 pagesHow Do PH Meters WorkismahNo ratings yet

- VISCOWRAP-HT Product Data Sheet EnglishDocument2 pagesVISCOWRAP-HT Product Data Sheet EnglishJA BustosNo ratings yet

- IUPAC Name 18th Sep 15Document8 pagesIUPAC Name 18th Sep 15samarthNo ratings yet

- 1st Quarter Exam G7Document2 pages1st Quarter Exam G7Alma Almodiel MacarioNo ratings yet

- Parafin 3Document1 pageParafin 3Andrianna NastasyaNo ratings yet

- Chemdur - 42 RHDocument3 pagesChemdur - 42 RHICPL-RWPNo ratings yet

- Chemistry of Crude OilDocument33 pagesChemistry of Crude OilCNAltNo ratings yet

- UntitledDocument3 pagesUntitledafifiNo ratings yet

Global Pulley Specification - QF

Global Pulley Specification - QF

Uploaded by

rrobles011Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Global Pulley Specification - QF

Global Pulley Specification - QF

Uploaded by

rrobles011Copyright:

Available Formats

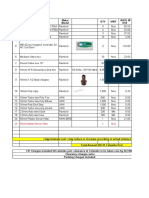

Global Pulley Specifications

Warranty 1 year 1 year 2 year with loading info" 2 year with loading info" 2 year with loading Mb',

2 year with loading info" 2 year with loading info"

RIM Straight or Straight or Straight or Straight Straight

Crown per B105.1 Crown per 8105.1 Crown per B105.1

FW = BW + for x42" = SW + for 047' = OW + 2" for x42" BW + 3' for > 42" = 13W + =BW+ 12"

=BW+3"for>42" = SW + 3" for > 42"

Yield . 24.500 psi > 24.500 psi > 24,500 psi > 24,500 osl > 36,000 psi

Max.Carbon Content 0.26% 0,26% VC% 0,26% 26%

Minimum Thickness 6-12 1/4 6-12 1/4 0.5", or greater based on design req.

14 - 20 3/8 14 - 20 318

24 - 48 1/2 24 -48 1/2

Machined PIW >800 Machine turned Rim 0.30 TIR PIW >800 Machine turned Rim 0.30 TIR Machine turned Rim Machine turned Rid,

Joint preparation Fully Machined including Rim ID

Concentricklly Dia (in.) and Max TIR Dia (in.) and Max TiR Dia (id) and Max TIR 0.030" TIR MAX 0.015" -DR MAX

8-24 0125 8-24 0.125 8-24 0.125

30 - 48 0.188 30 - 48 0.188 30 - 48 0.188

64 - 60 0,250 54 - 60 0.250 54 -60 0.250

Material certified lamination tree with 190%

search

End Discs Hub welded to end disc, flexible or rigid design MD = Hub Welded to End disc Integral hub (HE) Integral hub, turbine, flexible design T Section or Notched T

MDX = Integral Hub Profiled, flexible design(keyless)

End Disc Welded to Rim End Disc Welded to Rim End Disc Welded to Rim End Disc Welded to Rim End Disc Welded to Rim with Complete

Penetration Weld

Yield > 30,000 psi > 30,000 psi > 30,000 psi > 30,000 psi 38,000 psi

Max.Carbon Content 0,28% 0,26% 0,26% 0,26% 0,26%

Flexible / Rigid Flexible! Rigid Rigid Rigid / Flexible Flexible) Rigid Flexible! Rigid

Material certified lamination freewill) 100%

search

Point/Coating high solids, corrosion resistant paint high solids, corrosion resistant paint high solids, corrosion resistant paint high solids, corrosion resistant paint high solids, corrosion resistant paint,

dust shields

Shafts

> 45.000 psi > 45,000 psi > 45,000 pal > 45,000 psi > 62,000 psi

Min Carbon Content 0,43% 0,43% 0.43% 11,43% 0,313%

Type Cold Forged < 6" Dia. Cold Forged < Dia_ Cold Forged < 6' Dia. Cold Forged c 6' Dia. Hot Rolled or Forged Steel

Hot Rolled or forged steel > 6" Dia. Hot Rolled or forged steel ? 6" Dia. Hot Rolled or forged steel > 6' Dia. Hot Rolled or forged steel > 6" Dia. (No solo,* Heat Treatment Allowed/

Full Matching Yes Yes Yes Yes Yes

Fillet Radial > 25% of smaller diameter or > 25% of smaller diameter or > 25% of smaller diameter or difference In > 25% of smaller diameter or 25% of smaller diameter or

difference in diameters (larger one) difference in diameters (larger one) diameters (larger one) _ difference in diameters gamer one) difference in diameters (larger one)

Pillow Block Turndown > 75% of motor shaft diameter > 75% of major shaft diameter > 75% of major shaft diameter > 75% of major shaft diameter 75% of major shaft diameter

Kb = 1.5 = 1.5 = 1.5 = 1.5 = 1.5

= 2.5 for overhung loads 2.5 for overhung loads 2.5 for overhung loads = 2.5 for overhung loads = 2.5 for overhung toads

Kt = 1.0 = 1.0 =10 = 1.0 = 1.0

Strees at Hub Combined Bending and Torsional <8,000 psi Combined Bending and Torsional <8,000 psi Combined Bending and Torsion./ <8,000 psi Combined Bending and Torsional <8,000 psi Combined Bending and Torsional <10,000 psi

Combined Bending and Torsional stress at Combined Bending and Torsional stress at Combined Bending and Torsional stress Combined Bending and Torsional stress Combined Bending and Torsional stress at

tumdovms <10,657 psi turndowns <10,607 psi at turndowns <10,607 psi at turndowns <10,667 psi turndowns <13,333 psi

Slope at ED CI < 0.0023 irdin 0_0023 irdin < 0.0015 in/in <0.0015 jnfin, fabric 0 00101ndin, steel or Kevlar <0.0010 inifin

Material 1045 1045 1045 1045 4140

Inspecction Ultrasonic before machining, dye penetrant after

machining.

Paint/Cooling non-water soluble rust Inhibitor. non-water soluble rust Inhibitor. non-water soluble rust Inhibitor. non-water soluble rust inhibitor. non-water soluble rust inhibitor.

Hubs and Bushings HE HE HE/ Keyless locking assy Keyless looking assy Keyless locking assy

Welding Submerged arc process Submerged arc process Submerged arc process Submerged arc process Submerged arc process

Longitudinal weld seams on rim od Longitudinal weld seams on rim od Longitudinal weld seams on rim od Longitudinal weld seams on rim od Complete penetration butt welds, no backing

with full length, complete with full length, complete with full length, complete with full length, complete plates.

penetration Penetration penetration. penetration.

Weld filler materials shall be low hydrogen

Center discs welded from bore Stitch Weld > Center discs welded from bore Center discs welded from bore Center discs welded from bore No Center Discs Allowed.

30% of circumference Continuous Weld Continuous Weld Continuous Weld

End Discs continuously welded to rim and End Discs continuously welded to the rim. End Discs continuously welded to the rim. End Discs continuously welded to the rim. Circumferential welds to be finished smooth.

continuously welded to both sides of hub

Welding byAWS D1.1 personnel Welding byAWS D1.1 personnel.

10096 Ultrasonic inspection 100% Ultrasonic Inspection

Magnetic Particle Inspection over entire Magnetic Particle Inspection over entire length

length

'Thermally stress relived before machining. Thermally stress relived before machining.

Hot vulcenized to pulley face (drum) Hot vulcanized to pulley face (drum) Hot vulcanized to pulley face (drum) Hot vulcanized to pulley face Hot vuleenized to pulley face or Cold Bond to

Lagging pulley face

High Tension Pulleys 0.375' thick, 60 Duro Shore A, herringbone 0.5" thick. 60 Duro Shore A, herringbone 0.5" thick. 60 Duro Shore A, herringbone 0.5" thick, 60 Duro Shore A. Diamond 01." thick, 60 Dar° Shore A. Diamond

Low Tension Pulleys 0.375" thick 60 Duro Shore A 0.375" thick. 60 Duro Share A 0.375" thick. 60 Duro Shore A 0.375" thick. 60 Duro Shore A 0.5" thick. 60 Duro Shore A

Material SBR unless otherwise specified SBR unless otherwise specified SBR unless otherwise specified SBR unless otherwise specified D-Lag for high abrasion resistance

D-Lag for high abrasion resistance D-Lag for high abrasion resistance D-Lag for high abrasion resistance D-Lag for high abrasion resistance Neoprene for underground or on resistant

Neoprene for underground or all resistant Neoprene for underground or oil resistant Neoprene for underground or oil resistant Neoprene for underground or oil resistant

Na Tape wrap impression present No. Tape wrap impression present Yes PIW . 800 Machined with pulley mounted on shaft, max Machined with pulley mounted on shalt, Ines

Machined TIR 0.030". TIR 0.030'.

Pulley Direction Clearly marked, when required Clearly marked, when required Clearly marked, when required Clearly marked, when required Clearly marked, when required

Protective Covering Yes. Yes. Yes. Yes. Yes.

Wing Pulleys CEMAB501, <350 P1W at Pulley MD < 350 PIW I MDX < 450 PM/ N/A NIA NIA

No Steel or Keeler Belting No Sleet or Kevlar Belting

Min Contact Bar 1 S' X 0.25" 1.5" X 0.625" / 2.0" x 075"

Lagging Extruded urethane replaceable (optional) Extruded urethane replaceable (optional)

Welding MIG MID

Assembly waterproof rust inhibitor waterproof rust inhibitor waterproof rust inhibitor waterproof rust inhibitor waterproof rust inhibitor

Paint/Coating applied to exposed/machined areas applied to exposed/machined areas applied to exposed/machined areas applied to exposedlinachined areas applied to exposed/machined areas

Identification ID Tag applied to end disc ID Tag applied to end disc, and shalt stamped ID Tag applied to end disc., and shaft stamped

Statie per ISO 1940/1-1966 Static per ISO 104111-1986

One weight per end disc, securely welded. Shall One weight per end disc, securely welded. Shall

Balancing

not project beyond face of pulley. not project beyond face of pulley

Minimum searing L10 60000 Hrs. 100,000 Hrs. 100,000 Hrs. 100,000 Hrs. 100,000 Hrs_

You might also like

- Dow Polyurethanes Flexible FoamsDocument480 pagesDow Polyurethanes Flexible FoamsPk Keller92% (12)

- Molarity, Molality, Normality, and Mass Percent Worksheet II Answer Key 11-12 PDFDocument3 pagesMolarity, Molality, Normality, and Mass Percent Worksheet II Answer Key 11-12 PDFGerald KamulanjeNo ratings yet

- Tub Mill Fist Piece & Inprocess Inspection ReportDocument1 pageTub Mill Fist Piece & Inprocess Inspection ReportZeeshan PathanNo ratings yet

- MT-I NotesDocument79 pagesMT-I NotesPrakhar AggarwalNo ratings yet

- Temp 2Document3 pagesTemp 2dasdsaNo ratings yet

- Master Mto Sheet-Unit 1Document541 pagesMaster Mto Sheet-Unit 1shreearihantamolsNo ratings yet

- Chart W Line Ontop1275 PDFDocument1 pageChart W Line Ontop1275 PDFKamel HocineNo ratings yet

- PDB241-GTR Series - 24 MM Guitar Potentiometer: FeaturesDocument2 pagesPDB241-GTR Series - 24 MM Guitar Potentiometer: FeaturesTiago Santa RosaNo ratings yet

- Chart W Line Ontop320-1 PDFDocument1 pageChart W Line Ontop320-1 PDFMiri HasanovNo ratings yet

- TOPS 7oz Choco Butts 18s 2x3x3Document1 pageTOPS 7oz Choco Butts 18s 2x3x3Casandra MontesNo ratings yet

- Flexitallic Spiralwound CgiDocument1 pageFlexitallic Spiralwound CgiDiego Martínez FernándezNo ratings yet

- Victaulic Vic-Flange Adapters Styles 741 and 743: 1.0 Product DescriptionDocument14 pagesVictaulic Vic-Flange Adapters Styles 741 and 743: 1.0 Product Descriptiongabriel_127971761No ratings yet

- 460V Heat Recovery: Simultaneous Heating and Cooling From A Single SystemDocument1 page460V Heat Recovery: Simultaneous Heating and Cooling From A Single SystemJosephRusselVizmanosNo ratings yet

- BASEDocument3 pagesBASEalexlo999chipNo ratings yet

- Umc 1500duoDocument4 pagesUmc 1500duoadul jangsawangNo ratings yet

- Alternator: SpecificationsDocument4 pagesAlternator: SpecificationsjogremaurNo ratings yet

- Simple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)Document5 pagesSimple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)Bißék ŚílwàlNo ratings yet

- Ventilinsel HF04: Profile Trimming Unit Application ControllerDocument1 pageVentilinsel HF04: Profile Trimming Unit Application ControllerRogério Ferreira de SouzaNo ratings yet

- Origin Equipment Tag Number Equipment Description Category: Insurace Capital Spares Consumables Equip Purch Order NumberDocument23 pagesOrigin Equipment Tag Number Equipment Description Category: Insurace Capital Spares Consumables Equip Purch Order NumberMarudavanan SomasundaramNo ratings yet

- 19 TWA TN Koma-Tsudakoma-23.0-finalDocument2 pages19 TWA TN Koma-Tsudakoma-23.0-finalDong BuiNo ratings yet

- 133 T - Pot Ptfe-Free-R0-GadDocument1 page133 T - Pot Ptfe-Free-R0-Gadankit19200No ratings yet

- Origin Equipment Tag Number Equipment Description Category: Insurace Capital Spares Consumables Equip Purch Order NumberDocument38 pagesOrigin Equipment Tag Number Equipment Description Category: Insurace Capital Spares Consumables Equip Purch Order NumberMarudavanan SomasundaramNo ratings yet

- ARBURG ALLROUNDER 170S TD 525600 en GBDocument6 pagesARBURG ALLROUNDER 170S TD 525600 en GBIsmail ElisNo ratings yet

- 19 Producto PDF Pastera BobcatDocument2 pages19 Producto PDF Pastera Bobcatraul_beronNo ratings yet

- KR - SCAC (R410A - 50,60Hz) - Saudi - CO - MFL67986317 - 0CSL0-03B (Mar.2020) - IDU Duct - SpecDocument2 pagesKR - SCAC (R410A - 50,60Hz) - Saudi - CO - MFL67986317 - 0CSL0-03B (Mar.2020) - IDU Duct - SpecNikolaNo ratings yet

- Flat Ribbon Fibre Optic Patch CableDocument2 pagesFlat Ribbon Fibre Optic Patch CableAmir SalahNo ratings yet

- Ape Diesel D125 D180 Manual 20100402Document30 pagesApe Diesel D125 D180 Manual 20100402Binh le ThanhNo ratings yet

- 4tnv88 Bdsa BroDocument1 page4tnv88 Bdsa BroKevin HarrisNo ratings yet

- Manual de Instalação Samsung FJM Duto SlimDocument16 pagesManual de Instalação Samsung FJM Duto SlimRobson FreitasNo ratings yet

- General Product Catalog Low Res Part43Document1 pageGeneral Product Catalog Low Res Part43JosephRusselVizmanosNo ratings yet

- Fluid Power Metric Catalogue 2018 720 WebDocument4 pagesFluid Power Metric Catalogue 2018 720 WebMarcio RibeiroNo ratings yet

- N X y P ƩM ƩM ƩX Ʃy: Pile FoundationDocument5 pagesN X y P ƩM ƩM ƩX Ʃy: Pile FoundationAnkush KumarNo ratings yet

- 2009manual ST-2TDocument12 pages2009manual ST-2TJean Michel BattailNo ratings yet

- 460V Heat Pump: A Complete, Engineered Heating and Cooling SolutionDocument1 page460V Heat Pump: A Complete, Engineered Heating and Cooling SolutionJosephRusselVizmanosNo ratings yet

- Finglow N7Document2 pagesFinglow N7RobinReyndersNo ratings yet

- TATA Blue BookDocument201 pagesTATA Blue BookmrswcecivilNo ratings yet

- Big Kaiser2019 PDFDocument624 pagesBig Kaiser2019 PDFGoto SamNo ratings yet

- Big Kaiser High Performance Tooling Solutions 2018-2019Document624 pagesBig Kaiser High Performance Tooling Solutions 2018-2019DEANo ratings yet

- AASHTO Bridge Design (Girder + Deck)Document82 pagesAASHTO Bridge Design (Girder + Deck)Samjang CastillejosNo ratings yet

- S355 To Hardox 450Document1 pageS355 To Hardox 450Bien NguyenDuyNo ratings yet

- 25 90mm Metal Screen Filter 1 NosDocument2 pages25 90mm Metal Screen Filter 1 NosMilinda DiasNo ratings yet

- L370 L370-M L370-W L370-MW L470 L470-M: SpecificationsDocument1 pageL370 L370-M L370-W L370-MW L470 L470-M: SpecificationsDumbo_balenoNo ratings yet

- Diamondspark S 55 HP: Seamless Basic Cored Wire With Interesting Potential To Increase Submerged Arc Welding ProductivityDocument2 pagesDiamondspark S 55 HP: Seamless Basic Cored Wire With Interesting Potential To Increase Submerged Arc Welding ProductivityRMNo ratings yet

- Makita HR2230Document2 pagesMakita HR2230adinugrohoNo ratings yet

- Siat SK2 - S26 13549Document2 pagesSiat SK2 - S26 13549ataraxia57No ratings yet

- PF FitDocument2 pagesPF Fitadninfirdaus95No ratings yet

- Datasheet UH CC 5 24Document1 pageDatasheet UH CC 5 24R MdzaNo ratings yet

- BLANKING VAM TOP ® HC 7in. 26lb-ft API DriftDocument1 pageBLANKING VAM TOP ® HC 7in. 26lb-ft API DriftbmwoooooNo ratings yet

- Vessel Analytical Calculation For:: InputsDocument2 pagesVessel Analytical Calculation For:: InputsmakamahamisuNo ratings yet

- Transformer Equipment AllbroDocument48 pagesTransformer Equipment AllbrorafeeqNo ratings yet

- 3362 - 1/4 Square Trimpot Trimming Potentiometer: FeaturesDocument3 pages3362 - 1/4 Square Trimpot Trimming Potentiometer: FeaturesPhan Ngọc DuyNo ratings yet

- Valores de Correcion Del Factor de Velocidad de Las Grasas LubricantesDocument8 pagesValores de Correcion Del Factor de Velocidad de Las Grasas LubricantesLeonardo CardosoNo ratings yet

- Quotation Scheme Jstomi: Equiptech (PVT.) LTDDocument4 pagesQuotation Scheme Jstomi: Equiptech (PVT.) LTDvasiliy vasilievichNo ratings yet

- Rittal - The SystemDocument17 pagesRittal - The SystemrabloNo ratings yet

- Barden - 107Document1 pageBarden - 107Linh LạiNo ratings yet

- BAU1SLX27 - ΤσιμουχαDocument2 pagesBAU1SLX27 - ΤσιμουχαDiam BkNo ratings yet

- Ducted Type: Air Conditioner WibxmDocument2 pagesDucted Type: Air Conditioner WibxmMarco QuitoNo ratings yet

- Widxm-36sva2 PDFDocument2 pagesWidxm-36sva2 PDFMarco Quito0% (1)

- One Tough Animal One Tough Animal: Brushcat Rotary Cutter AttachmentDocument2 pagesOne Tough Animal One Tough Animal: Brushcat Rotary Cutter AttachmentJhon jaider Álvarez BarbozaNo ratings yet

- TOPS 7oz Choco Butts 18s 2x3x4Document1 pageTOPS 7oz Choco Butts 18s 2x3x4Casandra MontesNo ratings yet

- Screenshot 2023-11-16 at 3.45.42 PMDocument20 pagesScreenshot 2023-11-16 at 3.45.42 PMrajeevbhardwaj20No ratings yet

- M3 Catalogo ENGDocument84 pagesM3 Catalogo ENGJose GonzalezNo ratings yet

- Speed Changers, Drives & Gears World Summary: Market Values & Financials by CountryFrom EverandSpeed Changers, Drives & Gears World Summary: Market Values & Financials by CountryNo ratings yet

- Engine, Turbine & Power Transmission Equipment World Summary: Market Values & Financials by CountryFrom EverandEngine, Turbine & Power Transmission Equipment World Summary: Market Values & Financials by CountryNo ratings yet

- BDocument1 pageBrrobles011No ratings yet

- OT1GN01 - Bearing Dimensional Interchange Chart - 0622 (W)Document2 pagesOT1GN01 - Bearing Dimensional Interchange Chart - 0622 (W)rrobles011No ratings yet

- EM3665T InfoPacket 5HP 1750RPMDocument10 pagesEM3665T InfoPacket 5HP 1750RPMrrobles011No ratings yet

- 8.2 Dodge Extreme Duty Ball BearingsDocument11 pages8.2 Dodge Extreme Duty Ball Bearingsrrobles011No ratings yet

- WP0351Dodge Torque-Arm Family Screw Conveyor Driveshafts - EDocument7 pagesWP0351Dodge Torque-Arm Family Screw Conveyor Driveshafts - Errobles011No ratings yet

- 8.3 Dodge Washdown Ball BearingsDocument16 pages8.3 Dodge Washdown Ball Bearingsrrobles011No ratings yet

- Data Sheet QF 2-12-Premium-100 0.75HP With 3Document3 pagesData Sheet QF 2-12-Premium-100 0.75HP With 3rrobles011No ratings yet

- Para-Flex Couplings: Includes ATEX Certified Couplings Instruction ManualDocument4 pagesPara-Flex Couplings: Includes ATEX Certified Couplings Instruction Manualrrobles011No ratings yet

- 2022 - Smart Sensor X MechanicalProducts - 9AKK107592Document16 pages2022 - Smart Sensor X MechanicalProducts - 9AKK107592rrobles011No ratings yet

- Selection Guide TAII Vs TXT, Browing, Falk, Sumitomo - MXDocument17 pagesSelection Guide TAII Vs TXT, Browing, Falk, Sumitomo - MXrrobles011No ratings yet

- 2009 - Sales Training Cement - InternationalDocument32 pages2009 - Sales Training Cement - Internationalrrobles011No ratings yet

- Gear Basics: Torque, HP, Efficiency & Service FactorDocument15 pagesGear Basics: Torque, HP, Efficiency & Service Factorrrobles011No ratings yet

- 2.0 TXT-SCXT 11Document30 pages2.0 TXT-SCXT 11rrobles011No ratings yet

- 8.4 Spherical Roller BearingsDocument68 pages8.4 Spherical Roller Bearingsrrobles011No ratings yet

- 3 - Conveyor - Components - Mexico IPTSDocument24 pages3 - Conveyor - Components - Mexico IPTSrrobles011No ratings yet

- BRG Isn BR3010 - 0709 - WebDocument8 pagesBRG Isn BR3010 - 0709 - Webrrobles011No ratings yet

- 7.0 PT ComponentsDocument52 pages7.0 PT Componentsrrobles011No ratings yet

- 1.1 Conveyor PulleysDocument34 pages1.1 Conveyor Pulleysrrobles011No ratings yet

- Catalogo Juntas Proco 230-232Document12 pagesCatalogo Juntas Proco 230-232rrobles011No ratings yet

- Tigear - 2 Gearing: Engineering CatalogDocument292 pagesTigear - 2 Gearing: Engineering Catalogrrobles011No ratings yet

- 8-MagnaGear4-3-08-Metric - CompDocument26 pages8-MagnaGear4-3-08-Metric - Comprrobles011No ratings yet

- 3GBA082320 ASC 3gba082320 AscDocument3 pages3GBA082320 ASC 3gba082320 Ascrrobles011No ratings yet

- It Tigear2Document2 pagesIt Tigear2rrobles011No ratings yet

- Emerging Material and Processes IEEE Paper NewDocument4 pagesEmerging Material and Processes IEEE Paper NewpriyanjanaNo ratings yet

- E406Document4 pagesE406diego100% (1)

- Primetals TechnologiesDocument2 pagesPrimetals TechnologiesJulioCesarLunaIbañezNo ratings yet

- Galenical PreperationDocument35 pagesGalenical PreperationAhmed ImranNo ratings yet

- Metal Matrix Composites: I. Kostikov A N D KilinDocument16 pagesMetal Matrix Composites: I. Kostikov A N D Kilinsupriyo1970No ratings yet

- Active Municipal Solid Waste Landfills in TexasDocument7 pagesActive Municipal Solid Waste Landfills in TexasPaul BowerNo ratings yet

- Katalog SimonDocument5 pagesKatalog SimonRiyadi tNo ratings yet

- Soil ClassificationDocument21 pagesSoil ClassificationGabby ChebetNo ratings yet

- Rock Baby RockDocument31 pagesRock Baby RockMarcbien EnocillasNo ratings yet

- Turco 4316: Heat Scale Conditioning CompoundDocument2 pagesTurco 4316: Heat Scale Conditioning CompoundMuhammad Ejaz QureshiNo ratings yet

- Rcc95 Continuous Beams (Tables)Document8 pagesRcc95 Continuous Beams (Tables)Steve JsobNo ratings yet

- Styrene Monomer: Storage & Handling Safety GuideDocument17 pagesStyrene Monomer: Storage & Handling Safety GuideRonak MotaNo ratings yet

- Spiral-Wound-Gaskets ASME B16 20 2012 Spiral Wound Gaskets For ASME B16.5 FlangesDocument6 pagesSpiral-Wound-Gaskets ASME B16 20 2012 Spiral Wound Gaskets For ASME B16.5 FlangesAntonio CardosoNo ratings yet

- DTM985 MDSDocument3 pagesDTM985 MDSSahanNo ratings yet

- Hsslive Xi Chem Pyq Ans 2. EletrochemistryDocument12 pagesHsslive Xi Chem Pyq Ans 2. EletrochemistryPritika RajendranNo ratings yet

- Behaviour of Al6061-T6 Alloy at Different Temperatures and Strain-Rates - Experimental Characterization and Material Modelling M. Scapin & A. ManesDocument34 pagesBehaviour of Al6061-T6 Alloy at Different Temperatures and Strain-Rates - Experimental Characterization and Material Modelling M. Scapin & A. Manestaylor.collins291100% (10)

- Eni Grease LCX 2-220 PDFDocument2 pagesEni Grease LCX 2-220 PDFranjanguptNo ratings yet

- PP GF30 - Hostacom PC072-3 NaturaleDocument3 pagesPP GF30 - Hostacom PC072-3 NaturalearmandoNo ratings yet

- How Do PH Meters WorkDocument11 pagesHow Do PH Meters WorkismahNo ratings yet

- VISCOWRAP-HT Product Data Sheet EnglishDocument2 pagesVISCOWRAP-HT Product Data Sheet EnglishJA BustosNo ratings yet

- IUPAC Name 18th Sep 15Document8 pagesIUPAC Name 18th Sep 15samarthNo ratings yet

- 1st Quarter Exam G7Document2 pages1st Quarter Exam G7Alma Almodiel MacarioNo ratings yet

- Parafin 3Document1 pageParafin 3Andrianna NastasyaNo ratings yet

- Chemdur - 42 RHDocument3 pagesChemdur - 42 RHICPL-RWPNo ratings yet

- Chemistry of Crude OilDocument33 pagesChemistry of Crude OilCNAltNo ratings yet

- UntitledDocument3 pagesUntitledafifiNo ratings yet