Professional Documents

Culture Documents

Adv Funct Materials - 2022 - Qu - Spherical TR

Adv Funct Materials - 2022 - Qu - Spherical TR

Uploaded by

Atharva SokhiyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adv Funct Materials - 2022 - Qu - Spherical TR

Adv Funct Materials - 2022 - Qu - Spherical TR

Uploaded by

Atharva SokhiyaCopyright:

Available Formats

Research Article

www.afm-journal.de

Spherical Triboelectric Nanogenerator Based on Eccentric

Structure for Omnidirectional Low Frequency Water Wave

Energy Harvesting

Zhigang Qu,* Mingkun Huang, Chuanxian Chen, Yang An, Hongze Liu,

Quanpeng Zhang, Xiaopeng Wang, Ying Liu,* Wuliang Yin,* and Xingfei Li*

been collected and utilized, such as wind

Ocean wave energy is a promising green energy source, but it is difficult energy, solar energy, ocean energy, etc.

to exploit on a large scale due to its low frequency and the random uncer- The energy of water waves in the ocean

tainty of its direction. In this study, a spherical eccentric structured tribo- can be exploited on a large scale as a

electric nanogenerator (Se-TENG) is designed to harvest omnidirectional promising renewable energy source.[1,2]

Current technologies for harvesting water

low-frequency water wave energy. Power management circuits (PMM) are wave energy are mainly based on electro-

designed to optimize the utilization of water wave energy at low frequencies magnetic generators (EMGs), however,

for large-scale conversion and storage. It is found that the output perfor- EMGs are not effective in harvesting water

mance of the Se-TENG device is influenced by the frequency of the water wave energy at low frequencies (<2.0 Hz)

waves, with the best output performance at a water wave frequency of 2.0 Hz, and have problems of large size, high

cost and corrosion.[3–6] Triboelectric nano-

given that the wave amplitude is 9 cm. It is verified that within the Se-TENG,

generators (TENGs) can efficiently collect

the parallel connections of eccentric structured triboelectric nanogenerators low-frequency mechanical energy,[7–12] pro-

(E-TENGs) are more conducive to energy storage and conversion. In addi- viding a new method for harvesting water

tion, the Se-TENG used in conjunction with an energy storage device is able wave energy.[13,14] Compared to EMGs,

to successfully power light-emitting diodes (LEDs) and digital thermometers, TENGs have the advantages of low manu-

demonstrating its ability to harvest low-frequency water wave energy in facturing costs, small size and wide range

of materials.[15–19] TENGs of the same

random directions. The unique structure of the Se-TENG offers an innovative volume collect low-frequency mechanical

and effective way of gathering blue energy on a large scale. energy more efficiently and therefore

have a significant advantage in harvesting

blue energy on a large scale.[20–22] TENGs

1. Introduction arrays are considered as a potential way to access blue energy

on a large scale.[23,24]

Energy is essential in the development of modern society and Designing power management modules enables the man-

the use of renewable energy has become a top priority in sci- agement of output energy. Xia Kequan et al. proposed a novel

entific research today. With the rapid growth of the world pulse controllable voltage source based on pulse controllable

economy, the energy demand is increasing. Still, fossil fuels voltage source (PCVS)-TENG[25] by combining a TENG with a

such as coal and oil are limited and contributory to global series of electronic components (a rectifier bridge, a capacitor)

warming, so the world urgently needs inexhaustible alter- and an unidirectional switch, which can exceed the impedance

native energy sources. At present, a host of clean energy has matching limit of conventional TENG, and realize controllable

Z. Qu, M. Huang, C. Chen, Y. An, H. Liu, Q. Zhang, X. Wang Y. Liu

College of Electronic Information and Automation College of Artificial Intelligence

Tianjin University of Science and Technology Tianjin University of Science and Technology

1038 Dagunan Road, Tianjin 300222, P. R. China 1038 Dagunan Road, Tianjin 300222, P. R. China

E-mail: zhigangqu@tust.edu.cn W. Yin

Z. Qu, Y. An, Y. Liu, W. Yin Department of Electrical and Electronic Engineering

Advanced Structural Integrity International Joint Research Centre The University of Manchester

Tianjin University of Science and Technology Sackville Street Building, Manchester M13 9PL, UK

1038 Dagunan Road, Tianjin 300222, P. R. China X. Li

E-mail: liu@tust.edu.cn; wuliang.yin@manchester.ac.uk The State Key Laboratory of Precision Measuring

Technology and Instruments

The ORCID identification number(s) for the author(s) of this article Tianjin University

can be found under https://doi.org/10.1002/adfm.202202048. Tianjin 30072, P. R. China

E-mail: lixf@tju.edu.cn

DOI: 10.1002/adfm.202202048

Adv. Funct. Mater. 2022, 2202048 2202048 (1 of 8) © 2022 Wiley-VCH GmbH

www.advancedsciencenews.com www.afm-journal.de

voltage output regardless the load resistance. Xu Zhiwei et al. Se-TENG with different connections. Furthermore, the energy

proposed a multiple-frequency triboelectric nanogenerator collected by Se-TENG is used to power sensors and drive light-

based on the water balloon (WB-TENG) for harvesting water emitting diodes, demonstrating the great advantages of TENG

wave energy in any direction. Owing to the high elasticity of the and PMM for large-scale blue energy harvesting, which has the

water balloon, the WB-TENG can realize a multiple-frequency potential to make a significant contribution to solving energy

response to low-frequency external mechanical simulations to issues and maintaining sustainable development.

generate high-frequency electrical output.[26]

Spherical structures are often used in TENGs of different

forms to collect water wave energy. Xi Liang et al. developed 2. Results and Discussion

a novel spherical TENG[12] to capture water wave energy by

combining the advantages of a spring-assisted system and The eccentric structure[29] was introduced into the spherical

an oscillating structure. Based on the optimization of TENG TENG to collect omnidirectional water wave energy and is

by adjusting the length of the spring and the diameter of the shown schematically in Figure 1a. The interior of this spherical

copper ball in the system, the charge excitation circuit (CEC) is structure is made up of regular dodecahedron as a substrate,

integrated with TENG to improve the output current. They also with twelve E-TENGs symmetrically distributed in different

measured the output performance of a natural water wave trig- directions. The length of the prism of a regular dodecahe-

gered TENG network under different water wave conditions, dron is 70 mm and a hollow cylinder with a diameter of 3 mm

investigated the effects of transverse sine waves, transverse and a length of 50 mm is located at the center of each of the

impulse excitation waves and longitudinal impulse excitation twelve hexagons. The regular dodecahedron and 12 E-TENGs

waves on the frequency and amplitude of water waves, and fab- connected by a stainless-steel screw with a diameter of 3 mm

ricated a hexagonal TENG network for collecting water wave and an overall length of 65 mm.

energy and managing the output energy through an integrated Each E-TENG is a separate sliding friction contact mode

power management module (PMM).[27] Due to the limitation in unit, as shown in Figure 1b, which consists of three parts: a cir-

spring direction, spherical TENGs can only generate electricity cular base, fixed metal electrodes, and an eccentric structured

in a specific water wave trigger direction and are not suitable rotor. The circular base is 3D printed with a resin material. The

for capturing irregular and random water wave energy, they circular base has a diameter of 90 mm and a hollow cylinder

then designed a spring-assisted multilayer structure to collect with a diameter of 3 mm is in the center. A circular acrylic plate

water wave energy from multiple trigger directions. with a diameter of 90 mm and a thickness of 2 mm is pasted

The output performance of TENG triggered by water waves on one side of the circular base, and a hollow cylinder with a

at different frequencies and amplitudes is systematically meas- diameter of 3 mm is located in the center. The stationary part is

ured, and the effect of azimuth angle, reflecting the direction of composed of two separated aluminum foils (60 µm in thickness

triggering, is discussed.[28] All the structures they have designed and 45 mm in diameter) with complementary four-segment

require the assisted springs to drive the TENG to work. In prac- shapes attached on a round-shape acrylic disk, which act as

tical applications, the spring is prone to damage, which directly two stationary electrodes. The gap between the aluminum elec-

affects its ability for long-term energy collection. trodes is 1 mm. The gap is inversely proportional to the output

This paper proposes the Se-TENG to collect omnidirec- performance,[30] the larger the gap the lower the output perfor-

tional water wave energy. This work not only provides a type mance of the Se-TENG. The innermost layer of the eccentric

of Se-TENG capable of harvesting omnidirectional water wave rotor is made of 100 µm thick fluorinated ethylene propylene

energy, but also effectively manages the output energy for prac-

(FEP) film glued to a semicircular acrylic plate with a diameter

tical implementation toward blue energy. The unique structure of 80 mm and a thickness of 2 mm as a friction layer. A hollow

of the Se-TENG offers an innovative and effective way of gath- cylinder with a diameter of 6 mm is left in the center. Inter-

ering blue energy potentially on a large scale. The eccentric mediate layer is supported by 2 mm thick iron lining. The

structure was introduced into the Se-TENG to enable self-driven bearing with an inner diameter of 6 mm and an outer diameter

energy harvesting without any additional devices. Twelve inde- of 10 mm is inlaid into the circle of the iron lining and acrylic

pendent triboelectric nanogenerator units are integrated into plate, and then the stainless steel shaft is installed on the whole

the spherical shell, in which the regular dodecahedron struc- device through the bearing.

ture improves space utilization and twelve E-TENGs operate in Due to its high density, tungsten-nickel (12.5 g cm−3) is

twelve different directions, capturing the energy generated by used to change the center of gravity and rotational inertia of

the movement of water waves in different directions. Se-TENG the rotor, so the outermost layer is counterweighted by a semi-

can collect randomly directed water wave energy without any circular tungsten–nickel alloy. According to the law of inertia,

additional tools. The output is managed by the PMM, which is the greater the moment of inertia of the rotor when the stator

used to maximize energy storage efficiency. This work firstly position changes, the easier it is for the rotor to maintain its

measured the output performance of the E-TENG in twelve original motion. When subjected to inertial forces, a relative

planes in the horizontal trigger direction and discussed the displacement occurs between the electrodes of the rotor and

effect of the horizontal trigger direction on the output perfor- stator, resulting in a change of charge between the electrodes.

mance in each plane, the output performance of Se-TENG was Triggered by the water waves, twelve E-TENGs are subjected

then systematically measured at different frequencies. The to inertial forces, the rotor spontaneously rotates, and the FEP

E-TENG network was integrated with the PMM to investigate film slides and rubs back and forth between the two parts of

the load resistance performance and charging performance of the aluminum foil making the E-TENGs work. A potential

Adv. Funct. Mater. 2022, 2202048 2202048 (2 of 8) © 2022 Wiley-VCH GmbH

www.advancedsciencenews.com www.afm-journal.de

Figure 1. The design of the spherical eccentric triboelectric nanogenerator. a) Schematic diagram of the Se-TENG structure model. b) Enlarged view of

the E-TENG structure. c) Photograph of the as-fabricated Se-TENG device. d) The relative positions of the twelve E-TENGs units in the dodecahedron.

e) Two planes that are centrally symmetric. f) Frame diagram of self-powered energy collection system.

difference is generated between the two parts of the electrodes, begins to rotate (step II), the segment of FEP starts to move

and the change in potential drives free electrons through the toward the segment of Al2. As a result, the electrons move back

external circuit, completing the conversion of mechanical from Al2 to Al1, leading to an output current in the opposite

energy to electrical energy. For the subsequent investigation of direction. When the segment of FEP moves to the segment of

the individual E-TENG performance, the relative positions of Al2, the potential difference reaches its maximum value, and

the twelve E-TENGs units in the dodecahedron are marked as the increase of potential difference provides the driving force

shown in Figure 1d. Figure 1d shows the six marked planes, for the electrons flowing in the external load. When the rotor

and the remaining six marked planes are centrally symmetric rotates in the opposite direction, the segment of FEP starts

with the six marked planes in the figure respectively, for to move toward the segment of Al1. As a result, the electrons

example, the plane of marker ② is centrosymmetric concerning move back from Al1 to Al2, leading to an output current with

the plane of marker , as shown in Figure 1e. the opposite direction (step IV), until the FEP layer returns to

Figure 1c is the photograph of an as-fabricated Se-TENG the original position after a full energy conversion cycle.

device with a diameter of 21 cm. For the practical application of There is a potential difference between the two fixed metal

Se-TENG, a self-powered energy harvesting system triggered by electrodes on twelve planes that were verified using finite ele-

water waves needs to be constructed, the framework of which ment analysis as illustrated in Figure 2b. As expected, the cal-

is shown in Figure 1f. First of all, the water waves drive the culation result shows there is no potential difference between

Se-TENG to work, converting the kinetic energy of the water the two electrodes (step I). Step II and step IV equipotential dif-

into electrical energy. In addition, the Se-TENG network is inte- ferences, the calculated induced potential difference reaches its

grated by connecting multiple Se-TENGs to form a large-scale maximum value (step III). A single plane is shown in Figure 2c.

water wave energy acquisition network. Eventually, the collected The potential contour clearly shows the potential difference

electricity is converted by the power management module into between the two electrodes, which drives the current flowing in

stable DC power which can be used to power sensors and drive the external circuit.

light-emitting diodes, etc. In the actual natural environment, a real water wave is in a

The working principle of the Se-TENG is schematically state of constantly random change, and its frequency is gener-

depicted in Figure 2a. When the rotor is not yet rotating (step I), ally in the range of 0.5–2.0 Hz. To better simulate real waves,

there is no charge transfer between the surfaces of the alu- the water tank is fixed on top of the trolley and a 250 W AC

minum foil (Al1) and the aluminum foil (Al2). When the rotor reciprocating motor is used to push and pull the trolley back

Adv. Funct. Mater. 2022, 2202048 2202048 (3 of 8) © 2022 Wiley-VCH GmbH

www.advancedsciencenews.com www.afm-journal.de

Figure 2. Theoretical study on the working principle of the Se-TENG. a) Schematic illustrations showing the working principle of the E-TENG.

b) Numerical calculations on the induced potential differences between the twelve flat fixed metal electrodes at the four steps of motion in a full cycle.

The right inset shows the color legend about the value of potential. c) The potential difference between two aluminium electrodes in a plane.

and forth. By adjusting the controller, the number of times This paper systematically investigates the effect of water wave

the trolley reciprocates per unit of time creates water waves of frequency on the output performance of Se-TENG. When water

different frequencies. The rotor in the Se-TENG structure is waves trigger Se-TENG, the twelve E-TENGs work simultane-

driven by a water wave and rubs against a fixed metal electrode, ously, but the E-TENG output performance varies from plane to

whose motion pattern is shown in Figure 3. plane. The output performance of each plane is tested by simu-

The output performance of the Se-TENG is related to the lating water waves at a frequency of 2.0 Hz. Figure 4a,b shows the

frequency and amplitude of the water waves. The real water output voltage of the E-TENG on twelve planes. The results show

waves, under a natural circumstance, vary randomly all the that when subjected to water waves, the maximum output voltage

time, prohibiting accurate artificial simulations on them. for planes ③ and ⑨ are subjected to horizontal forces, the rotor

However, a series of standard water waves with different wave rotates at the maximum angle and can rub more fully against

amplitude and frequencies can be detached from any kind of the fixed metal electrodes, resulting in higher electrical output

random waves and the wave frequency and height can be con- with 32Vp-p. The direction of E-TENG motion in the remaining

trolled independently by the following wave control method.[31] plane is at an angle to the water wave triggering direction, with

For the water wave frequency, the distance between two adja- a lower output than planes ③ and ⑨. The output of planes ② and

cent wave peaks can be changed by adjusting the time interval ④ is lower because the rotors of the E-TENG in planes ② and ④

between the round trips of the motor and then depending on basically do not rotate when subjected to a horizontal force and

the time interval, different frequencies of water waves can be there is only slight contact friction with the fixed metal elec-

obtained without affecting the wave amplitude. By control- trodes, resulting in a lower electrical output. The Se-TENG has

ling the speed and distance of the trolley, different amplitude good stability even after 2 h of continuous operation at different

of water wave is obtained. The wave amplitude was evaluated frequencies, and the stability test results are shown in Figure 4c.

from videos of water wave motions. The general properties To prevent output cancellation due to asynchronous motion,

of a periodic linear ocean wave including the period which is twelve E-TENGs were connected separately to the rectifier

the time it takes a wave to complete one cycle and the ampli- bridge and then connected in parallel, and the output voltage

tude which is the distance between the still water level and the and output current trends at 0.5–2.0 Hz were tested in parallel

wave crest, are linked to the amount of energy that is being for a wave amplitude of 9 cm and are shown in Figure 4d,e

transported by the wave.[32] Generally, actual ocean waves are respectively. It can be seen that as the water wave frequency

in a low frequency state below 2.0 Hz, but have a broad height increases from 0.5 to 2.0 Hz, the peak output voltage and cur-

range most cases from 0–1 m. In this work, the wave frequency rent increase, reaching a maximum value of 16 ± 2.4 V and

range of 0.5–2.0 Hz and wave amplitude range of 6–9 cm were 0.41 ± 0.08 µA at 2.0 Hz. This happens because the twelve

chosen as representatives to reveal their influences on the E-TENGs rotors all have high-density metal counterweights,

device performance. which cannot fully drive the Se-TENG operation when the water

Figure 3. Schematic scene exhibiting various motion patterns of the Se-TENG in the water waves generated by the standard wave tank equipment.

Adv. Funct. Mater. 2022, 2202048 2202048 (4 of 8) © 2022 Wiley-VCH GmbH

www.advancedsciencenews.com www.afm-journal.de

Figure 4. a,b) The output voltage of the E-TENG on twelve planes. c) Stability test of Se-TENG at different frequencies. d) Rectified output voltage at

various water wave frequencies. e) Rectified output current at various water wave frequencies. f) Power density at different frequencies at 9 cm wave

amplitude. g) Rectified output voltage at various water wave amplitudes. h) Rectified output current at various water wave amplitudes. i) Power density

at different wave amplitudes at a frequency of 2.0 Hz.

wave frequency is low. As the water wave frequency increases, To achieve efficient harvesting of water wave energy by the

it becomes more favorable for Se-TENG to work and the output TENG network, each of the twelve units of the E-TENG is con-

performance is better. The power density at different frequen- nected to a rectifier bridge with parallel and series connec-

cies at a wave amplitude of 9 cm is shown in Figure 4f, with the tions, respectively, and the schematic diagrams are shown in

highest power density of 0.22 ± 0.01 mW m−2 at 2.0 Hz Figure 5a,b respectively. To make the TENG network widely

After determining the optimum frequency of 2.0 Hz, the available, a power management module (PMM) was designed to

voltage and current were measured at 2.0 Hz for different manage the energy collected by the Se-TENG network. The cir-

water wave heights (6–9 cm), as shown in Figure 4g,h. It can be cuit schematic of the PMM is shown in Figure 5c. The PMM is

seen that the output voltage (peak current) increases from 6 V an AC–DC buck circuit consisting of an AC–DC rectifier circuit

(0.12 ± 0.1 µA) to 16 ± 2.4 V (0.41 ± 0.08 µA) as the amplitude and a DC–DC circuit. The components of the integrated circuit

of the wave increases from 6 to 9 cm. The experimental results include the rectifier bridge, the switches (S1, S2, S3), the shunt

show that the energy obtained is positively correlated with the diode D, the series inductor L (15 μH), the shunt capacitor C1

wave amplitude and increases with the increase of the wave (10 pF), the shunt capacitor C2 (10 pF), and the shunt capacitor

amplitude. The output performance is inferior at the low wave C3 (2.2 μF). In the PMM, the circuit is controlled by switching

height, because the slight waves cannot fully drive the Se-TENG on and off to store and release electrical energy. The LC unit

device due to its own weight. The power density at different in the charging circuit acts as a low-pass filter. The PMM is

wave amplitudes at a frequency of 2.0 Hz is shown in Figure 4i, capable of filtering out interfering signals and converting the

with the highest power density of 0.22 ± 0.01 mW m−2 at 9 cm. random and irregular electrical output into a stable DC voltage.

Adv. Funct. Mater. 2022, 2202048 2202048 (5 of 8) © 2022 Wiley-VCH GmbH

www.advancedsciencenews.com www.afm-journal.de

Figure 5. a) Schematic diagrams for the parallel connections between the E-TENG units inside the Se-TENG. b) Schematic diagrams for the series

connections between the E-TENG units inside the Se-TENG. c) The circuit schematic diagram of the PMM. d,e) Output voltage on a load resistance

produced by the power-managed Se-TENG with the parallel and series connections, respectively. f) The output voltage with respect to the load resist-

ance with parallel connections. g,h) Charging voltage on various load capacitors for the Se-TENG with the PMM in the parallel and series connections.

i) The output voltage with respect to the capacitance.

For comparing the voltage output and energy conversion in parallel and series connections for 60 s with different capacitors

parallel and series connections, the output voltages produced are shown in Figure 5i, indicating that the smaller the capaci-

by the power-managed Se-TENG in parallel and series with the tance, the faster the charging velocity. The voltage decreases as

internal E-TENG with different resistive loads are measured, as the capacitance increases and the charging voltage are higher at

shown in Figure 5d,e, showing that the voltage increases with the same time with a parallel connection than with a series con-

increasing resistance. Furthermore, the voltage for the parallel nection. Therefore, parallel connections are more conducive for

connection increases from 0.02 to 2.907 V as the resistance Se-TENG to energy storage and conversion.

varies from 10 KΩ to 500 MΩ, while the voltage for the series Finally, it is demonstrated that Se-TENG is used to collect water

connection only increases from 0.002 to 1.524 V. The peak wave energy in the sink. During the experiments, the ambient

output voltages generated by parallel and series connections at temperature was 23.8 °C and the air humidity was 26%. A water

different loads for 60 s are shown in Figure 5f, and the results tank filled with tap water was placed under Se-TENG. Then, the

show that the E-TENG can obtain a higher voltage output with force to drive the linear reciprocating motion of Se-TENG was

parallel connections. Then the charging performance of the Se- applied through the programed linear motor. The voltage, current

TENG with the PMM to load capacitors was also compared for and power of the Se-TENG and the voltage managed by the PMM

the parallel and series connections, as shown in Figure 5g,h, were measured by a current preamplifier (Keithley 6514 System

showing that the voltage decreases with increasing capacitance. Electrometer). The experimental schematic diagram is shown in

Furthermore, the voltage for the parallel connection decreases Figure 6a. The Se-TENG charges a 4.7 μF capacitor from 0 to 5 V

from 5.013 to 0.020 V as the capacitance varies from 3.3 to in 100 s and the Se-TENG is capable of powering up to 40 green

470 μF, while the voltage for the series connection decreases LEDs when excited by water waves. In addition, it can be used in

from 0.770 to 0.002 V. The peak output voltages generated in conjunction with energy storage devices as a power source for

Adv. Funct. Mater. 2022, 2202048 2202048 (6 of 8) © 2022 Wiley-VCH GmbH

www.advancedsciencenews.com www.afm-journal.de

Figure 6. Application of TENG in water wave energy collection. a) The experimental schematic diagram. b) Image of the thermometer powered and

40 green LEDs lighted by the Se-TENG. The inset is the charging voltage of the capacitor.

the commercial temperature sensor, as shown in Figure 6b. The the output performance of water waves and shows that the max-

use of an acrylic housing for the outermost layer of the Se-TENG imum output 16 ± 2.4 V, 0.41 ± 0.08 μA, and 0.22 ± 0.01 mW m−2

can effectively reduce the dielectric shielding of the device per- can be obtained when the frequency is 2.0 Hz and the wave

formance. Therefore, connecting more Se-TENGs in parallel can amplitude is 9 cm. The effect of the circuit connection manner

form an energy harvesting network. The design of the Se-TENG on the Se-TENG voltage output was verified. When connected

offers an innovative and effective way of harvesting blue energy to the same load, the internal E-TENG can be connected in par-

on a large scale, allowing the harvesting of water wave energy allel to obtain a higher voltage output. The results show that

over a large area, while also providing a viable power solution for parallel connections are more conducive for Se-TENG to energy

water parameter monitoring. storage and conversion. Finally, the Se-TENG is capable of pow-

ering 40 green LEDs driven by water waves, when used in con-

junction with the energy storage device, it can also successfully

3. Conclusions power a digital thermometer. The design of the Se-TENG offers

an innovative and effective way of harvesting blue energy on a

This paper presents and systematically investigates the design large scale.

of a triboelectric nanogenerator based on a spherical eccen-

tric structure. A dodecahedral structure is introduced into the

spherical shell for omnidirectional water wave energy har-

vesting, which effectively converts low-frequency wave energy Acknowledgements

in different directions into electrical energy and designs energy This work was funded by the National Natural Science Foundation of

management circuits to convert and store the collected energy. China (No 61873187, 62173246, and 61901299) and Tianjin post-graduate

This paper investigates the effect of water wave frequency on research and innovation project (YJSKC2021S07).

Adv. Funct. Mater. 2022, 2202048 2202048 (7 of 8) © 2022 Wiley-VCH GmbH

www.advancedsciencenews.com www.afm-journal.de

Conflict of Interest [11] K. W. Lim, M. Peddigari, C. H. Park, H. Y. Lee, Y. Min, J. W. Kim,

C. W. Ahn, J. J. Choi, B. D. Hagn, J. H. Choi, D. S. Park, J. K. Hong,

The authors declare no conflict of interest. J. T. Yeom, W. H. Yoon, J. Ryu, S. N. Yi, G. T. Hwang, Energy Environ.

Sci. 2019, 12, 666.

[12] B. S. Zhang, Y. J. Tang, R. R. Dai, H. Y. Wang, X. P. Sun, C. Qin,

Z. F. Pan, E. J. Liang, Y. C. Mao, Nano Energy 2019, 64, 103953.

Data Availability Statement [13] Z. L. Wang, Mater. Today 2017, 20, 74.

The data that support the findings of this study are available from the [14] Z. L. Wang, T. Jiang, L. Xu, Nano Energy 2017, 39, 9.

corresponding author upon reasonable request. [15] X. Wang, S. Niu, Y. Yin, F. Yi, Z. You, Z. L. Wang, Adv. Energy Mater.

2015, 5, 1501467.

[16] L. Zhang, C. Han, T. Jiang, T. Zhou, X. Li, C. Zhang, Z. L. Wang,

Nano Energy 2016, 22, 87.

Keywords [17] T. Xiao, T. Jiang, J. Zhu, X. Liang, L. Xu, J. Shao, C. Zhang, J. Wang,

Z. L. Wang, ACS Appl. Mater. Interfaces 2018, 10, 3616.

blue energy, eccentric, low frequency water waves, omni-directional, [18] K. Xia, D. Wu, J. Fu, N. A. Hoque, Y. Ye, Xu, Z. , J. Mater. Chem. A

spherical triboelectric nanogenerators 2020, 8, 25995.

[19] H. Wang, Q. Zhu, Z. Ding, Z. Li, H. Zheng, J. Fu, C. Diao, X. Zhang,

Received: February 20, 2022

J. Tian, Y. Zi, Nano Energy 2019, 57, 616.

Revised: March 26, 2022

[20] Z. L. Wang, Faraday Discuss. 2014, 176, 447.

Published online:

[21] J. Chen, J. Yang, Z. L. Li, X. Fan, Y. L. Zi, Q. S. Jing, H. Y. Guo,

Z. Wen, K. C. Pradel, S. M. Niu, Z. L. Wang, ACS Nano 2015, 9,

3324.

[22] X. F. Wang, S. M. Niu, Y. J. Yin, F. Yi, Z. You, Z. L. Wang, Adv. Energy

[1] X. Yang, L. Xu, P. Lin, W. Zhong, Y. Bai, J. Luo, J. Chen, Z. L. Wang, Mater. 2015, 5, 1501467.

Nano Energy 2019, 60, 404. [23] R. Henderson, Renewable Energy 2006, 31, 271.

[2] H. Yang, M. Deng, Q. Zeng, X. Zhang, J. Hu, Q. Tang, H. Yang, [24] A. Wolfbrandt, IEEE Trans. Magn. 2006, 42, 1812.

C. Hu, Y. Xi, Z. L. Wang, ACS Nano 2020, 14, 3328. [25] K. Xia, D. Wu, J. Fu, Z. Xu, Nano Energy 2020, 77, 105112.

[3] X. Wang, Y. Yang, Nano Energy 2017, 32, 36. [26] K. Xia, J. Fu, Z. Xu, Adv. Energy Mater. 2020, 10, 2000426.

[4] Z. Wu, H. Guo, W. Ding, Y. C. Wang, L. Zhang, Z. L. Wang, ACS [27] X. Liang, T. Jiang, G. X. Liu, T. X. Xiao, L. Xu, W. Li, F. B. Xi,

Nano 2019, 13, 2349. C. Zhang, Z. L. Wang, Adv. Funct. Mater. 2019, 29, 1807241.

[5] J. Wang, L. Pan, H. Guo, B. Zhang, R. Zhang, Z. Wu, C. Wu, L. Yang, [28] X. Liang, T. Jiang, G. X. Liu, Y. W. Feng, C. Zhang, Z. L. Wang, ACS

R. Liao, Z. L. Wang, Adv. Energy Mater. 2019, 9, 1802892. Appl. Mater. Interfaces 2015, 7, 28142.

[6] J. Zhao, G. Zhen, G. Liu, T. Bu, W. Liu, X. Fu, P. Zhang, C. Zhang, [29] Z. G. Qu, M. K. Huang, R. Dai, Y. An, C. X. Chen, G. Q. Nie,

Z. L. Wang, Nano Energy 2019, 61, 111. X. C. Wang, Y. Zhang, W. L. Yin, Nano Energy 2021, 87, 106159.

[7] S. H. Wang, Y. N. Xie, S. M. Niu, L. Lin, Z. L. Wang, Adv. Mater. [30] G. Zhu, J. Chen, T. Zhang, Q. Jing, Wang, Z. L. , Nat. Commun.

2014, 26, 2818. 2014, 5, 3426.

[8] K. Xia, Z. Zhu, H. Zhang, C. Du, Z. Xu, R. Wang, Nano Energy 2018, 50, 571. [31] J. An, Z. M. Wang, T. Jiang, X. Liang, Z. L. Wang, Adv. Funct. Mater.

[9] T. Jiang, X. Y. Chen, C. B. Han, W. Tang, Z. L. Wang, Adv. Funct. 2019, 29, 1904867.

Mater. 2015, 25, 2928. [32] C. Rodrigues, M. Ramos, R. Esteves, J. Correia, D. Clemente,

[10] Z. R. Liu, J. H. Nie, B. Miao, J. D. Li, Y. B. Cui, S. Wang, X. D. Zhang, F. Gonçalves, N. Mathiase, M. Gomese, J. Silvaa, C. Duarted,

G. R. Zhao, Y. B. Deng, Y. H. Wu, Z. Li, L. L. Li, Z. L. Wang, Adv. T. Moraise, P. Rosa-Santosc, F. Taveira-Pintoc, A. Pereiraa,

Mater. 2019, 31, 1807795. J. Ventura, Nano Energy 2021, 84, 105890.

Adv. Funct. Mater. 2022, 2202048 2202048 (8 of 8) © 2022 Wiley-VCH GmbH

You might also like

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingRating: 4.5 out of 5 stars4.5/5 (2)

- Adv Funct Materials - 2019 - Liang - TriboelecDocument9 pagesAdv Funct Materials - 2019 - Liang - TriboelecAtharva SokhiyaNo ratings yet

- Advanced Energy Materials - 2020 - Liang - TriDocument8 pagesAdvanced Energy Materials - 2020 - Liang - TriAtharva SokhiyaNo ratings yet

- 水下旗状纳米摩擦发电机Document10 pages水下旗状纳米摩擦发电机123No ratings yet

- Advanced Energy Materials - 2020 - Xia - MultiDocument9 pagesAdvanced Energy Materials - 2020 - Xia - MultiAtharva SokhiyaNo ratings yet

- (Luo Et Al.) Direct-Current Triboelectric Nanogenerator Realized PDFDocument8 pages(Luo Et Al.) Direct-Current Triboelectric Nanogenerator Realized PDFBhob Andreeve LignigNo ratings yet

- Harvesting Energy From The NaturalDocument8 pagesHarvesting Energy From The Naturalwang123218888No ratings yet

- 2020-21 Department of Electrical Engineering Geethanjali College of Engineering and Technology (An Autonomous Institute) HyderabadDocument13 pages2020-21 Department of Electrical Engineering Geethanjali College of Engineering and Technology (An Autonomous Institute) HyderabadSowmya KasojuNo ratings yet

- Kim 2016Document12 pagesKim 2016Sachin verma T20081No ratings yet

- 能量转换 电子表显示Document10 pages能量转换 电子表显示123No ratings yet

- Advanced Science - 2022 - ChiDocument8 pagesAdvanced Science - 2022 - ChiIRFAN BIN ASHRAFNo ratings yet

- Adfm 201806351Document20 pagesAdfm 201806351Rodrigo PaivaNo ratings yet

- Development, Applications, and Future Directions of Triboelectric NanogeneratorsDocument20 pagesDevelopment, Applications, and Future Directions of Triboelectric NanogeneratorsQuốc TínNo ratings yet

- 提高摩擦起电以及利用真空环境避免空气击穿Document9 pages提高摩擦起电以及利用真空环境避免空气击穿123No ratings yet

- Energies: Design and Implement of Three-Phase Permanent-Magnet Synchronous Wave Generator Using Taguchi ApproachDocument17 pagesEnergies: Design and Implement of Three-Phase Permanent-Magnet Synchronous Wave Generator Using Taguchi ApproachVô ƯuNo ratings yet

- A Leaf-Shaped Triboelectric Nanogenerator For Multiple Ambient Mechanical Energy HarvestingDocument7 pagesA Leaf-Shaped Triboelectric Nanogenerator For Multiple Ambient Mechanical Energy Harvestingirappa karaganviNo ratings yet

- Nanoenergyadv 02 00013 v2Document24 pagesNanoenergyadv 02 00013 v2Muhamad Praja DewanataNo ratings yet

- Experimental and Numerical Studies of A Soft Impact Piezoelectric Energy Harvesting Using An MR FluidDocument10 pagesExperimental and Numerical Studies of A Soft Impact Piezoelectric Energy Harvesting Using An MR FluidOleksii BalitskyiNo ratings yet

- Triboelectric Nanogenerators For Blue Energy Harvesting: ACS Nano July 2016Document5 pagesTriboelectric Nanogenerators For Blue Energy Harvesting: ACS Nano July 2016fjNo ratings yet

- International Journal of Mechanical SciencesDocument10 pagesInternational Journal of Mechanical Sciencesد. ثائر جبار نتيشNo ratings yet

- Shen 2017Document18 pagesShen 2017Shrinidhi D KulalNo ratings yet

- Power Generation Using Sea Tidal WavesDocument9 pagesPower Generation Using Sea Tidal WavesIJRASETPublicationsNo ratings yet

- Harvesting Water Drop Energy by A Sequential Contact Electrification andDocument7 pagesHarvesting Water Drop Energy by A Sequential Contact Electrification andREIVAX LOL REPLAYSNo ratings yet

- Wave Energy MHDDocument17 pagesWave Energy MHDBig Bob TankNo ratings yet

- Two-Dimensional Omnidirectional Wind Energy HarvesterDocument9 pagesTwo-Dimensional Omnidirectional Wind Energy HarvesterMuhammad AbbasNo ratings yet

- Related Reseach StudiesDocument19 pagesRelated Reseach StudiesAlvince YtacNo ratings yet

- Hybrid Energy Cell For Harvesting Mechanical Energy From One Motion Using Two ApproachesDocument9 pagesHybrid Energy Cell For Harvesting Mechanical Energy From One Motion Using Two ApproachesVKB Library iisuNo ratings yet

- Safaei, Sodano and Anton, 2019Document9 pagesSafaei, Sodano and Anton, 2019Muhammad Saad AbdullahNo ratings yet

- Buu BlerDocument13 pagesBuu BlerRichard TatamuésNo ratings yet

- Road Energy Harvester Designed As A Macro-Power Source Using The Piezoelectric EffectDocument6 pagesRoad Energy Harvester Designed As A Macro-Power Source Using The Piezoelectric EffectvisionNo ratings yet

- Study On A Wave Energy Based Power SystemDocument7 pagesStudy On A Wave Energy Based Power SystemTrain GuruNo ratings yet

- 4189-Article Text-17956-1-10-20180111Document9 pages4189-Article Text-17956-1-10-20180111mukund misNo ratings yet

- Developments and Future Prospects of Reverse Electrodialysis For SalinityDocument15 pagesDevelopments and Future Prospects of Reverse Electrodialysis For SalinityPaulina LizethNo ratings yet

- Shin Et Al-2016-International Journal of Energy ResearchDocument10 pagesShin Et Al-2016-International Journal of Energy ResearchBrnardo RanNo ratings yet

- A Study On A Near Shore Cantilevered Sea Wave Energy Harvester With A Variable Cross SectionDocument12 pagesA Study On A Near Shore Cantilevered Sea Wave Energy Harvester With A Variable Cross Sectionد. ثائر جبار نتيشNo ratings yet

- Piezoelectric Energy Harvesting For Self-Powered Wearable Upper Limb ApplicationsDocument21 pagesPiezoelectric Energy Harvesting For Self-Powered Wearable Upper Limb ApplicationsEdwinNo ratings yet

- A High-Efficient Wireless Power Receiver For Hybrid Energy-Harvesting SourcesDocument15 pagesA High-Efficient Wireless Power Receiver For Hybrid Energy-Harvesting SourcesGuillermo SerranoNo ratings yet

- Sensors and Actuators A: Physical: Phosy Panthongsy, Don Isarakorn, Pattanaphong Janphuang, Kazuhiko HamamotoDocument10 pagesSensors and Actuators A: Physical: Phosy Panthongsy, Don Isarakorn, Pattanaphong Janphuang, Kazuhiko HamamotoMiguel AngelNo ratings yet

- Tech ReportDocument23 pagesTech ReportUmesh GowdaNo ratings yet

- Triboelectric Nanogenerators As Exible Power Sources: Review ArticleDocument10 pagesTriboelectric Nanogenerators As Exible Power Sources: Review ArticleT Jah NepNo ratings yet

- Effect of Outlet Diameter On The Performance of Gravitational Vortex Turbine With Conical BasinDocument7 pagesEffect of Outlet Diameter On The Performance of Gravitational Vortex Turbine With Conical BasinJeff BarnardNo ratings yet

- 291 GarciaDocument6 pages291 GarciaRizkiNo ratings yet

- Surface Charge Density of Triboelectric Nanogenerators: Theoretical Boundary and Optimization MethodologyDocument8 pagesSurface Charge Density of Triboelectric Nanogenerators: Theoretical Boundary and Optimization MethodologyAqilAbbasiNo ratings yet

- 1 s2.0 S092442472400092X MainDocument11 pages1 s2.0 S092442472400092X Mainopenjavier5208No ratings yet

- Advanced Triboelectric Nanogenerator With Multi-Mode Energy Harvesting and Anti-Impact Properties For Smart Glove and Wearable E-TextileDocument10 pagesAdvanced Triboelectric Nanogenerator With Multi-Mode Energy Harvesting and Anti-Impact Properties For Smart Glove and Wearable E-TextilesovalaxNo ratings yet

- 1 s2.0 S1385894720316545 MainDocument9 pages1 s2.0 S1385894720316545 Main이채은No ratings yet

- 基于静电纺丝纳米纤维的可穿戴电子和自供电传感材料Document23 pages基于静电纺丝纳米纤维的可穿戴电子和自供电传感材料Gymnast PeakNo ratings yet

- Energy Harvesting From Water Distribution Systems: Journal of Energy Engineering March 2012Document12 pagesEnergy Harvesting From Water Distribution Systems: Journal of Energy Engineering March 2012raja maneNo ratings yet

- Intl J of Energy Research - 2020 - Hasan - Inorganic Thermoelectric Materials A ReviewDocument53 pagesIntl J of Energy Research - 2020 - Hasan - Inorganic Thermoelectric Materials A Reviewsc2208No ratings yet

- Piezo Literature ReviewDocument7 pagesPiezo Literature ReviewEngineering ProjectNo ratings yet

- Content ServerDocument10 pagesContent ServerImjusttryingtohelpNo ratings yet

- Design Optimization of PVDF-based Piezoelectric Energy HarvestersDocument18 pagesDesign Optimization of PVDF-based Piezoelectric Energy HarvestersArijit RoyNo ratings yet

- Piezo HarvestDocument14 pagesPiezo HarvestDavide Tanner TainiNo ratings yet

- Triboelectric Nanogenerators As New Energy Technology For Self-Powered Systems and As Active Mechanical and Chemical SensorsDocument25 pagesTriboelectric Nanogenerators As New Energy Technology For Self-Powered Systems and As Active Mechanical and Chemical SensorsAnonymous AEicha08AF100% (1)

- Renewable Energy: Mariano Buccino, Dimitris Stagonas, Diego VicinanzaDocument14 pagesRenewable Energy: Mariano Buccino, Dimitris Stagonas, Diego VicinanzaAnthropophobe NyctophileNo ratings yet

- 11 180815ASwitched-CapacitorBidirectionalDCDCDocument12 pages11 180815ASwitched-CapacitorBidirectionalDCDCPatil MounicareddyNo ratings yet

- Ieee Paper SeminarDocument10 pagesIeee Paper Seminarswathisreejith6No ratings yet

- Q1 - Annisa Cendani Haliman - 6 KIB - UTS - 24 Mei 2022 - Metodologi PenelitianDocument16 pagesQ1 - Annisa Cendani Haliman - 6 KIB - UTS - 24 Mei 2022 - Metodologi PenelitianSintya ningsihNo ratings yet

- Piezoelectric Tile: Harnessing Electricity From Mechanical Stress To Electrical EnergyDocument16 pagesPiezoelectric Tile: Harnessing Electricity From Mechanical Stress To Electrical EnergyJohn Kenneth Santiago PaulinoNo ratings yet

- Control and Energy Efficiency of PEM Water Electrolyzers in Renewable Energy SystemsDocument13 pagesControl and Energy Efficiency of PEM Water Electrolyzers in Renewable Energy SystemsMarcello SaviniNo ratings yet

- Advanced Energy Materials - 2020 - Liang - TriDocument8 pagesAdvanced Energy Materials - 2020 - Liang - TriAtharva SokhiyaNo ratings yet

- Advanced Energy Materials - 2020 - Xia - MultiDocument9 pagesAdvanced Energy Materials - 2020 - Xia - MultiAtharva SokhiyaNo ratings yet

- 1 s2.0 S2542435121002026 MainDocument12 pages1 s2.0 S2542435121002026 MainAtharva SokhiyaNo ratings yet

- Adv Funct Materials - 2019 - Liang - TriboelecDocument9 pagesAdv Funct Materials - 2019 - Liang - TriboelecAtharva SokhiyaNo ratings yet

- Motorcycle Engine Parts and Their FunctionsDocument3 pagesMotorcycle Engine Parts and Their FunctionsGovind NakhateNo ratings yet

- Cambridge IGCSE: Physics 0625/13Document16 pagesCambridge IGCSE: Physics 0625/13Nisha zehraNo ratings yet

- ASB 076 FP Diaphragm - NewDocument15 pagesASB 076 FP Diaphragm - NewAndrey NetyukhayloNo ratings yet

- Air Conditioning System Sizing For Pure Electric Vehicle: EVS28 KINTEX, Korea, May 3-6, 2015Document7 pagesAir Conditioning System Sizing For Pure Electric Vehicle: EVS28 KINTEX, Korea, May 3-6, 2015Naveen kumarNo ratings yet

- Use and Maintenance Manual: Silent Electric Rotary Screw CompressorsDocument70 pagesUse and Maintenance Manual: Silent Electric Rotary Screw CompressorslivproNo ratings yet

- Mechanical SpringDocument49 pagesMechanical SpringYeamlak SisayNo ratings yet

- Oil SeparatorDocument102 pagesOil SeparatorĐTĐCNHT PXĐTĐNo ratings yet

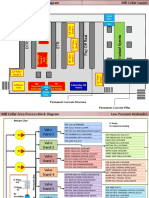

- Process Block Diagram and Process Flow Diagram-Mill Cellar Area-OK-04.pptx (Repaired)Document24 pagesProcess Block Diagram and Process Flow Diagram-Mill Cellar Area-OK-04.pptx (Repaired)vedprakashNo ratings yet

- ICAE 2022 Program Book Final - 2022 08 02Document5 pagesICAE 2022 Program Book Final - 2022 08 02YuneskyNo ratings yet

- Internship ReportDocument17 pagesInternship ReportkannanNo ratings yet

- الطاقة المتجددة كخيار استراتيجي لتحقيق التنمية المستدامةDocument14 pagesالطاقة المتجددة كخيار استراتيجي لتحقيق التنمية المستدامةُElhadj arabaNo ratings yet

- LHB Coach TL AC SystemsDocument61 pagesLHB Coach TL AC SystemsRamesh Raj chaudharyNo ratings yet

- Compliance To Philippine Grid CodeDocument200 pagesCompliance To Philippine Grid CodeEdward NewgateNo ratings yet

- iSitePower Equipment Cabinet MTS9510A-AX2007 (01075859) DatasheetDocument2 pagesiSitePower Equipment Cabinet MTS9510A-AX2007 (01075859) DatasheetScott SearsNo ratings yet

- VPS JtacDocument9 pagesVPS JtacRuchita PoilkarNo ratings yet

- ET Training ID Fan CBDDocument22 pagesET Training ID Fan CBDVishal HiremathNo ratings yet

- Essay Plan Epq PDFDocument3 pagesEssay Plan Epq PDFcravens.leads.0jNo ratings yet

- Log Sheet Ting Kok Road Sewage Pumping Station No.5Document2 pagesLog Sheet Ting Kok Road Sewage Pumping Station No.5Sumwing ChanNo ratings yet

- Manual de Instalação WarnerDocument8 pagesManual de Instalação WarnerЭлектроника EletroeletrônicaNo ratings yet

- Template - 1º A e B Atividade Avaliativa de InglesDocument2 pagesTemplate - 1º A e B Atividade Avaliativa de Inglesalexrucoy17No ratings yet

- 11 Wind Load CalculationDocument4 pages11 Wind Load CalculationMustafizur RahmanNo ratings yet

- Scie7 Q4M2 FNHSDocument32 pagesScie7 Q4M2 FNHSTeacher JoanNo ratings yet

- Volkmann Technical Exclusive Vacuum ConveyingDocument3 pagesVolkmann Technical Exclusive Vacuum ConveyingMarkNo ratings yet

- Mineral Pre-Made Mortar Rendering and Plastering Mortar Normalfinishing Render or PlasterDocument12 pagesMineral Pre-Made Mortar Rendering and Plastering Mortar Normalfinishing Render or PlasterBruno HuetNo ratings yet

- Oem Price FordDocument28 pagesOem Price FordFernandoNo ratings yet

- Electric Potential and CapacitanceDocument14 pagesElectric Potential and CapacitanceCHINMAY UPADHYAYA X-DNo ratings yet

- AIR Conditioner: Owner'S ManualDocument23 pagesAIR Conditioner: Owner'S ManualmmiltamNo ratings yet

- Mars Off Grid Solar Power SystemDocument20 pagesMars Off Grid Solar Power SystemEben KinaboNo ratings yet

- Artikel KeimigrasianDocument13 pagesArtikel Keimigrasianadiwahyudi220790No ratings yet

- Cpp-Electrochemistry-Pkd VyDocument2 pagesCpp-Electrochemistry-Pkd VyVIVEK KUMARNo ratings yet