Professional Documents

Culture Documents

PP41 Rev.3

PP41 Rev.3

Uploaded by

Ashish ChackoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PP41 Rev.3

PP41 Rev.3

Uploaded by

Ashish ChackoCopyright:

Available Formats

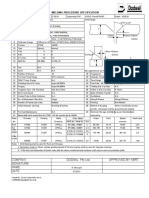

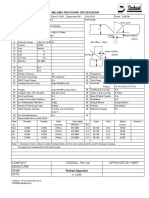

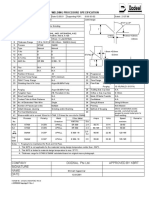

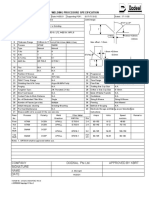

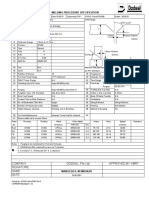

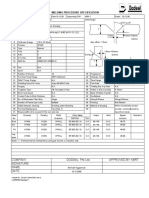

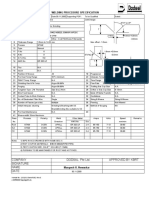

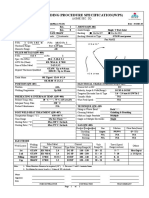

1 7979/WPS/PP/41 Rev.

3 Supporting PQR :

2 Joint Design Single "V" Groove Joint Design

3 Backing None 37.5° ± 2.5°

4 Joint Prep. Machining and/or Grinding

5 Base Metal Spec. P8 G1 T

6 Base Metal A312-TP304/304L, A182-F304/304L,

A403-WP304/304L, A358-304/304L 2-3mm 1.0mm +0mm

7 Pipe Dia Range All Other : O-LETS/All size Fillet welds -0.8mm

8 Thickness Range 3.55MM TO 13.51MM

9 Process GTAW GTAW

10 Type Manual Manual

11 F.No - 6 1.0mm +0mm

12 A.No - 8 37.5°±2.5° -0.8mm

13 S.F.A No. 5.22 5.9

14 AWS No. R308 LTI-S ER 308L T 2-3mm

14A TRADE NAME KOBE TGX 308L -

15 Flux CORED N.A.

16 Insert N.A. N.A.

17 Position Of Groove All 18 Progression Vertical Uphill

19 Pre Heat Temp Range 10°C minimum 20 Interpass Temp. 170°C Max.

21 PWHT Temp. Range N.A. 22 Time Range N.A.

23 Shielding Gas & % Comp Argon 99.99% 24 Flow Rate - 20-35CFH Purging - NA

25 Purging N.A. 26 Trailling Gas Cup Size N.A.

27 Tungsten Type : 2% Thoriated Size Dia 2.4mm 28 Orifice or Gas Cup Size 8-13mm

29 Wire Feed Speed N.A. 30 Mode Of Metal Transfer N.A.

31 Contact Tube to Work Distance N.A. 32 Oscillations N.A.

33 No. of Electrodes/ Filler Wire Single 34 String & Weave String & Weave

35 Number of Passes (per side) Multiple 36 Peening Not Allowed

37 Initial/ interpass cleaning Grinding/ Brushing 38 Method of Gouging N.A.

39 Pre Heat Maintenance N.A. 40

41 Weave width not to exceed 10mm

Pass Process Polarity Weld Filler Metal Amps Volts Speed Heat Input

No. Direction AWS No/TR.NAME. Dia mm/min (Kj/MM)

Root GTAW DCEN UPHILL KOBETGX308L 2.2 65-85 9-12 36-55 1.75

1.6 /

Hot GTAW DCEN UPHILL ER 308L 2.4 75-105 8-12.5 90-95 0.875

Fill

1.6 /

(Multi

2.4

) GTAW DCEN UPHILL ER 308L 90-105 8-12.5 90-110 0.875

Cap

1.6 /

(Multi

2.4

) GTAW DCEN UPHILL ER 308L 90-105 9-12.5 90-100 0.875

Notes 1. WPS to be used in conjunction with the relevant Application Index

2. Aluminium Oxide or Silicon Carbide grinding wheels & SS wire brushes shall be used for interpass cleaning.

3. KBRT QC department written Approval shall be taken for each joint welded by this WPS.

COMPANY

SIGNATURE

NAME

DATE

Format No : DOD/Q-Chem/F082 Rev 0

c:\DIR00001\wps\pp41rev-3

You might also like

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Red Bull Precess of Globalization in EuropeDocument3 pagesRed Bull Precess of Globalization in EuropeSilviu Popa100% (1)

- Standard Safety Practices ManualDocument350 pagesStandard Safety Practices Manualrs_hendarsah100% (14)

- Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06Document1 pageFormat No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- Tag No FT-1033: SHEET: 27 OF 102Document1 pageTag No FT-1033: SHEET: 27 OF 102hendra hermawanNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- Mechanical Finishing of NonwovensDocument23 pagesMechanical Finishing of Nonwovensmahes_tex100% (1)

- BJTDocument30 pagesBJTSwarna AshokNo ratings yet

- Swot Analysis of OgdclDocument2 pagesSwot Analysis of OgdclMuhammad Ahmer100% (2)

- Ic Engines PDFDocument18 pagesIc Engines PDFChaitanya Kishore ChitikenaNo ratings yet

- CPC 18 2 CarbonationDocument3 pagesCPC 18 2 Carbonationheidi333No ratings yet

- Cummins 330 PDFDocument3 pagesCummins 330 PDFMarcelo Herrera100% (1)

- Longitudinal Butt Joint Circumferential Lap Joint For Boiler ShellDocument3 pagesLongitudinal Butt Joint Circumferential Lap Joint For Boiler ShellAlvin Tung Kwong ChoongNo ratings yet

- 02 - 2 WaDocument17 pages02 - 2 WaJoshua MenesesNo ratings yet

- WCH01 01 Que 20170111Document24 pagesWCH01 01 Que 20170111Niranjan BhuvanaratnamNo ratings yet

- Fire Safety PPT (RP) 1Document26 pagesFire Safety PPT (RP) 1Priyamvada BijuNo ratings yet

- Fichas Técnicas 500 GPM at 180 PSIDocument165 pagesFichas Técnicas 500 GPM at 180 PSIIvan Martinez100% (1)

- Determination of Salt Content in Crude Oil, Turbine Oil and Some Refinery Products VolumetricallyDocument4 pagesDetermination of Salt Content in Crude Oil, Turbine Oil and Some Refinery Products VolumetricallyJabbarKaddemNo ratings yet

- LS Cable: Offshore & MarineDocument4 pagesLS Cable: Offshore & MarinetranminhtrunglsvinaNo ratings yet

- Normas EcuasalDocument4 pagesNormas EcuasalJose Gabriel Aguirre AndradeNo ratings yet

- Guide To Small Scale MiningDocument61 pagesGuide To Small Scale MiningMika Prameswari100% (2)

- Daily HSE Summary Report 16-02-2018Document3 pagesDaily HSE Summary Report 16-02-2018Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- Cash FlowDocument38 pagesCash FlowRadu MirceaNo ratings yet

- UK Conductive Heater RangeDocument4 pagesUK Conductive Heater RangeAnonymous zwSP5gvNo ratings yet

- BagchutDocument212 pagesBagchutANILNo ratings yet

- s10 Mini ProjectDocument6 pagess10 Mini Projectmohammed shabeerNo ratings yet

- SideWinder 42 62 82 CHMCL PMP IOMDocument4 pagesSideWinder 42 62 82 CHMCL PMP IOMSH McNo ratings yet

- Tan Jan Lloyd C. Chapter 4 Linear Momentum 11 13Document7 pagesTan Jan Lloyd C. Chapter 4 Linear Momentum 11 13Norjana BarabatoNo ratings yet

- Relay Protection Setting For Preparing ReportDocument12 pagesRelay Protection Setting For Preparing ReportRajeev ValunjkarNo ratings yet

- JGJ16-2008 民用建筑电气设计规范Document406 pagesJGJ16-2008 民用建筑电气设计规范Wilfred NgNo ratings yet

- CV Kadji Wolieu OMDocument2 pagesCV Kadji Wolieu OMkadjididieNo ratings yet

- Highly Efficient Water Heaters Using Magnetron EffectsDocument5 pagesHighly Efficient Water Heaters Using Magnetron Effectsmarkus steinbacherNo ratings yet

- Evolution of Designed Industrial Symbiosis Networks in The Ulsan Eco-Industrial Park - Research and Development Into Business ADocument10 pagesEvolution of Designed Industrial Symbiosis Networks in The Ulsan Eco-Industrial Park - Research and Development Into Business Asanyukta sinhaNo ratings yet

- Table 4B1 and 4E4ADocument2 pagesTable 4B1 and 4E4Ahachan100% (2)