Professional Documents

Culture Documents

Liquid - Gas Fuel Operated Steam Boilers With Opposite Pressure TS 497 - TS EN 303-1/2/3 High Fluid Cover Technology. Fire Concrete Problems Are Over

Liquid - Gas Fuel Operated Steam Boilers With Opposite Pressure TS 497 - TS EN 303-1/2/3 High Fluid Cover Technology. Fire Concrete Problems Are Over

Uploaded by

Sharif MalekzadaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liquid - Gas Fuel Operated Steam Boilers With Opposite Pressure TS 497 - TS EN 303-1/2/3 High Fluid Cover Technology. Fire Concrete Problems Are Over

Liquid - Gas Fuel Operated Steam Boilers With Opposite Pressure TS 497 - TS EN 303-1/2/3 High Fluid Cover Technology. Fire Concrete Problems Are Over

Uploaded by

Sharif MalekzadaCopyright:

Available Formats

High fluid cover technology.

Fire concrete Problems are over

Liquid - Gas Fuel Operated Steam Boilers With Opposite Pressure TS 497 - TS EN 303-1/2/3

00

1. Digital control panel 6. Smoke chamber

2. Hot water exit line 7. Watery hinge

3. Front watery lid 8. Cleaning lid

4. Lifting ring 9. Hot water return line

5. Safety return 10. Burner flange

AKB Liquid - Gas Fuel Operated Steam Boilers With Opposite Pressure

AKB LIQUID - GAS FUEL OPERATED STEAM BOILERS WITH OPPOSITE PRESSURE SPECIFICATIONS Boiler Type AKB 80 AKB 250 AKB 300 AKB 350

Capacity (kCal/h) 150.000 200.000 250.000 300.000 350.000 400.000 450.000

^ The efficiency is increased by 5% for the boiler and the fuel consumption is decreased 5% for the fuel by the incredible technology Capacity (kW) 174 233 291 349 407 465 523

of water cap. Width (mm) 1000 1000 1200 1200 1200 1360 1360

The problems concerning refractory concrete are avoided by means of water cap technology. Lenght (mm) 1550 1550 1850 1850 1850 2150 1850 2150

It has advanced manufacturing technology. Height (mm) 830 1050 1050 1050 1250 1250 1250 1410 1410

It is produced under the conditions of high quality and sensitivity. Departure/Return 2" 065 065 080 080 080 080 080 0100

It provides ECONOMICAL ease-of-use due to high efficiency design and low fuel consumption. Safety Exit 11/4" 11/4" 11/2" 11/2" 11/2" 11/2"

It is comply with the use of natural gas, LPG and liquid fuel, and is high efficient and long life. Safety Return 1" 1" 11/4" 11/4" 11/4" 11/4" 11/2" 11/2"

It is affected at minimal level from the residues and limes inside water due to design. Chimney (mm) 150 200 200 250 300 300 350 350

It has an easy expansion capacity by the design causing to stabilize the heat differences in the boiler.

Weight (Kg) 372 492 555 639 849 897 1019 1119

It is manufactured completely by using domestic goods, work and automation facilities with the technology of developed opposite

Water Volume (Lt) 188 247 286 441 520 480 645 710

pressure in our factory.

Opposide Pressure (mBar) 0,1 0,1 0,2 0,2 0,3 0,3 0,4 0,4

It has a flexibility to be manufactured in place.

It satisfy easy transportation facility. AKB 550 AKB 600 AKB 700 AKB 800 AKB 1000 AKB 1250 AKB 1500 AKB 2000 AKB 3000

Boiler Type

It has ergonomic design.

Capacity (kCal/h) 500.000 550.000 600.000 700.000 800.000 1.000.000 1.250.000 1.500.000 2.000.000 3.000.000

The flame is come back in the same cell and provides high efficiency combustion by the technology of opposite pressure.

Capacity (kW) 581 640 698 814 930 1163 1453 1744 2326 3488

The gasses and the fuel particles semi-burned when encounter with the burner flame secondly are transformed into energy and

Width (mm) 1400 1340 1400 1550 1550 1550 1700 1700 1900 2000

then the fuel is burned out completely.

The bright flame created in the fire sleeve chamber in which double pass intensive combustion occurs is transferred to the water Lenght (mm) 2100 2250 2450 2650 2650 2950 3050 3250 4550 4600

from the combustion cell by the way of "radiation heat transfer". Height (mm) 1450 1410 1450 1600 1600 1600 1750 1750 2000 2100

The turbulators that cause the gas delay are incurred to transfer the heat at maximum level by reducing the speed of smoke and Departure /Return 0100 0100 0100 0125 0125 0150 0150 0150 0200 0200

gasses within the flame tubes. Safety Exit 2" 2" 2" 065 065 065 080 080 080 0100

The endurance for the boiler types having cylindrical inner design with the big capacities are increased due to corrugated furnace Safety Return 11/2" 11/2" 11/2" 2" 2" 2" 065 065 065 080

construction and an aesthetic and modern view is obtained due to prismatic external outlook. Chimney (mm) 450 450 500 500 600 600 750 750

It provides ease of use in small areas due to suitable sizes. Weight (Kg) 1371 1551 1904 2046 2280 2850 3400 4560 6800

It is manufactures between the capacity ranges of 50.000 to 5.000.000 kcal/h. Water Volume (Lt) 775 848 1086 1484 1398 1661 2076 2490 3300 4950

It is manufactured in accordance with the TSE 303 and TRD standards.

Opposide Pressure (mBar) 0,5 0,6 0,6 0,8 0,9 1,0 1,3 1,5 2 3,1

It can be controlled wireless by remotely.

The pressure data can be read from the card by the digital pressure indicator and the pressure control can be checked by the The right to make changes in technical issues is reserved by our company.

Special design and production can be made.

program desired.

It feels proud of rightful trust achieved by the consequence of the work of non-tolerant and precise with the understanding of service

in production and after sales.

You might also like

- Research Paper G-10 ST - John (New)Document66 pagesResearch Paper G-10 ST - John (New)Neil Patrick Lajera CruzNo ratings yet

- Chemistry Book GrADE 7Document30 pagesChemistry Book GrADE 7Widya Kusumaningrum100% (3)

- Karamat Sidi Ahmad Ibn Idris p59cDocument2 pagesKaramat Sidi Ahmad Ibn Idris p59cibnbadawiNo ratings yet

- Tesla Coil ReportDocument15 pagesTesla Coil ReportPiyush Raj50% (2)

- X341allegatoDEPLIANT1-2X XC-K enDocument6 pagesX341allegatoDEPLIANT1-2X XC-K endaboo sanatNo ratings yet

- Fujikura MV Power Cable CatalogueDocument94 pagesFujikura MV Power Cable Catalogueezpme0% (1)

- Euromax: Three-Pass Hot Water BoilerDocument1 pageEuromax: Three-Pass Hot Water BoilerLEONARDO MOLERO CLEMENTENo ratings yet

- Evomax 2 30kW Spec Sheet 2020Document4 pagesEvomax 2 30kW Spec Sheet 2020SupyNo ratings yet

- 1029 Series Fuel Energy Cold AIR Baffle Burner: CapabilitiesDocument4 pages1029 Series Fuel Energy Cold AIR Baffle Burner: CapabilitiesSubhra SinhaNo ratings yet

- Atlantic Water HeaterDocument2 pagesAtlantic Water HeaterNelson SanchezNo ratings yet

- Ecostat_Catloge_1Document4 pagesEcostat_Catloge_1Raj KaradaniNo ratings yet

- Continuous Vulcanization Cured Rubber - Versus - Mold (Lead) Cured Rubber - for-Extra-Heavy Duty (EHD) Mining Cables JacketsDocument7 pagesContinuous Vulcanization Cured Rubber - Versus - Mold (Lead) Cured Rubber - for-Extra-Heavy Duty (EHD) Mining Cables JacketsShubham BaderiyaNo ratings yet

- 5 1 Calpak Products Mark5 ManualDocument55 pages5 1 Calpak Products Mark5 ManualΑΝΑΣΤΑΣΙΟΣ ΣΑΦΡΙΔΗΣ100% (1)

- 200 KW - 595 KWDocument8 pages200 KW - 595 KWاحمد حسنNo ratings yet

- C13 - C15 - C18 Weather Protective Enclosure SpecDocument7 pagesC13 - C15 - C18 Weather Protective Enclosure Specsajeesh5113699No ratings yet

- Azeovaire Hot Water ASDI 1Document4 pagesAzeovaire Hot Water ASDI 1frank cevallosNo ratings yet

- Vitogas 100-gs1 TDMDocument12 pagesVitogas 100-gs1 TDMigaoua.coordefNo ratings yet

- Kamco Power Flushing Pumps UkDocument2 pagesKamco Power Flushing Pumps Ukamigo_mbNo ratings yet

- MVE Eterne Series: - 190°C Vapor StorageDocument2 pagesMVE Eterne Series: - 190°C Vapor StorageraviNo ratings yet

- ARI ENCOsys Datasheet Rev 7Document6 pagesARI ENCOsys Datasheet Rev 7Daniel Alam SubiruNo ratings yet

- Co Axial CablesDocument4 pagesCo Axial CablesKCTV NEWS PUNGANURNo ratings yet

- 18 8041 FT e Series en M o BD v1Document2 pages18 8041 FT e Series en M o BD v1Zain ShariffNo ratings yet

- CBN 09Document2 pagesCBN 09qwertNo ratings yet

- Speciality Insulation System For CementDocument16 pagesSpeciality Insulation System For CementGuilherme Augusto de OliveiraNo ratings yet

- Kelvion K°Bloc: Welded Plate Heat ExchangerDocument50 pagesKelvion K°Bloc: Welded Plate Heat ExchangerDipankar KhawasNo ratings yet

- 6.2 Mmbtu Zone Ii Steam GeneratorDocument2 pages6.2 Mmbtu Zone Ii Steam GeneratorAbboud KingNo ratings yet

- Dijp CursoDocument2 pagesDijp CursoJorgeNo ratings yet

- Mohawk Riserlite Indoor Outdoor Fiber CableDocument2 pagesMohawk Riserlite Indoor Outdoor Fiber CablecolinyNo ratings yet

- Thermax Combloc Multi Fuel Compact 1500 6000 KG Steam BoilerDocument2 pagesThermax Combloc Multi Fuel Compact 1500 6000 KG Steam BoilerPRABA KARAN100% (1)

- Model E1004 1000 BHP Steam Generator SpecificationsDocument2 pagesModel E1004 1000 BHP Steam Generator SpecificationsTiconderosa CosmeticosNo ratings yet

- Cortherm TankDocument9 pagesCortherm TankPely NdNo ratings yet

- Viadrus U22 Upute Za Ugradnju I KorištenjeDocument28 pagesViadrus U22 Upute Za Ugradnju I KorištenjevladoNo ratings yet

- Model E404 400 BHP Steam Generator Specifications 1Document2 pagesModel E404 400 BHP Steam Generator Specifications 1Ticonderosa CosmeticosNo ratings yet

- Juhas ENGLISHDocument14 pagesJuhas ENGLISHghiocel apinteiNo ratings yet

- Packman Domestic Hot WaterDocument10 pagesPackman Domestic Hot WaterAmir ShamshiriNo ratings yet

- Cazan Installation-Manual-FbgDocument20 pagesCazan Installation-Manual-FbgCretu Stefan-DanielNo ratings yet

- Calderas Lochinvar CBN 645-2066Document2 pagesCalderas Lochinvar CBN 645-2066borisNo ratings yet

- Atlantic OPRO Classic 1.2kWDocument2 pagesAtlantic OPRO Classic 1.2kWMohammad ZeeshanNo ratings yet

- Aercel SP20Document2 pagesAercel SP20Yassin Abd El AalNo ratings yet

- Katalog Defro - en 01 - 2022Document36 pagesKatalog Defro - en 01 - 2022Octavian MrejeruNo ratings yet

- Plumbing Design Analysis: M Cistern VolumeDocument4 pagesPlumbing Design Analysis: M Cistern VolumeZan Ojeda100% (1)

- Aicool XB - SeriesDocument9 pagesAicool XB - Seriessarjono100% (1)

- PAC1000D-S RefDocument2 pagesPAC1000D-S Refyassiroutisket2No ratings yet

- Atmos Wood Boiler ManualDocument29 pagesAtmos Wood Boiler ManualglynisNo ratings yet

- Vertical Bulk Storage Tanks: Taylor-Wharton Malaysia Sdn. BHDDocument2 pagesVertical Bulk Storage Tanks: Taylor-Wharton Malaysia Sdn. BHDSCALE Ingeniería y ConstrucciónNo ratings yet

- TDS Flexalen-600-SLP v1.0EU 20200423Document2 pagesTDS Flexalen-600-SLP v1.0EU 20200423michel.cermenoNo ratings yet

- PROPOSAL Nickel SmelterDocument16 pagesPROPOSAL Nickel Smelterzmahfudz100% (1)

- Indirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhDocument6 pagesIndirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhMuhammad AhsanNo ratings yet

- Clion-Marine Chiller Specs 2017Document1 pageClion-Marine Chiller Specs 2017Sandy NugrahaNo ratings yet

- 001 Horno.20af - Quincy LabDocument2 pages001 Horno.20af - Quincy LabJose ReyesNo ratings yet

- Tempest Indirect - Data Sheet2-187Document2 pagesTempest Indirect - Data Sheet2-187ErikNo ratings yet

- H425 EKO Manual - EN - 30.3.16Document31 pagesH425 EKO Manual - EN - 30.3.16ghiocel apinteiNo ratings yet

- Boiler Heating SurfacesDocument12 pagesBoiler Heating SurfacesHai NguyenNo ratings yet

- OPRO ClassicDocument2 pagesOPRO ClassicMohammad ZeeshanNo ratings yet

- Presentación Claudius Peters-EnfriadorDocument24 pagesPresentación Claudius Peters-EnfriadoremadsabriNo ratings yet

- 4.5 Mmbtu Rigsafe / Safe Area Steam GeneratorDocument2 pages4.5 Mmbtu Rigsafe / Safe Area Steam GeneratormakramNo ratings yet

- John Thompson Europac Boiler BrochureDocument2 pagesJohn Thompson Europac Boiler BrochureHafid NaufalNo ratings yet

- HT Xlpe CableDocument10 pagesHT Xlpe CableJaks JaksNo ratings yet

- Vdocuments - MX Tower Erection TesmecDocument16 pagesVdocuments - MX Tower Erection Tesmecrafael granadosNo ratings yet

- Taking Advantage of Waste Heat: Kelvion Exhaust Gas Heat ExchangerDocument2 pagesTaking Advantage of Waste Heat: Kelvion Exhaust Gas Heat ExchangerJeff LangleyNo ratings yet

- 4.5 Mmbtu Rigsafe / Safe Area Steam GeneratorDocument2 pages4.5 Mmbtu Rigsafe / Safe Area Steam GeneratorAbboud KingNo ratings yet

- K 450 Plus PDFDocument8 pagesK 450 Plus PDFrkssNo ratings yet

- K 450 Plus PDFDocument8 pagesK 450 Plus PDFrkssNo ratings yet

- Renewal Energy Engineer - Jobs - AfDocument5 pagesRenewal Energy Engineer - Jobs - AfSharif MalekzadaNo ratings yet

- Greening Federal FacilitiesDocument8 pagesGreening Federal FacilitiesSharif MalekzadaNo ratings yet

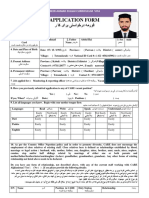

- Job Application Form: AfghanistanDocument10 pagesJob Application Form: AfghanistanSharif MalekzadaNo ratings yet

- Job Application Form: AfghanistanDocument4 pagesJob Application Form: AfghanistanSharif Malekzada0% (1)

- Position Title: Finance AssociateDocument9 pagesPosition Title: Finance AssociateSharif MalekzadaNo ratings yet

- Position Title: Monitoring & Reporting OfficerDocument6 pagesPosition Title: Monitoring & Reporting OfficerSharif MalekzadaNo ratings yet

- Application Letter: Naseer Ahmad Zulgai Curriculum VitaDocument5 pagesApplication Letter: Naseer Ahmad Zulgai Curriculum VitaSharif MalekzadaNo ratings yet

- BSH Home Appliances: By: Finn O'Toole Luke Wilson Mohammad Saghir Hannah Morrison Nicole SaundersDocument12 pagesBSH Home Appliances: By: Finn O'Toole Luke Wilson Mohammad Saghir Hannah Morrison Nicole SaundersByan SaghirNo ratings yet

- Narrative Report in ResearchDocument2 pagesNarrative Report in ResearchSarah Jane EnriquezNo ratings yet

- 21 Century Literature From The Philippines and The World: RD STDocument3 pages21 Century Literature From The Philippines and The World: RD STRhaedenNarababYalanibNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityJaineshNo ratings yet

- ETI 22618 UT2 Question Bank 2022-23 240523Document19 pagesETI 22618 UT2 Question Bank 2022-23 240523Harshal MakodeNo ratings yet

- Prehistoric Era Art - Rock Paintings (Indian Culture Series - NCERT)Document6 pagesPrehistoric Era Art - Rock Paintings (Indian Culture Series - NCERT)Aurinjoy BiswasNo ratings yet

- Apollonius of Rhodes - ArgonauticaDocument438 pagesApollonius of Rhodes - Argonauticajoaquin ojedaNo ratings yet

- Source: Family Background:: Flight Mechanic World War II Oklahoma Dust BowlDocument4 pagesSource: Family Background:: Flight Mechanic World War II Oklahoma Dust BowlClay Cyril Jastiva LambitNo ratings yet

- wpc6hg015083 - Bom 1701Document4 pageswpc6hg015083 - Bom 1701rajitkumar.3005No ratings yet

- Features: CCM PFC ControllerDocument35 pagesFeatures: CCM PFC ControllerLAN JR HOUSENo ratings yet

- Camacho2007 PDFDocument24 pagesCamacho2007 PDFFabianOmarValdiviaPurizacaNo ratings yet

- WEEK 1 Concept of PolynomialDocument8 pagesWEEK 1 Concept of PolynomialAngelo Rey NavaNo ratings yet

- Department of Management Studies MS 5320-Human Resource ManagementDocument3 pagesDepartment of Management Studies MS 5320-Human Resource ManagementNaji DhanishNo ratings yet

- Jollibee V. Mcdonald'S in The PhilippinesDocument12 pagesJollibee V. Mcdonald'S in The PhilippinesCharls DNo ratings yet

- Myanmar Community Security Cartoon Booklet EnglishDocument15 pagesMyanmar Community Security Cartoon Booklet EnglishSaw HsarNo ratings yet

- End Length OffsetsDocument5 pagesEnd Length OffsetsvardogerNo ratings yet

- Hari Donthireddy Resume-3Document1 pageHari Donthireddy Resume-3api-667792083No ratings yet

- Meg Barnett Resume 2012Document1 pageMeg Barnett Resume 2012barnett_meghaneNo ratings yet

- What Is An IP AddressDocument4 pagesWhat Is An IP Addresschandvinay_singhNo ratings yet

- Cadbury GokulDocument69 pagesCadbury GokulGokulkrishnaNo ratings yet

- From WID To GAD: Conceptual Shifts in The Women and Development DiscourseDocument57 pagesFrom WID To GAD: Conceptual Shifts in The Women and Development DiscourseUnited Nations Research Institute for Social DevelopmentNo ratings yet

- QNet Company Profile 2011Document52 pagesQNet Company Profile 2011qnetofficial50% (2)

- 6 SigmnaDocument15 pages6 SigmnaArjun SinghNo ratings yet

- Pigment Volume Concentration Part IDocument5 pagesPigment Volume Concentration Part IEmilio HipolaNo ratings yet

- 1 Analytic FunctionDocument3 pages1 Analytic FunctionrobNo ratings yet

- Infinite Series - Cauchy's Root TestDocument7 pagesInfinite Series - Cauchy's Root TestSanjay GuptaNo ratings yet