Professional Documents

Culture Documents

Derating of Boiler

Derating of Boiler

Uploaded by

Ajim Mokashi0 ratings0% found this document useful (0 votes)

52 views1 pageOriginal Title

Derating of boiler

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

52 views1 pageDerating of Boiler

Derating of Boiler

Uploaded by

Ajim MokashiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Officer of the Watch

Marine Boilers Oil

Contamination

Officer of the Watch 9 years ago

In early October DNV released a technical newsletter

focusing on the immediate and consequential impact

of oil contamination on auxiliary boilers. This kind of

leakage in coil flanges or broken gaskets in plate heat

exchangers frequently occurs. If the problem is not

observed in time, the boiler could be

completely destroyed due to overheating of the

furnace because of reduced water flow and minimised

heat transfer/cooling of the boiler tubes.

Notwithstanding the protective devices fitted on

steam plants exposed to the risk of oil contamination,

it is still not rare to experience various degrees of

contamination of boilers and associated systems.

Cracks and an associated loss of integrity at high heat

transfer areas are also encountered in some cases.

Most of them result in expensive and time-consuming

repairs involving the replacement of pressure parts,

chemical-mechanical cleaning and downtime.

The most common sources of oil contamination

observed on boilers originate from leaking heating

coils fitted in fuel oil tanks, fuel/lub oil heaters,

cylinder lub oil from reciprocating steam engines for

pumps and heating coils in double bottom tanks

dedicated for sludge/waste oil tanks. It is also not rare

for cargo tank heating coils and tank cleaning heaters

fitted on the cargo side to contribute to the

contamination in some cases. However, main

propulsion boiler plants with a segregated

saturated steam system as the main source of

heating medium are least likely to be

contaminated by oil.

The immediate effects of oil contamination range

from foaming and carry over in oil-fired boilers due to

increased tension at the water surface to the

malfunction of boiler water level controls and even

protective shutdown devices. In the worst cases, the

carry-over of water and moisture with the steam may

even reach the intensity of priming, causing havoc to

consumers, eg: turbines, super heaters, steam piping

and associated gaskets. Severe oil contamination

leads to a collapse of the heat transfer rate through

the boiler steel, contributing to a higher metal

temperature than the design value.

Even an oil film or deposit as thin as 0.5 mm on the

water side can easily increase the metal temperature

on the furnace side from the design value of 250 deg

C to well above 600 deg C under normal operating

conditions on an auxiliary boiler rated at 7 bar. This

has a domino effect of exponentially reducing the

yield strength of the material until the pressure parts

subjected to active heat transfer fail. In cases where

the reduction in the strength does not lead to

immediate failure, the boiler steel can still be

subjected to a time-dependent creep zone that is hard

to evaluate unless catered to at the design stage by

alloying.

In the case of exhaust gas water tube boilers with an

extended surface area that forms part of the steam

generation system by forced circulation, this may in

the worst cases lead to soot fires due to a lack of heat

transfer from the gas side and rise in the metal

temperatures due to the uncooled boundaries. Smoke

tube exhaust gas boilers are prone to cracks on the

tube terminations, due to differential expansion of the

overheated tubes with respect to the shell. Some of

the problems encountered due to boiler oil

contamination are shown in the following images.

Oil contaminated marine boilers

Left: Soot fire raging from the stack

Right: Oil contamination into water side of boiler

Left: Tube burst due to short-term overheating

Right: Corroded boiler furnace dome and convection

tubes

Left: Creep cracks in a boiler end plate due to long-

term overheating

Right: The result of oil contamination in an oil-fired

boiler

One of the first preventive actions to be taken when

oil leakage into the feedwater system is suspected is

to take a look in the cascade or hotwell tanks. If oil is

found in the last compartment just before the

water enters the feedwater piping, it is recommended

to check whether a dark oily film contaminates

the boiler water level glasses inside. If so, the boiler

should not be blown down from the bottom, only

surface blow for several times. If the boiler is bottom

blown, it will become totally covered in oil. The boiler

should be shut down and released from pressure and

the venting valve opened. Afterwards, the boiler can

be drained slowly until water stops flowing from the

loosened, upper manhole door before opening up the

manhole for inspection. The oil will now only cover

the boiler in the normal water level range and can be

manually removed. Hot or cold water high-

pressure jet equipment together with oil dispersive

additives would be efficient for removal of the oil. In

case the boiler is completely oily inside, the cleaning

work could be turned over to a cleaning

company specialised in such work.

Furthermore a careful examination and hydrotest of

all suspected heating coils, heaters or whatever is

leaking in the steam/condensate system should be

conducted. Even when one leakage is found, there

could be several more remaining. When it is

assured that no more leakage can be found, the piping

system, coils and heaters have to be cleaned of all

remaining oil. The oil-fired boiler must not be started

up again until an oil-free feedwater supply is

guaranteed.

Oil contamination on boilers should lead to the

rectification of the heat-transfer surfaces on the water

and steam side prior to the boiler being put back into

service. Boiling out the water side of the boiler using

recommended chemicals and/or mechanical cleaning

are normal procedures undertaken to facilitate

satisfactory cleaning. This may be additionally

supported by hardness checks and a hydrostatic

pressure test at 1.5 times the design working pressure

to ensure the expected safety factor at the design

temperature. In view of the oil deposits on the water

side, it is also imperative that the impulse piping to

the level transmitters is blown through and safety

functions verified for satisfactory operation.

In exceptional cases and only in order to support

main functions, the short-term use of oil

contaminated boilers may be allowed and only after

careful assessment of the heat-transfer surfaces on

the water and steam side and satisfactory isolation of

the source of the contamination. In order to balance

the use of an oil contaminated boiler

as precautionary measure the firing rate/heat input in

conjunction with the design working pressure could

be reduced. A reduction in the design pressure is

deemed necessary when the stress levels are expected

to exceed the acceptable limits at the design pressure

and temperature conditions with the required safety

factor. Some of the common reasons range from

local/general corrosion, the adverse impact of

contaminants on the boiler pressure parts and

conditional temporary repairs. However, the

reduction in the design pressure has an impact on the

specific volume of steam and subsequently the

relieving capacity of the safety valves, the attachment

to the boiler shell and the waste steam piping.

The derating of design pressure must always be

compensated by a corresponding reduction in the

firing rate to limit the evaporation rates for the

satisfactory operation of the safety valves at an

increased specific volume of steam. This can be

verified by either design calculations or an

accumulation test at the revised evaporation rate and

derated pressure testing.

In all cases consultation with the manufacturer

should also be acquired in order to ensure proper

repair of the boiler system.

Source:

Share this:

! "

Related

Damage to Exhaust Gas Boiler Due to Dry Running

December 14, 2012

In "OOW FOCUS"

Incident Information on Thermal Oil Heater Fire in the

Funnel

May 30, 2013

In "OOW FOCUS"

Sea Chest Corrosion With Box Cooler Arrangement

November 1, 2013

In "OOW FOCUS"

Categories: OOW FOCUS

Tags: Boiler, coil flanges, gaskets, heat exchanger, marine

boiler, oil contamination, Technical, tube

Leave a Comment

Officer of the Watch

Back to top

You might also like

- Metallic Materials Specification HandbookDocument842 pagesMetallic Materials Specification HandbookVelmohana89% (9)

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewFrom EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewRating: 5 out of 5 stars5/5 (1)

- Prepare A Boiler For SurveyDocument9 pagesPrepare A Boiler For SurveyLakshmikanthNo ratings yet

- CFBC Refractory Dryout Along With Atmospheric Boilout FinalDocument7 pagesCFBC Refractory Dryout Along With Atmospheric Boilout FinalpurvgargNo ratings yet

- High-Rise Fire Protection System Design - Zoning & Series PumpingDocument4 pagesHigh-Rise Fire Protection System Design - Zoning & Series PumpingminiongskyNo ratings yet

- IMPORTANT Boiler Repairs Problems Marine Education MarineexamDocument8 pagesIMPORTANT Boiler Repairs Problems Marine Education MarineexamEge CNo ratings yet

- Problem in BoilerDocument8 pagesProblem in Boileraadarsh kumarNo ratings yet

- Oil Contamination in Marine BoilerDocument2 pagesOil Contamination in Marine BoilerManish KhakhraNo ratings yet

- University of Cebu Main-Campus College of Engineering Mechanical EngineeringDocument6 pagesUniversity of Cebu Main-Campus College of Engineering Mechanical EngineeringRhadel GantuangcoNo ratings yet

- Hotwell and Oil in Boiler WaterDocument5 pagesHotwell and Oil in Boiler WaterAbrham DubeNo ratings yet

- How To Destroy Boiler FullDocument18 pagesHow To Destroy Boiler Fullbanhquangduy90100% (1)

- 5 Boiler OperationDocument12 pages5 Boiler OperationAllen AnyayahanNo ratings yet

- Blow-Down Procedure For Marine Boilers PDFDocument7 pagesBlow-Down Procedure For Marine Boilers PDFRejoGevargheseRajanNo ratings yet

- Section 1.4 - Processing Control EquipmentDocument35 pagesSection 1.4 - Processing Control EquipmentLakshman Kumar JulapalliNo ratings yet

- How To Destroy A Boiler - Part 1Document5 pagesHow To Destroy A Boiler - Part 1CayixNo ratings yet

- How To Destroy A Boiler - Part 1Document5 pagesHow To Destroy A Boiler - Part 1mancini10No ratings yet

- Oil contamination in marine boiler 【Subject model: Aux. Boiler, Composite Boiler】Document3 pagesOil contamination in marine boiler 【Subject model: Aux. Boiler, Composite Boiler】Vyas SrinivasanNo ratings yet

- Aph FireDocument25 pagesAph Firesekhar_ntpcNo ratings yet

- Phase II Boiler QuestionsDocument12 pagesPhase II Boiler QuestionsNithin VargheseNo ratings yet

- Caldeira PEGASUS F2Document5 pagesCaldeira PEGASUS F2goncalo30No ratings yet

- Operation and Maintenance of Boilers: Prepared byDocument22 pagesOperation and Maintenance of Boilers: Prepared byZAHID HUSSAIN100% (1)

- Crude Overhead DesignDocument5 pagesCrude Overhead DesignDaniele CirinaNo ratings yet

- Boiler EfficiencyDocument28 pagesBoiler EfficiencyRintu BiswasNo ratings yet

- Boiler Inspection Guidance PDFDocument5 pagesBoiler Inspection Guidance PDFAnonymous yCpjZF1rFNo ratings yet

- Why HT Water Temp Should Be Between 75 - 90 Deg. C (Or) Why Preheating of Engine Required?Document14 pagesWhy HT Water Temp Should Be Between 75 - 90 Deg. C (Or) Why Preheating of Engine Required?Ganapathi SankarNo ratings yet

- 7 Steam - SafetyDocument5 pages7 Steam - SafetyYeshitilaAyalewNo ratings yet

- CH - Mates PH II - Boiler QuestionsDocument13 pagesCH - Mates PH II - Boiler QuestionsArun GeorgeNo ratings yet

- Why Air Vent Should Be Closed Maintaining 2kg/cm 2 Drum Level Pressure at Starting of Boiler Operation?Document2 pagesWhy Air Vent Should Be Closed Maintaining 2kg/cm 2 Drum Level Pressure at Starting of Boiler Operation?Ashish KapoorNo ratings yet

- Factors Responsible For Destruction of Boilers: A Guide For PreventionDocument26 pagesFactors Responsible For Destruction of Boilers: A Guide For Preventionkcp1986No ratings yet

- Furnace Design and Operation: Fuel Handling SystemsDocument45 pagesFurnace Design and Operation: Fuel Handling SystemskINGNo ratings yet

- Crude Treating & DesaltingDocument37 pagesCrude Treating & Desaltinggegio6080% (5)

- Boiler Inspection MaintenanceDocument5 pagesBoiler Inspection Maintenanceskthen72No ratings yet

- Chemical Cleaning of Steam Generator System by GEDocument6 pagesChemical Cleaning of Steam Generator System by GEBapu612345No ratings yet

- Pressure Vessel & Boiler: High Consequences & HazardsDocument19 pagesPressure Vessel & Boiler: High Consequences & HazardsMakhrus ShofiNo ratings yet

- Economizers: Plant Engineer's Reference Book (Second Edition)Document11 pagesEconomizers: Plant Engineer's Reference Book (Second Edition)Khurram ShahzadNo ratings yet

- Boiler Questions BtechDocument5 pagesBoiler Questions BtechRishav Raj100% (1)

- PPS Boiler Safe OperationDocument9 pagesPPS Boiler Safe OperationAraNo ratings yet

- BOILER-trouble ShootingDocument5 pagesBOILER-trouble ShootingAnonymous Q9i062VNo ratings yet

- Boiler Tube Failure and ImpactsDocument8 pagesBoiler Tube Failure and ImpactsUdhayakumar VenkataramanNo ratings yet

- Maintenance Boiler Maintenance - Thermal Power Plant A-ZDocument4 pagesMaintenance Boiler Maintenance - Thermal Power Plant A-ZkriziameiahnNo ratings yet

- Boiler Safe OperationDocument9 pagesBoiler Safe OperationMARISSA DINLASANNo ratings yet

- Boiler-Steam Generator Protection PDFDocument12 pagesBoiler-Steam Generator Protection PDFأمير حارث100% (1)

- Boiler Maintenance 101Document9 pagesBoiler Maintenance 101tubaNo ratings yet

- How To Destroy A Boiler - Part 3Document3 pagesHow To Destroy A Boiler - Part 3Thiago CosenzaNo ratings yet

- Why Compressors Fail Part 1 - Refrigerant Flood BackDocument4 pagesWhy Compressors Fail Part 1 - Refrigerant Flood BackvickersNo ratings yet

- PPE-REPORT .Docx (FINAL)Document25 pagesPPE-REPORT .Docx (FINAL)Meer UmarNo ratings yet

- Boiler Hydrostatic Testing ProcedureDocument5 pagesBoiler Hydrostatic Testing ProcedureMico CampoNo ratings yet

- Boiler Operation and MaintenanceDocument25 pagesBoiler Operation and MaintenanceJom BonhayagNo ratings yet

- Evaluating Deaerator OperationDocument5 pagesEvaluating Deaerator OperationYanuar KrisnahadiNo ratings yet

- GAPS Guidelines: Boiler FundamentalsDocument4 pagesGAPS Guidelines: Boiler FundamentalstilayeyidegNo ratings yet

- Marine BoilersDocument16 pagesMarine BoilersPawan Beniwal100% (1)

- Fig. 8.1: A Shell Boiler With An EconomizerDocument11 pagesFig. 8.1: A Shell Boiler With An EconomizerMuhammad Alam Zaib KhanNo ratings yet

- Smoke Tube Boilers: Tank (Scotch) BoilerDocument4 pagesSmoke Tube Boilers: Tank (Scotch) BoilerMeghanath AdkonkarNo ratings yet

- 1 Boilers MmsDocument35 pages1 Boilers MmsTahir MahmoodNo ratings yet

- Cracks in Boiler PlantsDocument2 pagesCracks in Boiler Plantshpss77No ratings yet

- Xxvi. Data Records AND Problem AnalysisDocument8 pagesXxvi. Data Records AND Problem AnalysisRaja RamNo ratings yet

- Boiler Tubes Overheating Failures and Actions To Control ThemDocument2 pagesBoiler Tubes Overheating Failures and Actions To Control ThemThanhluan NguyenNo ratings yet

- Boiler SurveyDocument7 pagesBoiler SurveyrajishrrrNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Process Engineering: Facts, Fiction and FablesFrom EverandProcess Engineering: Facts, Fiction and FablesRating: 3 out of 5 stars3/5 (2)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- VtcatDocument72 pagesVtcatCalidad - TGINo ratings yet

- The Third Industrial RevolutionDocument5 pagesThe Third Industrial RevolutionanafabizNo ratings yet

- Master List - Welding EquipmentDocument3 pagesMaster List - Welding EquipmentarnolhariNo ratings yet

- ManufacturingDocument17 pagesManufacturingPadmaNo ratings yet

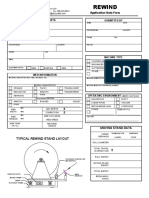

- Customer Data Submitted By: Typical Rewind Stand LayoutDocument2 pagesCustomer Data Submitted By: Typical Rewind Stand Layoutjroyal69No ratings yet

- SM Chapter 16 PDFDocument45 pagesSM Chapter 16 PDF李承家No ratings yet

- Aplicatii PT Aparat de DilutieDocument4 pagesAplicatii PT Aparat de DilutieCorina StanculescuNo ratings yet

- Mdgassupplysystemgroup 5medical 170124160041Document30 pagesMdgassupplysystemgroup 5medical 170124160041Azmi PatarNo ratings yet

- Lebm7301 04 PDFDocument94 pagesLebm7301 04 PDFVictor Nunez100% (1)

- MEMS Variable CapacitorDocument2 pagesMEMS Variable CapacitorRipan DeuriNo ratings yet

- Contents 1Document1 pageContents 1qaNo ratings yet

- Design Report of Intz Type Water Tank-Bia-01.07.2015 PDFDocument56 pagesDesign Report of Intz Type Water Tank-Bia-01.07.2015 PDFGR Kanna100% (1)

- Unit - 6Document22 pagesUnit - 6N Dhanunjaya Rao BorraNo ratings yet

- Selection of Inherently Safer Process Routes: A Case StudyDocument7 pagesSelection of Inherently Safer Process Routes: A Case StudyJames EdwardsNo ratings yet

- Nibco CatalogueDocument104 pagesNibco CatalogueIvan KolicNo ratings yet

- Tolerance ManualDocument187 pagesTolerance ManualRenish RegiNo ratings yet

- Chem 131......... 2Document13 pagesChem 131......... 2Nicholas Bonn SingNo ratings yet

- Is 14593 - 1998 Design and Construction of Bored Cast In-Situ Piles Founded On Rocks - GuidelinesDocument12 pagesIs 14593 - 1998 Design and Construction of Bored Cast In-Situ Piles Founded On Rocks - GuidelinesRavitejaNo ratings yet

- Your Solution Network: Middle EastDocument24 pagesYour Solution Network: Middle EastDrPadipat ChaemmangkangNo ratings yet

- Siegel Et Al 2014 Neutral Plane Method For Drag Force of Deep Foundations and The AASHTO LRFD Bridge Design SpecificatiDocument10 pagesSiegel Et Al 2014 Neutral Plane Method For Drag Force of Deep Foundations and The AASHTO LRFD Bridge Design SpecificatirotkviceNo ratings yet

- Mapua Univeristy: Muralla ST., Intramuros, Manila Department of Civil, Environmental, and Geological EngineeringDocument43 pagesMapua Univeristy: Muralla ST., Intramuros, Manila Department of Civil, Environmental, and Geological EngineeringCha RobinNo ratings yet

- 124712-00 UBQ Materials NL B.V. Grounding Report FGDocument1 page124712-00 UBQ Materials NL B.V. Grounding Report FG6mw6djgv7rNo ratings yet

- Oil Interceptor Type: SWOBK 100/ 500: Owership: Material: PolyethyleneDocument1 pageOil Interceptor Type: SWOBK 100/ 500: Owership: Material: PolyethyleneAldea CatalinNo ratings yet

- Manual Manitou Mt625 - enDocument130 pagesManual Manitou Mt625 - enAnonymous 1XBCMXNo ratings yet

- Rajkumar Honey HACCP PlanDocument26 pagesRajkumar Honey HACCP PlanMarlan Cole80% (5)

- G 09Document10 pagesG 09zbkt07No ratings yet

- CNC Web Handout 20091001Document25 pagesCNC Web Handout 20091001Daniel MabengoNo ratings yet

- Current Overview of EncapsulationDocument8 pagesCurrent Overview of EncapsulationFKUPN 2002100% (1)