Professional Documents

Culture Documents

Kingpin KGZ 31 MUB005002M01 REV-D 07-2020 EN Red

Kingpin KGZ 31 MUB005002M01 REV-D 07-2020 EN Red

Uploaded by

Anton Van NiekerkOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kingpin KGZ 31 MUB005002M01 REV-D 07-2020 EN Red

Kingpin KGZ 31 MUB005002M01 REV-D 07-2020 EN Red

Uploaded by

Anton Van NiekerkCopyright:

Available Formats

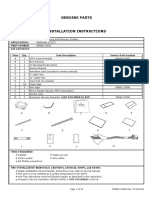

Kingpin KGZ 31

EN Installation and operating instruction

2 MUB 005 002 M01 (REV-D) 07-2020 Kingpin KGZ 31

Table of contents

1 Explanation of symbols................................................. 4

EN

2 Safety information........................................................ 5

2.1 Safety information for installation............................ 5

2.2 Safety information for servicing............................... 5

3 Proper usage................................................................. 6

3.1 Application................................................................ 6

3.2 Design....................................................................... 6

4 Installation.................................................................... 7

4.1 Suggested installations............................................. 9

4.2 Weld seam thickness................................................ 10

5 Servicing and testing..................................................... 11

5.1 Kingpin 50 (2").......................................................... 11

5.2 Test instructions........................................................ 11

5.3 To check for wear..................................................... 11

Kingpin KGZ 31 MUB 005 002 M01 (REV-D) 07-2020 3

1 Explanation of symbols

WARNING!

Means that death, serious phys-

ical injury or significant mater-

ial damage can occur if the rel-

evant safety instructions are not

followed.

ATTENTION!

Means that slight physical injury

or material damage can occur if

the relevant safety instructions

are not followed.

ADVICE!

Contains additional important

information.

4 MUB 005 002 M01 (REV-D) 07-2020 Kingpin KGZ 31

2 Safety information

Pay attention to the relevant safety regu- 2.1 Safety information for installation 2.2 Safety information for servicing

EN

lations in your country when handling fifth

wheel couplings, tractor units, semi-trailers – Only use genuine JOST spare parts. – Only use the specified lubricants for

and the kingpin (e.g. the Road Traffic Law – Damaged and repaired (e.g. repair by servicing work.

in Germany). deposition welding) individual parts – The servicing work should only be

must not be used. completed by trained personnel.

The relevant safety information in the – If the kingpin is not installed correctly,

owner's handbook for the tractor unit and all warranty claims against the manu- The licensing regulations of the appropri-

the semi-trailer remains valid and must be facturer and the supplier of the king- ate country must also be complied with.

followed. pin will be rendered void.

– The kingpin must only be installed by

The following safety information applies authorised specialist workshops.

to the operating, servicing and assembly – Refer to the instructions issued by the

work. Safety information directly linked to vehicle manufacturer, for example

the activity is listed again individually. regarding the type of fastening, fifth

wheel position, fifth wheel height, axle

ADVICE! load, clearance, etc.

Technical modifications

reserved. The latest information

can be found at:

www.jost-world.com

Kingpin KGZ 31 MUB 005 002 M01 (REV-D) 07-2020 5

3 Proper usage

3.1 Application 3.2 Design The permitted D value can be found in the

table below. This information can also be

Kingpins provide the link between the trac- The D value is a criterion for the load capac- found on the relevant pages of the JOST

tor unit and the semi-trailer. They are ity of kingpins. It is calculated using the fol- catalogue and is embossed on the front of

designed for mounting on the semi-trailer. lowing formula: the kingpin.

Kingpins are vehicle-connecting parts that D = Draw bar value [kN]

must comply with very high safety require- g = 9.81 m/s2

ments and must also undergo design R = Max. total weight

approval tests. Semi-trailer [t]

p = Max. total weight 1

1 n

16 X 3 pi

D - Z g

Modifications of any kind will render both

50 G in

X

H pK K

X

Weight of the towing vehicle,

X

X

01

the warranty and the design approval void

-

including U [t]

R

Ty

55

and therefore also cancel the vehicle's

2

U = Permitted fifth wheel load [t]

1

E

operating licence.

D = g x 0.6 x T x R [kN] 2

T+R-U KGZ/039

Sample calculation: 1 Type

2 D value in KN

R = 33 t

p = 17 t If they are subject to additional dynamic

U = 10.5 t forces, for example if they are used on

uneven road surfaces or on construction

0,6 x 17 x 33 sites, do not use the complete fifth wheel

D = 9,81 x = 83,6 kN load and D value, or alternatively, consult

17 + 33 - 10,5

JOST.

Permitted load data

Type Test mark Design designation D value [kN]

KGZ 31 E1 55R - 01 2719 KGZ 3106 - KGZ 3112 162

6 MUB 005 002 M01 (REV-D) 07-2020 Kingpin KGZ 31

4 Installation

Before installation, the semi-trailer plate

EN

ADVICE! must be checked to ensure it is even, and

When installed, the kingpins the semi-trailer plate thickness must also

must extend by a tolerated be checked. The unevenness of the semi-

longitudinal distance from the trailer plate must be no more than 2 mm in

semi-trailer plate. the load-bearing section of the fifth wheel

coupling. The semi-trailer plate must cover

the fifth wheel coupling's set-down surface

WARNING! in every position. The design designation of

Sharp edges and protruding the kingpins is made up as follows:

welding seams can cause serious

For example:

injuries. KGZ31 12

12 mm semi-trailer plate thickness in mm

KGZ31 - type (type series)

Permissible tolerances of the semi-trailer

plate in mm:

+ 0.6 + 0.6 + 0.4 + 0.4 + 0.2

6 mm 7 mm 8 mm 10 mm 12 mm

- 0.1 - 0.1 - 0.3 - 0.3 - 0.5

Kingpin KGZ 31 MUB 005 002 M01 (REV-D) 07-2020 7

4 Installation

When the mounting flanges or mounting cones are being welded, the following welding methods are permitted with the specified

additional materials and welding materials:

Welding method according to 111 135 135

ISO 4063

Welding additive

(approved by one of the follow- Rod electrode Welding wire Inert gas

ing organisations: BV, DB, DNV,

GL, LR, TÜV)

Standard name ISO 2560-A- E 35 3 B ISO 14341-A-G 38 3 C1 2Si ISO 14175 - C1

Welding additive/

Welding consumables ISO 2560-A- E 38 3 B ISO 14341-A-G 42 3 M21 2Si ISO 14175 - M21

ISO 2560-A- E 42 3 B ISO 14341-A-G 42 3 C1 3Si1

ISO 14341-A-G 42 4 M21 3Si1

ISO 14341-A-G 46 3 C1 4Si1

ISO 14341-A-G 46 4 M21 4Si1

ATTENTION!

The quality of the welding must satisfy the requirements of evaluation group B in accordance with EN ISO 5817.

The choice of welding material must be made in accordance with the stability of the substrate material used.

8 MUB 005 002 M01 (REV-D) 07-2020 Kingpin KGZ 31

4 Installation

Welding seam preparation is the responsi- 4.1 Suggested installations

EN

bility of the user, in accordance with tech- ATTENTION!

nological regulations. The semi-trailer plate The installed kingpins must be Depending on the type of semi-trailer

must be adequately reinforced according protected from weld spatter. plate, there are different options for fit-

to the load. The vehicle constructor will After welding, the fastening nuts ting the kingpins. The various options are

decide on the type and dimensions of and screws must be checked described in graphic form below. (The

the reinforcement. For stability reasons we to ensure they are at the cor- flange hole pattern is shown rotated

recommend a semi-trailer plate thickness rect tightening torque and tight- around 22.5°).

of 12 mm for 2" kingpins (recommended ened as necessary. After installa- The residual collar protects the mounted

material: EN 10025 S355J2G3). The king- tion, check the tolerated length parts during the coupling process and must

pins must be installed centred and at right dimension by which the kingpin be installed in the direction of travel (see

angles. Suggested installations and tighten- projects out of the semi-trailer Details 3).

ing torques can be found in the following plate. The adjustment and func-

table: tional surfaces must be masked 1 Direction of travel

before painting. A

Screw/nut Tight-

Type des- ening

ignation Art. No. Size torque

in Nm B B

A A-A

KGZ 3106-

KZE1012-03 M14 x 35 190 ± 10

KGZ 3112

B-B a

a KGZ/40

ADVICE!

For safety reasons, we recom- 2 3 Direction of travel

mend using bolts only once.

a

a

Residual collar KGZ/41

Kingpin KGZ 31 MUB 005 002 M01 (REV-D) 07-2020 9

4 Installation

4.2 Weld seam thickness

a

2

b

1

a

KGZ/06

The required weld thickness "a" for welding

the mounting flange depends on the thick-

ness of the semi-trailer plate.

b (semi- a (weld seam

Type des- trailer thickness)

ignation plate thick-

KZ 31YY 1 2

ness)

YY = 06 6 mm 4 mm 6 mm

YY = 07 7 mm 5 mm 6 mm

YY = 08 8 mm 5 mm 7 mm

YY = 10 10 mm 7 mm 7 mm

YY = 12 12 mm 8 mm 8 mm

10 MUB 005 002 M01 (REV-D) 07-2020 Kingpin KGZ 31

5 Servicing and testing

Before commissioning the semi-trailer, the 5.2 Test instructions When the wear limit on the kingpin has

EN

kingpin, the semi-trailer plate and the fifth been reached, it must be replaced. After

wheel coupling lock must be greased thor- Depending on the conditions of use, but the kingpin has been replaced, the lock-

oughly. We recommend the use of JOST after no more than 50,000 km or every ing mechanism on the fifth wheel coupling

high-performance lubricant (Art. No. SKE six months, the mounting plate, the king- must be reset. Play caused by wear on the

005 670 000). Generous lubrication of the pins and the fastening elements must be kingpin should either be accepted within

kingpin and fifth wheel coupling is essential checked to ensure they are functioning the permitted wear limit for the kingpin or

for a long service life. properly and are free from wear, damage should be rectified by fitting a new kingpin.

or cracks and repaired as necessary. The

fastening elements must be checked to

5.1 Kingpin 50 (2") ensure that they are tightened to the cor-

rect torque.

New diameter 73 5.3 To check for wear

min diameter 71

Fifth wheel couplings and kingpins are sub-

.

ject to more or less wear depending on the

min82.5 mm

max 84 mm

New diameter 50.8

conditions in which they are used, and this

.

min diameter 49

.

wear is noticeable by play towards the front

.

of the vehicle. Excessive play causes shocks

and may lead to instability on the road and

KGZ/43 damage to the fifth wheel coupling, mount-

ing plate and vehicle chassis.

ATTENTION!

The wear on the kingpin must

not be compensated by adjust-

ing the fifth wheel coupling.

Kingpin KGZ 31 MUB 005 002 M01 (REV-D) 07-2020 11

Member of JOST World

JOST, Germany, Tel. +49 6102 295-0, tkd-technik@jost-world.com, www.jost-world.com

MUB 005 002 M01 (REV-D) 07-2020 • 5.0

1176926

You might also like

- GeN2-Regen (1150kg-2000kg) Installation ManualDocument164 pagesGeN2-Regen (1150kg-2000kg) Installation ManualAbubeker Jemal67% (3)

- Iso 612 1978Document11 pagesIso 612 1978Education forme100% (1)

- Driving A Heavy Class VehicleDocument500 pagesDriving A Heavy Class VehicleElizabeth Ann Dulgar100% (1)

- 8M0110489 - JPO Starfish Manual de ServiçoDocument435 pages8M0110489 - JPO Starfish Manual de ServiçoJairPedroni0% (1)

- Autopilot NP2015/2025: Type 102 - 886 NG001Document105 pagesAutopilot NP2015/2025: Type 102 - 886 NG001Alexey Plekhanov100% (1)

- Heavy Duty Wheeled Vehicles Design, Theory, CalculationsDocument11 pagesHeavy Duty Wheeled Vehicles Design, Theory, CalculationszhenyupanNo ratings yet

- DRD'S' 920937-9407 02-03Document227 pagesDRD'S' 920937-9407 02-03Cao Lan100% (1)

- Instruction Handbook Man 618 - Biffi Icon2000Document116 pagesInstruction Handbook Man 618 - Biffi Icon2000NicuVisan50% (2)

- Grounding and Bonding For Oil and Gas Drilling or PDFDocument8 pagesGrounding and Bonding For Oil and Gas Drilling or PDFAdrian Cantaragiu100% (2)

- Oisd STD 179 CNGDocument28 pagesOisd STD 179 CNGMukesh Shukla77% (13)

- Kingpin Kingpin: Installation and Operating Instructions For Installation and Operating Instructions ForDocument16 pagesKingpin Kingpin: Installation and Operating Instructions For Installation and Operating Instructions Forhilman dave mustaineNo ratings yet

- Kingpin MUB005004M01 REV-B 02-2023 En-UkDocument16 pagesKingpin MUB005004M01 REV-B 02-2023 En-UkMishka_198No ratings yet

- JSK SL JSK SL: Installation and Operating Instructions Installation and Operating InstructionsDocument20 pagesJSK SL JSK SL: Installation and Operating Instructions Installation and Operating InstructionsJiebond SiddiqNo ratings yet

- Jost Kingpin DatasheetDocument10 pagesJost Kingpin DatasheetDian AntoniNo ratings yet

- 256 Mub016022m30 Rev - 01 2016 enDocument16 pages256 Mub016022m30 Rev - 01 2016 envictor hugoNo ratings yet

- VR 550Document90 pagesVR 550Estaban GuardiaNo ratings yet

- Truck Total Vehicle Actros, Type 930-934 Introductory Training Final TestDocument10 pagesTruck Total Vehicle Actros, Type 930-934 Introductory Training Final TestengdistyaNo ratings yet

- Operating Instructions: N - R 472C en 05.12Document42 pagesOperating Instructions: N - R 472C en 05.12Long HuynhNo ratings yet

- Manual: Simrad Panorama Mk2 Rudder Angle IndicatorDocument25 pagesManual: Simrad Panorama Mk2 Rudder Angle IndicatoraaaguilarmNo ratings yet

- Hak Retrofit Instalacja EN ESDocument28 pagesHak Retrofit Instalacja EN ESiwo3211231No ratings yet

- NP2035 Anschutz 3578 E 032 A4 PDFDocument119 pagesNP2035 Anschutz 3578 E 032 A4 PDFmrservice7782No ratings yet

- ASG-11.65.031 Maintenance KDL32Document12 pagesASG-11.65.031 Maintenance KDL32Mike Rushe100% (1)

- PW10A - Manual - A02427Document36 pagesPW10A - Manual - A02427Leandro MoriciNo ratings yet

- Bobcat T35120SL-MP Service Manual Telescopic Handler 2005 ModelDocument812 pagesBobcat T35120SL-MP Service Manual Telescopic Handler 2005 Modelprojektowanie.plcNo ratings yet

- ECE 220 / 225 ECE 220XL / 225XL: Operating InstructionsDocument91 pagesECE 220 / 225 ECE 220XL / 225XL: Operating InstructionsHandy Lee100% (1)

- Truck Total Vehicle, Final TestDocument10 pagesTruck Total Vehicle, Final TestPutra JawaNo ratings yet

- MHDP-08-R-01 YDH BRA Full Report Issue 6.0 PDFDocument159 pagesMHDP-08-R-01 YDH BRA Full Report Issue 6.0 PDFbillNo ratings yet

- Imb SH Hse 0009 03Document63 pagesImb SH Hse 0009 0301095902062ahmedNo ratings yet

- Truck Total Vehicle Actros, Type 930-934 Introductory Training Final TestDocument10 pagesTruck Total Vehicle Actros, Type 930-934 Introductory Training Final TestengdistyaNo ratings yet

- Montageanleitung Notice de Montage: Mounting InstructionsDocument36 pagesMontageanleitung Notice de Montage: Mounting Instructionssrinivas raghavanNo ratings yet

- Genuine Parts: Description: Application: Part Number: Kit Contents: Item Qty. Service Part Number Part DescriptionDocument10 pagesGenuine Parts: Description: Application: Part Number: Kit Contents: Item Qty. Service Part Number Part DescriptionNguyen DuyNo ratings yet

- MC 10213515 0001Document4 pagesMC 10213515 0001Jesus MedNo ratings yet

- PSIG EscalatorDocument31 pagesPSIG EscalatorNaseer KhanNo ratings yet

- UI Bulletin 124jDocument22 pagesUI Bulletin 124jJoshNo ratings yet

- Mil STD 781C PDFDocument136 pagesMil STD 781C PDFgiovannobgNo ratings yet

- BR Iom Bx-Be-Bn-Mx-Me-M STD Eng r02 1Document36 pagesBR Iom Bx-Be-Bn-Mx-Me-M STD Eng r02 1Hoài LyNo ratings yet

- Service Manual: Kodak Dryview 8150 Laser ImagerDocument470 pagesService Manual: Kodak Dryview 8150 Laser ImagerTausif AliNo ratings yet

- DG Set Installation Recommendations: Rev-06 Dated 31-03 - 2016Document74 pagesDG Set Installation Recommendations: Rev-06 Dated 31-03 - 2016Quang Pham100% (1)

- 307-01 Automatic Transmission 10 Speed - Removal and Installation - TransmissionDocument31 pages307-01 Automatic Transmission 10 Speed - Removal and Installation - Transmissionpxg8zdd7grNo ratings yet

- DCD320 500 TDCD01 - 03GBDocument344 pagesDCD320 500 TDCD01 - 03GBJarren GallmoreNo ratings yet

- Manual Fx20gmDocument8 pagesManual Fx20gmHarmawan FebriantoNo ratings yet

- Mil HDBK 263BDocument171 pagesMil HDBK 263BRosendo RizoNo ratings yet

- TM 11-1520-237-23-2 Em0014 30may2014 PDFDocument827 pagesTM 11-1520-237-23-2 Em0014 30may2014 PDFjoel alvaradoNo ratings yet

- Engine Lubrication System: SectionDocument20 pagesEngine Lubrication System: SectionSilvers Rayleigh Pangeran KegelapanNo ratings yet

- Lu PDFDocument16 pagesLu PDFLino Bello RezamanoNo ratings yet

- Engine Lubrication System: SectionDocument16 pagesEngine Lubrication System: SectionLino Bello RezamanoNo ratings yet

- Toyota Tundra TRD Sway Bar Installation InstructionsDocument5 pagesToyota Tundra TRD Sway Bar Installation InstructionsJason LancasterNo ratings yet

- 1 42 5 1152 1 A B Descender User Instruction Manual PDFDocument2 pages1 42 5 1152 1 A B Descender User Instruction Manual PDFYamil RodriguezNo ratings yet

- AX50 BX50: Operation & Maintenance ManualDocument21 pagesAX50 BX50: Operation & Maintenance ManualHoàng Tô0% (1)

- DFPI - ND2P C1V NB3P A - 2019 03a - 8109748g1Document4 pagesDFPI - ND2P C1V NB3P A - 2019 03a - 8109748g1Rodrigo PereiraNo ratings yet

- Simg 8832Document24 pagesSimg 8832marcosNo ratings yet

- R3923 8 Inch Jumper Roll UpDocument50 pagesR3923 8 Inch Jumper Roll UpLinda Cendekia SuproboNo ratings yet

- 6179 UseDirectional 20211014 WebDocument17 pages6179 UseDirectional 20211014 WebSuat KaracanNo ratings yet

- Installatie HandleidingDocument21 pagesInstallatie HandleidingGeert MertensNo ratings yet

- 628-SCR#2 BUCKET BOLT TIGHTENING and CHANGINGDocument4 pages628-SCR#2 BUCKET BOLT TIGHTENING and CHANGINGBuddy HartNo ratings yet

- Grounding and Bonding For Oil and Gas Drilling orDocument8 pagesGrounding and Bonding For Oil and Gas Drilling orgerrzen64No ratings yet

- Grounding and Bonding For Oil and Gas Drilling orDocument8 pagesGrounding and Bonding For Oil and Gas Drilling orarwa zeglam100% (1)

- Grounding and Bonding For Oil and Gas Drilling orDocument8 pagesGrounding and Bonding For Oil and Gas Drilling orMadhusudhana RajuNo ratings yet

- Advisory:: UI Bulletin #161bDocument6 pagesAdvisory:: UI Bulletin #161bSalvador PinedaNo ratings yet

- Diagnostic: K/ Varidor 20 604511 - F 02Document17 pagesDiagnostic: K/ Varidor 20 604511 - F 02jacqueminattouekouassiNo ratings yet

- ManualDocument24 pagesManualsadrak velhoNo ratings yet

- 212MM212MMCH09Document6 pages212MM212MMCH09cristianNo ratings yet

- Fuel Adjustment June 2022Document4 pagesFuel Adjustment June 2022Anton Van NiekerkNo ratings yet

- Maintenance Schedule: MAN Marine Diesel Engines V8 / V12 Light DutyDocument40 pagesMaintenance Schedule: MAN Marine Diesel Engines V8 / V12 Light DutyAnton Van NiekerkNo ratings yet

- Workshop Manual: BPW Trailer Axles With Drum BrakesDocument69 pagesWorkshop Manual: BPW Trailer Axles With Drum BrakesAnton Van NiekerkNo ratings yet

- Vecton Long Drain 10W-40 LS: DescriptionDocument2 pagesVecton Long Drain 10W-40 LS: DescriptionAnton Van NiekerkNo ratings yet

- BPW Maintenance Manual 2021Document92 pagesBPW Maintenance Manual 2021Anton Van NiekerkNo ratings yet

- Permit Desk Guide: M 3037.18 June 2017Document104 pagesPermit Desk Guide: M 3037.18 June 2017Costel Constantin MarmotaNo ratings yet

- Escort Requirement - VIC PDFDocument4 pagesEscort Requirement - VIC PDFlin yuNo ratings yet

- Commercial Vehicles 1. What Are LCVS, MHCVS, HcvsDocument2 pagesCommercial Vehicles 1. What Are LCVS, MHCVS, HcvsSubbiah SomasundaramNo ratings yet

- Driver and Maintenance Operations TD Steering SystemDocument52 pagesDriver and Maintenance Operations TD Steering SystemmuratNo ratings yet

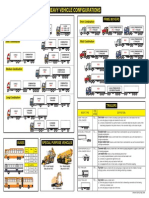

- Heavy Vehicle ConfigurationsDocument1 pageHeavy Vehicle ConfigurationsTimonPumbaNo ratings yet

- klapan - rastormajivaniya - haldex мойDocument2 pagesklapan - rastormajivaniya - haldex мойВячеслав ОпацкийNo ratings yet

- Operating Manual Maxtrailer N enDocument35 pagesOperating Manual Maxtrailer N enFeraru Valentin0% (1)

- XZC710Document3 pagesXZC710ZubairAhmedSiddiquiNo ratings yet

- Iva Inspection Manual For Categories O1 O2 O3 and O4 TrailersDocument133 pagesIva Inspection Manual For Categories O1 O2 O3 and O4 Trailerss0mniNo ratings yet

- Truck-Mounted Concrete Pump S 36 XDocument6 pagesTruck-Mounted Concrete Pump S 36 XRajput AkshayNo ratings yet

- TrucksDocument10 pagesTrucksAditi BazajNo ratings yet

- Distribusi Muatan Sumbu Terberat Kendaraan Niaga: No. Description Load Distribution Example MST (Ton)Document4 pagesDistribusi Muatan Sumbu Terberat Kendaraan Niaga: No. Description Load Distribution Example MST (Ton)aristya_redmi2No ratings yet

- Bogged Vehicle RecoveryDocument7 pagesBogged Vehicle RecoveryPeter BennettNo ratings yet

- Release of Information To SIAM With Respect To Sale Volume of VE Commercial Vehicles Limited For The Month of May 2016 (Company Update)Document2 pagesRelease of Information To SIAM With Respect To Sale Volume of VE Commercial Vehicles Limited For The Month of May 2016 (Company Update)Shyam SunderNo ratings yet

- Hwy Cap Estimation PDFDocument7 pagesHwy Cap Estimation PDFDondon DondonNo ratings yet

- Introduction of The New Truck Generation The New Arocs (Model 964)Document96 pagesIntroduction of The New Truck Generation The New Arocs (Model 964)Mahmoud El-Megheny100% (1)

- Design of Flexible Pavements For Low Volume Rural Roads - FinalDocument31 pagesDesign of Flexible Pavements For Low Volume Rural Roads - FinalAsit MohantyNo ratings yet

- Notifications Under The Motor Vehicles ActDocument33 pagesNotifications Under The Motor Vehicles ActSatyadip TeraiyaNo ratings yet

- Cuevas Jayson Assignment No. 3 Aadtvcr and LosDocument4 pagesCuevas Jayson Assignment No. 3 Aadtvcr and LosAnthony Carl PS HortilanoNo ratings yet

- Trejler Ebs eDocument43 pagesTrejler Ebs eВиктор СабовNo ratings yet

- Traffic Management Plan Sample Report Updated 2022Document4 pagesTraffic Management Plan Sample Report Updated 2022Imran KhanNo ratings yet

- Building Permission HDMCDocument36 pagesBuilding Permission HDMCPavan ReddyNo ratings yet

- TRB - ACRP Report 40 Airport Curbside and Terminal Area Roadway Operations - 2010 PDFDocument165 pagesTRB - ACRP Report 40 Airport Curbside and Terminal Area Roadway Operations - 2010 PDFFrankCapraNo ratings yet

- Ap G34 13 PDFDocument26 pagesAp G34 13 PDFJames Mellan100% (1)

- Glosario Ingles LogisticaDocument18 pagesGlosario Ingles LogisticaCarlos WcNo ratings yet

- Key Performance Indicators For The Food Supply Chain: Benchmarking GuideDocument16 pagesKey Performance Indicators For The Food Supply Chain: Benchmarking GuideAnonymous PK9uwwMU4RNo ratings yet