Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

6 viewsRecommended Joint For Tube

Recommended Joint For Tube

Uploaded by

Rana Muhammad Abdullah WakeelCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Tim Button, Sean Walsh - Philosophy and Model Theory (2018, Oxford University Press)Document534 pagesTim Button, Sean Walsh - Philosophy and Model Theory (2018, Oxford University Press)Carlos Diaz Huerta100% (1)

- Studio 5000 Logix Designer Advanced Lab ManualDocument280 pagesStudio 5000 Logix Designer Advanced Lab ManualOtávio Martins100% (1)

- National Pipe Thread Chart PDFDocument1 pageNational Pipe Thread Chart PDFLiu YangtzeNo ratings yet

- Pco Controller +Document164 pagesPco Controller +Luis Fernando Mateus Delgado0% (1)

- Reference For Orifice SelectionDocument1 pageReference For Orifice Selectiondeepak_313No ratings yet

- Espacio Entre TuberíasDocument1 pageEspacio Entre TuberíasRamón ZavalaNo ratings yet

- NPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Document1 pageNPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Carlos Andrés Mancera TrejosNo ratings yet

- National Pipe Thread ChartDocument1 pageNational Pipe Thread Chartafiqaziz86No ratings yet

- NPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Document1 pageNPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460RicNo ratings yet

- National Pipe Thread Chart OPT PDocument1 pageNational Pipe Thread Chart OPT PAbhi PrajapatiNo ratings yet

- NPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Document1 pageNPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Deden SobirinNo ratings yet

- National Pipe Thread Chart OPT PDocument1 pageNational Pipe Thread Chart OPT PAbhi PrajapatiNo ratings yet

- National Pipe Thread Chart OPT P PDFDocument1 pageNational Pipe Thread Chart OPT P PDFRoselio MayoNo ratings yet

- National Pipe Thread Chart OPT PDocument1 pageNational Pipe Thread Chart OPT PVasantha KumarNo ratings yet

- National Pipe Thread Chart PDFDocument1 pageNational Pipe Thread Chart PDFafiqaziz86No ratings yet

- B Shifting ToolDocument1 pageB Shifting ToolAmanda Delgado67% (3)

- TIC-Wireline Tools and Equipment Catalog - 部分225Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分225zbhdzpNo ratings yet

- Section 10Document53 pagesSection 10Palmério CarvalhoNo ratings yet

- Thread Dimensions: Tapered Threads Straight ThreadsDocument1 pageThread Dimensions: Tapered Threads Straight ThreadsImtiaz NusratNo ratings yet

- NPT Thread EngagementDocument1 pageNPT Thread Engagementmdambros1No ratings yet

- DixonCatalog1 Page525Document1 pageDixonCatalog1 Page525GhislainTremblayNo ratings yet

- DixonCatalog1 Page525Document1 pageDixonCatalog1 Page525karthikNo ratings yet

- Broch ArmacellProductSelector - en.US.2023 9Document1 pageBroch ArmacellProductSelector - en.US.2023 9Nadeer Mon PNo ratings yet

- Torque APIDocument1 pageTorque APIStefan do Nascimento da SilvaNo ratings yet

- Flange Leakage - NC 3658.3Document4 pagesFlange Leakage - NC 3658.3gharsallah mounaNo ratings yet

- Catálogo de Blocos Blank Catalog: For Quality SurfboardsDocument158 pagesCatálogo de Blocos Blank Catalog: For Quality SurfboardsEduardo DutraNo ratings yet

- Hex Socket Head Cap Screws Partially / Fully Threaded, With UNC Thread BN 13Document3 pagesHex Socket Head Cap Screws Partially / Fully Threaded, With UNC Thread BN 13razvan65No ratings yet

- 3 Retenes Timken 2Document1 page3 Retenes Timken 2a04205No ratings yet

- Thread Dimensions: Nominal Dimensions of Standard ThreadsDocument1 pageThread Dimensions: Nominal Dimensions of Standard ThreadsGhislainTremblayNo ratings yet

- Tabla de Bridas y Esparragos PDFDocument1 pageTabla de Bridas y Esparragos PDFjairo ardila100% (1)

- 22 Space Heavy Duty Grating: (1-3/8") Load TableDocument1 page22 Space Heavy Duty Grating: (1-3/8") Load TableSohag114No ratings yet

- Dimensiones Bridas PozosDocument1 pageDimensiones Bridas PozosNatanael León CastroNo ratings yet

- CDR Tee StrainersDocument2 pagesCDR Tee StrainersM JohnNo ratings yet

- CDR Orifice Plate Paddle TypeDocument1 pageCDR Orifice Plate Paddle TypeAksheyNo ratings yet

- Formulas, Facts and Figures PDFDocument13 pagesFormulas, Facts and Figures PDFश्रीराज् कथलियिल्No ratings yet

- Fricton Loss in Valves & FittingsDocument3 pagesFricton Loss in Valves & FittingsBen LimNo ratings yet

- TexasFlange - Bolt and Stud Dimensions ASME B16.5Document2 pagesTexasFlange - Bolt and Stud Dimensions ASME B16.5cristinelbNo ratings yet

- Standard Dimensions of Spectacle Blind ThicknessDocument10 pagesStandard Dimensions of Spectacle Blind ThicknessSubrata MukherjeeNo ratings yet

- Guia Parafusos, Arruelas E Porcas 1Document156 pagesGuia Parafusos, Arruelas E Porcas 1Adrian VerattiNo ratings yet

- 04 Tabla de Bridas y EsparragosDocument1 page04 Tabla de Bridas y EsparragosAlberto VELOSA ROANo ratings yet

- 04 Tabla de Bridas y EsparragosDocument1 page04 Tabla de Bridas y EsparragosDIEGO NAPOLEON RODRIGUEZ AGUILARNo ratings yet

- Tabla de Bridas y Esparragos y ComalesDocument1 pageTabla de Bridas y Esparragos y ComalesAlex el proNo ratings yet

- Doyles Catalog - GateValvesDocument5 pagesDoyles Catalog - GateValvesShag ShaggyNo ratings yet

- Screw Conveyor Components and DesignDocument3 pagesScrew Conveyor Components and DesignuripssgmailNo ratings yet

- BO Shifting Tool HuntingDocument2 pagesBO Shifting Tool HuntingMANUEL ISAZANo ratings yet

- Round Bend U-Bolts: 8%Row6Shflàfdwlrqv U-Bolts & 2 Nuts U-Bolts, Plates & 2 NutsDocument5 pagesRound Bend U-Bolts: 8%Row6Shflàfdwlrqv U-Bolts & 2 Nuts U-Bolts, Plates & 2 NutsRaging Red HippoNo ratings yet

- "Ju" Series Pulling ToolDocument1 page"Ju" Series Pulling ToolebeNo ratings yet

- Flange TableDocument2 pagesFlange TableTeodor Ioan Ghinet Ghinet DorinaNo ratings yet

- Flange APIDocument29 pagesFlange APIputujuliandikaNo ratings yet

- SAE and NPT Pipe and Port SizesDocument1 pageSAE and NPT Pipe and Port Sizeskasparob25No ratings yet

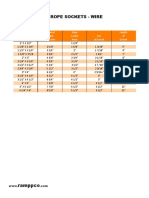

- Rope Socket DimensionsDocument1 pageRope Socket DimensionsmeryNo ratings yet

- Bolt Torquing Value (FT-LBS) For Spiral Wound Gasket Bolt Torquing Value (FT-LBS) For Spiral Wound GasketDocument2 pagesBolt Torquing Value (FT-LBS) For Spiral Wound Gasket Bolt Torquing Value (FT-LBS) For Spiral Wound GasketDhameemAnsariNo ratings yet

- Untitled 1Document8 pagesUntitled 1Ryanbruckshit IngkingNo ratings yet

- Obtegachi 1 PDFDocument4 pagesObtegachi 1 PDFSvetoslav SpasovNo ratings yet

- Steel Bar Grating Stair Tread DetailsDocument1 pageSteel Bar Grating Stair Tread DetailsJovito EdillonNo ratings yet

- Sandale IPS PE 3408 4710 Pipe ChartDocument2 pagesSandale IPS PE 3408 4710 Pipe ChartMarco Antonio Carrillo FalconNo ratings yet

- Preinstallation VerificationDocument5 pagesPreinstallation VerificationbalamuruganNo ratings yet

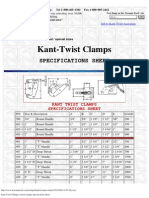

- Kant-Twist Clamps: Specifications SheetDocument3 pagesKant-Twist Clamps: Specifications SheetOmegacoolNo ratings yet

- Fillet Weld CapacityDocument1 pageFillet Weld CapacityjxsnyderNo ratings yet

- ChannelsDocument4 pagesChannelsjcNo ratings yet

- Section Properties (Fy 40 Ksi) : 1-1/2" Composite CellularDocument1 pageSection Properties (Fy 40 Ksi) : 1-1/2" Composite CellularIsbel PulidoNo ratings yet

- Table 1 Calculated Bolt Sizes: 2.4.8 Recommendations For Anchor Bolt and Foundation DesignDocument1 pageTable 1 Calculated Bolt Sizes: 2.4.8 Recommendations For Anchor Bolt and Foundation Designanwarali1975No ratings yet

- The Global Player: How to become "the logistics company for the world"From EverandThe Global Player: How to become "the logistics company for the world"No ratings yet

- CLASS X CHEMISTRY Solution-988039Document5 pagesCLASS X CHEMISTRY Solution-988039abiniveshofficial4708No ratings yet

- 201183-B-00-20 Part ListDocument19 pages201183-B-00-20 Part ListMohamed IsmailNo ratings yet

- Seasonal Variations in Kangra Tea QualityDocument6 pagesSeasonal Variations in Kangra Tea QualityashugulatiNo ratings yet

- Reusable Instrument Line en V8Document12 pagesReusable Instrument Line en V8Agon KarakashiNo ratings yet

- Courant: S. R. S. VaradhanDocument16 pagesCourant: S. R. S. Varadhan马牧之0% (1)

- Generator Protection PPT TurboDocument29 pagesGenerator Protection PPT TurbocheshankarNo ratings yet

- Brondizio Et Al 2009 Connectivity and The Governance of Multilevel Social Ecological Systems The Role of Social CapitalDocument29 pagesBrondizio Et Al 2009 Connectivity and The Governance of Multilevel Social Ecological Systems The Role of Social CapitalCHrisNo ratings yet

- Amphibians: Class AmphibiaDocument33 pagesAmphibians: Class Amphibiaisfi farihaNo ratings yet

- What Hetman Do I NeedDocument2 pagesWhat Hetman Do I NeedCem GüngörNo ratings yet

- Activity 7 Classifying of Sugars: Biochemistry LaboratoryDocument27 pagesActivity 7 Classifying of Sugars: Biochemistry LaboratoryWappy WepwepNo ratings yet

- Ostrich RacingDocument4 pagesOstrich RacingalexmadoareNo ratings yet

- PITE Ground Fault Locator GFL3836-User-manualDocument33 pagesPITE Ground Fault Locator GFL3836-User-manualMarinda FebriNo ratings yet

- Chemistry Final Exam PracticeDocument22 pagesChemistry Final Exam PracticeRida Muhammad RazaNo ratings yet

- Biocompatibility of Dental MaterialsDocument55 pagesBiocompatibility of Dental Materialsshivanshi jainNo ratings yet

- TM103 Chapter 1Document24 pagesTM103 Chapter 1johnnader1254No ratings yet

- Chapter 2 - DC Motor - SlidesDocument16 pagesChapter 2 - DC Motor - SlidesNurul ShathirahNo ratings yet

- Google - Cloud Digital Leader.v2023 06 22.q106Document50 pagesGoogle - Cloud Digital Leader.v2023 06 22.q106peacegroupngNo ratings yet

- Designing and Analysis of Pumping Solar PV System Using Pvsyst SoftwareDocument5 pagesDesigning and Analysis of Pumping Solar PV System Using Pvsyst SoftwareabfstbmsodNo ratings yet

- Research Report: G Fryer, J Carub, S MclverDocument7 pagesResearch Report: G Fryer, J Carub, S MclverMitchTolontanNo ratings yet

- Astm A570 1979Document5 pagesAstm A570 1979set_ltdaNo ratings yet

- Being and Power in Heidegger and FoucaultDocument14 pagesBeing and Power in Heidegger and Foucaultkostas8827No ratings yet

- Product Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5Document27 pagesProduct Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5marciocambruzziNo ratings yet

- CorrelationDoesntMeanCause WorksheetDocument8 pagesCorrelationDoesntMeanCause WorksheetYoung ThomzNo ratings yet

- Comparative Evaluation of Antibacterial Efficacy.9Document6 pagesComparative Evaluation of Antibacterial Efficacy.9Shivani DubeyNo ratings yet

- Magallona Vs ErmitaDocument13 pagesMagallona Vs ErmitaERNIL L BAWA100% (1)

- DSL & Its TypesDocument24 pagesDSL & Its TypesahmedNo ratings yet

- O Malley 2002 2Document284 pagesO Malley 2002 2Aziz NasutionNo ratings yet

Recommended Joint For Tube

Recommended Joint For Tube

Uploaded by

Rana Muhammad Abdullah Wakeel0 ratings0% found this document useful (0 votes)

6 views1 pageOriginal Title

Recommended Joint for tube

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

6 views1 pageRecommended Joint For Tube

Recommended Joint For Tube

Uploaded by

Rana Muhammad Abdullah WakeelCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

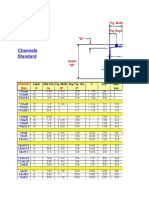

RECOMMENDED EXPANSION OF TUBES FOR OPTIMUM JOINT STRENGTH

IN HEAT EXCHANGERS AND CONDENSERS

Use expansion listed in tube expansion column plus clearance between tube O.D. and sheet hole I.D.

Recommended expansion may be plus or minus .001”.

O.D. Tube O.D. Tube O.D. Tube

Size GA Expansion Size GA Expansion Size GA Expansion

1/2” 14 .006” 3/4” 10 .008” 1-1/4” 8 .010”

1/2” 15 .006” 3/4” 11 .008” 1-1/4” 10 .010”

1/2” 16 .006” 3/4” 12 .008” 1-1/4” 12 .009”

1/2” 17 .005” 3/4” 13 .008” 1-1/4” 14 .008”

1/2” 18 .005” 3/4” 14 .008” 1-1/4” 16 .007”

1/2” 19 .004” 3/4” 15 .007” 1-1/4” 18 .006”

1/2” 20 .004” 3/4” 16 .006”

1/2” 21 .004” 3/4” 17 .005” 1-1/2” 8 .012”

3/4” 18 .005” 1-1/2” 10 .012”

5/8” 12 .006” 3/4” 19 .005” 1-1/2” 12 .010”

5/8” 13 .006” 3/4” 20 .005” 1-1/2” 14 .010”

5/8” 14 .006” 3/4” 21 .004” 1-1/2” 16 .008”

5/8” 15 .006” 1-1/2” 18 .008”

5/8” 16 .006” 1” 8 .009”

5/8” 17 .005” 1” 9 .009” 2” 8 .012”

5/8” 18 .005” 1” 10 .009” 2” 10 .012”

5/8” 19 .004” 1” 11 .009” 2” 12 .011”

5/8” 20 .004” 1” 12 .009” 2” 14 .010”

5/8” 21 .004” 1” 13 .008” 2” 16 .008”

1” 14 .008” 2” 18 .008”

1” 15 .007”

1” 16 .006”

1” 17 .005”

1” 18 .005”

ADDITIONAL SIZES

1/4” O.D. tube - expand all gauges .003” after contact with tube sheet hole

3/8” O.D. tube - expand all gauges .004” after contact with tube sheet hole

EXAMPLE

3/4” O.D. x 14 gauge tubes

Recommended expansion .............................................. .008”

Tube sheet hole ............................................................. .760”

Therefore, expand as follows:

Tube I.D. before expanding ............................................ .584”

Recommended expansion .............................................. .008”

Clearance between tube & tube sheet hole .................... .010”

FINISH I.D. .602”

The above recommendation is based on our experience. However, this does not constitute a

guarantee because of the great variety of materials, tubes and tube sheets used. Some conditions

will require experimental rolling to be certain that the rolled joints will be satisfactory.

You might also like

- Tim Button, Sean Walsh - Philosophy and Model Theory (2018, Oxford University Press)Document534 pagesTim Button, Sean Walsh - Philosophy and Model Theory (2018, Oxford University Press)Carlos Diaz Huerta100% (1)

- Studio 5000 Logix Designer Advanced Lab ManualDocument280 pagesStudio 5000 Logix Designer Advanced Lab ManualOtávio Martins100% (1)

- National Pipe Thread Chart PDFDocument1 pageNational Pipe Thread Chart PDFLiu YangtzeNo ratings yet

- Pco Controller +Document164 pagesPco Controller +Luis Fernando Mateus Delgado0% (1)

- Reference For Orifice SelectionDocument1 pageReference For Orifice Selectiondeepak_313No ratings yet

- Espacio Entre TuberíasDocument1 pageEspacio Entre TuberíasRamón ZavalaNo ratings yet

- NPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Document1 pageNPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Carlos Andrés Mancera TrejosNo ratings yet

- National Pipe Thread ChartDocument1 pageNational Pipe Thread Chartafiqaziz86No ratings yet

- NPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Document1 pageNPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460RicNo ratings yet

- National Pipe Thread Chart OPT PDocument1 pageNational Pipe Thread Chart OPT PAbhi PrajapatiNo ratings yet

- NPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Document1 pageNPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Deden SobirinNo ratings yet

- National Pipe Thread Chart OPT PDocument1 pageNational Pipe Thread Chart OPT PAbhi PrajapatiNo ratings yet

- National Pipe Thread Chart OPT P PDFDocument1 pageNational Pipe Thread Chart OPT P PDFRoselio MayoNo ratings yet

- National Pipe Thread Chart OPT PDocument1 pageNational Pipe Thread Chart OPT PVasantha KumarNo ratings yet

- National Pipe Thread Chart PDFDocument1 pageNational Pipe Thread Chart PDFafiqaziz86No ratings yet

- B Shifting ToolDocument1 pageB Shifting ToolAmanda Delgado67% (3)

- TIC-Wireline Tools and Equipment Catalog - 部分225Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分225zbhdzpNo ratings yet

- Section 10Document53 pagesSection 10Palmério CarvalhoNo ratings yet

- Thread Dimensions: Tapered Threads Straight ThreadsDocument1 pageThread Dimensions: Tapered Threads Straight ThreadsImtiaz NusratNo ratings yet

- NPT Thread EngagementDocument1 pageNPT Thread Engagementmdambros1No ratings yet

- DixonCatalog1 Page525Document1 pageDixonCatalog1 Page525GhislainTremblayNo ratings yet

- DixonCatalog1 Page525Document1 pageDixonCatalog1 Page525karthikNo ratings yet

- Broch ArmacellProductSelector - en.US.2023 9Document1 pageBroch ArmacellProductSelector - en.US.2023 9Nadeer Mon PNo ratings yet

- Torque APIDocument1 pageTorque APIStefan do Nascimento da SilvaNo ratings yet

- Flange Leakage - NC 3658.3Document4 pagesFlange Leakage - NC 3658.3gharsallah mounaNo ratings yet

- Catálogo de Blocos Blank Catalog: For Quality SurfboardsDocument158 pagesCatálogo de Blocos Blank Catalog: For Quality SurfboardsEduardo DutraNo ratings yet

- Hex Socket Head Cap Screws Partially / Fully Threaded, With UNC Thread BN 13Document3 pagesHex Socket Head Cap Screws Partially / Fully Threaded, With UNC Thread BN 13razvan65No ratings yet

- 3 Retenes Timken 2Document1 page3 Retenes Timken 2a04205No ratings yet

- Thread Dimensions: Nominal Dimensions of Standard ThreadsDocument1 pageThread Dimensions: Nominal Dimensions of Standard ThreadsGhislainTremblayNo ratings yet

- Tabla de Bridas y Esparragos PDFDocument1 pageTabla de Bridas y Esparragos PDFjairo ardila100% (1)

- 22 Space Heavy Duty Grating: (1-3/8") Load TableDocument1 page22 Space Heavy Duty Grating: (1-3/8") Load TableSohag114No ratings yet

- Dimensiones Bridas PozosDocument1 pageDimensiones Bridas PozosNatanael León CastroNo ratings yet

- CDR Tee StrainersDocument2 pagesCDR Tee StrainersM JohnNo ratings yet

- CDR Orifice Plate Paddle TypeDocument1 pageCDR Orifice Plate Paddle TypeAksheyNo ratings yet

- Formulas, Facts and Figures PDFDocument13 pagesFormulas, Facts and Figures PDFश्रीराज् कथलियिल्No ratings yet

- Fricton Loss in Valves & FittingsDocument3 pagesFricton Loss in Valves & FittingsBen LimNo ratings yet

- TexasFlange - Bolt and Stud Dimensions ASME B16.5Document2 pagesTexasFlange - Bolt and Stud Dimensions ASME B16.5cristinelbNo ratings yet

- Standard Dimensions of Spectacle Blind ThicknessDocument10 pagesStandard Dimensions of Spectacle Blind ThicknessSubrata MukherjeeNo ratings yet

- Guia Parafusos, Arruelas E Porcas 1Document156 pagesGuia Parafusos, Arruelas E Porcas 1Adrian VerattiNo ratings yet

- 04 Tabla de Bridas y EsparragosDocument1 page04 Tabla de Bridas y EsparragosAlberto VELOSA ROANo ratings yet

- 04 Tabla de Bridas y EsparragosDocument1 page04 Tabla de Bridas y EsparragosDIEGO NAPOLEON RODRIGUEZ AGUILARNo ratings yet

- Tabla de Bridas y Esparragos y ComalesDocument1 pageTabla de Bridas y Esparragos y ComalesAlex el proNo ratings yet

- Doyles Catalog - GateValvesDocument5 pagesDoyles Catalog - GateValvesShag ShaggyNo ratings yet

- Screw Conveyor Components and DesignDocument3 pagesScrew Conveyor Components and DesignuripssgmailNo ratings yet

- BO Shifting Tool HuntingDocument2 pagesBO Shifting Tool HuntingMANUEL ISAZANo ratings yet

- Round Bend U-Bolts: 8%Row6Shflàfdwlrqv U-Bolts & 2 Nuts U-Bolts, Plates & 2 NutsDocument5 pagesRound Bend U-Bolts: 8%Row6Shflàfdwlrqv U-Bolts & 2 Nuts U-Bolts, Plates & 2 NutsRaging Red HippoNo ratings yet

- "Ju" Series Pulling ToolDocument1 page"Ju" Series Pulling ToolebeNo ratings yet

- Flange TableDocument2 pagesFlange TableTeodor Ioan Ghinet Ghinet DorinaNo ratings yet

- Flange APIDocument29 pagesFlange APIputujuliandikaNo ratings yet

- SAE and NPT Pipe and Port SizesDocument1 pageSAE and NPT Pipe and Port Sizeskasparob25No ratings yet

- Rope Socket DimensionsDocument1 pageRope Socket DimensionsmeryNo ratings yet

- Bolt Torquing Value (FT-LBS) For Spiral Wound Gasket Bolt Torquing Value (FT-LBS) For Spiral Wound GasketDocument2 pagesBolt Torquing Value (FT-LBS) For Spiral Wound Gasket Bolt Torquing Value (FT-LBS) For Spiral Wound GasketDhameemAnsariNo ratings yet

- Untitled 1Document8 pagesUntitled 1Ryanbruckshit IngkingNo ratings yet

- Obtegachi 1 PDFDocument4 pagesObtegachi 1 PDFSvetoslav SpasovNo ratings yet

- Steel Bar Grating Stair Tread DetailsDocument1 pageSteel Bar Grating Stair Tread DetailsJovito EdillonNo ratings yet

- Sandale IPS PE 3408 4710 Pipe ChartDocument2 pagesSandale IPS PE 3408 4710 Pipe ChartMarco Antonio Carrillo FalconNo ratings yet

- Preinstallation VerificationDocument5 pagesPreinstallation VerificationbalamuruganNo ratings yet

- Kant-Twist Clamps: Specifications SheetDocument3 pagesKant-Twist Clamps: Specifications SheetOmegacoolNo ratings yet

- Fillet Weld CapacityDocument1 pageFillet Weld CapacityjxsnyderNo ratings yet

- ChannelsDocument4 pagesChannelsjcNo ratings yet

- Section Properties (Fy 40 Ksi) : 1-1/2" Composite CellularDocument1 pageSection Properties (Fy 40 Ksi) : 1-1/2" Composite CellularIsbel PulidoNo ratings yet

- Table 1 Calculated Bolt Sizes: 2.4.8 Recommendations For Anchor Bolt and Foundation DesignDocument1 pageTable 1 Calculated Bolt Sizes: 2.4.8 Recommendations For Anchor Bolt and Foundation Designanwarali1975No ratings yet

- The Global Player: How to become "the logistics company for the world"From EverandThe Global Player: How to become "the logistics company for the world"No ratings yet

- CLASS X CHEMISTRY Solution-988039Document5 pagesCLASS X CHEMISTRY Solution-988039abiniveshofficial4708No ratings yet

- 201183-B-00-20 Part ListDocument19 pages201183-B-00-20 Part ListMohamed IsmailNo ratings yet

- Seasonal Variations in Kangra Tea QualityDocument6 pagesSeasonal Variations in Kangra Tea QualityashugulatiNo ratings yet

- Reusable Instrument Line en V8Document12 pagesReusable Instrument Line en V8Agon KarakashiNo ratings yet

- Courant: S. R. S. VaradhanDocument16 pagesCourant: S. R. S. Varadhan马牧之0% (1)

- Generator Protection PPT TurboDocument29 pagesGenerator Protection PPT TurbocheshankarNo ratings yet

- Brondizio Et Al 2009 Connectivity and The Governance of Multilevel Social Ecological Systems The Role of Social CapitalDocument29 pagesBrondizio Et Al 2009 Connectivity and The Governance of Multilevel Social Ecological Systems The Role of Social CapitalCHrisNo ratings yet

- Amphibians: Class AmphibiaDocument33 pagesAmphibians: Class Amphibiaisfi farihaNo ratings yet

- What Hetman Do I NeedDocument2 pagesWhat Hetman Do I NeedCem GüngörNo ratings yet

- Activity 7 Classifying of Sugars: Biochemistry LaboratoryDocument27 pagesActivity 7 Classifying of Sugars: Biochemistry LaboratoryWappy WepwepNo ratings yet

- Ostrich RacingDocument4 pagesOstrich RacingalexmadoareNo ratings yet

- PITE Ground Fault Locator GFL3836-User-manualDocument33 pagesPITE Ground Fault Locator GFL3836-User-manualMarinda FebriNo ratings yet

- Chemistry Final Exam PracticeDocument22 pagesChemistry Final Exam PracticeRida Muhammad RazaNo ratings yet

- Biocompatibility of Dental MaterialsDocument55 pagesBiocompatibility of Dental Materialsshivanshi jainNo ratings yet

- TM103 Chapter 1Document24 pagesTM103 Chapter 1johnnader1254No ratings yet

- Chapter 2 - DC Motor - SlidesDocument16 pagesChapter 2 - DC Motor - SlidesNurul ShathirahNo ratings yet

- Google - Cloud Digital Leader.v2023 06 22.q106Document50 pagesGoogle - Cloud Digital Leader.v2023 06 22.q106peacegroupngNo ratings yet

- Designing and Analysis of Pumping Solar PV System Using Pvsyst SoftwareDocument5 pagesDesigning and Analysis of Pumping Solar PV System Using Pvsyst SoftwareabfstbmsodNo ratings yet

- Research Report: G Fryer, J Carub, S MclverDocument7 pagesResearch Report: G Fryer, J Carub, S MclverMitchTolontanNo ratings yet

- Astm A570 1979Document5 pagesAstm A570 1979set_ltdaNo ratings yet

- Being and Power in Heidegger and FoucaultDocument14 pagesBeing and Power in Heidegger and Foucaultkostas8827No ratings yet

- Product Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5Document27 pagesProduct Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5marciocambruzziNo ratings yet

- CorrelationDoesntMeanCause WorksheetDocument8 pagesCorrelationDoesntMeanCause WorksheetYoung ThomzNo ratings yet

- Comparative Evaluation of Antibacterial Efficacy.9Document6 pagesComparative Evaluation of Antibacterial Efficacy.9Shivani DubeyNo ratings yet

- Magallona Vs ErmitaDocument13 pagesMagallona Vs ErmitaERNIL L BAWA100% (1)

- DSL & Its TypesDocument24 pagesDSL & Its TypesahmedNo ratings yet

- O Malley 2002 2Document284 pagesO Malley 2002 2Aziz NasutionNo ratings yet