Professional Documents

Culture Documents

63ea36cce4b081b6f18bd6e1 Original

63ea36cce4b081b6f18bd6e1 Original

Uploaded by

TM GamingCopyright:

Available Formats

You might also like

- Business Continuity PlanDocument40 pagesBusiness Continuity PlanSirengo Maurice100% (4)

- Sop ReceivingDocument6 pagesSop Receivingwaqaas125100% (2)

- Standard Costing & Variances ProblemDocument15 pagesStandard Costing & Variances Problemtaurus100% (4)

- Chapter 11 Hilton - SolutionsDocument11 pagesChapter 11 Hilton - SolutionsUmair Ayaz60% (5)

- LO215 - Production OrdersDocument380 pagesLO215 - Production OrdersrukometlasNo ratings yet

- Costing Chapterwise PYQsDocument192 pagesCosting Chapterwise PYQshet PanchalNo ratings yet

- 54605bos43769 p3Document25 pages54605bos43769 p3Mukesh jivrajikaNo ratings yet

- 49390bosqp Inter p3 Cp2Document3 pages49390bosqp Inter p3 Cp2Pranav ThiteNo ratings yet

- Cost and Management Accounting AssignmentDocument3 pagesCost and Management Accounting AssignmentSrabon BaruaNo ratings yet

- 1 Eoq PDFDocument12 pages1 Eoq PDFLyber Pereira100% (1)

- Cma Test 2 Solution Material Cost and Employee CostDocument3 pagesCma Test 2 Solution Material Cost and Employee CostdpgtransportserviceNo ratings yet

- CA Inter Costing Important Question For May22 @canotes IpccDocument100 pagesCA Inter Costing Important Question For May22 @canotes IpccChhaya JajuNo ratings yet

- Material Assignment PDFDocument21 pagesMaterial Assignment PDFjoeyNo ratings yet

- InventorymDocument7 pagesInventorymstudentofmmNo ratings yet

- Budgets For Control, Part 2Document29 pagesBudgets For Control, Part 2vukicevic.ivan5No ratings yet

- Costing - Type Wise Practical Mcq-Executive-RevisionDocument71 pagesCosting - Type Wise Practical Mcq-Executive-RevisionShruthi ParameshwaranNo ratings yet

- P1 Solution CMA JUNE 2020Document5 pagesP1 Solution CMA JUNE 2020Awal ShekNo ratings yet

- Accounting For MaterialsDocument12 pagesAccounting For MaterialsCrystal MtnzNo ratings yet

- Accounting and Management DDocument2 pagesAccounting and Management DKarìũki Wa MbìgìNo ratings yet

- DocxDocument15 pagesDocxAhsan IqbalNo ratings yet

- Absorption and Variable Costing, and Inventory Management: Discussion QuestionsDocument28 pagesAbsorption and Variable Costing, and Inventory Management: Discussion QuestionsParth GandhiNo ratings yet

- Cost Accounting Level 3/series 3-2009Document19 pagesCost Accounting Level 3/series 3-2009Hein Linn Kyaw100% (2)

- Category: (B) X 2,400 Units Y 1,800 Units X 4,800Document3 pagesCategory: (B) X 2,400 Units Y 1,800 Units X 4,800Abhijit HoroNo ratings yet

- MTP 3 16 Answers 1681098469Document13 pagesMTP 3 16 Answers 1681098469Umar MalikNo ratings yet

- MASQUIZDocument11 pagesMASQUIZGelyn CruzNo ratings yet

- ACC2052 T 3 SGDocument23 pagesACC2052 T 3 SGNitinNo ratings yet

- Lecture 16Document9 pagesLecture 16nikhilNo ratings yet

- Solved Case StudyDocument6 pagesSolved Case Studyasif lashariNo ratings yet

- Operations Management Krajewski 9th Edition Solutions ManualDocument24 pagesOperations Management Krajewski 9th Edition Solutions ManualMaryHowardcwzan100% (42)

- FFM1-Ch 2.1. Inventory ManagementDocument37 pagesFFM1-Ch 2.1. Inventory ManagementQuỳnhNo ratings yet

- Materials: Solutions To Assignment ProblemsDocument18 pagesMaterials: Solutions To Assignment ProblemsRahul Kumar Sharma 17No ratings yet

- Ilovepdf Merged PDFDocument666 pagesIlovepdf Merged PDFchandraNo ratings yet

- Week 4-Lecture Notes (L2)Document38 pagesWeek 4-Lecture Notes (L2)Kasmira K.Bathu GanesanNo ratings yet

- Materials Problem-1.Document2 pagesMaterials Problem-1.Tanvir Ahmed ChowdhuryNo ratings yet

- p1 Cima Workbook Q & A PDFDocument232 pagesp1 Cima Workbook Q & A PDFKamil Sanif100% (1)

- CMA Chapter 1 To 7 A - 29971676Document16 pagesCMA Chapter 1 To 7 A - 29971676Aryan SharmaNo ratings yet

- Test-1 (Cost and Management Accounting) CHAPTER-1,2,3: A-1 Workings: Monthly Production of X 30,000 KgsDocument9 pagesTest-1 (Cost and Management Accounting) CHAPTER-1,2,3: A-1 Workings: Monthly Production of X 30,000 KgsAtharv aNo ratings yet

- Full Download Foundations of Operations Management Canadian 4th Edition Ritzman Solutions ManualDocument22 pagesFull Download Foundations of Operations Management Canadian 4th Edition Ritzman Solutions Manualrigveda.nominalfcekbn100% (38)

- Foundations of Operations Management Canadian 4th Edition Ritzman Solutions ManualDocument26 pagesFoundations of Operations Management Canadian 4th Edition Ritzman Solutions ManualMaryMurphyatqb98% (55)

- Bosmtpfinaloldp 5 AnsDocument13 pagesBosmtpfinaloldp 5 AnsharoldpsbNo ratings yet

- Material Costing Practice ExamplesDocument9 pagesMaterial Costing Practice Examplesdoshiviraj77No ratings yet

- CostingDocument30 pagesCostingSanjana SharmaNo ratings yet

- PROBLEMSChap 7 SMDocument27 pagesPROBLEMSChap 7 SMVillena Divina VictoriaNo ratings yet

- Chapter 8 MowenDocument25 pagesChapter 8 MowenRosamae PialaneNo ratings yet

- NALO - Inventory Management - Asynchronous ActivityDocument3 pagesNALO - Inventory Management - Asynchronous Activitynaloma.juliacamilleNo ratings yet

- Question 1-1-1Document14 pagesQuestion 1-1-1Aqsa AnumNo ratings yet

- Exercises of Inventory ManagementDocument7 pagesExercises of Inventory ManagementĐức NguyễnNo ratings yet

- Assignment #3 InventoryDocument13 pagesAssignment #3 InventoryAnkit SainiNo ratings yet

- Inventory Control ModelDocument11 pagesInventory Control ModelMd Aulad Hossain100% (1)

- 4 2004 Jun ADocument9 pages4 2004 Jun Aapi-19836745No ratings yet

- LA53 - GSLC Materials & Labor Controlling, Costing, and Planning - 2602065105 - Karina OliviaDocument4 pagesLA53 - GSLC Materials & Labor Controlling, Costing, and Planning - 2602065105 - Karina OliviajaeminkkyuNo ratings yet

- Chapter 10 Solutions - Inclass ExercisesDocument12 pagesChapter 10 Solutions - Inclass ExercisesSummerNo ratings yet

- Chapter 2 Accounting For MaterialsDocument6 pagesChapter 2 Accounting For MaterialsJanina FranciscoNo ratings yet

- Revision Notes & Question May 2024 - CA Aman AgarwalDocument159 pagesRevision Notes & Question May 2024 - CA Aman Agarwalmayankpantgg.14No ratings yet

- Inventories ATs Garcia CristineJoy G BSA-1BDocument4 pagesInventories ATs Garcia CristineJoy G BSA-1BCj GarciaNo ratings yet

- Accounting For Materials: Problem 2.4Document11 pagesAccounting For Materials: Problem 2.4Liana Monica LopezNo ratings yet

- Visual Financial Accounting for You: Greatly Modified Chess Positions as Financial and Accounting ConceptsFrom EverandVisual Financial Accounting for You: Greatly Modified Chess Positions as Financial and Accounting ConceptsNo ratings yet

- EFC 2000 2001 AccountsDocument31 pagesEFC 2000 2001 AccountsKeeping Everton In Our CityNo ratings yet

- Front Page FormatDocument7 pagesFront Page FormatArunKumarNo ratings yet

- Strategic Development at Virgin 2013: About The Virgin GroupDocument6 pagesStrategic Development at Virgin 2013: About The Virgin GrouphjNo ratings yet

- Tchaikovsky, Peter Ilyitch The Seasons Op.37Document0 pagesTchaikovsky, Peter Ilyitch The Seasons Op.37Paul LinNo ratings yet

- Xtraex 03Document4 pagesXtraex 03friendlylionNo ratings yet

- Rupees in '000 Rupees in '000: Balance Sheet 2008 2009Document22 pagesRupees in '000 Rupees in '000: Balance Sheet 2008 2009Ch Altaf HussainNo ratings yet

- Chapter 4Document17 pagesChapter 4Genanew AbebeNo ratings yet

- Liran Farm Kamis - SignedDocument1 pageLiran Farm Kamis - SignedGustu LiranNo ratings yet

- Lenovo Case StudyDocument5 pagesLenovo Case Studycharantejch100% (1)

- Matrix Safety & Loss Control Overview)Document10 pagesMatrix Safety & Loss Control Overview)Rahul_Gohil_1376No ratings yet

- Part Submission WarrantDocument1 pagePart Submission WarrantMahes kumarNo ratings yet

- The Revenue Cycle: Sales and Cash Collections: Suggested Answers To Discussion Questions 10.1Document45 pagesThe Revenue Cycle: Sales and Cash Collections: Suggested Answers To Discussion Questions 10.1roselle0212No ratings yet

- Woodland Project ReportDocument30 pagesWoodland Project ReportVicky Singh100% (1)

- BPM Vs SharepointDocument8 pagesBPM Vs SharepointalejandromoninaNo ratings yet

- JADUAL KOD BANK TERKINI (Kemaskini 10012022)Document1 pageJADUAL KOD BANK TERKINI (Kemaskini 10012022)DygKuNormarzuraNo ratings yet

- Routing TypesDocument87 pagesRouting TypesAlwin Lasarudin100% (3)

- AtulDocument45 pagesAtulabhishek singhNo ratings yet

- CFMitonUKSmallerCompanies FactsheetDocument2 pagesCFMitonUKSmallerCompanies Factsheetmissteeray 1No ratings yet

- International Trade TestDocument2 pagesInternational Trade TestFifi FifilacheNo ratings yet

- Mohammad Abu Taher: Apply For: QA/QC (Senior Piping Welding Inspector) Personal DetailsDocument10 pagesMohammad Abu Taher: Apply For: QA/QC (Senior Piping Welding Inspector) Personal DetailsRajkumar ANo ratings yet

- Well Service Fluid Ends // 2013: Smart Solutions. Powerful ProductsDocument10 pagesWell Service Fluid Ends // 2013: Smart Solutions. Powerful ProductsShoppingpak comNo ratings yet

- Labor Relations NotesDocument24 pagesLabor Relations NotesJunior Felipz100% (1)

- Backward On Linkages in The Textile and Clothing Sector of BangladeshDocument13 pagesBackward On Linkages in The Textile and Clothing Sector of Bangladeshtdebnath_3No ratings yet

- Corporate Social Responsibility: Doing The Most Good For Your Company and Your CauseDocument69 pagesCorporate Social Responsibility: Doing The Most Good For Your Company and Your CauseNabilaNo ratings yet

- Envision AssignmentDocument6 pagesEnvision AssignmentAnkushNo ratings yet

- Retroactive Price in Procurement CloudDocument14 pagesRetroactive Price in Procurement CloudranvijayNo ratings yet

- Retail ManagementDocument10 pagesRetail ManagementPRANAV GOYALNo ratings yet

63ea36cce4b081b6f18bd6e1 Original

63ea36cce4b081b6f18bd6e1 Original

Uploaded by

TM GamingOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

63ea36cce4b081b6f18bd6e1 Original

63ea36cce4b081b6f18bd6e1 Original

Uploaded by

TM GamingCopyright:

Available Formats

www.escholars.

in

Assignment

Material Cost

Q. Questions & Solutions

No.

1. A Company manufactures 5000 units of a product per month. The cost of placing an order

is ₹100. The purchase price of the raw material is ₹10 per kg. The re-order period is 4 to 8

weeks. The consumption of raw materials varies from 100 kg to 450 kg per week, the

average consumption being 275 kg. The carrying cost of inventory is 20% per annum.

You are required to Calculate: -

a) Re-Order Quantity.

b) Re-Order Level.

c) Maximum Level.

d) Minimum Level.

e) Average Stock Level.

(Nov. 2002, May 2006, Nov 2018, ICAI SM, Modified Nov. 2022, MTP July 2021)

Ans. a) Re-Order Quantity;

When price discount is not involved re-order quantity should be such a quantity of

ordering/order at which the total cost of ordering and carrying inventory p.a. is the

least. This is known as EOQ.

Calculate as under: -

2AO

EOQ; =√

C

✓ A = Annual Requirement = Avg. Consumption per week × 52 weeks.

= 275 kg. week × 52 weeks

= 14,300 kgs.

✓ O = Ordering Cost/Order = ₹ 100 per order

✓ P= Price per unit = ₹ 10 per kg.

✓ C = Stock Holding rate p.a. = 20 %

✓ C = Carrying Cost/unit p.a. = ₹ 10 × 20% = ₹ 2

2×14,300×100

=√ 2

= √14,30,000

= 1,196 kgs (approx. )

b) Re-Order Level; = Maximum Usage × Maximum Lead Time

= 450 kgs. per week × 8 week

= 3,600 kgs.

c) Maximum Level; = Reorder Level + Reorder Qty – (Minimum Usage × Minimum

Lead Time)

= 3,600 kg. + 1,196 kg. - (100 kgs per week × 4 weeks)

= 4,796 kgs.−400 kgs.

= 4,396 kgs.

d) Minimum Level; Re-order Level−(Average Usage × Average Lead Time)

100+450 4+8

= 3,600 kgs - [( 2 ) + ( 2 )]

= 3,600− (275 ×6)

= 3,600− 1,650

=1,950 kgs.

888 888 0402 support@escholars.in 1

www.escholars.in

e) Average Stock =

Maximum Level+Minimum Level

Level; 4396 + 1950

2

= 2

= 3,173 kgs.

Alternatively;

1

Average Stock Level = Minimum Level + (2 × Re − Order Qty. )

1196

= 1,950 kgs. + ( kg. ) = 1,950 + 598 kg. = 2,548 kgs.

2

2 From the following data for the year ended 31st March, 20X2, Calculate the inventory

turnover ratio of the two items and put forward your comments on them.

Particulars Material A (₹) Material B (₹)

✓ Opening Stock 1.04.20X1 10,000 9,000

✓ Purchase during the year 52,000 27,000

✓ Closing Stock 31.3.20X2 6,000 11,000

(ICAI SM, May 2018, RTP Nov-2021, Modified Dec 2021)

[Hint: The number of days for which the average inventory is held]

Ans. 1) Inventory Turnover ratio; (Consumption ÷ Average inventory)

Cost of Materials Consumed Material A Material B

(₹) (₹)

✓ Opening Stock 10,000 9,000

✓ Add: Purchases 52,000 27,000

62,000 36,000

✓ Less: Closing Stock 6,000 11,000

✓ Materials Consumed 56,000 25,000

✓ Average inventory: (Opening Stock + Closing 8,000 10,000

Stock) ÷ 2

✓ Inventory Turnover ratio; 7 Times 2.5 times

2) Average no. of days of Inventory holding= (Number 52 days 146 days

of Days in a year/ IT ratio)

Comments;

*Material A is moving faster than Material B.

3. A Company uses four raw materials A, B, C and D for a particular’s product for which

the following data apply: -

Raw Usage Re-order Price Delivery period Re- Minimum

Material Per Unit Quantity Per (in weeks) Order Level

Of (kg.) kg. Level (kg.)

Product (₹) (kg.)

(Kg.)

Min. Avg. Max.

A 12 12,000 12 2 3 4 60,000 ?

B 8 8,000 22 5 6 7 70,000 ?

C 6 10,000 18 3 5 7 ? 25,500

D 5 9,000 20 1 2 3 ? ?

Weekly production varies from 550 to 1,250 units, averaging 900 units of the said

product. What would be the following quantities:-

a) Minimum Stock of A?

b) Maximum Stock of B?

c) Re-Order level of C?

d) Average Stock level of A?

888 888 0402 support@escholars.in 2

www.escholars.in

e) Re-Order Level of D?

f) Minimum Stock Level of D?

(RTP Nov. 2020, ICAI SM, Modified Nov. 2022)

Ans. a) Minimum Stock of A;

Re-Order Level− (Average Consumption × Average Time Required to obtain delivery)

= 60,000 kg. – (900 units × 12 kg. × 3 weeks)= 27,600 kg.

b) Maximum Stock of B;

Re-Order Level + Re-Order Quantity – (Minimum. Consumption × Minimum Re-Order

Period.)

= 70,000 kg. + 8,000 kg− (550 Units × 8 kg × 5 weeks).

= 78,000−22,000=56,000 kg.

c) Re-Order Level of C;

Maximum Re-Order Period × Maximum Usage

= 7 weeks × (1,250 Units × 6 Kg.) = 52,500 kg.

OR

= Minimum Stock Level of C + (Average Consumption × Average delivery time)

= 25,500 kg + [(900 units × 6 kg) × 5 weeks] = 52,500 kg.

d) Average Stock Level of A;

Minimum Stock Level + Maximum Stock Level

= 2

(Refer to Working Note)

27,600+58,800

= = 43,200 kg.

2

Working Notes: -

Maximum Stock of A = ROL + ROQ− (Minimum Consumption × Minimum Re-Order

Period.)

= 60,000 kg + 12,000 kg – [(550 units × 12 kg.) × 2 weeks] = 58,800 kg.

e) Re-Order Level of D;

Maximum Re-Order Period × Maximum Usage

= 3 weeks × (1,250 units × 5 kg) = 18,750 kg

f) Minimum Stock of D;

Re-Order Level−(Average Consumption × Average time required to obtain delivery)

= 18,750 kg. – (900 units × 5 kg. × 2 weeks) = 9,750 kg.

4. a) EXE Limited has received an offer of quantity discounts on its order of materials as

under;

Price per ton (₹) Ton (Nos.)

1,200 Less than 500

1,180 500 and less than 1,000

1,160 1,000 and less than 2,000

1,140 2,000 and less than 3,000

1,120 3,000 and above.

The annual requirement for the material is 5,000 tons. The ordering Cost per order is

₹1,200 and the Stock holding cost is estimated at 20% of material cost per annum. You

are required to Compute the most economical purchase level.

b) What will be your answer to the above question if there are no discounts offered and

the price per ton is ₹1,500?

(ICAI SM, Nov 2004)

888 888 0402 support@escholars.in 3

www.escholars.in

Ans. a)

Total Order No. of Cost of Ordering Carrying Total

Annual Size Orders Inventory Cost Cost Cost

Requirement (Tone) A/Q A × Per tonne A/Q × ₹ p. t. p.a. (4+5+6)

(A) (Q) Cost 1200 1/2 × Q × (₹)

(₹) (₹) 20% of Cost

p.u.

(₹)

1 2 3 4 5 6 7

5,000 400 12.5 60,00,000 48,000

(13)* 15,600 60,63,600

Ton (5,000×₹1200) (200×₹240)

500 10 59,00,000 12,000 59,000 59,71000

(5,000×₹1180) (250×₹236)

1,000 5 58,00,000 6,000 1,16,000 59,22,000

(5,000×₹ 1160) (500×₹232)

2,000 2.5 57,00,000 2,28,000 59,31,600

(3)* 3,600

(5,000×₹1140) (1,000×₹228)

3,000 1.666 56,00,000 3,36,000

(2)* 2,400

(5,000×₹1120) (1,500×₹224) 59,38,400

*Since number of orders cannot be in decimals, thus 12.5 orders are taken as 13 orders,

2.5 are taken as 3 order and 1.66 orders are taken as 2 orders.

The above table shows that the total cost of 5,000 units including ordering and carrying

cost is minimum (₹59,22,000) when the order size is 1,000 units. Hence the most

economical purchase level is 1,000 units.

b) If there are no discounts offered then the purchase quantity should be equal to EOQ.

The EOQ is as follows;

2 AO

EOQ = √ C

Where,

A = annual inventory requirement,

O= Ordering cost per order and

C= Carrying Cost per unit per annum.

2×5,000 units×₹ 1,200

=√ 20%×₹ 1,500

= 200 units

5. KL Limited produces product ‘M’ Which has a quarterly demand of 8,000 units. The product

requires 3 kgs. Quantity of material ‘X’ for every finished unit of product. The other

information are follows;

✓ Cost of material ‘X’ = ₹ 20 per kg.

✓ Cost of placing an order = 1,000 per order

✓ Carrying Cost = 15% per annum of average inventory

You are required: -

a) Calculate the Economic Order Quantity for Material ‘X’.

b) Should the company accept an offer of 2 percent discount by the supplier, if they want

to supply the annual requirement of material ‘X’ in 4 equal quarterly Instalments?

(May 2012, Modified Nov. 2019, Modified MTP Nov 2020)

Ans. Annual demand of material ‘X’

= 8000 units (per quarter) × 4 (No. of Quarter in a year) × 3 kgs. (for every finished product)

= 96,000 kgs.

888 888 0402 support@escholars.in 4

www.escholars.in

a) Calculation of Economic Order Quantity (EOQ) for material ‘X’.

2×Annual demand ×Ordering Cost

EOQ = √

Carrying cost per unit per annum

2×96,000×1000

=√ 20×15%

= 8,000 kg.

b) Analysis of Cost under different options of ‘order quantity’.

Particulars When EOQ is When discount of 2% is

ordered accepted and supply is in 4

equal instalments

Order size 8,000 kgs. 96,000

= 24,000 kgs.

4

No. of order 96,000 kgs

= 12

96,000 kgs

=4

8,000 kgs 24,000 kgs

Purchase Cost per kg. ₹ 20 (20− 2% ₹ 20) = ₹ 19.60

Total Purchase Cost (A) (96,000 kgs.× ₹ 20) (96,000 kgs.× 19.6)

= ₹ 19,20,000 = ₹ 18,81,600

Ordering Cost (B) 12 orders × ₹ 1000 4 orders × ₹ 1,000

= ₹ 12,000 = ₹ 4,000

Carrying Cost (C) 8,000 kgs

× 15% × 20

24,000 kgs

× 15% × 19.6

2 2

= ₹ 12,000 = ₹ 35,280

Total Cost (A+B+C) ₹ 19,44,000 ₹ 19,20,880

Advice: -

The total Cost is lower if Company accept an offer at 2% discount by the supplier, when

supply of the annual requirement of material ‘X’ is made in 4 equal instalments. Hence, the

company should accept the offer of 2% discount.

6. Arnav Electronics manufactures electronic home appliances. It follows weighted average

Cost method for inventory valuation. Following are the data of component:

Date Particulars Units Rate per units

15-12-X1 Purchase Order- 008 10,000 9,930

30-12-X1 Purchase Order- 009 10,000 9,780

01-01-X2 Opening Stock 3,500 9,810

05-01- X2 GRN*- 008 (against the Purchase Order- 10,000 ----

008)

05-01- X2 MRN**-003 (against the Purchase Order- 500 ----

008)

06-01- X2 Material Requisition-011 3,000 ----

07-01- X2 Purchase Order- 010 10,000 9,750

10-01- X2 Material Requisition-012 4,500 ----

12-01- X2 GRN-009 (against Purchase Order-009) 10,000 ----

12-01- X2 MRN-004 (against the Purchase Order- 400 ----

009)

15-01- X2 Material Requisition-013 2,200 ----

24-01- X2 Material Requisition-014 1,500 ----

25-01- X2 GRN-010 (against the Purchase Order- 10,000 ----

010)

28-01- X2 Material Requisition- 0.15 4,000 ----

30-01- X2 Material Requesiton-016 3,200 ----

*GRN-Goods Received Not; ** MRN-Material Required Note

Based on the above data, you are required to Calculate;

888 888 0402 support@escholars.in 5

www.escholars.in

a) Re-order level

b) Maximum Stock level

c) Minimum Stock level

d) Prepare Store Ledger for the period January 20X2 and determine the value of Stock as

on 31-01-20X2.

e) Value of Components used during the month January, 20X2.

f) Inventory turnover ratio.

(ICAI SM, RTP May 2020)

Ans. Calculation: -

a) Re-Order Level;

= Maximum Usage × Maximum lead time

= 4,500 units × 21 days = 94,500 units

b) Maximum Stock Level;

= Re − order level + Re − order Quantity − (Min. Usage × Min. lead time)

= 94,500 Units + 10,000 units − (1,500 units × 13 days)

= 1,04,500 units − 19,500 units = 85,000 units.

c) Minimum Stock Level;

= Re − order level − (Average Consumption × Average lead time)

= 94,500 units − (3,000 units × 17days)

= 94,500 units − 52,500 units

= 43,500 units

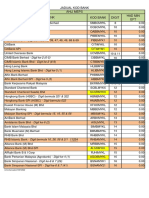

d) Store Ledger for the month of January 20X2; (Weighted Average Method);

Date Receipts Issue Balance

GRN/ Units Rate (₹) MRN Units Rate (‘000’) Units Rate (₹)

MRN (‘000’) /MR (‘000’)

01-01-X2 ---- ---- ---- ---- ---- ---- ---- 3500 9,810 34,335

05-01- 008 10,000 9,930 99,300 003 500 9,930 4,965 13,000 9,898 1,28,670

X2

06-01- ---- ---- ---- ---- 011 3,000 9,898 29,694 10,000 9,898 98,980

X2

10-01- ---- ---- ---- ---- 012 4,500 9,898 44,541 5,500 9,898 54,439

X2

12-01- 009 10,000 9,780 97,800 004 400 9,780 3,912 15,100 9,823 1,48,327

X2

15-01- ---- ---- ---- ---- 013 2.200 9,823 21,611 12,900 9,823 1,26,716

X2

24-01- ---- ---- ---- ---- 014 1,500 9,823 14,734 11,400 9,823 1,11,982

X2

25-1- X2 010 10,000 9,750 97,500 ---- ---- ------ 21,400 9,789 2,09,482

28-01- ---- ---- ---- ---- 015 4,000 9,789 39,156 17,400 9,789 1,70,328

X2

30-01- ---- ---- ---- ---- 016 3,200 9,789 31,325 14,200 9,789 1,39,004

X2

e) Value of components used during the month of January 20X2:

Sum of material requisitions 011 to 016 (‘000)

= ₹29,694 + ₹44,541 + ₹21,611 + ₹ 14,734 + ₹ 39,156 + ₹ 31,325

= ₹1,81,061

888 888 0402 support@escholars.in 6

www.escholars.in

f) Inventory Turnover Ratio

Value of material consumed

Inventory Turnover Ratio =

Average Inventory

1,81,061 1,81,061

Inventory Turnover Ratio = = = 2.09

(1,39,004 + 34,335)/2 86,669.5

Workings: -

Consumption is Calculated on the basis of Material Requisitions: -

Maximum component usage = 4,500units (Material requisition on 10 − 01 − X2)

Minimum component usage = 1,500 units (Material requisition on 24 − 01 − X2)

Lead time is calculated from purchase order date to material received date;

Maximum lead time = 21 days (15 − 12 − 20X1 to 05 − 01 − 20X2)

Minimum lead time = 13 days (30 − 12 − 20X1 to 12 − 01 − 20X2)

Re-order quantity (observed) = 10,000 units

Date Material Requisition Units

number

06-01-20X2 11 3,000

10-01-20 X2 12 4,500 (Maximum)

15-01-20 X2 13 2,200

24-01-20 X2 14 1,500 (Minimum)

28-01-20 X2 15 4,000

30-01-20 X2 16 3,200

7. A Company manufactures a product from a raw material, which is purchased at ₹ 80 per kg.

The Company incurs a handling cost of ₹ 370 plus freight of ₹ 380 per order.

The incremental carrying cost of inventory of raw materials is ₹ 0.25 per kg per month. In

addition, the cost of working capital finance on the investment in inventory of raw material

is ₹ 12 per kg per annum. The annual production of the product is 1,00,000 units and 2.5

units are obtained from one kg. of raw material.

Required: -

a) Calculate the economic order quantity of raw materials.

b) Advise, how frequently company should order for procurement be placed.

c) If the company proposes to rationalize placement of orders on quarterly basis, what

percentage of discount in the price of raw materials should be negotiated?

Assume 360 days in a year.

(May 2014, Modified Nov 2020, Modified MTP May 2020)

Ans. a) Economic Order Quantity;

2 AO

EOQ = √ C

2×40,000 ×750

=√ 15

= 2,000 kg.

A = Annual units required

1,00,000

= 2.5

= 40,000 kg.

Ordering Cost = O = 370 + 380 = ₹ 750

Carrying Cost = C = 12 + 3= 15

(∵ Incremental carrying cost = 0.25 p.m. / per kg.)

888 888 0402 support@escholars.in 7

www.escholars.in

b) Computation of days of placing Next Order;

For 40,000 units – 360 days

For 2,000 units − ? days

2,000×360

Days required = 40,000

= 18 days.

Alternative;

Frequency of placing orders for procurement;

Annual Consumption (A) = 40,000 kg.

Quantity per order (E.O.Q) = 2,000 kg.

A 40,000 kg

No. of orders per annum (E.O.Q) = 2,000 𝑘𝑔 = 20 orders.

360 days

Frequency of placing orders (in days) = 20 orders

= 18 days

c) Percentage of discount in the price of raw materials to be negotiated:

Particulars On Quarterly Basis On E.O.Q. Basis

1) Annual Usage (in kg.) 40,000 kg. 40,000 kg.

2) Size of the order 10,000 kg. 2,000 kg.

3) No. of orders (1÷2) 4 20

4) Cost of placing orders or ₹ 3000 ₹ 15,000

Ordering cost (No. of orders × (4 orders × ₹ 750) (20 orders × ₹ 750)

Cost per order)

5) Inventory Carrying Cost ₹ 75,000 ₹ 15,000

(Average inventory × Carrying (10,000 kg × ½ × ₹15) (2,000 kg × ½ × ₹15)

cost per unit)

6) Total Cost (4 + 5) ₹ 78,000 ₹ 30,000

When order is placed on quarterly basis the ordering cost and carrying cost increased

by ₹ 48,000 (₹ 78,000− ₹ 30,000).

So, discount required = ₹ 48,000

Total annual purchase = 40,000 kg. × ₹ 80 = ₹ 32,00,000.

Therefore, Percentage of discount to be negotiated

₹ 48,000

= ₹ 32,00,000 × 100 = 1.5%.

8. Calculate the Economic Order Quantity from the following information. Also State the

number of orders to be placed in a year.

Consumption of Materials per annum 10,000 kg.

Order placing Cost per order ₹ 50

Cost per kg. of raw Materials ₹2

Storage Costs 8% on average inventory

(ICAI SM)

Ans. 2×A×o

Economic Order Quantity = √ C

A = Units Consumed during year = 10,000

O = Ordering Cost per order = 50

C = Inventory Carrying Cost per unit per annum, = 8% of ₹ 2

2×10,000×50

Economic Order Quantity = √ 2×8 = 𝟐, 𝟓𝟎𝟎 𝐤𝐠

100

Total Consumption of Materials per annum

No. of orders to be placed in a year =

EOQ

10,000 kg.

No. of orders to be placed in a year = 2,500 kg.

= 𝟒 𝐎𝐫𝐝𝐞𝐫𝐬 𝐩𝐞𝐫 𝐲𝐞𝐚𝐫

888 888 0402 support@escholars.in 8

www.escholars.in

9. a) Compute E.O.Q and the total cost for the following;

✓ Annual Demand = 5,000 units

✓ Unit price = ₹ 20.00

✓ Order Cost = ₹ 16.00

✓ Storage rate = 2% per annum

✓ Interest rate = 12% per annum

✓ Obsolescence rate = 6% per annum

b) Determine the total cost that would result for the items if a new price of ₹12.80 is used.

(ICAI SM)

Ans. 2 AO

a) Economic Order Quantity = √ C

Carrying cost (C)

✓ Storage rate = 2%

✓ Interest Rate = 12%

✓ Obsolescence Rate = 6%

Total = 20% per annum

✓ C = 20% of ₹ 20 = ₹ 4 per unit per annum

2×5000×16

=√ = √40,000 = 200 Units.

4

Total Cost: -

Particulars (₹)

✓ Purchase price of 5,000 units @ ₹ 20.00 per unit = ₹ 1,00,000

✓ Ordering Cost =

5000

= 25 orders@ ₹ 16 = ₹ 400

200

✓ Carrying cost of average inventory =

200

= = ₹ 400

2

100 units @ ₹ 4

Total Cost ₹ 1,00,800

b) If the new price of ₹12.80 used;

C =20% of 12.80 =₹ 2.56 per unit per annum.

2×5,000×16

Economic Order Quantity = √ 2.56

= 250 units

Total Cost;

Particulars (₹)

✓ Purchase price of 5,000 units @ ₹ 12.80 per unit = 64,000

5,000

✓ Ordering Cost = 250 = 20 Orders @ ₹ 16 = 320

✓ Carrying cost (of average inventory) =

250

= 125 units @ ₹ 2.56 = 320

2

Total Cost 64,640

10. From the details given below. Calculate;

a) Re-Ordering level

b) Maximum level

c) Minimum level

d) Danger level.

Re-Ordering quantity is to be calculated on the basis of following information;

i) Cost of placing a purchase order is ₹ 20

ii) Number of units to be purchased during the year is 5,000

iii) Purchase price per unit inclusive of transportation cost is ₹ 50

iv) Annual cost of storage per units is ₹ 5.

888 888 0402 support@escholars.in 9

www.escholars.in

v) Details of lead time: - Average −10 days, Maximum – 15 days, Minimum−5 days for

emergency purchases−4 days.

vi) Rate of consumption: - Average 15 units per day, Maximum: 20 units per day.

(ICAI SM 2 times)

Ans. Computations;

a) (ROL) Re-Ordering level;

− = Maximum usage per period × Maximum lead time

− = 20 units per day × 15 days = 300 units.

b) Maximum level;

− ROL + ROQ−[Min.rate of consumption × Min. (Refer to working notes 1 and 2)

lead time]

− = 300 units + 200 units –[10 units per day × 5 days]

− = 450 Units.

c) Minimum level;

− = ROL−Average rate of consumption × Average re-order period

− = 300 units− (15 units per day × 10 days) = 150 Units.

d) Danger level;

= Average Consumption × Lead time for emergency purchases

= 15 units per day × 4 days = 60 Units.

Working Notes: -

1) Minimum rate of consumption per day

Minimum rate of Maximum rate of

+

Consumption Consumption

− Average rate of consumption =

2

X units/day+20 units per day

− 15 units per day = 2

or X = 10 units per day

2) Re-order Quantity (ROQ) or Economic Order Quantity (EOQ)

2×5,000 units×₹20

=√ = 200 units

5

A (Number of units to be purchased annually) = 5,000 units

O (Ordering cost per order) = ₹ 20

C (Annual cost of storage per unit) =₹5

Purchase price per unit inclusive of transportation cost = ₹ 50.

11. M/s Tyro tubes trades in four-wheeler tyres and tubes. It stocks sufficient quantity of tyres

of almost every vehicle. In year and 202X-X1, the report of sales manager revealed that M/s

Tyro tubes experienced stock-out of tyres.

The Stock-out data is as follows: -

Stock-Out of No. of times of

Tyres Stock Out

100 2

80 5

50 10

20 20

10 30

0 33

888 888 0402 support@escholars.in 10

www.escholars.in

M/s Tyro tubes loses ₹150 per unit due to stock-out and spends ₹50 per unit on carrying of

inventory.

Determine optimum safest stock level.

(ICAI SM)

Ans. Computation of Stock-out and Inventory Carrying Cost;

Safety Stock Probability Stock Expected Inventory Total

Stock Out (3) Out Cost Stock-out Carrying Cost (₹)

Level (Units) (₹) Cost (₹) Cost (7) = (5)

(Units) (2) (4) = (2) (5) = (3) (₹) + (6)

(1) × ₹ 150 × (4) (6) = (1) ×

₹ 50

100 0 0.00 0 0 5,000 5,000

80 20 0.02 3,000 60 4,000 4,060

50 50 0.02 7,500 150

30 0.05 4,500 225

12,000 375 2,500 2,875

20 80 0.02 12,000 240

60 0.05 9,000 450

30 0.10 4,500 450

25,500 1,140 1,000 2,140

10 90 0.02 13,500 270

70 0.05 10,500 525

40 0.10 6,000 600

10 0.20 1,500 300

31,500 1,695 500 2,195

0 100 0.02 15,000 300 2,700

80 0.05 12,000 600

50 0.10 7,500 750

20 0.20 3,000 600

10 0.30 1,500 450

39,000 2,700 0 2,700

At Safety Stock level of 20 units, total cost is least i.e., ₹2,140.

Working Notes: -

Computation of Probability of Stock-out;

✓ Stock-out (units) 100 80 50 20 10 0 Total

✓ Nos. of times 2 5 10 20 30 33 100

✓ Probability 0.02 0.05 0.10 0.20 0.30 0.33 1.00

12. From the following details, Draw a plan of ABC selective control;

Items Units Units Cost (₹)

1 7,000 4.450

2 4,000 19.140

3 1,500 8.90

4 29,000 0.180

5 10,000 8.190

6 40,000 0.450

7 60,000 0.180

8 13,000 0.980

9 10,000 0.205

10 29,000 0.360

11 11,500 6.320

12 4,000 5.220

(ICAI SM)

888 888 0402 support@escholars.in 11

www.escholars.in

Ans. Statement of Total Cost and Ranking;

Item Units % of Units Total % of Ranking

Total Cost (₹) Cost (₹) Total

Units Cost

1 7,000 3.1963 4.450 31,150 8.7557 4

2 4,000 1.8265 19.140 76,560 21.5195 2

3 1,500 0.6849 8.90 13,350 3.754 7

4 29,000 13.2420 0.180 5,220 1.4672 11

5 10,000 4.5662 8.190 81,900 23.0205 1

6 40,000 18.2648 0.450 18,000 5.0594 6

7 60,000 27.3973 0.180 10,800 3.0357 9

8 13,000 5.9361 0.980 12,740 3.5810 8

9 10,000 4.5662 0.205 2050 0.5762 12

10 29,000 13.2420 0.360 10,440 2.9345 10

11 11,500 5.2511 6.320 72,680 20.4289 3

12 4,000 1.8265 5.220 20,880 5.8690 5

2,19,000 100 3,55,770 100

Basis for selective control (Assumed)

− ₹ 50,000 & above ---- ‘A’ Item

− ₹ 13,000 to 50000 ---- ‘B’ Item

− Below ₹13,000 ---- ‘C’ Item

On this basis, a plan of A, B C selective control is given below;

Ranking Item % of Total Cost (d) % of Total Category

Nos. Units Cost

1 5 4.5662 81,900 23.0205

2 2 1.8265 76,560 21.5195

3 11 5.2511 72,680 20.4289

Total 3 11.6438 2,31,140 64.9689 A

4 1 3.1963 31,150 8.7557

5 12 1.8265 20,880 5.8690

6 6 18.2648 18,000 5.0594

7 3 0.6849 13,350 3.7524

Total 4 23.9726 83,380 23.4365 B

8 8 5.9361 12,740 3.5810

9 7 27.3973 10,800 3.0357

10 10 13.2420 10,440 2.9345

11 4 13.2420 5,220 1.4672

12 9 4.5662 2050 0.5762

Total 5 64.3836 41,250 11.5946 C

Grand Total 12 100 3,55,770 100

1) Advantages of ABC analysis: - The advantages of ABC analysis are the following: -

a) Continuity in production: - It ensures that, without there being any danger of

interruption of production for want of materials or stores, minimum investment

will be made in inventories of stocks of materials or stocks to be carried.

b) Lower Cost: - The Cost of placing orders, receiving goods and maintaining stocks

is minimised specially if the system is coupled with the determination of proper

economic order quantities.

888 888 0402 support@escholars.in 12

www.escholars.in

c) Less attention required: - Management time is saved since attention need to be

paid only to some of the items rather than all the items, as would be the case if the

ABC system was not in operation.

d) Systematic working: - With the introduction of the ABC system, much of the work

connected with purchases can be systematized on a routine basis, to be handled by

subordinate staff.

13. A Factory uses 4,000 varieties of inventory. In terms of inventory holding and inventory

usage, the following information is compiled;

No. of varieties of % % Value of inventory % Of inventory

inventory holding (average) usage (in end-

product)

3,875 96.875 20 5

110 2.750 30 10

15 0.375 50 85

4,000 100.00 100 100

Classify the items of inventory as per ABC analysis with reason. (ICAI SM)

Ans. Classification of the items of inventory as per ABC analysis;

1) 15 number of varieties of inventory items should be classified as ‘A’ category

items because of the following reasons;

a) Constitute 0.375% of total number of varieties of inventory handled by stores of

factory. Which is minimum as per given classification in the table.

b) 50% of total use value of inventory holding (average), which is maximum,

according to the given table.

c) Highest in consumption, about 85% of inventory usage (in end-product).

2) 110 number of varieties of inventory items should be classified as ‘B’ category

items because of the following reasons;

a) Constitute 2.750% of the total number of varieties of inventory items handled by

stores of factory.

b) Requires moderate investment of about 30% of total use value of inventory

holding (average).

c) Moderate in consumption, about 10% of inventory usage (in end-product)

3) 3,875 number of varieties of inventory items should be classified as ‘C’ category

items because of the following reasons;

a) Constitute 96.875% of total varieties of inventory items handled by stores of

factory.

b) Requires about 20% of total use value of inventory holding (average.)

c) Minimum inventory consumption, i.e., about 5% of inventory usage (in end-

product).

14. The following transactions in respect of material Y occurred during the six months ended

30th June, 202X;

Month Purchase Price per unit (₹) Issued units

(units)

✓ January 200 25 Nil

✓ February 300 24 250

✓ March 425 26 300

✓ April 475 23 550

✓ May 500 25 800

✓ June 600 30 400

888 888 0402 support@escholars.in 13

www.escholars.in

Required: -

a) The Chief Accountant argues that the value of closing stock remains the same no matter

which method of pricing of material issues is used. Do you agree? Why or why not?

Explain. Detailed stores ledgers are not required.

b) State When and Why would you recommend the LIFO method of pricing material

issues?

(ICAI SM)

Ans. a) Total number of units purchase = 2,500

✓ Total number of units issued = 2,300

✓ The Closing Stock at the end of six months’ period i.e., on 30th June, 202X will be

200 units.

✓ Up to the end of May 202X, total purchases coincide with the total issues i.e., 1,900

units. It means that at the end of May 202X, there was no closing stock. In the month

of June 202X, 600 units were purchased out of which 400 units were issued. Since

there was only one purchase and one issue in the month of June, 202X and there

was no opening Stock on 1st June 202X, the Closing Stock of 200 units is to be valued

at ₹30 per unit.

✓ In the view of this, the argument of the Chief Accountant appears to be correct.

Where there is only one purchase and one issue in a month with no opening Stock,

the method of pricing of material issues becomes irrelevant. Therefore, in the given

case one should agree with the argument of the Chief Accountant that the value of

closing stock remains the same no matter which method of pricing the issue is used.

✓ It may, however, be noted that the argument of Chief Accountant would not stand if

one finds the value of the Closing Stock at the end of each month.

b) LIFO method has an edge over FIFO or any other method of pricing material issues

due to the following advantages;

✓ The Cost of the materials issued will be either nearer or will reflect the current

market price. Thus, the cost of goods produced will be related to the trend of the

market price of materials. Such a trend in price of materials enables the matching

of cost of production with current sales revenues.

✓ The use of the method during the period of rising prices does not reflect undue

high profit in the income statement, as it was under the first-in-first-out or average

method. In fact, the profit shown here is relatively lower because the cost of

production takes into account the rising trend of material prices.

✓ In the case of falling prices. Profit trends to rise due to lower material cost, yet the

finished products appear to be more competitive and are at market price.

During the period of inflation, LIFO will tend to show the correct profit and thus, avoid

paying undue taxes to some extent.

15. The following information is provided by Sunrise Industries for the fortnight of April, 202X;

Material Exe;

Stock on 1-4-20X1 100 units at ₹5 per unit.

Purchase;

5-4-20X1, 300 units at ₹6

8-4-20 X1, 500 units at ₹7

12-4-20 X1, 600 units at ₹8

Issues;

6-4-20 X1, 250 units

10-4-20 X1, 400 units

14-4-20 X1, 500 units

888 888 0402 support@escholars.in 14

www.escholars.in

Required: -

a) Calculate using FIFO and LIFO methods of pricing issues;

i) The value of materials consumed during the period.

ii) The value of stock of materials on 15-04-20X1

b) Explain why the figures in (i) and (ii) in part A of this question are different under the

two methods of pricing of materials issues used. You need not draw up the stores

Ledgers.

(ICAI SM)

Ans. a)

i) Value of Material Exe Consumed during the period;

1-4-20X1 to 15-4-20X1 by using FIFO method.

Date Description Units Qty. Rate (₹) (₹)

(Units)

1-4-20X1 Opening balance 100 5 500

5-4-20X1 Purchase 300 6 1,800

6-4-20X1 Issued 100 5 1,400

150 6

8-4-20X1 Purchased 500 7 3,500

10-4-20X1 Issued 150 6 2,650

250 7

12-4-20X1 Purchased 600 8 4,800

14-4-20X1 Issued 250 7 3,750

250 8

15-4-20X1 Balance 350 8 2,800

Total value of material Exe consumed during the period under FIFO method comes to

(₹1,400 + ₹ 2,650 + ₹ 3,750) ₹ 7,800 and balance on 15-4-2020 is of ₹ 2,800.

ii) Value of material Exe Consumed during the period 01-04-20X1 to 15-4-20X1 by using

LIFO method;

Date Description Units Qty. (Units) Rate (₹) (₹)

1-4-20X1 Opening balance 100 5 500

5-4-20X1 Purchase 300 6 1,800

6-4-20X1 Issued 250 6 1,500

8-4-20X1 Purchased 500 7 3,500

10-4-20X1 Issued 400 7 2,800

12-4-20X1 Purchased 600 8 4,800

14-4-20X1 Issued 500 8 4,000

15-4-20X1 Balance 350 ---- 2,300*

Total value of material Exe issued under LIFO method comes to (₹1,500 + ₹2,800 + ₹4,000)

₹8,300.

*The balance 350 units on 15-4-20X1 of ₹2,300. Relates to opening balance on 1-4-20X1 and

purchases made on 5-4-20X1, 8-4-20X1 and 12-4-20X1, (100 units @ ₹5, 50 units @ ₹6,100

units @ ₹7 and 100 units @ ₹8.)

As shown in (a) above, the value of stock of materials on 15-4-20X1;

✓ Under FIFO method ₹2,800

✓ Under LIFO method ₹2,300

Total value of material Exe issued to production under FIFO and LIFO methods comes to

₹7,800 and ₹8,300 respectively. The value of closing stock of material Exe on 15-4-20X1

under FIFO and LIFO methods comes to ₹2,800 and ₹2,300 respectively.

888 888 0402 support@escholars.in 15

www.escholars.in

b) The reasons for the difference of ₹ 500 (₹ 8,300 − ₹ 7,800) as shown by the following

table in the value of material Exe, issued to production under FIFO and LIFO as follows;

Date Quantity Value Total Value Total

Issued FIFO LIFO

(Units) (₹) (₹) (₹) (₹)

6-4-20X1 250 1,400 1,500

10-4-20X1 400 2,650 2,800

14-4-20X1 500 3,750 7,800 4,000 8,300

1) On 6-4-20X1, 250 units were issued to production. Under FIFO their value comes to

1,400 (100 units × ₹ 5 + 150 units × 6) and under LIFO ₹ 1,500 (250 × ₹ 6). Hence,

₹100 more was charged to production under LIFO.

2) On 10-4-20X1, 400 units were issued to production. Under FIFO their value comes

to ₹ 2,650 (150 × 6 + 250× ₹7) and under LIFO ₹2,800 (400 × ₹7). Hence, ₹150 more

was charged to production under LIFO.

3) On 14-4-20X1, 500 units were issued to production. Under FIFO their value comes

to ₹ 3,750 (250 × ₹7 + 250 × ₹8) and under LIFO ₹4,000 (500 × ₹8.), Hence, ₹250

more was charged to production under LIFO.

Thus, the total excess amount charged to production under LIFO comes to ₹500.

The reasons for the difference of ₹ 500 (₹ 2,800−₹ 2,300) in the value of 350 units of

Closing Stock of material Exe under FIFO and LIFO are as follows;

1) In the case of FIFO, all the 350 units of the closing Stock belongs to the purchase of

material made on 12-4-20X1, whereas under LIFO these units were from opening

balance and purchase made on 5-4-20X1, 8-4-20X1 and 12-4-20X1.

2) Due to different purchase price paid by the concern on difference days of purchase,

the value of Closing Stock differed under FIFO and LIFO. Under FIFO 350 units of

Closing Stock were Value @ ₹ 8 p.u. Whereas under LIFO first 100 units were valued

@ ₹ 5 p.u. next 50 units @ ₹ 6 p.u. next 100 units @ ₹ 7 p.u. and last 100 units @ ₹ 8

p.u.

Thus, under FIFO, the value of Closing Stock increased by ₹ 500.

16. An invoice in respect of a consignment of chemicals A and B provides the following

information:

Particulars (₹)

− Chemical A: 10,000 kgs. At ₹ 10 per kg. 1,00,000

− Chemical B: 8,000 kgs. At ₹ 13 per kg. 1,04,000

− Basic custom duty @ 10% (Credit is not allowed) 20,400

− Railway freight 3,840

Total Cost 2,28,240

A shortage of 500 kgs. In chemical A and 320 kgs. In chemical B is noticed due to normal

breakages. You are required to Compute the rate per kg. of each chemical, assuming a

provision of 2% for further deterioration.

(ICAI SM)

888 888 0402 support@escholars.in 16

www.escholars.in

Ans. Statement Showing the computation of rate per kg. of each chemical;

Particulars Chemical A (₹) Chemical B (₹)

Purchase price 10,000 @ ₹10 per kg. 8,000 @ ₹ 13 1,00,000 1,04,000

per kg.

Add: Basic Custom Duty @ 10% 10,000 10,400

Add: Railway freight 2,133 1,707

(in the ratio of quantity purchase i.e., 5:4)

Total Cost (A) 1,12,133 1,16,107

Effective Quantity (See Working) (B) 9,310 kg. 7,526.4 kg

Rate per kg. (A ÷ B) 12.04 15.43

Workings: -

Computation of effective quantity of each chemical available for use;

Particulars Chemical A Chemical B

(Kg.) (Kg.)

Quantity purchased 10,000 8,000

Less: Shortage due to normal breakages 500 320

9,500 7,680

Less: Provision for deterioration 2% 190 153.6

Quantity available 9,310 7,526.4

17. Anil & Company buys its annual requirement of 36,000 units in 6 instalments. Each unit

costs ₹1 and the ordering cost is ₹25. The inventory carrying cost is estimated at 20% of unit

value. Find the total annual cost of the existing inventory policy. Calculate, how much money

can be saved by Economic Order Quantity?

(ICAI SM)

Ans. a) Total Annual Cost in Existing Inventory Policy;

Particulars (₹)

− Ordering Cost (6 orders @ ₹ 25) 150

− Carrying Cost of average inventory (36,000 ÷ 6) = 6,000 units per

order

− Average inventory = 3,000 units

− Carrying Cost = 20% of ₹ 1 × 3,000 = 3,000 × 0.20 600

Total Cost A 750

b) Total Annual Cost in Economic Order Quantity;

2×36,000×25

Economic Order Quantity = √ = 3,000 units.

₹1×20%

Particulars (₹)

− No. of orders = 36,000 ÷ 3,000 units = 12 orders

Ordering Cost (12 × ₹25) = 300

− Carrying Cost of average inventory (3,000 × 0.20) ÷ 2 = 300

Total Cost B 600

− Savings due to E.O.Q ₹ (750−600) (A−B) 150

Note: -

As the units purchase Cost of ₹1 does not change in both the computation. The same has not

been considered to arrive at total cost of inventory for the purpose of savings.

18. A Company manufactures a special product which requires a component ‘Alpha’. The

following particulars are collected for the year 20X1;

888 888 0402 support@escholars.in 17

www.escholars.in

Annual demand of Alpha 8,000 units

Cost of placing an order ₹ 200 per order

Cost per unit of Alpha ₹ 400

Carrying cost p.a. 20%

The Company has been offered a quantity discount of 4% on the purchase of ‘Alpha’

provided the order size is 4,000 components at a time.

Required: -

a) Compute the economic order quantity.

b) State whether the quantity discount offer can be accepted.

(ICAI SM)

Ans. 1) Calculation of Economic Order Quantity

2 AO 2×8,000 units ×₹ 200

EOQ −√ =√ 20 = 𝟐𝟎𝟎 𝐮𝐧𝐢𝐭𝐬

C ₹ 400×

100

2) Evaluation of Profitability of Different Options of Order Quantity;

a) When EOQ is ordered

Particulars (₹)

✓ Purchase Cost − (8,000 units × ₹ 400) 32,00,000

✓ Ordering Cost − [(8,000 units/200 units) × ₹ 200] 8,000

✓ Carrying Cost − (200 units × ₹ 400 × ½ × 20/100) 8,000

Total Cost 32,16,000

b) When Quantity Discount is accepted;

Particulars (₹)

✓ Purchase Cost − (8,000 units × ₹ 384 *) 30,72,000

✓ Ordering Cost − [(8,000 units/4000 units) × ₹ 200] 400

✓ Carrying − (4000 units × ₹ 384 × ½ × 20/100) 1,53,600

Cost

Total Cost 32,26,000

− *Unit Cost ₹ 400

− Less Quantity Discount @ 4% = 16

− Purchase Cost = 400−16 = ₹ 384

Advise− The total cost of inventory is lower if EOQ is adopted. Hence, the company is

advised not to accept the quantity discount.

19. The Complete Gardener is deciding on the economic order quantity for two brands of lawn

fertilizer – Super Grow and Nature’s Own. The following information is collected;

Particulars Fertilizer

Super Glow Nature’s Own

✓ Annual demand 2,000 bags 1,280 bags

✓ Relevant ordering cost per purchase order ₹ 1,200 ₹ 1,400

✓ Annual relevant carrying cost per bag ₹ 480 ₹ 560

Required: -

a) Compute EOQ for Super Grow and Nature’s Own.

b) For the EOQ. What is the sum of the total annual relevant ordering costs and total annual

relevant carrying costs for Super Grow and Nature’s own?

c) For the EOQ, Compute the number of deliveries per year for Super Grow and Nature’s

Own.

(ICAI SM)

888 888 0402 support@escholars.in 18

www.escholars.in

Ans. 2 AO

Economic Order Quantity = √

C

Where,

− A=Annual Demand

− O=Ordering Cost per order

− C=Inventory Carrying Cost per unit per annum

a) Calculation of EOQ;

✓ Super Grow;

2×2,000×1,200

− EOQ = √ 480

= √10,000 or 100 bags

✓ Nature’s Own;

2×1,280×1,400

− EOQ = √ 560

= √6,400 or 80 bags

b) Total annual relevant cost = Total annual relevant ordering costs + Total annual

relevant carrying cost;

Particulars Super Grow Nature’s Own

✓ Number of Orders = Annual = 2,000/100 = 1,280/80

Requirement ÷ EOQ = 20 orders = 16 orders

✓ Ordering Cost 20 × 1200 = ₹ 24000 16 × 1400 = ₹ 22,400

✓ Carrying Cost ½ × 100 × 480 = ₹24,000 ½ × 80 × 560 × ₹ 22,400

✓ Total of Ordering and = ₹ 24,000 + ₹ 24,000 ₹ 22,400 + ₹ 22,400 =

Carrying Cost =₹ 48,000 ₹ 44,800

c) Number of deliveries for Super Grow and Nature’s own fertilizer per year =

Annual demand for fertilizer bags

EOQ

Super Grow Nature’s Own

2,000 bags

− = = 20 orders − =

1,280 bags

= 16 Orders.

100 bags 80 bags

20. G. Ltd., produces a product which has a monthly demand of 4,000 units. The product

requires a component X which is purchased at ₹20. For every finished product. One unit of

component is required. The ordering cost is ₹120 order and the holding cost is 10% p.a.

You are required to Calculate: -

a) Economic order quantity.

b) If the minimum lot size to be supplied is 4,000 units, what is the extra cost, the company

has to incur?

c) What is the minimum carrying cost, the company has to incur?

(ICAI SM)

Ans. a) Economic order quantity: -

− A (Annual requirement or Component ‘X’) = 4,000 units per month × 12 months =

48,000 units

− O (Ordering Cost per order) = ₹120

− C (Holding Cost) = 10% per annum

− (Purchase Cost per unit) = ₹20

2AO 2×48,000 units×₹ 120

− Economic Order Quantity = √ C

=√ 10% 𝑜𝑓 ₹ 20

= 2,400 units

888 888 0402 support@escholars.in 19

www.escholars.in

b) Extra Cost incurred by the Company: -

i) Total Cost when order size is equal 4,000 units;

− Total Cost = Total ordering Cost + Total Carrying Cost

A 1

− = × O + Q(C)

Q 2

48,000 units 1

− = ( 4,000 units × ₹120) + (2 × 4,000 units × 10% × ₹20)

− = ₹ 1,440 + ₹4,000 = ₹ 5,440

ii) Total Cost when order size is equal EOQ i.e., 2,400 units;

48,000 units 1

− Total Cost = ( 2,400 units × ₹ 120) + (2 × 2,400 units × 10% × ₹20)

− = ₹ 2,400 + ₹ 2,400 = ₹4,800

− Extra Cost that the company has to incur = (A) –(B) = ₹ 5,440−₹ 4,800 =

₹ 640

c) Minimum Carrying Cost: -

Carrying Cost depends upon the size of the order. It will be minimum on the least order

size. (In this part of the question the two order sizes are 2,400 units and 4,000 units.

Here 2,400 units is the least of the two order sizes. At this order size carrying Cost will

be minimum.)

− The minimum Carrying cost in this case can be computed as under: -

1

Minimum Carrying Cost = × 2,400 units × 10% × ₹ 20 = ₹ 𝟐, 𝟒𝟎𝟎.

2

21. ‘AT’ Ltd. furnishes the following store transactions for September, 20X1.

1-9-X1 − Opening balance 25 units value ₹ 162.560

4-9-X1 − Issues Req. No. 85 8 Units

6-9-X1 − Receipts from B & Co. GRN No. 26 50 Units @ ₹ 5.75 per unit

7-9-X1 − Issues Req. No. 97 12 Units

10-9-X1 − Return to B & Co. 10 Units

12-9-X1 − Issues Req. No. 108 15 Units

13-9-X1 − Issues Req. No. 110 20 Units

15-9-X1 − Receipts from M & Co. GRN No. 33 25 Units @ ₹ 6.10 per unit

17-9-X1 − Issues Req. No. 121 10 Units

19-9-X1 − Received replacement from B & Co.

− GRN No. 38 10 units

20-9-X1 − Returned from department materials 5 Units

of M & Co. MRR No. 4

22-9-X1 − Transfer from Job182 to Job 187 in 5 units

the Dept. MTR 6

26-9-X1 − Issues Req. No. 146 10 units

29-9-X1 − Transfer from Dept. “A” to Dept “B”

MTR 10

30-9-X1 − Shortage in Stock taking 2 units

Prepare the priced stores ledger on FIFO Method and State how would you treat the

shortage in stock taking.

(ICAI SM)

Ans. Stores Ledger of AT Ltd. for the month of September, 20X1 (FIFO Method)

Date Receipt Issue Balance

GRN Qty Rate (₹) Requisition Qty Rate (₹) Qty. Rate (₹)

No Units (₹) No Units (₹) Units (₹)

MRR

No.

1 2 3 4 5 6 7 8 9 10 11 12

1-9-X1 ---- ---- ---- ---- ---- ---- ---- ---- 25 6.50 162.50

4-9-X1 ---- ---- ---- ---- 85 8 6.50 52 17 6.50 110.50

888 888 0402 support@escholars.in 20

www.escholars.in

6-9-X1 26 50 5.75 287.50 ---- ---- ---- ---- 17 6.50 110.5

50 5.75 287.5

7-9-X1 ---- ---- ---- ---- 97 12 6.50 78 5 6.50 32.5

50 5.75 287.5

10-9-X1 ---- ---- ---- ---- Return 10 5.75 57.50 5 6.50 32.5

40 5.75 230

12-9-X1 ---- ---- ---- ---- 108 5 6.50 32.50 30 5.75 172.50

10 5.75 57.50

13-9-X1 ---- ---- ---- ---- 110 20 5.75 115 10 5.75 57.50

15-9-X1 33 25 6.10 152.50 ---- ---- ---- ---- 10 5.75 57.50

25 6.10 152.50

17-9-X1 ---- ---- ---- ---- 121 10 5.75 57.50 25 6.10 152.50

19-9-X1 38 10 5.75 57.50 ---- ---- ---- ---- 25 6.10 152.50

10 5.75 57.50

20-9-X1 4 5 5.75 28.75 ---- ---- ---- ---- 5 5.75 28.75

25 6.10 152.50

10 5.75 57.50

26-9-X1 ---- ---- ---- ---- 146 5 5.75 28.50 20 6.10 122

5 6.10 30.50 10 5.75 57.50

30-9-X1 ---- ---- ---- ---- Shortage 2 6.10 12.20 18 6.10 109.80

10 5.75 163.70

Working Notes: -

1) The Material received as replacement from vendor is treated as fresh supply.

2) In the absence of any information, the price of the material returned from a user

department on 20-09-20X1 has been taken at the price of the latest issue made on 17-

09-X1. In FIFO method, physical flow of the material is irrelevant, and issue price is

based on first in first out.

3) The issue of Material on 26-9-X1 is made out of the material received from a user

department on 20-9-X1.

4) The entries for transfer of materials from one job and department to another on 22-9-

X1 and 29-9-X1 respectively. Do not affect the store ledger. However, adjustment

entries to calculation of Cost of respective jobs and departments are made in Cost

Accounts.

5) The Material found short as a result of stock taking has been written off at relevant issue

price.

22. The following information is extracted from the Stores Ledger: -

Material X

Opening Stock Nil

Purchases;

Jan-1 100@ ₹ 1 per unit

Jan-20 100 @ ₹ 2 per unit

Issues: -

Jan-22 60 for Job W 16

Jan-23 60 for Job W 17

Complete the receipts and issues valuation by adopting the first-in-first-out, Last-in-first-

out and the weighted average method Tabulate the values allocated to Job W 16, W 17, and

the Closing Stock under the methods aforesaid and discuss from different points of view

which method you would prefer.

(ICAI SM)

888 888 0402 support@escholars.in 21

www.escholars.in

Ans. From the point of view of cost of Material charged to each job, it is minimum under FIFO and

maximum under LIFO (Refer to Tables). During the period of rising prices, the use of FIFO

give rise to hight profits and that of LFIO low profits. In the case of weighted average, there

is no significant adverse or favourable effect on the cost of material as well as on profits.

From the point of view of valuation of closing stock, it is apparent from the above statement,

that it is maximum under FIFO, moderate under weighted average and minimum under

LIFO.

It is clear from the tables that the use of weighted average evens out the fluctuations in the

prices, under this method, the cost of materials issued to the jobs and the cost of material in

hands reflects greater uniformity than under FIFO and LIFO. Thus, from different points of

view, weighted average method is preferred over LIFO and FIFO.

Statement of receipts and issues by adopting First-in-First-Out Method

Date Particulars Receipts Issues Balance

Units Rate Value Units Rate Value Units Rate Value

No. (₹) (₹) No. (₹) (₹) No. (₹) (₹)

Jan.1 Purchase 100 1 100 ---- ---- ---- 100 1 100

Jan.20 Purchase 100 2 200 ---- ---- ---- 100 1 100

100 2 200

Jan.22 Issue to Job ---- ---- ---- 60 1 60 40 1 40

W 16 100 2 200

Jan.23 Issue to Job ---- ---- ---- 40 1 40 80 2 160

W 17 20 2 40

Statement of receipts and issues by adopting Last-In-First-Out Method

Date Particulars Receipts Issues Balance

Units Rate Value Units Rate Value Units Rate Value

No. (₹) (₹) No. (₹) (₹) No. (₹) (₹)

Jan.1 Purchase 100 1 100 ---- ---- ---- 100 1 100

Jan.20 Purchase 100 2 200 ---- ---- ---- 100 1 100

100 2 200

Jan.22 Issue to Job W ---- ---- ---- 60 2 120 100 1 100

16 40 2 80

Jan.23 Issue to Job W ---- ---- ---- 40 2 80 80 1 80

17 20 1 20

Statement of Receipt and Issues by adopting weighted Average method

Date Particulars Receipts Issues Balance

Units Rate Value Units Rate Value Units Rate Value

No. (₹) (₹) No. (₹) (₹) No. (₹) (₹)

Jan.1 Purchase 100 1 100 ---- ---- ---- 100 1 100

Jan.20 Purchase 100 2 200 ---- ---- ---- 200 1.50 300

Jan.22 Issue to Job ---- ---- ---- 60 1.50 90 140 1.50 210

W 16

Jan.23 Issue to Job ---- ---- ---- 60 1.50 90 80 1.50 120

W 17

Statement of Material Values allocated to Job W 16, Job 17 and Closing Stock, under

aforesaid methods;

Particulars FIFO LIFO Weighted

(₹) (₹) Average (₹)

− Material for Job W 16 60 120 90

− Material for Job W 17 80 100 90

− Closing Stock 160 80 120

Total 300 300 300

888 888 0402 support@escholars.in 22

www.escholars.in

23. A Ltd. produces a product ‘X’ using a raw material ‘D’. To produce one unit of X, 4 kg of D is

required. As per the sales forecast conducted by the company. It will be able to sale 20,000

units of X in the coming year.

The following are the information related to the raw material D;

i) The Re-order quantity is 400 kg. less than the Economic Order Quantity (EOQ.)

ii) Maximum Consumption per day is 40 kg. more than the average consumption per day.

iii) There is an opening stock of 2,000 kg.

iv) Time required to get the raw materials from the suppliers is 4 to 8 days.

v) The purchase price is ₹250 per kg.

− There is an opening stock of 1,800 units of the finished product X.

− The Carrying cost of inventory is 14% p.a.

− To place an order company has to incur ₹1,340 on paper and documentation work.

− From the above information. Find Out the followings in relation to raw material D:

a) Re-Order Quantity

b) Maximum Stock level

c) Minimum Stock level

d) Calculate the impact on the profitability of the company by not ordering the EOQ. (Take

300 days for a year]

(RTP May 2021, Modified MTP May 2019, Modified MTP Nov 2022)

Ans. a) Re-Order Quantity: -

− EOQ−400 kg. = 2,328 kg−400 kg. = 1,928 kg.

b) Maximum Stock Level;

− = Re order level + Re order Quantity − (Minimum . Consumption per day ×

Minimum lead time)

− = 2,208 kg + 1,928 kg − (196 kg × 4 days) = 4,136 kg − 784 kg = 3,352 kg.

c) Minimum Stock Level: -

− = Re order level − (Average Consumption per day × Average lead time)

− = 2,208 kg − (236 kg × 6 days) = 792 kg.

d) Impact on the profitability of the company by not ordering the EOQ;

Particulars When purchasing the When purchasing the

ROQ EOQ

1) Order Quantity 1,928 kg. 2,328 kg.

2) No. of orders a year 70,800 kg

=

70,800 kg

=

1,928 kg 2,328 kg

36.72 or 37 orders 30.41 or 31 orders

3) Ordering Cost 37 orders × ₹ 1,340 = ₹ 31 orders × ₹ 1,340 =

49,580 ₹ 41,540

4) Average Inventory 1,928 kg

= 964 kg.

2,328 kg

= 1,164 kg

2 2

5) Carrying Cost 964 kg × ₹ 35 = ₹ 33,740 1,164 kg × ₹ 35 =

₹ 40,740

Total Cost ₹ 83,320 ₹ 82,280

*Extra Cost incurred due to not ordering EOQ = ₹ 83,320 − ₹ 82,280 = ₹ 1,040.

888 888 0402 support@escholars.in 23

www.escholars.in

Working Notes: -

i) Computation of Annual Consumption & Annual Demand for raw material ‘D’;

✓ Sales forecast of the product ‘X’ 20,000 units

✓ Less: Opening Stock of ‘X’ 1,800 units

✓ Fresh Units of ‘X’ to be produced 18,200 units

✓ Raw material required to produce 18,200 units of ‘X’ 72,800 kg.

(18,200 units × 4 kg.)

✓ Less: Opening Stock of ‘D’ 2,000 kg.

✓ Annual demand for raw material ‘D’ 70,800 kg.

ii) Computation of Economic Order Quantity (EOQ);

2×Annual demand of ′D′ ×Ordering Cost

− EOQ= √

Carrying Cost per unit per annum

2×70,800 kg×₹ 1,340 2×70,800 kg×₹ 1,340

− =√ ₹ 250×14%

=√ ₹ 35

= 2,328 kg.

iii) Re-Order level;

− = (Maximum Consumption per day × Maximum lead time)

Annual Consumption of ′D′

− = {( + 40 kg. ) × 8 days}

300 days

70,800 kg.

− = {( + 40 kg. ) × 8 days} = 2,208 kg.

300 days

iv) Minimum Consumption per day of raw material ‘D’;

− Average Consumption per day = 236 kg.

− Hence, Maximum Consumption per day = 236 kg. + 40 kg. = 276 kg.

− So, Minimum Consumption per day will be

Min.Consumption+Max Consumption

− Average Consumption = 2

Min Consumption +276 kg.

− Or, 236 kg. = 2

− Or, Min. Consumption = 472 kg − 276 kg = 196 kg

24. When tenders were invited for a store, quotations were received as under;

Supplier X;

i) Rate ₹2 each;

ii) Trade discount 10%;’

iii) Cash discount 5% if bills are paid within a fortnight after receipt;

iv) Transport charges ₹1 per 100 units.

Supplier Y;

i) Rate ₹1.80 each (up to 1,000 units), ₹1.60 each (for orders above 1,000 units);

ii) 6% Interest per annum will be added if bills are not paid within a fortnight after receipt

of the materials;

iii) Transport charges ₹3 per 100 units.

Assuming that 5,000 units are required every month and that quality and other conditions

of supply are the same, offer your comments as to whom purchase order can be issued. The

factory pays 50% of its total monthly bills every fortnight.

(RTP)

888 888 0402 support@escholars.in 24

www.escholars.in

Ans. Comparative Statement of Cost of Materials of two quotations;

Ordering Quantity = 5,000 Units Supplier X Supplier Y

✓ 5,000 units @ ₹ 2 per unit 10,000

✓ 5,000 units @ ₹ 1.60 per unit 8,000

✓ Less: Trade discount @ 10% 1,000

9,000

✓ Transport Charges @ ₹ 1 per 100 units 50

✓ Transport Charges @ ₹ 3 per 100 units 150

9,050 8,150

✓ Less: Cash discount @ 5% on half of the amount of 226.25

₹ 9,050 paid within 15 days

✓ Add: Interest @ 6% on half of the amount of ₹ 8,150

not paid within 15 days for the next 15 days of the 10.2

month

6 1

(4,075 × 100 × 24)

Total Cost of Materials 8,823.75 8,160.2

*The Purchase Order should be issued to Supplier Y because of the lower cost of material.

25. PQR Tubes Ltd. are the manufactures of picture tubes for T.V. The following are the details

of their operations during 20X1-20X2;

Ordering Cost − ₹ 100 per order

Inventory Carrying Cost − 20% p.a.

Cost of tubes − ₹ 500 per tube

Normal usage − 100 tubes per week

Minimum usage − 50 tubes per week

Maximum usage − 200 tubes per week

Lead time to supply − 6-8 weeks

Required: -

a) Economic Order Quantity. If the supplier is willing to supply quarterly 1,500 units at a

discount of 5%, is it worth accepting?

b) Re-order level

c) Maximum level of stock

d) Minimum level of stock.

May 2000 RTP)

Ans. a) Computation of EOQ;

2×𝐴×𝑂

EOQ = √ C

=

✓ Let U = Annual Usage = Normal Usage per week × 52 weeks

= 100 × 52

= 5,200 tubes

✓ O = Ordering Cost per order = ₹ 100

✓ P= Cost per unit = ₹ 500/tube

✓ C = Stock holding rate p.a. = ₹ 20% p.a.

✓ Q= Re-order Quantity

✓ C = Carrying cost per unit p.a. = 500 × 20% = ₹ 100

2×5,.200×100

=√ 100

102 Units (appx)

888 888 0402 support@escholars.in 25

www.escholars.in

Evaluation of Price discount offer;

✓ The price discount offer can be decided upon only after comparing the total annual

inventory cost at EOQ & total annual inventory cost at 1500 units of order size.

✓ Total annual inventory cost = Total Purchase Cost + Total ordering cost + Total

carrying cost of average inventory.

U 1

− = (U × C) + ( × O) + × Q × CS

Q 2

5,200 1

− At Q = 102 units (i. e. , EOQ) = (5,200 × 500) + ( × 100) + ( × 102 × 100)

102 2

− = 26,00,000 + 5098 + 5100

− = ₹ 25,10,198 (appro. . )

5,200

− At quarterly supply = 1,500 Units = [5200 × (500−5%)] + ( × 100) +

1,500

1

[ × 1,500 × (500 − 5% × 20%)]

2

− = 24,70,000 + 347 + 71,250

− = ₹ 25,41,597 (App.)

*Since, total annual inventory cost is lower, if the re-order quantity is fixed at 1,500

units, so the discount offer should be accepted.

b) Re-Order Level = Maximum Usage × Maximum Lead Time

= 200 tubes per week × 8 weeks

= 1,600 Units.

Since, there is no specification about reorder quantity, it has been assumed to be equal

to EOQ units i.e., 102 tubes per order.

c) Maximum Stock Level= Re-order level + Re-order Quantity – (Minimum usage ×

Minimum Lead Time)

− = 1,600 (W. N. 1) + 102 (W. N. 2) − (50 tubes per week × 6 weeks)

− = 1,402 tubes.

d) Minimum Stock Level = Re-Order Level−(Average/Normal usage × Average. Lead time)

6+8

− = 1,600 − (100 × ( ))

2

− = 1,600 − 700

− = 900 Units.

26. A Company has the option to procure a particular material from two sources;

Source I; assures that defectives will not be more than 2% of supplied quantity.

Source II; does not give any assurance, but on the basis of past experience of supplies

received from it, it is observed that defective percentage is 2.8%.

The Material is supplied in lots of 1,000 units. Source II Supplies the lot at a price, which is

lower by ₹100 as compared to Source I. The defective units of material can be rectified for

use at a cost of 5 per unit.

You are required to find out which of the two sources is more economical.

(May 2001)

Ans. Statement of Cost of procurement of material for a lot size of 1,000 units;

Particulars Source I Source II

1) Lot Size (Given) 1,000 units 1,000 units

2) Percentage of defective units 2% 2.8%

3) Defective units (1×2) 20 units 28 units

4) Additional price paid per lot ₹ 100 ----

888 888 0402 support@escholars.in 26

www.escholars.in

5) Cost of rectifying defective unit @ ₹ 5 per unit ₹ 100 ₹ 140

× (3)

Total Relevant Cost (4 + 5) ₹ 200 ₹ 140

On Comparing the total Relevant Cost, we can say it is more economical to procure materials

from Source II.

Alternatively (Using Incremental Method);

Saving/(Loss) in procuring materials from source II (₹)

✓ Saving in purchase price per lot of 1,000 units if purchased from 100

Source II

✓ Less: Extra Cost incurred in rectifying defective units as compared to 40

the same cost incurred if supplier procured from Source I = (28

units−20 units) × ₹ 5

✓ Net savings if supplies are procured from Source II

✓ (W.r.t. lot size of 1,000 units) as compared to Source I 60

✓ Hence, Source II is more economical than Source I.

27. A Company manufactures a product from a raw material, which is purchased at ₹60 per kg.

The Company incurs a handling cost of ₹360 plus freight of ₹390 per order. The incremental

carrying cost of inventory of raw material is Re. 0.50 per kg. per month, In addition, the cost

of working capital finance on the investment in inventory of raw material is ₹9 per kg. per

annum. The annual production of the product is 1,00,000 units and 2.5 units are obtained

from one kg. of raw material.

Required: -

a) Calculate the economic order quantity of raw materials.

b) Advise, how frequently should orders for procurement be placed.

c) If the company proposes to rationalise placement of orders on quarterly basis, what

percentage of discount in the price of raw materials should be negotiated?

(Nov 2001)

Ans. a) Economic Order Quantity;

− A = Annual usage of Raw Material

− = 1 unit of material gives 2.5 units of Finished Goods

1,00,000

− For 1,00,000 units of finished goods, material required = 2.5 = 40,000 kgs.

− O = Ordering cost per order = Handling Cost + freight per order

= ₹ 360 + ₹ 390 = ₹ 750

− P = Cost/kg. of material = ₹ 60 per kg.

− C= Carrying Cost or Holding Cost of Inventory per unit p.a.

− = Carrying cost per unit p.a. + Interest cost of investment in inventory per unit p.a.

− = (₹ 0.50 per unit per month × 12 months) + ₹ 9 per kg. p.a.

− = ₹ 6 + ₹9 = ₹ 15 per unit p. a.

− Q = Reorder Quantity.

2 AO

− =√ C

2×40,000×750

− =√ = √40,00,000 = 2,000 kgs.

15

b) Frequency of placing orders/time interval between orders;

365 days or 12 months

− = No.or orders

Annual requirement

− = No. of orders = EOQ

40,000 kgs.

− = = 20 orders

2,000 kgs

888 888 0402 support@escholars.in 27

www.escholars.in

− Frequency of placing orders

12 months

− =

20 orders

− = 0.6 months

− (Or)

365 days

− = 18 days (approx. )

20 orders

c) (%) Discount to be negotiated for placing quarterly orders;

− No. of orders if orders are placed quarterly

12 months

− (i.e., at every three months) = 3 months = 4 orders

Annual Requirement

− Order Size per quarterly order =

No.of orders

40,000 kgs.

− = = 10,000 kgs.

4 Orders

− Total Annual Cost = Total annual Ordering Cost + Total Annual Carrying Cost

U Q

− = (Q × O) + ( 2 × PC)

− At Q = 2,000 kgs. (i.e., at EOQ)

40,000 2000

− = ( 2,000 × 750) + ( 2 × 15)

− = 15000 + 15000 = ₹ 30,000

− At Q= 10,000 kgs. (i.e., at quantity orders)

40,000 10,000

− =( × 750) + ( × 15)

10,000 2

− = 3,000 + 75,000 = ₹ 78,000

On analysis of the total annual ordering & carrying cost as above it can be said that if we

place quarterly orders of 10,000 kgs. Each then we would incur extra ordering & carrying

cost of ₹48,000 (i.e., ₹78,000-30,000).

In Order to avoid or compensate this increase in cost of ₹48,000 we will have to negotiate

3 discount which will, result in a total decrease in purchase cost by atleast ₹48,000.

✓ Total discount required on annual requirement of;

− =40,000 kgs. = ₹ 48,000

✓ Required Discount per kg. of raw material;

48,000

− = = ₹ 1.2 per kg.

40,000 kgs.

✓ Percentage of Discount to be negotiated;

Discount/kg. 1.2

= Currect Price/kg × 100 = 60 × 100 = 2%

28. The Quarterly production of a company’s product which has a steady market is 20,000

units. Each unit of a product requires 0.5 kg. of raw material. The cost of placing one order

for raw material is ₹100 and the inventory carrying cost is ₹2 per annum. The lead time for

procurement of raw material is 36 days and a safety stock of 1,000 kg. of raw materials is

maintained by the company. The company has been able to negotiate the following discount

structure with the raw material supplier;

Order Quantity (kgs.) Discounts (₹)

Up to 6,000 − Nil

6,000−8,000 − 400

8,000−16,000 − 2,000

16,000−30,000 − 3,200

30,000−45,000 − 4,000

888 888 0402 support@escholars.in 28

www.escholars.in

You are required to: -

a) Calculate the re-order point taking 30 days in a month;

b) Prepare a statement showing the total cost of procurement and storage of raw

materials after considering the discount if the company elects to place one, two, four

or six orders in the year.

c) State the number of orders which the company should place to minimise the costs after

taking EOQ also into consideration.

(May 2002 RTP, Modified MTP Dec 2021)

Ans. a) Re-Order Level or Point = (Maximum Usage × Maximum Lead Time) + Safety Stock

− Quarterly (i.e., 3 months) production of finished goods

− = 20,000 units

− Raw Material required per unit of finished goods.

− = 0.5 kgs. of raw material

− ∴ Raw material required for 20,000 units of finished goods

− = 20,000 × 0.5 𝑘𝑔

− = 10,000 kg of raw material

− Daily requirement of raw material

10,000 kg

− = 3 months ×30 days

− = 111.11 kg per day.

− Re-order Level = 4000 kg (111.11 kg × 36 days) + 1,000 kg = 5,000 kg.

b) Statement of total cost of procurement and storage of raw materials;

i) No. of Orders to be place (given) 1 2 4 6

ii) Annual requirement (in kgs.) [(20,000 40,000 40,000 40,000 4,00,000

units of finished goods per quarter × 4

quarter) × 0.5 kg.]

iii) Order size/Reorder Quantity (B/A) 40,000 20,000 10,000 6,667

units

iv) Ordering cost per order 100 100 100 100

v) Carrying cost per unit p.a. 2 2 2 2

vi) Total Storage Cost of raw material 40,000 20,000 10,000 6,667

1

2

× Reorder Quantity ×

Cost

Carrying unit p. a.

1

=2×C×E

vii) Total Cost of procurement (Ordering) = 100 200 400 600

B

No. of orders × Cost of ordering = C × D