Professional Documents

Culture Documents

Axeon XE1 Membrane Spec Sheet

Axeon XE1 Membrane Spec Sheet

Uploaded by

amanuel waleluCopyright:

Available Formats

You might also like

- J N H Tiratsoo - Pipeline Pigging and Integrity Technology PDFDocument519 pagesJ N H Tiratsoo - Pipeline Pigging and Integrity Technology PDFfhtgerthrgerg50% (2)

- Мембрана TM810 SpecDocument2 pagesМембрана TM810 SpecAlexanderNo ratings yet

- Axeon FH1-4040Document2 pagesAxeon FH1-4040Alejandro AliNo ratings yet

- Sea Water RO Elements: DimensionsDocument2 pagesSea Water RO Elements: Dimensionswahyu raharjoNo ratings yet

- Swro TM800KDocument2 pagesSwro TM800KthanhhuyenNo ratings yet

- Dowex HCR SS LDocument2 pagesDowex HCR SS LOmar SaeedNo ratings yet

- Dowex Marathon C: Ion Exchange ResinDocument12 pagesDowex Marathon C: Ion Exchange ResinZeeshan TalibNo ratings yet

- TC FLS Sihi Leh 1200 1500 1800 enDocument10 pagesTC FLS Sihi Leh 1200 1500 1800 enGustavo ZavalaNo ratings yet

- Bosch Rexroth - Datasheet - Counterbalance ValvesDocument2 pagesBosch Rexroth - Datasheet - Counterbalance ValvesDiogo LuisNo ratings yet

- Digital Pressure Calibrator Nvision Product Drawing UsDocument2 pagesDigital Pressure Calibrator Nvision Product Drawing Us张凯权No ratings yet

- Katalog SIHI Liquid Ring Vacuum PumpsDocument12 pagesKatalog SIHI Liquid Ring Vacuum PumpsTrisna RamadhanNo ratings yet

- Toray TM820M 440 - Spec - SheetDocument2 pagesToray TM820M 440 - Spec - SheetJoselito CortesNo ratings yet

- Dowex-Marathon-A RESINA ANIÔNICADocument3 pagesDowex-Marathon-A RESINA ANIÔNICAMarcus FreitasNo ratings yet

- Dowex Marathon CDocument2 pagesDowex Marathon CMuhammad ImranNo ratings yet

- Product Information: Motor-Driven Diaphragm Dosing Pumps Memdos E/DxDocument19 pagesProduct Information: Motor-Driven Diaphragm Dosing Pumps Memdos E/DxSufian LucasNo ratings yet

- Erapol E90A: Technical DatasheetDocument2 pagesErapol E90A: Technical Datasheetmgamal1080No ratings yet

- EAIR06ADocument2 pagesEAIR06ARay GongNo ratings yet

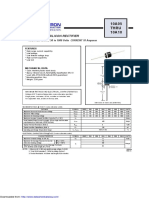

- 1N5400 THRU 1N5408: General Purpose Silicon RectifierDocument2 pages1N5400 THRU 1N5408: General Purpose Silicon RectifierfelipeNo ratings yet

- DC Components Co., LTD.: 10A05 Thru 10A10Document3 pagesDC Components Co., LTD.: 10A05 Thru 10A10Faulhaber AdrianNo ratings yet

- Tecothane TPU ClearDocument3 pagesTecothane TPU ClearKhoa HuynhdangNo ratings yet

- KDS 1c326000ab0ar 3225 X'talDocument13 pagesKDS 1c326000ab0ar 3225 X'talYujia LiNo ratings yet

- SanRO HS PDFDocument1 pageSanRO HS PDFjohn_paisNo ratings yet

- Dow Water & Process SolutionsDocument11 pagesDow Water & Process SolutionsZulfikri ZulkifliNo ratings yet

- Dowex Upcore Mono C600 LDocument2 pagesDowex Upcore Mono C600 Lengineer.humgNo ratings yet

- Technical Data Sheet Linen PhenolicDocument1 pageTechnical Data Sheet Linen PhenolicKissa DolautaNo ratings yet

- Gemini Column CareDocument3 pagesGemini Column CareLee MingTingNo ratings yet

- NP 140Document5 pagesNP 140Nicole YangNo ratings yet

- TM800VDocument2 pagesTM800VMoustafa GamilNo ratings yet

- UF4001-4007 (1A 高速)Document2 pagesUF4001-4007 (1A 高速)vetchboyNo ratings yet

- Single-Phase Glass Passivated Silicon Bridge Rectifier: RS401L Thru RS407LDocument5 pagesSingle-Phase Glass Passivated Silicon Bridge Rectifier: RS401L Thru RS407Lalexnder gallegoNo ratings yet

- CEM 3 10 - DatasheetDocument1 pageCEM 3 10 - Datasheetmccornejo1617No ratings yet

- 10A05 Thru 10A10: Silicon RectifierDocument4 pages10A05 Thru 10A10: Silicon RectifierTECELENAV SANo ratings yet

- Pro XP1Document2 pagesPro XP1sunil patelNo ratings yet

- DC Components Co., LTD.: RL201 Thru RL207Document3 pagesDC Components Co., LTD.: RL201 Thru RL207cclodoaldo1577No ratings yet

- Liquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340Document10 pagesLiquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340pablodugalNo ratings yet

- Model Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADocument2 pagesModel Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AAnurag JainNo ratings yet

- Toray TM820V 400 Sea Water RO Element LDocument2 pagesToray TM820V 400 Sea Water RO Element LLuzmaNo ratings yet

- Dominion Aluminium LV Cable Technical Data SheetDocument2 pagesDominion Aluminium LV Cable Technical Data SheetRonish ChandraNo ratings yet

- RPG 15aDocument2 pagesRPG 15aCARLOS ARGUELLES RODRIGUEZNo ratings yet

- PDF Kingboard KB 6160A Data SheetDocument2 pagesPDF Kingboard KB 6160A Data SheetAlex Prim NavajasNo ratings yet

- EM-S570 Datasheet (Preliminary) 20231130 - 24011013537Document1 pageEM-S570 Datasheet (Preliminary) 20231130 - 24011013537AhSangCheeSangNo ratings yet

- Continental Device India Limited: Fast Recovery Rectifiers 1N4933 - 1N4937 DO-41 (Plastic) Axial Lead Plastic PackageDocument5 pagesContinental Device India Limited: Fast Recovery Rectifiers 1N4933 - 1N4937 DO-41 (Plastic) Axial Lead Plastic Packagevoll.stefanNo ratings yet

- Ag 4040Document2 pagesAg 4040Aravind RaoNo ratings yet

- SB5150 SB5200: Schottky Barrier Rectifier Diodes PRV: 150 200 Volts I: 5.0 AmperesDocument2 pagesSB5150 SB5200: Schottky Barrier Rectifier Diodes PRV: 150 200 Volts I: 5.0 AmperesRafael LehmkuhlNo ratings yet

- Technical Data Sheet Nylon: (Polyamide)Document3 pagesTechnical Data Sheet Nylon: (Polyamide)Dharmendra DubeyNo ratings yet

- C42-4122-202201-2842 - For Proposal - 20220203Document4 pagesC42-4122-202201-2842 - For Proposal - 20220203Juliyanto STNo ratings yet

- Filmtec BW30-2540Document3 pagesFilmtec BW30-2540PT Deltapuro IndonesiaNo ratings yet

- Divlab Touch Screen 2017 UpradableDocument5 pagesDivlab Touch Screen 2017 UpradableAxcel Helsing100% (1)

- Datasheet of Electrical Motor: 1.0 Supplier InformationDocument2 pagesDatasheet of Electrical Motor: 1.0 Supplier InformationRenzo Malcolm Garcia PickmannNo ratings yet

- RO4400 PrepregDocument2 pagesRO4400 Prepreggcohen03No ratings yet

- Jesco Motordriven Kolvdoserpump Typ Fedos Rekos Kardos-Manual ENG 0Document121 pagesJesco Motordriven Kolvdoserpump Typ Fedos Rekos Kardos-Manual ENG 0Luis TeixeiraNo ratings yet

- Hf23e 0Document2 pagesHf23e 0BokiNo ratings yet

- Dowex Marathon C (HT)Document2 pagesDowex Marathon C (HT)juan grasselerNo ratings yet

- Static Dissipative Polyetherimide (Pei) / Static Dissipative UltemDocument1 pageStatic Dissipative Polyetherimide (Pei) / Static Dissipative UltemVC KannanNo ratings yet

- Dowex Marathon ADocument2 pagesDowex Marathon Ajuan grasselerNo ratings yet

- YD 90L 4 6 DatasheetDocument1 pageYD 90L 4 6 DatasheetLance AyoubNo ratings yet

- Sihi Lem 90 - 125 - 150 DetailsDocument4 pagesSihi Lem 90 - 125 - 150 DetailsElmer RchNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- 4 5805228864158306714Document1 page4 5805228864158306714amanuel waleluNo ratings yet

- Uro Felege Hiwot HospitalDocument2 pagesUro Felege Hiwot Hospitalamanuel waleluNo ratings yet

- Patient MonitorsDocument2 pagesPatient Monitorsamanuel waleluNo ratings yet

- WHO-water Purificatio SystemsDocument5 pagesWHO-water Purificatio Systemsamanuel waleluNo ratings yet

- Regions InvitationsDocument1 pageRegions Invitationsamanuel waleluNo ratings yet

- Ehsig Assment Handbook Latest VersionDocument162 pagesEhsig Assment Handbook Latest Versionamanuel walelu100% (6)

- Medical Equipment ListDocument10 pagesMedical Equipment Listamanuel waleluNo ratings yet

- Aquasystem: Purity For LifeDocument7 pagesAquasystem: Purity For LifejpfamiliabNo ratings yet

- Pulse OximeterDocument13 pagesPulse Oximeteramanuel waleluNo ratings yet

- Oxygen CylinderDocument16 pagesOxygen Cylinderamanuel walelu100% (2)

- DRF-1 - HF 80kW Digital RF X-Ray System - 201706Document7 pagesDRF-1 - HF 80kW Digital RF X-Ray System - 201706amanuel walelu100% (1)

- MN150 3 B PDFDocument157 pagesMN150 3 B PDFamanuel waleluNo ratings yet

- ASD T 901889 - 02USE Operator Manual PDFDocument156 pagesASD T 901889 - 02USE Operator Manual PDFamanuel waleluNo ratings yet

- Flowmeter ManualDocument46 pagesFlowmeter Manualamanuel waleluNo ratings yet

- Manual 2V3B-4.1V - RevEDocument79 pagesManual 2V3B-4.1V - RevEamanuel walelu100% (2)

- Airsep Corporation As-J-600-Hmfm Duplex Psa Oxygen System: Instruction ManualDocument61 pagesAirsep Corporation As-J-600-Hmfm Duplex Psa Oxygen System: Instruction Manualamanuel walelu100% (1)

- 3M - Scotchcast Brand Flame Retardant Compound 2130Document8 pages3M - Scotchcast Brand Flame Retardant Compound 2130jaredf@jfelectric.comNo ratings yet

- Antiarrhythmic Drugs-Test-1-QuestionsDocument7 pagesAntiarrhythmic Drugs-Test-1-QuestionsDrishya Bioplannet100% (2)

- Clinical Biochemistry Exam-2 andDocument1 pageClinical Biochemistry Exam-2 andMina MansourNo ratings yet

- Heat GunDocument11 pagesHeat GunMary Grace Aboque-Tan SangcomNo ratings yet

- Neodyl PDFDocument2 pagesNeodyl PDFvranceanu.ovidiu-1No ratings yet

- Alkali Industry Caustic Soda Ash To ClasDocument56 pagesAlkali Industry Caustic Soda Ash To Classelvaraj5natesanNo ratings yet

- Pipe Fittings and Port AdaptersDocument26 pagesPipe Fittings and Port AdaptersdekgaleNo ratings yet

- Dci PipesDocument24 pagesDci PipesshamashergyNo ratings yet

- ... - Oil Painting Without SolventsDocument2 pages... - Oil Painting Without Solventsdorut50% (2)

- Charge On Gas BubbleDocument9 pagesCharge On Gas BubbleB A NaiduNo ratings yet

- Lab 8 Crystal Structure Analysis in Engineering MaterialsDocument6 pagesLab 8 Crystal Structure Analysis in Engineering MaterialsTommy MilesNo ratings yet

- Material Properties Filament Wound Composite Structures: A Versatile Solution To Today's Design ProblemsDocument4 pagesMaterial Properties Filament Wound Composite Structures: A Versatile Solution To Today's Design ProblemsOliver RisteskiNo ratings yet

- Enimex - BVFL - GB PDFDocument6 pagesEnimex - BVFL - GB PDFAlienshowNo ratings yet

- Hydrifin BrochureDocument10 pagesHydrifin BrochureDmitryNo ratings yet

- Heat Treatment of Low Carbon SteelDocument39 pagesHeat Treatment of Low Carbon SteelHEMANTKHERANo ratings yet

- SKL 3013: Chemistry Laboratory Management Techniques: Fatini Zakirah Binti Zaharin D20161073878Document11 pagesSKL 3013: Chemistry Laboratory Management Techniques: Fatini Zakirah Binti Zaharin D20161073878nadhirahNo ratings yet

- Green ElectronicsDocument11 pagesGreen Electronicsashutosh199625No ratings yet

- Geology and Drilling TheoryDocument20 pagesGeology and Drilling TheoryJose Antonio Sanchez SegoviaNo ratings yet

- Unit 1Document40 pagesUnit 1Ram SaaceNo ratings yet

- Plant JeopardyDocument73 pagesPlant JeopardymrsklipfelNo ratings yet

- Turbocharger Troubleshooting: 1 Compressor SurgingDocument3 pagesTurbocharger Troubleshooting: 1 Compressor SurgingJatin JainNo ratings yet

- Emulsion Separation and Fouling of Electrospun Polyacrylonitrile Membranes For Produced Water Applications - ScienceDirectDocument52 pagesEmulsion Separation and Fouling of Electrospun Polyacrylonitrile Membranes For Produced Water Applications - ScienceDirectMOH AMANNo ratings yet

- 131276-Article Text-354363-1-10-20160301Document16 pages131276-Article Text-354363-1-10-20160301Osaruchi MICHAEL100% (1)

- Electrochemistry Part 1Document10 pagesElectrochemistry Part 1Shofwa AnnisaaNo ratings yet

- Design and Rating of Trayed Distillation Columns PDFDocument45 pagesDesign and Rating of Trayed Distillation Columns PDFaliarbiNo ratings yet

- Printtt 2Document1 pagePrinttt 2chelcea estrabelaNo ratings yet

- ASTM D 1292 Odor in WaterDocument7 pagesASTM D 1292 Odor in WaterBalas43No ratings yet

- Lab Safety Dos DontsDocument3 pagesLab Safety Dos DontsMurali KrishnaNo ratings yet

- Lecture #22-23 - Without Annotation PDFDocument18 pagesLecture #22-23 - Without Annotation PDFHritik LalNo ratings yet

Axeon XE1 Membrane Spec Sheet

Axeon XE1 Membrane Spec Sheet

Uploaded by

amanuel waleluOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Axeon XE1 Membrane Spec Sheet

Axeon XE1 Membrane Spec Sheet

Uploaded by

amanuel waleluCopyright:

Available Formats

PRODUCT SPECIFICATIONS

XE1 – SERIES MEMBRANE ELEMENTS

AXEON® XE1 – Series Membrane Elements offer enhanced performance and

extra energy savings for reverse osmosis systems by operating at a low applied

pressure of 100 psi with a nominal rejection rate of 99.2%. AXEON XE1 – Series

are fiberglass wrapped and manufactured in a state–of–the–art, ISO–9001

compliant automated rolling facility and are shipped dry for extended shelf life.

OPERATING LIMITS SPECIFICATIONS

Membrane Type Polyamide Thin – Film Composite APPLIED PRESSURE PERMEATE FLOW RATE NOMINAL SALT

DESCRIPTION

(PSI / BAR) (GPD / M3/D) REJECTION %

Maximum Operating Temperature (°F / °C) 113 / 45

XE1 – 2521 300 / 1.14

Maximum Operating Pressure (psi / bar) 600 / 41

XE1 – 2540 600 / 2.27

pH Range, Continuous Operation* 2 – 11 100 / 6.89 99.20

XE1 – 4040 2400 / 9.09

pH Range, Short Term Cleaning (30 Min.) 1 – 13 XE1 – 8040 11000 / 41.63

Maximum Feed Silt Density Index (SDI) 5

Warranty Evaluation Test Conditions: Permeate flow and salt rejection based on the following

Chlorine / Chloramine Tolerance (ppm) 0 test conditions – 550 ppm, filtered and dechlorinated municipal tap water, 77°F / 25°C, 8% recov-

ery 2521, and 15% recovery 2540, 4040, 8040 at the specified operating pressure. Minimum salt

Maximum Feed Flow Rate (gpm) 2.5” = 6, 4.0” = 14, 8.0” = 75

rejection is 96%. Permeate flows for warranty evaluation may vary +/-20%.

* Maximum temperature for continuous operations above pH10 is 95°F / 35°C.

A

DIMENSIONS (IN / MM)

A

FLOW DIRECTION

C

FLOW DIRECTION DESCRIPTION A B C D

C

D XE1 – 2521 21 / 533 1.12 0.75 / 19.10 2.40 / 61

D

XE1 – 2540 40 / 1016 1.12 0.75 / 19.10 2.40 / 61

B 4040 MEMBRANE XE1 – 4040 40 / 1016 1.04 0.75 / 19.10 3.90 / 99

B 4040 MEMBRANE XE1 – 8040 40 / 1016 N/A 1.12 / 28.50 7.91 / 201

A

A

FLOW DIRECTION All 2521 and 2540 elements fit nominal 2.50” I.D. membrane housings, all 4040 elements fit nominal

4.00” I.D. membrane housings, and all 8040 elements fit nominal 8.00” I.D. membrane housings.

FLOW DIRECTION

D

D

8040 MEMBRANE C

Proper start – up of reverse osmosis water 8040 MEMBRANE

treatment systems is essential C

to prepare the membranes for operating service and to prevent membrane damage due to overfeeding or hydraulic shock.

Before initiating system start–up procedures, membrane pretreatment, loading of the membrane elements, instrument calibration and other system checks should be completed.

Avoid any abrupt pressure or cross–flow variations on the spiral elements during start–up, shutdown, cleaning or other sequences to prevent possible membrane damage. During start–up, a gradual

change from a standstill to operating state is recommended as follows:

• Feed pressure should be increased gradually over a 30 – 60 second time frame.

• Cross – flow velocity at set operating point should be achieved gradually over 15 – 20 seconds.

• Permeate obtained from first hour of operation should be discarded.

• Maximum pressure drop across an entire pressure vessel (housing) is 15 psi / 1.03 bar.

• Avoid static permeate – side backpressure at all times.

Under certain conditions, the presence of free chlorine, chloramines and other oxidizing agents will cause premature membrane failure. Since oxidation damage is not covered under warranty, the

manufacturer recommends removing all oxidizing agents by pretreatment prior to membrane exposure. Please contact the manufacturer or your supplier for more information.

Do not use this initial permeate for drinking water or food preparation. Keep elements moist at all times after initial wetting. To prevent biological growth during prolonged system shutdowns, it is

recommended that membrane elements be immersed in a preservative solution. Rinse out the preservative before use. For membrane warranty details, please contact the manufacturer or your supplier

for more information.

If operating limits and guidelines given in this product specification sheet are not strictly followed, the warranty will be null and void. The customer is fully responsible for the effects of incompatible

chemicals and lubricants on elements. Use of any such chemicals or lubricants will void the warranty. These membranes may be subject to drinking water application restrictions in some countries:

please check the application status before use and sale. The use of this product in and of itself does not necessarily guarantee the removal of cysts and pathogens from water. Effective cyst and

pathogen reduction is dependent on the complete system design and on the operation and maintenance of the system.

No freedom from infringement of any patent owned by the manufacturer or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may

change with time, customer is responsible for determining whether products and the information in this document are appropriate for customer’s use and for ensuring that customer’s workplace and

disposal practices are in compliance with applicable laws and other governmental enactments. The claims made may not have been approved for use in all countries. The manufacturer assumes no

obligation or liability for the information in this document. AXEON reserves the right to update this information periodically for the purposes of quality and accuracy. NO WARRANTIES ARE GIVEN;

ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

800-320-4074 axeonwater.com

MKT – 578 – A 09/23/20 ©2020 AXEON Water Technologies

You might also like

- J N H Tiratsoo - Pipeline Pigging and Integrity Technology PDFDocument519 pagesJ N H Tiratsoo - Pipeline Pigging and Integrity Technology PDFfhtgerthrgerg50% (2)

- Мембрана TM810 SpecDocument2 pagesМембрана TM810 SpecAlexanderNo ratings yet

- Axeon FH1-4040Document2 pagesAxeon FH1-4040Alejandro AliNo ratings yet

- Sea Water RO Elements: DimensionsDocument2 pagesSea Water RO Elements: Dimensionswahyu raharjoNo ratings yet

- Swro TM800KDocument2 pagesSwro TM800KthanhhuyenNo ratings yet

- Dowex HCR SS LDocument2 pagesDowex HCR SS LOmar SaeedNo ratings yet

- Dowex Marathon C: Ion Exchange ResinDocument12 pagesDowex Marathon C: Ion Exchange ResinZeeshan TalibNo ratings yet

- TC FLS Sihi Leh 1200 1500 1800 enDocument10 pagesTC FLS Sihi Leh 1200 1500 1800 enGustavo ZavalaNo ratings yet

- Bosch Rexroth - Datasheet - Counterbalance ValvesDocument2 pagesBosch Rexroth - Datasheet - Counterbalance ValvesDiogo LuisNo ratings yet

- Digital Pressure Calibrator Nvision Product Drawing UsDocument2 pagesDigital Pressure Calibrator Nvision Product Drawing Us张凯权No ratings yet

- Katalog SIHI Liquid Ring Vacuum PumpsDocument12 pagesKatalog SIHI Liquid Ring Vacuum PumpsTrisna RamadhanNo ratings yet

- Toray TM820M 440 - Spec - SheetDocument2 pagesToray TM820M 440 - Spec - SheetJoselito CortesNo ratings yet

- Dowex-Marathon-A RESINA ANIÔNICADocument3 pagesDowex-Marathon-A RESINA ANIÔNICAMarcus FreitasNo ratings yet

- Dowex Marathon CDocument2 pagesDowex Marathon CMuhammad ImranNo ratings yet

- Product Information: Motor-Driven Diaphragm Dosing Pumps Memdos E/DxDocument19 pagesProduct Information: Motor-Driven Diaphragm Dosing Pumps Memdos E/DxSufian LucasNo ratings yet

- Erapol E90A: Technical DatasheetDocument2 pagesErapol E90A: Technical Datasheetmgamal1080No ratings yet

- EAIR06ADocument2 pagesEAIR06ARay GongNo ratings yet

- 1N5400 THRU 1N5408: General Purpose Silicon RectifierDocument2 pages1N5400 THRU 1N5408: General Purpose Silicon RectifierfelipeNo ratings yet

- DC Components Co., LTD.: 10A05 Thru 10A10Document3 pagesDC Components Co., LTD.: 10A05 Thru 10A10Faulhaber AdrianNo ratings yet

- Tecothane TPU ClearDocument3 pagesTecothane TPU ClearKhoa HuynhdangNo ratings yet

- KDS 1c326000ab0ar 3225 X'talDocument13 pagesKDS 1c326000ab0ar 3225 X'talYujia LiNo ratings yet

- SanRO HS PDFDocument1 pageSanRO HS PDFjohn_paisNo ratings yet

- Dow Water & Process SolutionsDocument11 pagesDow Water & Process SolutionsZulfikri ZulkifliNo ratings yet

- Dowex Upcore Mono C600 LDocument2 pagesDowex Upcore Mono C600 Lengineer.humgNo ratings yet

- Technical Data Sheet Linen PhenolicDocument1 pageTechnical Data Sheet Linen PhenolicKissa DolautaNo ratings yet

- Gemini Column CareDocument3 pagesGemini Column CareLee MingTingNo ratings yet

- NP 140Document5 pagesNP 140Nicole YangNo ratings yet

- TM800VDocument2 pagesTM800VMoustafa GamilNo ratings yet

- UF4001-4007 (1A 高速)Document2 pagesUF4001-4007 (1A 高速)vetchboyNo ratings yet

- Single-Phase Glass Passivated Silicon Bridge Rectifier: RS401L Thru RS407LDocument5 pagesSingle-Phase Glass Passivated Silicon Bridge Rectifier: RS401L Thru RS407Lalexnder gallegoNo ratings yet

- CEM 3 10 - DatasheetDocument1 pageCEM 3 10 - Datasheetmccornejo1617No ratings yet

- 10A05 Thru 10A10: Silicon RectifierDocument4 pages10A05 Thru 10A10: Silicon RectifierTECELENAV SANo ratings yet

- Pro XP1Document2 pagesPro XP1sunil patelNo ratings yet

- DC Components Co., LTD.: RL201 Thru RL207Document3 pagesDC Components Co., LTD.: RL201 Thru RL207cclodoaldo1577No ratings yet

- Liquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340Document10 pagesLiquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340pablodugalNo ratings yet

- Model Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADocument2 pagesModel Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AAnurag JainNo ratings yet

- Toray TM820V 400 Sea Water RO Element LDocument2 pagesToray TM820V 400 Sea Water RO Element LLuzmaNo ratings yet

- Dominion Aluminium LV Cable Technical Data SheetDocument2 pagesDominion Aluminium LV Cable Technical Data SheetRonish ChandraNo ratings yet

- RPG 15aDocument2 pagesRPG 15aCARLOS ARGUELLES RODRIGUEZNo ratings yet

- PDF Kingboard KB 6160A Data SheetDocument2 pagesPDF Kingboard KB 6160A Data SheetAlex Prim NavajasNo ratings yet

- EM-S570 Datasheet (Preliminary) 20231130 - 24011013537Document1 pageEM-S570 Datasheet (Preliminary) 20231130 - 24011013537AhSangCheeSangNo ratings yet

- Continental Device India Limited: Fast Recovery Rectifiers 1N4933 - 1N4937 DO-41 (Plastic) Axial Lead Plastic PackageDocument5 pagesContinental Device India Limited: Fast Recovery Rectifiers 1N4933 - 1N4937 DO-41 (Plastic) Axial Lead Plastic Packagevoll.stefanNo ratings yet

- Ag 4040Document2 pagesAg 4040Aravind RaoNo ratings yet

- SB5150 SB5200: Schottky Barrier Rectifier Diodes PRV: 150 200 Volts I: 5.0 AmperesDocument2 pagesSB5150 SB5200: Schottky Barrier Rectifier Diodes PRV: 150 200 Volts I: 5.0 AmperesRafael LehmkuhlNo ratings yet

- Technical Data Sheet Nylon: (Polyamide)Document3 pagesTechnical Data Sheet Nylon: (Polyamide)Dharmendra DubeyNo ratings yet

- C42-4122-202201-2842 - For Proposal - 20220203Document4 pagesC42-4122-202201-2842 - For Proposal - 20220203Juliyanto STNo ratings yet

- Filmtec BW30-2540Document3 pagesFilmtec BW30-2540PT Deltapuro IndonesiaNo ratings yet

- Divlab Touch Screen 2017 UpradableDocument5 pagesDivlab Touch Screen 2017 UpradableAxcel Helsing100% (1)

- Datasheet of Electrical Motor: 1.0 Supplier InformationDocument2 pagesDatasheet of Electrical Motor: 1.0 Supplier InformationRenzo Malcolm Garcia PickmannNo ratings yet

- RO4400 PrepregDocument2 pagesRO4400 Prepreggcohen03No ratings yet

- Jesco Motordriven Kolvdoserpump Typ Fedos Rekos Kardos-Manual ENG 0Document121 pagesJesco Motordriven Kolvdoserpump Typ Fedos Rekos Kardos-Manual ENG 0Luis TeixeiraNo ratings yet

- Hf23e 0Document2 pagesHf23e 0BokiNo ratings yet

- Dowex Marathon C (HT)Document2 pagesDowex Marathon C (HT)juan grasselerNo ratings yet

- Static Dissipative Polyetherimide (Pei) / Static Dissipative UltemDocument1 pageStatic Dissipative Polyetherimide (Pei) / Static Dissipative UltemVC KannanNo ratings yet

- Dowex Marathon ADocument2 pagesDowex Marathon Ajuan grasselerNo ratings yet

- YD 90L 4 6 DatasheetDocument1 pageYD 90L 4 6 DatasheetLance AyoubNo ratings yet

- Sihi Lem 90 - 125 - 150 DetailsDocument4 pagesSihi Lem 90 - 125 - 150 DetailsElmer RchNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- 4 5805228864158306714Document1 page4 5805228864158306714amanuel waleluNo ratings yet

- Uro Felege Hiwot HospitalDocument2 pagesUro Felege Hiwot Hospitalamanuel waleluNo ratings yet

- Patient MonitorsDocument2 pagesPatient Monitorsamanuel waleluNo ratings yet

- WHO-water Purificatio SystemsDocument5 pagesWHO-water Purificatio Systemsamanuel waleluNo ratings yet

- Regions InvitationsDocument1 pageRegions Invitationsamanuel waleluNo ratings yet

- Ehsig Assment Handbook Latest VersionDocument162 pagesEhsig Assment Handbook Latest Versionamanuel walelu100% (6)

- Medical Equipment ListDocument10 pagesMedical Equipment Listamanuel waleluNo ratings yet

- Aquasystem: Purity For LifeDocument7 pagesAquasystem: Purity For LifejpfamiliabNo ratings yet

- Pulse OximeterDocument13 pagesPulse Oximeteramanuel waleluNo ratings yet

- Oxygen CylinderDocument16 pagesOxygen Cylinderamanuel walelu100% (2)

- DRF-1 - HF 80kW Digital RF X-Ray System - 201706Document7 pagesDRF-1 - HF 80kW Digital RF X-Ray System - 201706amanuel walelu100% (1)

- MN150 3 B PDFDocument157 pagesMN150 3 B PDFamanuel waleluNo ratings yet

- ASD T 901889 - 02USE Operator Manual PDFDocument156 pagesASD T 901889 - 02USE Operator Manual PDFamanuel waleluNo ratings yet

- Flowmeter ManualDocument46 pagesFlowmeter Manualamanuel waleluNo ratings yet

- Manual 2V3B-4.1V - RevEDocument79 pagesManual 2V3B-4.1V - RevEamanuel walelu100% (2)

- Airsep Corporation As-J-600-Hmfm Duplex Psa Oxygen System: Instruction ManualDocument61 pagesAirsep Corporation As-J-600-Hmfm Duplex Psa Oxygen System: Instruction Manualamanuel walelu100% (1)

- 3M - Scotchcast Brand Flame Retardant Compound 2130Document8 pages3M - Scotchcast Brand Flame Retardant Compound 2130jaredf@jfelectric.comNo ratings yet

- Antiarrhythmic Drugs-Test-1-QuestionsDocument7 pagesAntiarrhythmic Drugs-Test-1-QuestionsDrishya Bioplannet100% (2)

- Clinical Biochemistry Exam-2 andDocument1 pageClinical Biochemistry Exam-2 andMina MansourNo ratings yet

- Heat GunDocument11 pagesHeat GunMary Grace Aboque-Tan SangcomNo ratings yet

- Neodyl PDFDocument2 pagesNeodyl PDFvranceanu.ovidiu-1No ratings yet

- Alkali Industry Caustic Soda Ash To ClasDocument56 pagesAlkali Industry Caustic Soda Ash To Classelvaraj5natesanNo ratings yet

- Pipe Fittings and Port AdaptersDocument26 pagesPipe Fittings and Port AdaptersdekgaleNo ratings yet

- Dci PipesDocument24 pagesDci PipesshamashergyNo ratings yet

- ... - Oil Painting Without SolventsDocument2 pages... - Oil Painting Without Solventsdorut50% (2)

- Charge On Gas BubbleDocument9 pagesCharge On Gas BubbleB A NaiduNo ratings yet

- Lab 8 Crystal Structure Analysis in Engineering MaterialsDocument6 pagesLab 8 Crystal Structure Analysis in Engineering MaterialsTommy MilesNo ratings yet

- Material Properties Filament Wound Composite Structures: A Versatile Solution To Today's Design ProblemsDocument4 pagesMaterial Properties Filament Wound Composite Structures: A Versatile Solution To Today's Design ProblemsOliver RisteskiNo ratings yet

- Enimex - BVFL - GB PDFDocument6 pagesEnimex - BVFL - GB PDFAlienshowNo ratings yet

- Hydrifin BrochureDocument10 pagesHydrifin BrochureDmitryNo ratings yet

- Heat Treatment of Low Carbon SteelDocument39 pagesHeat Treatment of Low Carbon SteelHEMANTKHERANo ratings yet

- SKL 3013: Chemistry Laboratory Management Techniques: Fatini Zakirah Binti Zaharin D20161073878Document11 pagesSKL 3013: Chemistry Laboratory Management Techniques: Fatini Zakirah Binti Zaharin D20161073878nadhirahNo ratings yet

- Green ElectronicsDocument11 pagesGreen Electronicsashutosh199625No ratings yet

- Geology and Drilling TheoryDocument20 pagesGeology and Drilling TheoryJose Antonio Sanchez SegoviaNo ratings yet

- Unit 1Document40 pagesUnit 1Ram SaaceNo ratings yet

- Plant JeopardyDocument73 pagesPlant JeopardymrsklipfelNo ratings yet

- Turbocharger Troubleshooting: 1 Compressor SurgingDocument3 pagesTurbocharger Troubleshooting: 1 Compressor SurgingJatin JainNo ratings yet

- Emulsion Separation and Fouling of Electrospun Polyacrylonitrile Membranes For Produced Water Applications - ScienceDirectDocument52 pagesEmulsion Separation and Fouling of Electrospun Polyacrylonitrile Membranes For Produced Water Applications - ScienceDirectMOH AMANNo ratings yet

- 131276-Article Text-354363-1-10-20160301Document16 pages131276-Article Text-354363-1-10-20160301Osaruchi MICHAEL100% (1)

- Electrochemistry Part 1Document10 pagesElectrochemistry Part 1Shofwa AnnisaaNo ratings yet

- Design and Rating of Trayed Distillation Columns PDFDocument45 pagesDesign and Rating of Trayed Distillation Columns PDFaliarbiNo ratings yet

- Printtt 2Document1 pagePrinttt 2chelcea estrabelaNo ratings yet

- ASTM D 1292 Odor in WaterDocument7 pagesASTM D 1292 Odor in WaterBalas43No ratings yet

- Lab Safety Dos DontsDocument3 pagesLab Safety Dos DontsMurali KrishnaNo ratings yet

- Lecture #22-23 - Without Annotation PDFDocument18 pagesLecture #22-23 - Without Annotation PDFHritik LalNo ratings yet