Professional Documents

Culture Documents

Mitek - Internal Load Bearing 10 - 2011

Mitek - Internal Load Bearing 10 - 2011

Uploaded by

Yanina MashkinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mitek - Internal Load Bearing 10 - 2011

Mitek - Internal Load Bearing 10 - 2011

Uploaded by

Yanina MashkinaCopyright:

Available Formats

10/2011

INTERNAL LOAD BEARING

ON CONCRETE FLOOR SLABS

Covers floor thickening and supporting stud requirements.

Covers floor slabs on buildings complying with NZS 3604:2011.

All concrete slabs to be constructed as per NZS 3604:2011.

Thickening requirements apply to reinforced floor slabs.

Provides solutions for stud requirements where point loads exceed 10 kN.

All slabs assumed to be supported on soils that have Ultimate Bearing Capacity

of 300 kPa (Øb=0.50).

© Copyright 2011 MiTek Holdings, Inc.

All rights reserved.

Establishing Thickening & Stud Requirements

1. Establish the type of load applied to the floor as being either a UDL (uniformly distributed load) or a

concentrated load. Girder trusses will always give concentrated loads and a run of two or more

trusses with the same loads will give a UDL.

2. Establish the maximum load value via the MiTek 20/20® Truss Design Software by using the Truss

Bearings Exceeding 10 kN Report (see example below). Choose the maximum DOWN value in kN.

3. Go to the Slab Thickening & Stud Requirement Table on page 3 and choose from the appropriate

section; either no change for up to 10 kN, FP1 and FS1 for up to 20 kN, or FP2 and FS2 for up to 30 kN.

4. Choose from the selection of stud options (height, centres and grade).

5. Apply the relevant slab and stud requirements as specified and detailed on page 3.

6. Where the maximum positive bearing reaction exceeds 10 kN (uplift), refer to MiTek for Special

Design.

MiTek 20/20® Example Selection

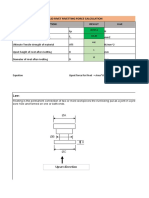

TRUSS BEARINGS EXCEEDING 10 kN REPORT

Truss List

Legend: ? = input only, Txx = failed design, Unmarked trusses = designed successfully

Critical Trusses Qty Span Joint Bearing Reactions (kN)

(mm) Down Uplift

GT01 1 8000 J 16.177 7.292

Girder truss GT01

B J O

2400

Maximum down Studs @

value = -16.177 kN 600 crs.

MSG8

Grade

375 x 375 Square pad as per detail FP1 2 Studs required under truss

SINGLE STUD OPTION MULTIPLE STUD OPTION

Top plate arrangement * Max. 50mm tolerance Loaded truss

as per NZS 3604:2011 for truss location

Top plate arrangement

as per NZS 3604:2011

Truss can be located Multiple studs as indicated

anywhere on the top plate by design table on page 3

© Copyright 2011 MiTek Holdings, Inc.

All rights reserved.

2

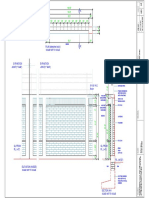

Slab Thickening & Stud Requirement Table

CONSTRUCTION SPECIFICATIONS

Max. truss crs. @ 1200mm, Min. truss crs. @ 600mm.

Assume walls are fully lined on at least one face.

Assume full bearing on top plate (i.e. no eccentric loading).

STUD REQUIREMENTS

TRUSS BEARING SLAB THICKENING DETAIL

UNIFORM DIST. LOADS OR CONCENTRATED LOADS

REACTION

CONCENTRATED LOAD UNIFORM DIST. LOAD STUD HEIGHT STUD REQUIREMENTS

Bearing reaction up 2400

to & including STANDARD STANDARD

reinforced slab floor reinforced slab floor 2700 Refer to NZS 3604:2011

10 kN as per NZS 3604:2011 as per NZS 3604:2011 3000

NO. OF STUD

STUD HEIGHT MIN. TIMBER SIZE

UNDER TRUSS

Bearing reaction up 2400 2 90 x 35

to & including TYPE FP1 TYPE FS1

2700 2 90 x 45

20 kN 375 x 375 PAD 300 STRIP THICKENING

3000 3 90 x 45

NO. OF STUD

STUD HEIGHT MIN. TIMBER SIZE

UNDER TRUSS

Bearing reaction up 2400 3 90 x 45

to & including TYPE FP2 TYPE FS2

2700 3 90 x 45

30 kN 450 x 450 PAD 450 STRIP THICKENING

3000 4 90 x 45

TIMBER SPECIFICATIONS * Note:The stud requirement for 20 kN &

Timber properties based on NZS 3603:1993 Amendment No.4 March 2005. 30 kN bearing reactions can be applied to

Minimum grade specified is SG8 unless otherwise noted. external walls as well.

For SG6 use the studs for the next highest category.

i.e. - For loads up to 10 kN select studs from the 20 kN table.

- For loads up to 20 kN select studs from the 30 kN table.

- For loads above 20 kN Special Design is required.

Slab Thickening Details

CONCRETE PAD CONTINUOUS CONCRETE

OPTIONS THICKENING OPTIONS

(for concentrated loads) (for uniformly distributed loads)

Stud wall as per Standard 100mm reinforced Stud wall as per Standard 100mm reinforced

NZS 3604:2011 slab, as per NZS 3604:2011 NZS 3604:2011 slab, as per NZS 3604:2011

100 100

STANDARD 100mm SLAB STANDARD 100mm SLAB

Stud Stud

requirements requirements Stud requirements Continuous strip thickening

as per table 2 D12 Bars both ways as per table as per table above along length of wall below

above above loaded trusses

R10 Bars @ 600 crs.

100 100 100

75 100 75 100 75 cover 100

cover cover

2 D12

100 375 100 TYPE FP1 100 375 100 TYPE FS1 100 300 100

Stud Stud

requirements requirements Stud requirements Continuous strip thickening

as per table 3 D12 Bars both ways as per table as per table above along length of wall below

above above loaded trusses

R10 Bars @ 600 crs.

100 100 100

75 100 75 100 75 cover 100

cover cover

3 D12

100 450 100 TYPE FP2 100 450 100 TYPE FS2 100 450 100

NOTE: FP = Foundation Pad FS = Foundation Strip

© Copyright 2011 MiTek Holdings, Inc.

All rights reserved.

3

Retro Fitted Load Bearing Option

Note:

Covers slab details where no thickening has been built into the foundation.

For loads exceeding 10 kN install bottom lintel (300 x 100) between two adjacent studs as detailed

below. For loads 30 kN or more, special design is required.

Ensure the studs comply with requirements on page 3 and are located directly under concentrated

loads. This may require on-site installation of these studs.

Concentrated Load

TRUSS BEARING LOAD

Studs as per table on page 3 LUMBERLOK

CPC80 each side

6 x 90mm nails through

studs into bottom lintel LUMBERLOK

at each end CPC80 each side

2 / 300 x 50 or 1 / 300 x 100 SG8 bottom

lintel. Nail as standard pre-cut details

Uniformly Distributed Loads

TRUSSES LOADING ON TO TOP PLATE UNIFORMLY

(locations indicative only)

Internal load bearing wall

Number of studs shown

indicative only

LUMBERLOK

6 x 90mm nails through CPC80 each stud

studs into bottom lintel

at each end

2 / 300 x 50 or 1 / 300 x 100 SG8 bottom

lintel. Nail as standard pre-cut details

MiTek New Zealand Limited

AUCKLAND CHRISTCHURCH

PO Box 58-014, Botany 2163 PO Box 8387, Riccarton 8440

Phone: 09-274 7109 Phone: 03-348 8691

© Copyright 2011 MiTek Holdings, Inc.

4

Fax: 09-274 7100 Fax: 03-348 0314

All rights reserved.

www.miteknz.co.nz

GANG-NAIL® LUMBERLOK® BOWMAC®

You might also like

- List of Ch. 7+300: Design of Abutment A2Document44 pagesList of Ch. 7+300: Design of Abutment A2Nilay Gandhi100% (5)

- Solid Rivet Upset Force CalculationDocument7 pagesSolid Rivet Upset Force CalculationVenkateswaran venkateswaranNo ratings yet

- Anchor Bolt Design IS Code LSDDocument33 pagesAnchor Bolt Design IS Code LSDdebjyoti_das_667% (9)

- Anchor Bolt DesignDocument3 pagesAnchor Bolt Designvaibhavd123No ratings yet

- INSTRUCCIONES LAMIDISC English 1001-I (Reva)Document4 pagesINSTRUCCIONES LAMIDISC English 1001-I (Reva)tm5u2rNo ratings yet

- DropinsubmittalsDocument2 pagesDropinsubmittalsRenzo CarmenNo ratings yet

- Base Shear Resistance Calculation - R1Document8 pagesBase Shear Resistance Calculation - R1suman_civilNo ratings yet

- Base Plate With BoltsDocument3 pagesBase Plate With BoltsAbu KhatriNo ratings yet

- Masonry Anchor Bolt DesignDocument1 pageMasonry Anchor Bolt DesignEdgardo ArriesgadoNo ratings yet

- 8 CE133P Ultimate Strength Design One Way Slabs Rev (Robles) 2Document12 pages8 CE133P Ultimate Strength Design One Way Slabs Rev (Robles) 2KC Paguinto100% (1)

- 8 CE133P Ultimate Strength Design One Way Slabs RevDocument12 pages8 CE133P Ultimate Strength Design One Way Slabs RevJohn Cedric Garganera100% (1)

- Anchor Bolt Design IS Code LSDDocument56 pagesAnchor Bolt Design IS Code LSDajNo ratings yet

- EC Drive - EC PlusDocument21 pagesEC Drive - EC PlusMohammed FarhanNo ratings yet

- Tubular Steel PilesDocument4 pagesTubular Steel PilesRyan Achmad FadhillahNo ratings yet

- Taranto Tubular PilesDocument4 pagesTaranto Tubular PilesNitaiGauranga108100% (1)

- Hl707 Adicg CR 001 r0 (Load Out Ramp)Document8 pagesHl707 Adicg CR 001 r0 (Load Out Ramp)dheeraj SureshNo ratings yet

- Design Features Report: Standards ReferencedDocument2 pagesDesign Features Report: Standards Referencedtimur sibaevNo ratings yet

- K Series 20 31 - CatalogueDocument19 pagesK Series 20 31 - CatalogueFilip StenströmNo ratings yet

- Analysis, Design and Estimation of Multi-Storey Building Using Build MasterDocument37 pagesAnalysis, Design and Estimation of Multi-Storey Building Using Build MasternaveenNo ratings yet

- Highload Anchor SZDocument10 pagesHighload Anchor SZKha PhucNo ratings yet

- A2-Pile Calculation - BH M1Document90 pagesA2-Pile Calculation - BH M1Priya GopalNo ratings yet

- Foundation Design ReportDocument5 pagesFoundation Design ReportShashankSinghNo ratings yet

- Beam Design For Moment, Shear & TorsionDocument6 pagesBeam Design For Moment, Shear & Torsionsidiq7No ratings yet

- Design Detail: Beta Tester For IES, Inc. F-5Document7 pagesDesign Detail: Beta Tester For IES, Inc. F-5Mark Gregory RimandoNo ratings yet

- Pad Foundation Design To Bs 81101997Document23 pagesPad Foundation Design To Bs 81101997Anonymous 66uWhphVNo ratings yet

- CAT 3905 en - Triple-Sealed - Bearings - For - Bearing - UnitsDocument15 pagesCAT 3905 en - Triple-Sealed - Bearings - For - Bearing - UnitsJesusNo ratings yet

- ESR-2427 TB - July2010 PDFDocument13 pagesESR-2427 TB - July2010 PDFReinel OrjuelaNo ratings yet

- Working Ranges Specifications: SK12SR-3Document4 pagesWorking Ranges Specifications: SK12SR-3Akhmad SebehNo ratings yet

- Design Beam For Shear & TorsionDocument332 pagesDesign Beam For Shear & Torsionsidiq7No ratings yet

- Self Drilling Hollow Bars - Ground Anchor, Tension Pile or Soil NailDocument16 pagesSelf Drilling Hollow Bars - Ground Anchor, Tension Pile or Soil NailShiela Mae Intia MagalonaNo ratings yet

- Hiking Superior Industrial Co., Limited: Certificate of Detailed QualityDocument1 pageHiking Superior Industrial Co., Limited: Certificate of Detailed QualityCarlos CordovaNo ratings yet

- Lysaght Trimdek: Subtle Square Fluted Steel CladdingDocument6 pagesLysaght Trimdek: Subtle Square Fluted Steel Claddingfahim007No ratings yet

- Minor Bridge Design at CH 313+766Document48 pagesMinor Bridge Design at CH 313+766Aman HoodaNo ratings yet

- C7CH20050 - Wall - Reinforcement - WR2Document20 pagesC7CH20050 - Wall - Reinforcement - WR2Mahadev Sastry100% (1)

- Comments Marked in Grade Slab Design For 20T/m2 Also Applicable For This Document. UpdateDocument2 pagesComments Marked in Grade Slab Design For 20T/m2 Also Applicable For This Document. UpdateElancheliyan0% (2)

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangNo ratings yet

- Anchor Bolt Design, IS Code LSDDocument33 pagesAnchor Bolt Design, IS Code LSDamlan jyoti ChakravortyNo ratings yet

- 3 Splice-Ismb500 FinalDocument7 pages3 Splice-Ismb500 FinalAvishek DeyNo ratings yet

- Anchor Rod Check - PedestalDocument370 pagesAnchor Rod Check - PedestalharsharanmannNo ratings yet

- Timber Connectors Characteristic Loadings DataDocument8 pagesTimber Connectors Characteristic Loadings DataDinh Nam NguyenNo ratings yet

- Rf-Design&crack CheckDocument16 pagesRf-Design&crack CheckMukarramuddinNo ratings yet

- Introduction To AND: Reinforcement Detailing DrawingDocument43 pagesIntroduction To AND: Reinforcement Detailing DrawingSandgrouse Raj100% (1)

- 1 Input Data: WWW - Hilti.inDocument5 pages1 Input Data: WWW - Hilti.inRomyMohanNo ratings yet

- P1 Scrubber CalculationDocument46 pagesP1 Scrubber CalculationFARHANAH AFIQAH RAZMANNo ratings yet

- RCC81 - FOOTING - External Ballroom East SideDocument18 pagesRCC81 - FOOTING - External Ballroom East SideMIHDI PALAPUZNo ratings yet

- Steel One Linear NotesDocument102 pagesSteel One Linear NotesUtkarsh KumarNo ratings yet

- SpeedBrace RoofingDocument8 pagesSpeedBrace RoofingArdenNo ratings yet

- Ductile Detailing BeamDocument21 pagesDuctile Detailing BeamUjwal Karki100% (1)

- Aisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1Document2 pagesAisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1GousePeerzadeNo ratings yet

- Spreadsheets To BS 8110: Advisory Group Level - 1 Base B1 RMW 113 CHG - R68Document14 pagesSpreadsheets To BS 8110: Advisory Group Level - 1 Base B1 RMW 113 CHG - R68Kasirun -No ratings yet

- RCC81 Foundation PadsDocument16 pagesRCC81 Foundation PadsjagogambarNo ratings yet

- Off-The-Road Tires: Ultra-Heavy-Duty Mining PerformanceDocument2 pagesOff-The-Road Tires: Ultra-Heavy-Duty Mining PerformanceJAVIER BERMUDEZNo ratings yet

- Structural Design of Single Cell Box CulvertDocument1 pageStructural Design of Single Cell Box CulvertMahmoud HamadaNo ratings yet

- ACME-J-228-Unit-2 Shed-Estimate-R0Document1 pageACME-J-228-Unit-2 Shed-Estimate-R0Sunil RahangdaleNo ratings yet

- 8-Bearing PedestalDocument2 pages8-Bearing Pedestalsanjay vermaNo ratings yet

- 3916-Informe Analisis Viga Ipe 120Document11 pages3916-Informe Analisis Viga Ipe 120FELIPENo ratings yet

- Base Plate Andf Anchor Bolt Design For Minor Axis MomentDocument2 pagesBase Plate Andf Anchor Bolt Design For Minor Axis MomentSunil Pulikkal100% (1)

- 3-Design For ULS - Shear and Torsion (2016)Document22 pages3-Design For ULS - Shear and Torsion (2016)Jin PiaoNo ratings yet

- Done - SSAB - Welding of StrenxDocument16 pagesDone - SSAB - Welding of StrenxMONo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Turkey EphesusDocument1 pageTurkey EphesusUlaş Barış TeomanNo ratings yet

- Concrete WorksDocument14 pagesConcrete WorksOlivia OzneminNo ratings yet

- Revised Proposal For Pack House (On Farm Collection and Sorting Unit) Under Post Harvest ManagementDocument7 pagesRevised Proposal For Pack House (On Farm Collection and Sorting Unit) Under Post Harvest ManagementDHO PURBA BARDHAMANNo ratings yet

- SP Shukhobristhi - New Town Rajarhat, Kolkata: DescriptionDocument6 pagesSP Shukhobristhi - New Town Rajarhat, Kolkata: DescriptionRuchiraNo ratings yet

- Quiambao Residence Construction DrawingDocument13 pagesQuiambao Residence Construction DrawingJennifer Salonga ManinangNo ratings yet

- Area Covered by Fire Extinguisher (NBC) - Lceted PDFDocument6 pagesArea Covered by Fire Extinguisher (NBC) - Lceted PDFvignesh kumarNo ratings yet

- OSH Dashboard SampleDocument28 pagesOSH Dashboard SampleChung May LynnNo ratings yet

- ARENADocument9 pagesARENAAika KimNo ratings yet

- 03 - Preliminary Member SizingDocument6 pages03 - Preliminary Member SizingAmila Liyanaarachchi0% (1)

- The Construction of Soviet Culture FromDocument9 pagesThe Construction of Soviet Culture FromΑγις ΤσNo ratings yet

- Dreamfall GuideDocument50 pagesDreamfall Guidebudalastina1No ratings yet

- SCC Validation MixDocument5 pagesSCC Validation MixHumberto MorenoNo ratings yet

- Typical Gate Frame: Proposed Steel Gate and FenceDocument1 pageTypical Gate Frame: Proposed Steel Gate and FenceJoseph Cloyd LamberteNo ratings yet

- GFRG Panels: (Glassfibrereinforcedgypsumpanels)Document26 pagesGFRG Panels: (Glassfibrereinforcedgypsumpanels)abuzarNo ratings yet

- Activity Sheets QTR 2 Roof PlanDocument4 pagesActivity Sheets QTR 2 Roof PlanNa MieNo ratings yet

- Sunan Boundary Wall & Gate-Model2Document1 pageSunan Boundary Wall & Gate-Model2Abdur RazzakNo ratings yet

- Guidlines For Waffle Slab DesignDocument5 pagesGuidlines For Waffle Slab Designhafiz zain saeedNo ratings yet

- B Arch - Timetable - Allotment - Even Sem - 2023-15-12-2023.Document4 pagesB Arch - Timetable - Allotment - Even Sem - 2023-15-12-2023.Soundarya SahooNo ratings yet

- Gree Bora 18k Gwh18aad-K6dna4b Service ManualDocument85 pagesGree Bora 18k Gwh18aad-K6dna4b Service ManualMaurizio DumitracheNo ratings yet

- Capiz State University: Construction of Three Storey Commercial BuildingDocument1 pageCapiz State University: Construction of Three Storey Commercial BuildingDIAMA, JOYCE LYNN MAE B.No ratings yet

- Havelis of RajasthanDocument8 pagesHavelis of RajasthanKiran Kumar Sreedharan80% (5)

- 13bentonit SlurryDocument44 pages13bentonit SlurryBishow KCNo ratings yet

- Ar700 (T2) - Glazing ScheduleDocument1 pageAr700 (T2) - Glazing ScheduleErwin ObenzaNo ratings yet

- Taking Measures Across The Medieval LandscapeDocument11 pagesTaking Measures Across The Medieval LandscapeTuğman BüberciNo ratings yet

- Super Final File CMPMDocument15 pagesSuper Final File CMPMFOEBE MARREY MANUELNo ratings yet

- APM Series: Compact Axial FansDocument4 pagesAPM Series: Compact Axial FansCong VietNo ratings yet

- Naurang Yatri Niwas FinalDocument18 pagesNaurang Yatri Niwas FinalRiddhi Aggarwal100% (3)

- Mitra IsoDocument2 pagesMitra IsoJAMES ALLISON RAULENo ratings yet

- Polyalk WPDocument2 pagesPolyalk WPkalyanqaqc100% (1)

- Chapter-10-History - (The Legacy of The Mughals)Document2 pagesChapter-10-History - (The Legacy of The Mughals)Adam shakilNo ratings yet