Professional Documents

Culture Documents

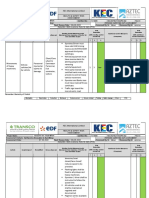

Risk Assessment-Pnuematic Test. Draft

Risk Assessment-Pnuematic Test. Draft

Uploaded by

Kono Nor AtanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment-Pnuematic Test. Draft

Risk Assessment-Pnuematic Test. Draft

Uploaded by

Kono Nor AtanCopyright:

Available Formats

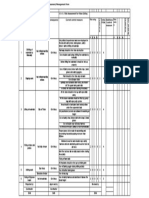

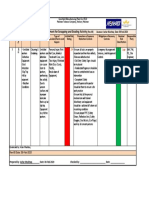

RISK ASSESSMENT FORM

Company: Ben Ching Engineering Pte Ltd

Location: Customer site

Pnuematic test with air with new vessels / Conducted by:

Activity : K. Raji Reddy and team; Wong SH, BV consultant

pipe (Names, designations)

Approved by:

(Name, designation, date) Sei Gim Hong Last Review Date: 22 Dec 2006 Next Review Date: As when needed

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

Potential Existing Risk Control Action Officer,

No. Work Activity Hazard Consequences / S L RR Additional Risk Control

Accidents (if any) (Follow-up date)

1 Blinding a) Nipping a) Fingers may cut Use Proper P.P.E hand 2 1 L 1. Permit to work before Fitter, Worker

hazard gloves, and proper tools commencement of work

b) Tripping b) Face burnt Wear face shield, and prevent 2 2 M 1. Lock out and Tag out Supervisor,

Hazard spills by containing the oil and worker

c) Oil/Steam using container 2. Permit to work

spillage

2 Air Filling a) High pressure a) Injuries Barricade the area, wear 3 1 M 1. Permit to work before Supervisor,

rupture or b) Vessel damage suitable P.P.E commencement of work Foreman,

damage 2. Use of pressure

vessel regulator to step down worker

designed to pressure before inlet to

low pressure the vessel. Pressure

setting to suite test

pressure.

3. Correct range of

pressure gauge to be

used.

4. Connections and

attachments shall be

checked to be tight and

of correct pressure

rating.

3 Pressurise up t o a) Tripping a) Face injury Barricade the area, wear 2 2 M 1. Adequate Lighting Foreman,

Required hazard. Face shield. 2. Proper access &

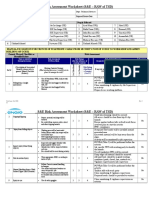

Risk Assessment Register - Draft

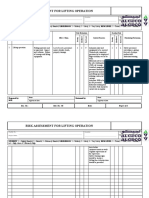

RISK ASSESSMENT FORM

Company: Ben Ching Engineering Pte Ltd

Location: Customer site

Pnuematic test with air with new vessels / Conducted by:

Activity : K. Raji Reddy and team; Wong SH, BV consultant

pipe (Names, designations)

Approved by:

(Name, designation, date) Sei Gim Hong Last Review Date: 22 Dec 2006 Next Review Date: As when needed

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

Potential Existing Risk Control Action Officer,

No. Work Activity Hazard Consequences / S L RR Additional Risk Control

Accidents (if any) (Follow-up date)

Pressure platform if vessel / pipe worker

line located above 2m

3. Do not exceed test

b) Failure of b) Same as above Procedure to build up pressure parameters.

equipment item 2 pressure slowly. 4. Test areas should not

during testing. ( others same as above item be left unattended

2) during the holding test

period.

4 Rectify defect or a) Nipping a) Fingers may cut a) Use Proper P.P.E hand 2 1 L 1. Adequate Lighting Foreman,

Leakage gloves, and proper tools 2. Proper access & worker

platform if pipe line

located above 2m

5 Release the a) Air release a) Injury to eyes a) Barricade the area; wear 1 1 L Permit to work Foreman,

pressure injure worker suitable face shield, worker

eyes gloves and safety shoes.

b) Keep workers away from

air release outlet.

c) Procedure to

depressurise before

unbolting.

6 De-blinding a) Nipping a) Fingers may cut a) Use Proper P.P.E hand 2 1 L 1. Permit to work before Fitter, Worker

hazard gloves, and proper tools commencement of

work.

Risk Assessment Register - Draft

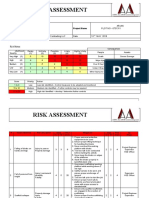

RISK ASSESSMENT FORM

Company: Ben Ching Engineering Pte Ltd

Location: Customer site

Pnuematic test with air with new vessels / Conducted by:

Activity : K. Raji Reddy and team; Wong SH, BV consultant

pipe (Names, designations)

Approved by:

(Name, designation, date) Sei Gim Hong Last Review Date: 22 Dec 2006 Next Review Date: As when needed

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

Potential Existing Risk Control Action Officer,

No. Work Activity Hazard Consequences / S L RR Additional Risk Control

Accidents (if any) (Follow-up date)

2. Procedure to first unbolt

bolts away from fitter.

Likelihood Remote Occasional Frequent

Severity (1) (2) (3)

Major (3) M H H

Moderate (2) L M H

Minor (1) L L M

Risk Assessment Register - Draft

You might also like

- Project Report On MS Pipe and TubeDocument9 pagesProject Report On MS Pipe and TubeEIRI Board of Consultants and PublishersNo ratings yet

- 27 Risk Assessment-Construction of Ecm Holding Tank and Silt TrapDocument5 pages27 Risk Assessment-Construction of Ecm Holding Tank and Silt TrapprabuNo ratings yet

- HIRA - Godrej GCR Project - PHE System-Water Supply WorkDocument11 pagesHIRA - Godrej GCR Project - PHE System-Water Supply WorkRajput AmitNo ratings yet

- Summer Working Plan: AppendicesDocument11 pagesSummer Working Plan: AppendicesArshath FleminNo ratings yet

- Survey Work HSE Risk AssessmentsDocument2 pagesSurvey Work HSE Risk AssessmentsSarfraz RandhawaNo ratings yet

- Scaffolding Risk AssessmentDocument4 pagesScaffolding Risk AssessmentDARENo ratings yet

- Daily JSA - Back Filling, Levelling and ComapactionDocument3 pagesDaily JSA - Back Filling, Levelling and Comapactionshoaib akhtarNo ratings yet

- JSP For SS 9013 No. JSP#04 Cutting and Bending of Steel Reinforcement BarsDocument8 pagesJSP For SS 9013 No. JSP#04 Cutting and Bending of Steel Reinforcement BarsAbdul Rasheed Mangrio100% (1)

- Iaslc Ra 013 Working Under Direct Sun LightDocument4 pagesIaslc Ra 013 Working Under Direct Sun LightJoe PsNo ratings yet

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDocument1 pageRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- JSA - Repair-Coating and Finition Work THDocument3 pagesJSA - Repair-Coating and Finition Work THKhorbi AbdeltifNo ratings yet

- Daily JSA - Fence Post InstallationDocument5 pagesDaily JSA - Fence Post Installationshoaib akhtarNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Risk Assessment For Lifting OperationDocument2 pagesRisk Assessment For Lifting OperationdsadasNo ratings yet

- Risk Assessment Carpentry Works For Dismantling Wooden BoxesDocument10 pagesRisk Assessment Carpentry Works For Dismantling Wooden BoxesSinaNo ratings yet

- Deep Excavation Risk AssessmentDocument12 pagesDeep Excavation Risk Assessmentdonfrancis639No ratings yet

- Block WorkDocument4 pagesBlock WorkAbdul GhaffarNo ratings yet

- Exacavation Job Safety AnalysisDocument1 pageExacavation Job Safety AnalysisNeelakantamNo ratings yet

- Project EHS KPI - 24 Agustus 2013Document1 pageProject EHS KPI - 24 Agustus 2013Crystin Rotua Hasmi PanjaitanNo ratings yet

- Risk Assessment - Portable Ladders - 2021Document3 pagesRisk Assessment - Portable Ladders - 2021Asakundwi MukhwaNo ratings yet

- 1 Earth WorksDocument5 pages1 Earth WorksMuhammad Shahid Iqbal100% (1)

- Site Inspection Workplace Trasport ChecklistDocument6 pagesSite Inspection Workplace Trasport ChecklisttipuNo ratings yet

- Hirac (Small Power Installation)Document4 pagesHirac (Small Power Installation)tanaNo ratings yet

- SS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksDocument6 pagesSS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksFarhat SetharNo ratings yet

- Risk Assessment Roller Shutter DoorDocument4 pagesRisk Assessment Roller Shutter DoorphoenixsafetyconsultantNo ratings yet

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- Cutting WorkDocument1 pageCutting WorkGudduNo ratings yet

- Job Safety Analysis (JSA) - Painting DateDocument2 pagesJob Safety Analysis (JSA) - Painting DatenabeelNo ratings yet

- QRC-RA-013-Removal of Existing Road StructureDocument10 pagesQRC-RA-013-Removal of Existing Road StructureKallem RajashekarNo ratings yet

- Risk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Document2 pagesRisk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Danny100% (1)

- OHS-PR-09-03-F02 HIRA - 002 Marking and Layout of Site Being Surveyed Rev. 2021Document11 pagesOHS-PR-09-03-F02 HIRA - 002 Marking and Layout of Site Being Surveyed Rev. 2021MuhammadAsimMuneerNo ratings yet

- Diesel Generator Hazard Assessment PDF Master HireDocument6 pagesDiesel Generator Hazard Assessment PDF Master HireMuhammad MalikNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- RA 02 - Earth WorkDocument38 pagesRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- Ra 02 - Anti-Termite TreatmentDocument4 pagesRa 02 - Anti-Termite TreatmentHafiz M WaqasNo ratings yet

- Risk Assessment Lifting Operations PDFDocument6 pagesRisk Assessment Lifting Operations PDFkim alfonsoNo ratings yet

- 22-RA-Paint WorkDocument2 pages22-RA-Paint Workravindra100% (1)

- Risk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Document3 pagesRisk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Kono Nor AtanNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- Hazard Identification and Risk Assessment LiftingDocument2 pagesHazard Identification and Risk Assessment LiftingHariharan Muthukrishanan100% (1)

- Risk Assessment ForkliftDocument2 pagesRisk Assessment Forkliftmohamed ghaly100% (2)

- Deshuttering WorkDocument1 pageDeshuttering WorkAhmed AbdulfatahNo ratings yet

- Job Safety Analysis & Risk Assessment For Scrapping and Grading ActivityDocument1 pageJob Safety Analysis & Risk Assessment For Scrapping and Grading ActivityAzhar Mushtaq100% (1)

- Backfilling, Leveling RISK ASSESSMENTDocument6 pagesBackfilling, Leveling RISK ASSESSMENTVimal ViswanathNo ratings yet

- 29 HIRA Annexure HDocument155 pages29 HIRA Annexure HSuraj Singh100% (1)

- BMR - Safety PPT Apr-2023Document17 pagesBMR - Safety PPT Apr-2023shamshad ahamedNo ratings yet

- Hazard IdentificationDocument13 pagesHazard Identificationdiviyanraj95No ratings yet

- HIRAC B224 Najarul On ConcreteDocument9 pagesHIRAC B224 Najarul On ConcreteSurendra JangidNo ratings yet

- Ra of Manual Excavation For Trench of Telephone CableDocument5 pagesRa of Manual Excavation For Trench of Telephone CableRaza Muhammad SoomroNo ratings yet

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- SS JSP - 009 Ground Preparation For Lean Concrete (Foundation Works)Document5 pagesSS JSP - 009 Ground Preparation For Lean Concrete (Foundation Works)Farhat SetharNo ratings yet

- RA0128 - Installation of UPS SystemDocument17 pagesRA0128 - Installation of UPS SystemExplore the world TodayNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- PlasteringDocument1 pagePlasteringAnna Marie Aranaydo100% (1)

- JHA For To Carryout Activities During Unloading of Product From Ship Rev00Document4 pagesJHA For To Carryout Activities During Unloading of Product From Ship Rev00Sreekumar100% (1)

- Daily JSA - Diesel FillingDocument3 pagesDaily JSA - Diesel Fillingshoaib akhtarNo ratings yet

- BSD - 019 Bulk EarthworksDocument3 pagesBSD - 019 Bulk EarthworksZakkaudin KhanNo ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970100% (1)

- Concrete Pouring JSaDocument12 pagesConcrete Pouring JSaTheo Vidallon BautistaNo ratings yet

- Risk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingDocument3 pagesRisk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingSafety Professional0% (1)

- JSA CTU Sand Clean Out BPPDocument8 pagesJSA CTU Sand Clean Out BPPLismi LismiNo ratings yet

- Water Rocket Launch: Lesson FocusDocument18 pagesWater Rocket Launch: Lesson FocusShahood AqilNo ratings yet

- Linear User Manual PDFDocument425 pagesLinear User Manual PDFasafridisNo ratings yet

- Unit 3Document18 pagesUnit 3Christel Joy TagubaNo ratings yet

- Management Funda UNIT II MCQDocument3 pagesManagement Funda UNIT II MCQTarunNo ratings yet

- The Girl With All The GiftsDocument4 pagesThe Girl With All The GiftsJuday MarquezNo ratings yet

- Application For The Post of Director, IPGTRA, GAU, JamnagarDocument12 pagesApplication For The Post of Director, IPGTRA, GAU, JamnagarKirankumar MutnaliNo ratings yet

- Motor CatalogDocument85 pagesMotor CatalogHarshad AthawaleNo ratings yet

- The Five People You Meet in Heaven.Document12 pagesThe Five People You Meet in Heaven.Kathleen AcadsNo ratings yet

- Strucni TekstDocument6 pagesStrucni TekstDusanNo ratings yet

- C++ Arrays (With Examples)Document16 pagesC++ Arrays (With Examples)Tania CENo ratings yet

- Intelligent Energy Management Systems: A Review: Stavros Mischos Eleanna Dalagdi Dimitrios VrakasDocument40 pagesIntelligent Energy Management Systems: A Review: Stavros Mischos Eleanna Dalagdi Dimitrios VrakasLakshmana Nainar Sundar S.No ratings yet

- Quality Service Management in Tourism and Hospitality 03 Worksheet 1 ARGDocument1 pageQuality Service Management in Tourism and Hospitality 03 Worksheet 1 ARGJoashley CarreonNo ratings yet

- English Text - FamilyDocument2 pagesEnglish Text - FamilyAna MendesNo ratings yet

- Qubit dsDNA HS Assay UGDocument8 pagesQubit dsDNA HS Assay UGJunior CaroNo ratings yet

- Lynne Layton (1998) Gender StudiesDocument11 pagesLynne Layton (1998) Gender StudiesatelierimkellerNo ratings yet

- Stadium Case StudyDocument42 pagesStadium Case StudyCurtis Abaiku ChristianNo ratings yet

- Unit Test1Document3 pagesUnit Test1Gonzalo VillanustreNo ratings yet

- When We Communicate With OthersDocument4 pagesWhen We Communicate With OthersSmaranda BerenghiaNo ratings yet

- Whitepaper: Trade Race ManagerDocument36 pagesWhitepaper: Trade Race ManagerGaëtan DEGUIGNENo ratings yet

- Honeywell 4100sm Installion ManualDocument4 pagesHoneywell 4100sm Installion ManualVictor AamNo ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument4 pagesCambridge International Advanced Subsidiary and Advanced LevelngenziianNo ratings yet

- Trailer CTIDocument2 pagesTrailer CTIhsjsdjkfNo ratings yet

- Evangeline Corridor Initiative DRAFT Charrette Report (August 2016)Document44 pagesEvangeline Corridor Initiative DRAFT Charrette Report (August 2016)Anthony KennersonNo ratings yet

- Quality Assurance Procedure QAP 5945: 1. ScopeDocument5 pagesQuality Assurance Procedure QAP 5945: 1. ScopeDark CenobiteNo ratings yet

- Tornado Codes and Luby Transform Codes PDFDocument12 pagesTornado Codes and Luby Transform Codes PDFpathmakerpkNo ratings yet

- ScaffoldsDocument1 pageScaffoldsChiara PaulinNo ratings yet

- IS 12701 Product ManualDocument8 pagesIS 12701 Product Manualhossam fatehyNo ratings yet

- VET Literacy and Numberacy Support GuideDocument296 pagesVET Literacy and Numberacy Support GuideTim GadenNo ratings yet

- MRF 1946aDocument6 pagesMRF 1946apl4tonasNo ratings yet