Professional Documents

Culture Documents

PDS Anderol 750

PDS Anderol 750

Uploaded by

Hiram GarciaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDS Anderol 750

PDS Anderol 750

Uploaded by

Hiram GarciaCopyright:

Available Formats

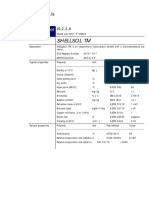

ANDEROL®750

SYNTHETIC COMPRESSOR OIL (ISO 150)

GENERAL INFORMATION

ANDEROL 750 is an ISO 150 diester-based lubricant designed to provide high temperature and long-term

lubrication with minimal deposit formation.

ANDEROL 750 is rated H2 for use in food processing plant applications.

TYPICAL PROPERTIES:

ANDEROL 750

SALES SPECIFICATIONS

PROPERTY TEST MIN MAX TYPICAL

METHOD RESULTS

Viscosity @ 40°C, cSt ASTM D-445 135 165 159.1

Viscosity @ 100°C, cSt ASTM D-445 --- --- 13.0

Pour Point, °C ASTM D-97 --- -23 -30

Flash Point, °C ASTM D-92 240 - 256

Specific Gravity, 15.6°C ASTM D-4052B 0.945 0.965 0.95

ADDITIONAL INFORMATION

PROPERTY TEST TYPICAL

METHOD RESULTS

Autoignition Temperature, °C ASTM E-659 410

Conradson Carbon Residue, % ASTM D-189 0.02

Evaporation, 22 hrs @ 99°C, % ASTM D-972 <1.0

Copper Strip Corrosion, 3 hrs @ 100°C ASTM D-130 1a

Demulsibility @ 54°C, ml oil/water/emulsion (min) ASTM D-1401 40/37/3 (<60)

Four-Ball Wear, 1200 rpm, 75°C, 40 kg, 1 hr, mm ASTM D-4172 0.7

®

ANDEROL is a reg. trademark of ANDEROL COMPANY.

This information is furnished without warranty, representation, inducement,

or license of any kind, except that it is accurate to the best of OUR

knowledge or obtained from sources believed by ANDEROL to be

For more information please refer to the accurate. ANDEROL does not assume any legal responsibility for use of

relevant Material Safety Data Sheet reliance upon it. Only chemists or chemically qualified lab technicians

should carry out tests. Before using any chemical, read its label and

accompanying each product. Material Safety Data Sheet.

APPLICATIONS

Cylinder and crankcase lubrication for reciprocating compressors and vacuum pumps for the following gases:

Air Hydrogen Carbon Dioxide (dry) Natural Gas

Butadiene Methane Ethylene Propane

Carbon Monoxide Nitrogen Helium Synthesis Gas

Furnace (crack) Gas Sulphur Hexafluoride Hydrogen Sulphide (dry)

ANDEROL 750 may also be considered for other applications requiring an oxidation resistant lubricant. Nominal

Operating Range is -5°C to 210°C (20°F to 410

ADVANTAGES

• Fewer oil changes • Lower oil consumption

• Reduces compressor maintenance • Eliminates lacquering and deposits

• Greatly reduces fire and explosion hazard • Reduces energy consumption

• Separates water condensate rapidly

APPROVALS

ANDEROL synthetic lubricants are the only long-life synthetic lubricants with over 30 years of successful

performance. They are field tested, approved or recommended by major compressor manufacturers. Should you

have any questions regarding the suitability of ANDEROL® 750 compressor lubricant for a specific manufacturer's

model compressor, please check with your ANDEROL lubricant supplier or contact Anderol Company.

COMPATIBILITY

The following seals, paints, and plastics are recommended for use in contact with Anderol Company Synthetic

Lubricants. Materials not recommended are also shown. For more information on other materials, see our

"Compatibility Guide."

RECOMMENDED - Viton, High Nitrile Buna N, Teflon, Epoxy Paint, Oil-Resistant Alkyd, Nylon, Delrin, Celcon, PBT

NOT RECOMMENDED - Neoprene, SBR Rubber, Low Nitrile Buna N, Acrylic Paint, Lacquer,

Polystyrene, PVC, ABS

A750b: 9/28/01eb

ANDEROL®

Specialty Lubricants

ANDEROL COMPANY

PO Box 518, 215 Merry Lane

East Hanover, New Jersey USA

Tel: 888-ANDEROL

Or Tel: (973) 887-7410

Fax: (973) 884-3825

E-mail: info2@anderol.com

You might also like

- 2-14 Determination of The Dissociation Constant of Weak AcidsDocument3 pages2-14 Determination of The Dissociation Constant of Weak Acidsdbroncos78087100% (6)

- Anderol 555Document2 pagesAnderol 555Barita_A_Limbo_4714No ratings yet

- PDS Anderol 3046Document2 pagesPDS Anderol 3046Michel Matzui OrtizNo ratings yet

- Royco 889Document2 pagesRoyco 889Anonymous oAbjbl4HNo ratings yet

- Anderol® 555 - en - USDocument3 pagesAnderol® 555 - en - USa3.msaputra0% (1)

- Anderol 6320: H1 High Performance Food Grade Gear LubricantDocument1 pageAnderol 6320: H1 High Performance Food Grade Gear Lubricanteka prayataNo ratings yet

- En Anderol 5320 Xep 20120328Document1 pageEn Anderol 5320 Xep 20120328Shaara NeyNo ratings yet

- Anderol 3057MDocument1 pageAnderol 3057MsanathcgrNo ratings yet

- Lanxess Anderol® 5999 XEP - en - USDocument4 pagesLanxess Anderol® 5999 XEP - en - USANo ratings yet

- After SSR Ultra-Plus CoolantDocument2 pagesAfter SSR Ultra-Plus CoolantGilarHerlianaPutra100% (1)

- Anderol® 3057M - en - USDocument4 pagesAnderol® 3057M - en - USFederico GomezNo ratings yet

- PisssDocument1 pagePisssMie IkanNo ratings yet

- Anderol 1255Document1 pageAnderol 1255Anonymous oAbjbl4HNo ratings yet

- Anderol 1255 PDFDocument1 pageAnderol 1255 PDFAnonymous oAbjbl4HNo ratings yet

- Mobil Polyrex EMDocument2 pagesMobil Polyrex EMthe anhNo ratings yet

- Datasheet PDFDocument1 pageDatasheet PDFMie IkanNo ratings yet

- Shelsol Shoc CardDocument3 pagesShelsol Shoc Cardvinil radhakrishnaNo ratings yet

- Specialty Lubricants: Molykote G-4500/G-4501 Multi-Purpose Synthetic GreaseDocument2 pagesSpecialty Lubricants: Molykote G-4500/G-4501 Multi-Purpose Synthetic GreaseRildo CarvalhoNo ratings yet

- Aircol PD RangeDocument2 pagesAircol PD RangecarmaNo ratings yet

- Anderol 555Document1 pageAnderol 555rewindingidsNo ratings yet

- Aircol SN 68 & 100: DescriptionDocument2 pagesAircol SN 68 & 100: DescriptionantonNo ratings yet

- Primol 542 Primol 542 Primol 542 Primol 542Document3 pagesPrimol 542 Primol 542 Primol 542 Primol 542Luis OteroNo ratings yet

- Daphne Alpha Screw 32: Lubricant Product InformationDocument2 pagesDaphne Alpha Screw 32: Lubricant Product InformationSadid ShahzadNo ratings yet

- Oloa 200 PDSDocument1 pageOloa 200 PDSAtman FozdarNo ratings yet

- Aircol SN RangeDocument2 pagesAircol SN RangecarmaNo ratings yet

- No-Tox BioFR Hydraulic 46Document2 pagesNo-Tox BioFR Hydraulic 46dhowardjNo ratings yet

- Dynamo Excellent 100 - TDS - ENDocument2 pagesDynamo Excellent 100 - TDS - ENyassineguenfoud412No ratings yet

- Oloa 11000: Ashless Succinimide DispersantDocument1 pageOloa 11000: Ashless Succinimide DispersantAtman FozdarNo ratings yet

- Sae 40Document1 pageSae 40DuraiMuruganNo ratings yet

- Molykote G 1001 PdsDocument2 pagesMolykote G 1001 PdsDicky PratamaNo ratings yet

- 8100 Eco-Nergy 0W-30: Fuel Economy Gasoline and Diesel Lubricant 100% SyntheticDocument2 pages8100 Eco-Nergy 0W-30: Fuel Economy Gasoline and Diesel Lubricant 100% SyntheticRadu George MotocNo ratings yet

- Mobil EAL Syndraulic 46Document2 pagesMobil EAL Syndraulic 46anibal_rios_rivasNo ratings yet

- 423-Renolin CLP-1Document1 page423-Renolin CLP-1Moutaz IsmailNo ratings yet

- Pds Etro 4plus 2022.01Document1 pagePds Etro 4plus 2022.01Samee84No ratings yet

- Calibration Oil 4113: DescriptionDocument2 pagesCalibration Oil 4113: DescriptionRoberto HidalgoNo ratings yet

- AffcvDocument2 pagesAffcvValentinNo ratings yet

- Spectrasyn™ 2E: Polyalphaolefin (Pao) FluidDocument1 pageSpectrasyn™ 2E: Polyalphaolefin (Pao) FluidMaram YasserNo ratings yet

- Product Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDocument3 pagesProduct Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDiegoNo ratings yet

- En Anderol 5460 Xep 20120328Document1 pageEn Anderol 5460 Xep 20120328Shaara NeyNo ratings yet

- Product Data Sheet: High Performance Cutting OilDocument1 pageProduct Data Sheet: High Performance Cutting OilSadid Shahzad100% (1)

- Product Data SheetDocument2 pagesProduct Data SheetPEDRO MIGUELNo ratings yet

- Aircol HC 7, HC 10Document2 pagesAircol HC 7, HC 10Vladislav TrempoletsNo ratings yet

- Duratec HPL Features and BenefitsDocument2 pagesDuratec HPL Features and BenefitsAbir MazumderNo ratings yet

- Belex Wireline LubricantDocument2 pagesBelex Wireline LubricantdhowardjNo ratings yet

- Castrol BRAYCOTE 601 EF - Pds - Eng - Rev. 2014.08.04Document2 pagesCastrol BRAYCOTE 601 EF - Pds - Eng - Rev. 2014.08.04Massimiliano VolaNo ratings yet

- Aircol AMS Range: Product DataDocument2 pagesAircol AMS Range: Product DataVladislav TrempoletsNo ratings yet

- Aircol PG 185Document2 pagesAircol PG 185nauta007No ratings yet

- Aircol PG 185Document2 pagesAircol PG 185carmaNo ratings yet

- Aircol SN RangeDocument2 pagesAircol SN Rangenauta007No ratings yet

- Repsol Telex HVLP 32Document2 pagesRepsol Telex HVLP 32ibrahim maulanaNo ratings yet

- Synthetic TBI ISO 32 46 Biodegradable Hydraulic OilDocument2 pagesSynthetic TBI ISO 32 46 Biodegradable Hydraulic Oilbrian5786No ratings yet

- Exxsol D60 TDSDocument1 pageExxsol D60 TDSmain.chfNo ratings yet

- Perfecto TR UN BPXE-9Z8VBQDocument2 pagesPerfecto TR UN BPXE-9Z8VBQRNo ratings yet

- Renolin Ac Compressor Oils: Product InformationDocument2 pagesRenolin Ac Compressor Oils: Product InformationSoporte Técnico RyRNo ratings yet

- Molykote Food Grade EP Bearing Grease - PDSDocument2 pagesMolykote Food Grade EP Bearing Grease - PDSabc xyzNo ratings yet

- PDS Perfecto XEPDocument3 pagesPDS Perfecto XEP邢焕震No ratings yet

- Aircol SW RangeDocument2 pagesAircol SW RangeDouglas Neves - UnaxNo ratings yet

- CPI - 4600 - Series - Refrigeration Compressor OilDocument2 pagesCPI - 4600 - Series - Refrigeration Compressor OilHisham MasadNo ratings yet

- Aircol PD RangeDocument2 pagesAircol PD RangeAlin BAMNo ratings yet

- Documento de Maia TostiDocument2 pagesDocumento de Maia TostimaiatostiNo ratings yet

- Concrete Slabs Strengthened With Basalt Fibres - Experimental Tests ResultsDocument8 pagesConcrete Slabs Strengthened With Basalt Fibres - Experimental Tests ResultsBanNo ratings yet

- Reactions of Synthetic ImportanceDocument28 pagesReactions of Synthetic ImportanceRx Nadeem ChhipaNo ratings yet

- 4ch1 1cr Que 20220528Document36 pages4ch1 1cr Que 20220528Abraham TyagarajNo ratings yet

- 2 National Seminar On Physics of Materials and Materials Based Device Fabrication (NSPM-MDF-2013)Document145 pages2 National Seminar On Physics of Materials and Materials Based Device Fabrication (NSPM-MDF-2013)Shridhar MathadNo ratings yet

- Rolon Dry Gas SealsDocument39 pagesRolon Dry Gas Sealsnarayan rajuNo ratings yet

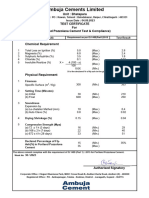

- Ambuja BHT-30 - 231027 - 171800Document2 pagesAmbuja BHT-30 - 231027 - 171800souravsrkNo ratings yet

- Exp2 Tutorial Conclusion RecommendationDocument5 pagesExp2 Tutorial Conclusion RecommendationSiti Hajar Mohamed0% (1)

- Synthesis and Characterization of Microporous Zeolite Materials From Kaolin Clay Obtained From Nsuakka and Its Application in The Adsorption of Divalent Lead Ions From Aqueous SolutionDocument42 pagesSynthesis and Characterization of Microporous Zeolite Materials From Kaolin Clay Obtained From Nsuakka and Its Application in The Adsorption of Divalent Lead Ions From Aqueous SolutionDave KoladeNo ratings yet

- Design Aspects of Tall Chimneys: S. N. ManoharDocument8 pagesDesign Aspects of Tall Chimneys: S. N. ManoharRama KrishnaNo ratings yet

- 125 A Mid 2 Chemistry-1Document24 pages125 A Mid 2 Chemistry-1syeda ruqaiyah ashfaqNo ratings yet

- SCBA Wiki PDFDocument6 pagesSCBA Wiki PDFomar benounaNo ratings yet

- Types of Chemical ReactionsDocument27 pagesTypes of Chemical ReactionsSheena LidasanNo ratings yet

- 1980 Macromolecular Electronic Device Field-Effect Transistor With A Polythiophene Thin FilmDocument4 pages1980 Macromolecular Electronic Device Field-Effect Transistor With A Polythiophene Thin FilmDoktor transmisionesNo ratings yet

- PSP TCDocument7 pagesPSP TCPSP kanpurdehatNo ratings yet

- CH. Venkata Ramana, Et AlDocument5 pagesCH. Venkata Ramana, Et Alrathan kumarNo ratings yet

- Prime Coat (PVT.) LTD: Rev: 3-4-2020 Ketonic Resin Pk-5851Document4 pagesPrime Coat (PVT.) LTD: Rev: 3-4-2020 Ketonic Resin Pk-5851khizer iqbalNo ratings yet

- Toxicology NotesDocument5 pagesToxicology Notesrostaminasab100% (1)

- EC Lab ManualDocument70 pagesEC Lab ManualAbhishek NanavateNo ratings yet

- Biochemistry Papers MSUDocument20 pagesBiochemistry Papers MSUShiv BhattNo ratings yet

- FT en Memomulti 2Document2 pagesFT en Memomulti 2kevin hadinNo ratings yet

- Bunker OilDocument5 pagesBunker OilJaymart Hernandez MojicaNo ratings yet

- A Brief History of CatalysisDocument9 pagesA Brief History of CatalysisKike BayonaNo ratings yet

- TL DescriptionsDocument8 pagesTL DescriptionsJo An MeMeNo ratings yet

- Indole MetallationDocument51 pagesIndole MetallationHerman Nikolayevskiy100% (1)

- Applications of Egg Shell and Egg Shell Membrane As AdsorbentsDocument13 pagesApplications of Egg Shell and Egg Shell Membrane As AdsorbentsAhmed AliNo ratings yet

- HetshortDocument4 pagesHetshortSallyCroyNo ratings yet

- Lesson - 1 PDFDocument5 pagesLesson - 1 PDFVikas Kumar ThakurNo ratings yet

- Paste ThickenerDocument18 pagesPaste Thickenerraymondt153905No ratings yet

- DFT L4Document18 pagesDFT L4Ali AhmadaliNo ratings yet