Professional Documents

Culture Documents

Proparation of Subgrade

Proparation of Subgrade

Uploaded by

emad safaaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Proparation of Subgrade

Proparation of Subgrade

Uploaded by

emad safaaCopyright:

Available Formats

VOLUME 3 TECHNICAL SPECIFICATIONS

DIVISION 2 – EARTHWORKS

2.7 PREPARATION OF SUBGRADE

2.7.1 Description

This work shall consist of the preparation of subgrade in embankment, or in cut by

scarifying, watering, compacting and shaping existing or previously placed material in

accordance with these Specifications and to the lines, levels, grades, dimensions and

cross sections shown on the Drawings or as required by the Engineer.

2.7.2 Materials

All subgrade material shall be from sources, which the contractor shall propose and

which shall be approved by the Engineer. The material shall be free from roots, sods or

other deleterious material and when compacted to 98% of maximum dry density

determined in accordance with STP 4.3 shall have a 4 day soaked CBR value of not

less than 5%.

Subgrade material shall satisfy the following criteria:

• Liquid limit of soil fraction passing 0.425 mm sieve not to exceed 50% (STP 3.2)

• Plasticity index of soil fraction passing 0.425 mm sieve not to exceed 15% (STP 3.2)

Any subgrade material in cut or existing old embankment, which is found to be

unsuitable, shall be removed and replaced as directed by the Engineer.

2.7.3 Construction Methods

The subgrade shall be prepared over the full width of the embankment including

shoulders. Part width working may be allowed with the prior written approval of the

Engineer.

The subgrade shall be prepared in lengths of not less than 100 metres at any one

time, unless otherwise approved by the Engineer.

Subgrade material shall be scarified to a depth of 150 mm until the soil is fully

loosened. Any lumps or clods shall be removed or broken to pass a 50 mm sieve.

If the Drawings require the subgrade to be compacted for a depth greater than 150

mm, the work shall be carried out in more than one layer, the material in the upper

layer being first removed in the case of road sections in cut.

The moisture content of the sub-grade material before compaction shall be within ±2%

of the predetermined optimum moisture content established in accordance with STP

4.3 (Standard Compaction). The achieved dry density after compaction of the

subgrade layer shall not be less than 98% of maximum dry density as determined in

accordance with STP 4.3.

When necessary, each layer, before being compacted, shall be allowed to dry or be

watered to bring the moisture content to within ±2% of optimum to make possible its

compaction to the required dry density. The material shall be so worked as to have a

uniform moisture content through the entire layer.

The subgrade material shall be compacted uniformly by use of adequate and

appropriate compaction equipment. The compaction shall be done in a longitudinal

direction along the embankment and shall generally begin at the outer edges and

progress toward the centre in such a manner that each section receives equal

compactive effort.

MAY 2001 Page

2.19

VOLUME 3 TECHNICAL SPECIFICATIONS

DIVISION 2 – EARTHWORKS

Samples to determine the compaction shall be taken regularly with a set of three

samples for each 1,000 square metres of finished layer or as decided by the Engineer

will be carried out according to STP 6.2. If the test results show that the density is less

than the required dry density, the Contractor shall carry out further compaction to

obtain at least the required dry density. The compacted subgrade layer shall be

approved by the Engineer before the Contractor can commence a new layer.

The surface of the finished subgrade shall be neat and workmanlike and have the

required form, super elevation, levels, grades and cross section. The finished surface

shall be constructed with a tolerance of 20 mm above or below the specified levels at

any point.

2.7.4 Measurement

Subgrade preparation shall be measured in square metres based on the surface area

of compacted and accepted subgrade actually completed in accordance with the

Specifications, to the lines, levels, grades and cross sections required as directed by

the Engineer. No allowance will be made for overlapping of areas due to half width

working.

Separate quantities shall be measured for subgrade compacted to different depths. No

differentiation will be made between subgrade compaction in cut or in fill.

2.7.5 Payment

This work measured as provided above shall be paid for at the Contract unit prices per

square metre. Payment shall be full compensation for performing the work and

providing all labour, equipment, tools and incidentals necessary to complete the work.

The rates shall not include the cost of furnishing the subgrade materials which, if not

existing, shall be included in the quantity for fill material as provided for in Section 2.6.

Pay items shall be:

2/7/1 Preparation of Subgrade 150 mm Depth Square Metre

2/7/2 Preparation of Subgrade 300 mm Depth Square Metre

MAY 2001 Page

2.20

You might also like

- Angular Observable TutorialDocument158 pagesAngular Observable Tutorialvrjs27 vNo ratings yet

- Method Statement For Roadbase ConstructionDocument3 pagesMethod Statement For Roadbase ConstructionNordin Yunus93% (84)

- Method Statement For Cold In-Place Recycling - CementDocument6 pagesMethod Statement For Cold In-Place Recycling - CementNordin Yunus100% (2)

- Method Statement - Kamal ConstructionsDocument17 pagesMethod Statement - Kamal ConstructionsShalika EkanayakeNo ratings yet

- TenneT TSO - PSCAD TrainingDocument3 pagesTenneT TSO - PSCAD TrainingMayur ChavdaNo ratings yet

- London TransportDocument22 pagesLondon TransportNoelia Peirats AymerichNo ratings yet

- Embankment PDFDocument3 pagesEmbankment PDFSugumarRaviNo ratings yet

- Embankment PDFDocument3 pagesEmbankment PDFahmed tahameemNo ratings yet

- Sub BaseDocument4 pagesSub BaseAnonymous Dk3ItoC8MFNo ratings yet

- 04 Subgrade ConstructionDocument3 pages04 Subgrade ConstructionAnish Panchal100% (1)

- Comapction and EmbankmentDocument2 pagesComapction and Embankmenttonmoyahmed06No ratings yet

- Item 200Document4 pagesItem 200Marc Dared Cagaoan50% (2)

- Road Construction-Placement of Sub Base and Road BaseDocument3 pagesRoad Construction-Placement of Sub Base and Road BasereaganNo ratings yet

- Section 3000 Maintenance of RoadDocument11 pagesSection 3000 Maintenance of RoadSarmistha Patowary100% (1)

- Part D - SUBBASE AND BASEDocument6 pagesPart D - SUBBASE AND BASEJonel TorresNo ratings yet

- b.6.19 - Std. Specification-Site GradingDocument5 pagesb.6.19 - Std. Specification-Site GradingdlloitNo ratings yet

- 7 Sc&s7 RoadworkDocument5 pages7 Sc&s7 RoadworkdophongxdNo ratings yet

- LAPRIL-C103 enDocument5 pagesLAPRIL-C103 enalpha NEPALNo ratings yet

- Project SpecificationsDocument23 pagesProject SpecificationsMydeen ThangalNo ratings yet

- 03 Embankment ConstructionDocument3 pages03 Embankment ConstructionAnish PanchalNo ratings yet

- 30.sec.3000 (Maintenance of Road)Document7 pages30.sec.3000 (Maintenance of Road)aalignup arc & const. pvt ltdNo ratings yet

- LTA M&W - Road Works MarkedDocument69 pagesLTA M&W - Road Works MarkedzawNo ratings yet

- Housing For Jazan Infrastructure & Utility Buildings P09-67400 02222-1 EmbankmentsDocument5 pagesHousing For Jazan Infrastructure & Utility Buildings P09-67400 02222-1 Embankmentstamer5046882No ratings yet

- Earthworks Chapter 07Document8 pagesEarthworks Chapter 07Taqi ZaidiNo ratings yet

- Subbase and Base CourseDocument33 pagesSubbase and Base CourseJohn vincent Salazar100% (1)

- Bituminous CoursesDocument16 pagesBituminous Coursestrilokbist04No ratings yet

- Methodology For Subgrade ConstructionDocument4 pagesMethodology For Subgrade ConstructionChalamaiah VMNo ratings yet

- 4-Specification For Box CellDocument110 pages4-Specification For Box CellMaulik RavalNo ratings yet

- Bituminous Tack CoatDocument2 pagesBituminous Tack CoatshawonscribdNo ratings yet

- Clearing, Grubbing and ExcavationDocument25 pagesClearing, Grubbing and ExcavationArah Louise ApostolNo ratings yet

- Aggregate Subbase Course: Item 200Document16 pagesAggregate Subbase Course: Item 200Ay BolzNo ratings yet

- Geotextile Fabric General SpecificationDocument3 pagesGeotextile Fabric General SpecificationjovindhaNo ratings yet

- Bituminous Prime Coat PDFDocument3 pagesBituminous Prime Coat PDFMuhammad ArifNo ratings yet

- Clearing, Grubbing and ExcavationDocument11 pagesClearing, Grubbing and ExcavationArah Louise ApostolNo ratings yet

- Method of Statement Road WorkDocument10 pagesMethod of Statement Road WorkAbu NijamNo ratings yet

- Item 804 - Embankment 804.1 DescriptionDocument9 pagesItem 804 - Embankment 804.1 DescriptionEster MarianNo ratings yet

- For INTERNAL USE ONLY Standard Specification For Road Works ...Document52 pagesFor INTERNAL USE ONLY Standard Specification For Road Works ...ahhlNo ratings yet

- Microsoft Word - Particular Specification For CivilDocument63 pagesMicrosoft Word - Particular Specification For CivilrajNo ratings yet

- Item 200 AGGREGATE SUBBASE COURSEDocument15 pagesItem 200 AGGREGATE SUBBASE COURSEKEZIAH JANE SULAPASNo ratings yet

- Spec Structural IsgDocument98 pagesSpec Structural IsgMoath AlhajiriNo ratings yet

- Foundation CriteriaDocument2 pagesFoundation CriteriaAbdullah Al MamunNo ratings yet

- Speci. Slab Drain On Moti Amrol To Sangpur Road Ta. Jetpur PaviDocument116 pagesSpeci. Slab Drain On Moti Amrol To Sangpur Road Ta. Jetpur PaviPranav ChovatiyaNo ratings yet

- Technical Specs LandscapingDocument22 pagesTechnical Specs LandscapingManish KumarNo ratings yet

- Microsoft Word - PARTICULAR SPECIFICATION FOR CIVIL PDFDocument63 pagesMicrosoft Word - PARTICULAR SPECIFICATION FOR CIVIL PDFMukhlish AkhatarNo ratings yet

- Method Statement Sub Base & Road BaseDocument1 pageMethod Statement Sub Base & Road Basefyzalazry100% (3)

- Method Statement For Embankment FillingDocument9 pagesMethod Statement For Embankment Fillingdamith50% (2)

- 04-400. Sub-Bases, (Non-Bituminous) and ShouldersDocument29 pages04-400. Sub-Bases, (Non-Bituminous) and ShouldersAnonymous g1LSaANo ratings yet

- Part D - Subbase and Base CourseDocument6 pagesPart D - Subbase and Base CourseAilene CataNo ratings yet

- ITEM 200 Latest 2004Document21 pagesITEM 200 Latest 2004Avelino De Leon JrNo ratings yet

- Caliche Base CourseDocument4 pagesCaliche Base CourseDevrim GürselNo ratings yet

- Section 12-Part 3-FillingDocument3 pagesSection 12-Part 3-FillingAdamNo ratings yet

- Water Proofing SpecificationDocument7 pagesWater Proofing SpecificationjeevanNo ratings yet

- Methodology of Earth WorksDocument8 pagesMethodology of Earth WorksMartinNo ratings yet

- Bituminous Surface TreatmentDocument7 pagesBituminous Surface TreatmentSenol KarakayaliNo ratings yet

- The Fabrication of Materials: Materials TechnologyFrom EverandThe Fabrication of Materials: Materials TechnologyRating: 5 out of 5 stars5/5 (1)

- Soil Investigation and Foundation DesignFrom EverandSoil Investigation and Foundation DesignRating: 4.5 out of 5 stars4.5/5 (9)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Geotechnical Investigations and Improvement of Ground ConditionsFrom EverandGeotechnical Investigations and Improvement of Ground ConditionsNo ratings yet

- How to Build a Simple Three Bedroom Shipping Container HouseFrom EverandHow to Build a Simple Three Bedroom Shipping Container HouseRating: 4 out of 5 stars4/5 (2)

- Nlint RulesDocument846 pagesNlint Rulesjit20088791No ratings yet

- For Preparation: Fuel Pump RemovalDocument8 pagesFor Preparation: Fuel Pump RemovalZoli BorbelyNo ratings yet

- 22 2 Manual Work GST Note 2458404 Import Data Dictionary StepsDocument5 pages22 2 Manual Work GST Note 2458404 Import Data Dictionary StepsgcldesignNo ratings yet

- 模型剪枝在2d3d卷积网络中的研究与应用-悉尼大学在读博士生郭晋阳 智东西公开课Document70 pages模型剪枝在2d3d卷积网络中的研究与应用-悉尼大学在读博士生郭晋阳 智东西公开课jiahao liNo ratings yet

- Content MarketingDocument2 pagesContent Marketingdigitaldynamo056No ratings yet

- "The Web Development Glossary": A New Reference Book Covering 2,000 Terms in Web Development and DesignDocument2 pages"The Web Development Glossary": A New Reference Book Covering 2,000 Terms in Web Development and DesignPR.comNo ratings yet

- Mock II Std. X - I.T. Paper IDocument11 pagesMock II Std. X - I.T. Paper IYashodhaNo ratings yet

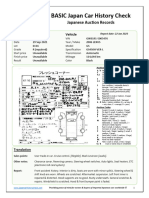

- Japan Car History Check Basic Report With Translation - Gws191-5005476Document2 pagesJapan Car History Check Basic Report With Translation - Gws191-5005476tutins5546No ratings yet

- J/SHS: Activity Sheet Quarter 2 - LO1Document11 pagesJ/SHS: Activity Sheet Quarter 2 - LO1Boiztupidoh Oof D'WestNo ratings yet

- Modeling and Simulation of Wear in A Pin On Disc TribometerDocument10 pagesModeling and Simulation of Wear in A Pin On Disc Tribometergoldy243usNo ratings yet

- Astm A588 A588m-10Document3 pagesAstm A588 A588m-10Pily JaimesNo ratings yet

- Making Conductive Ink Using Old Batteries, Pencil Lead, and Activated Charcoal With Glue and PaintDocument11 pagesMaking Conductive Ink Using Old Batteries, Pencil Lead, and Activated Charcoal With Glue and PaintGuian EitoNo ratings yet

- Entity Relationship ModelDocument41 pagesEntity Relationship ModelaziNo ratings yet

- Case Study - Business Intelligence Migration With Cubeport™Document11 pagesCase Study - Business Intelligence Migration With Cubeport™phanithotaNo ratings yet

- Ethics and Morality in The Fourth Industrial Revolution - Joa - Eng - 0421Document4 pagesEthics and Morality in The Fourth Industrial Revolution - Joa - Eng - 0421Nguyen KhangNo ratings yet

- Business Name Street LocalityDocument62 pagesBusiness Name Street LocalityJoseph MolenkoNo ratings yet

- IT - EDI - ORDRSP SAP IDOC XML Lieferant - EN PDFDocument2 pagesIT - EDI - ORDRSP SAP IDOC XML Lieferant - EN PDFJohn SmithNo ratings yet

- Cia Review: Part 2 Study Unit 2: Assurance and Compliance EngagementsDocument20 pagesCia Review: Part 2 Study Unit 2: Assurance and Compliance EngagementsjorgeNo ratings yet

- Price List AmtechDocument2 pagesPrice List AmtechAguz TinuzzNo ratings yet

- Hotel Management System: Software Engineering Lab. 3rd SemesterDocument15 pagesHotel Management System: Software Engineering Lab. 3rd SemesterMuhammad AbuzarNo ratings yet

- Bca Semester-Ii Assignments 2021-22Document18 pagesBca Semester-Ii Assignments 2021-22Saurav PandeyNo ratings yet

- Rts Plant Capacity Calculator RoiDocument1 pageRts Plant Capacity Calculator RoiUtkarsh VermaNo ratings yet

- BCA Final Year Project - Ecommerce SiteDocument63 pagesBCA Final Year Project - Ecommerce SiteMayil Raj SubramanianNo ratings yet

- Net Integration Using Message Broker and Ibm Integration BusDocument55 pagesNet Integration Using Message Broker and Ibm Integration BusMiguel Angel Hernández RuizNo ratings yet

- One-Stop Account Opening Process Retail Ver 3Document7 pagesOne-Stop Account Opening Process Retail Ver 3ዝምታ ተሻለNo ratings yet

- CDX CatalogueDocument2 pagesCDX CatalogueDMA ASIANo ratings yet

- Efs8-Sb Ed 2 - 14Document6 pagesEfs8-Sb Ed 2 - 14Samer dawanNo ratings yet