Professional Documents

Culture Documents

Welding Program

Welding Program

Uploaded by

ahmad exsan0 ratings0% found this document useful (0 votes)

10 views10 pagesThe Welding & Repair Technology Center (WRTC) focuses on identifying and addressing technology gaps related to welding, fabrication, and repair in the nuclear industry. It maintains 11 Strategic Focus Areas that establish project scopes to close these gaps. The WRTC also leads R&D activities and develops technologies to improve materials performance, enable component life extension, and reduce repair costs. Its goals are to support the nuclear industry and interact with codes and regulations.

Original Description:

Original Title

Welding program

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Welding & Repair Technology Center (WRTC) focuses on identifying and addressing technology gaps related to welding, fabrication, and repair in the nuclear industry. It maintains 11 Strategic Focus Areas that establish project scopes to close these gaps. The WRTC also leads R&D activities and develops technologies to improve materials performance, enable component life extension, and reduce repair costs. Its goals are to support the nuclear industry and interact with codes and regulations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

10 views10 pagesWelding Program

Welding Program

Uploaded by

ahmad exsanThe Welding & Repair Technology Center (WRTC) focuses on identifying and addressing technology gaps related to welding, fabrication, and repair in the nuclear industry. It maintains 11 Strategic Focus Areas that establish project scopes to close these gaps. The WRTC also leads R&D activities and develops technologies to improve materials performance, enable component life extension, and reduce repair costs. Its goals are to support the nuclear industry and interact with codes and regulations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 10

Welding & Repair

Technology Center

Overview

Annual NRC/Industry Technical

Exchange

Tuesday June 4, 2015

Steve McCracken,

EPRI – WRTC

© 2015 Electric Power Research Institute, Inc. All rights reserved.

Welding & Repair Technology Center -

Mission

• Focus on both tactical issues and strategic research

– Provide a framework for identifying, prioritizing,

and tracking welding, fabrication, and repair

related technology “gaps”

– Lead R&D activities and

technology development to

supplying the necessary

“TOOL” to address current and

future repair, fabrication, and

mitigation issues

© 2014 Electric Power Research Institute, Inc. All rights reserved. 2

WRTC Objectives

• Establish repair techniques and develop

technologies that can improve material

performance, enable component life extension,

increase plant availability, and reduce repair

costs and time.

• Research activities to support technical

interactions with Code (implementation)

• Forums for sharing operating experience,

discussing repair, fabrication and weld program

issues and industry emerging issues

• Provide access to materials, welding, and

repair experts across the EPRI and the nuclear

industry

© 2014 Electric Power Research Institute, Inc. All rights reserved. 3

WRTC - Overview

• WRTC maintains a balanced portfolio

– 11 Strategic Focus Areas (SFA) established

• WRTC identified technology gaps

• WRTC establishes project scope to address or close these

gaps

• SFA may also contain Executive Roadmaps

– Roadmaps address highly collaborative research areas

© 2014 Electric Power Research Institute, Inc. All rights reserved. 4

WRTC Strategic Focus Areas

• Solution Area 1a and 1b: Nickel-Base Filler

Metal Weldability: Alloy 52 Weldability and New

Alloy development

– optimization of Alloy 52 weldability

– alternate weld filler metal that retains adequate

margins to PWSCC

• Solution Area 2: Irradiated Materials Welding

Solutions

– focus on developing near-term solutions, and

fundamental research

• Solution Area 3: Identify, Research, Develop,

and Mature Advanced Welding Processes

– Keeping nuclear industry up with current 5% Augmented Strain

technology (welding and joining processes)

© 2014 Electric Power Research Institute, Inc. All rights reserved. 5

WRTC Strategic Focus Areas

• Solution Area 4a: Optimize Joining,

Fabrication, and Repair Processes

– Opportunity to optimize and improve

established welding processes and

procedures.

• Solution Area 4b: Stress Optimization

– Optimize residual stresses through

surface conditioning and other

techniques.

• Solution Area 5: Small Bore Piping

Asset

– Small bore piping issues and

eliminating small bore piping failures

© 2014 Electric Power Research Institute, Inc. All rights reserved. 6

WRTC Strategic Focus Areas

• Solution Area 6: Transfer & Promote

Fabrication & Joining Technologies into

Codes, Standards, & Regulations

– Promoting Code and Regulatory adoption of

code changes, Code Cases Hydrogen Testing SMAW TB – Code Case N-839

– Provide technical bases documents

• Solution Area 7: Buried Pipe Asset hardness indents (HV10)

Management / Repair Solutions

– repair/replacement issues

• Solution Area 8: Repair Solutions for

Structures: Containment and Fuel Pool

Asset Management

– Repair solutions for critical nuclear

structures

QW-290 updates & Temper bead qualification by new

hardness protocol

© 2014 Electric Power Research Institute, Inc. All rights reserved. 7

WRTC Strategic Focus Areas

• Solution Area 9: Tactical Implementation of PM 316L -- 1300F, 5hr

Repair Methods

– Guidance for implementation

• Solution Area 10: Document & Evaluate

Operating Experience for Welding & Repair

Programs

– This solution area addresses trending and tracking

343C (650F) Galling Wear

of industry performance and development. Behavior at 30 ksi

• Solution Area 11: Thermal spray, Coatings,

and Hardfacing Applications (including Powder Stellite 6 NitroMaxx

Metallurgy) (cobalt free)

– Solutions for surface conditioning, new

fabrication methods

© 2014 Electric Power Research Institute, Inc. All rights reserved. 8

Executive Roadmaps – WRTC

• New welding technology and guidance for

the repair of highly irradiated materials

• Alloy 52M Nickel-base filler metal weldability

guidance and material solutions

690 strip cladding mockups and process controls

• Advance welding process development in

nuclear power industry

• Advancements in Code and regulatory

requirements for repair, replacement and

mitigation techniques.

• Other supporting roadmaps or Solution

Areas:

Friction stir welding development

– Best Practices for Welding Residual Stress for

Repair and Fabrication

– Used Fuel Storage Issues regarding fabrication

and repair

– Nuclear Pool (Spent Fuel Pool) Leakage

– Socket Weld Resolutions

– Powder Metallurgy Materials

Welding residual stress measurements

© 2014 Electric Power Research Institute, Inc. All rights reserved. 9

Together…Shaping the Future of Electricity

10

© 2015 Electric Power Research Institute, Inc. All rights reserved.

You might also like

- Solar Project Example - FINAL - FINALDocument19 pagesSolar Project Example - FINAL - FINALYassine Iferden TorssanovskiNo ratings yet

- Energy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamFrom EverandEnergy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamNo ratings yet

- CO2 Declaration Summary - Template - 1.2Document3 pagesCO2 Declaration Summary - Template - 1.2Musa GürsoyNo ratings yet

- Curso B31.12Document18 pagesCurso B31.12rafaelespino1100% (3)

- Onshore Pipeline Design Course BrochureDocument6 pagesOnshore Pipeline Design Course Brochureilze86No ratings yet

- Power Zone Company ProfileDocument31 pagesPower Zone Company ProfileDanish HamidNo ratings yet

- EPRI Welding and Repair TechnologyDocument48 pagesEPRI Welding and Repair Technologymohamed samyNo ratings yet

- Event 1394656344 11474Document8 pagesEvent 1394656344 11474ahmad exsanNo ratings yet

- Api 1104Document15 pagesApi 1104Faiz Bokhadi0% (1)

- CTG Nescc Astm June11Document36 pagesCTG Nescc Astm June11shingkeongNo ratings yet

- CHENG Frank 2012-08-20 PipelineDocument15 pagesCHENG Frank 2012-08-20 PipelineSandeepSinghNo ratings yet

- Referencias SubseaDocument19 pagesReferencias SubseaEdgar I RamirezNo ratings yet

- ML 003727113Document486 pagesML 003727113technicalfrontierNo ratings yet

- Yang Wei CV 2021Document4 pagesYang Wei CV 2021Wison YangNo ratings yet

- ML 1015998765Document42 pagesML 1015998765ডঃ শুভম চ্যাটার্জীNo ratings yet

- Asmepcc 2repairleaks Article 4Document23 pagesAsmepcc 2repairleaks Article 4amalhaj2013No ratings yet

- EPRI05EPRIDocument15 pagesEPRI05EPRIntosheez4No ratings yet

- CSR IACS Council External Presentationrev1Document36 pagesCSR IACS Council External Presentationrev1api-3864361No ratings yet

- Ipp Review LBNL t2-0203v03Document19 pagesIpp Review LBNL t2-0203v03madhusoothanan100No ratings yet

- STSS Full PresentationV9Document18 pagesSTSS Full PresentationV9Mounir Es-sbaaNo ratings yet

- Some Characteristics of Weld Repair For Creep ApplicationsDocument32 pagesSome Characteristics of Weld Repair For Creep ApplicationsXNo ratings yet

- 33 KeynoteBruceDocument22 pages33 KeynoteBrucekatfy1No ratings yet

- In-Service Welding of Pipelines Industry Action PlanDocument13 pagesIn-Service Welding of Pipelines Industry Action Planعزت عبد المنعم100% (1)

- 96 Download Brochure SMMS PDFDocument8 pages96 Download Brochure SMMS PDFDivyansh Singh ChauhanNo ratings yet

- 23.3.6 T5 Eden CSAT 2016-4Document25 pages23.3.6 T5 Eden CSAT 2016-4gidlavinayNo ratings yet

- Manager Electrical Generation Operations in New Brunswick Nova Scotia Canada Resume James MacLeanDocument6 pagesManager Electrical Generation Operations in New Brunswick Nova Scotia Canada Resume James MacLeanJamesMacLeanNo ratings yet

- Oil & Gas - High ResolutionDocument24 pagesOil & Gas - High ResolutionSubhra S SanyalNo ratings yet

- Profile: Employment HistoryDocument5 pagesProfile: Employment HistoryMoin- ud-dinNo ratings yet

- Creep - Iwshibli PDFDocument32 pagesCreep - Iwshibli PDFIvanUribeNo ratings yet

- Epri - Ut in Lieu of RTDocument319 pagesEpri - Ut in Lieu of RTRamakrishnan AmbiSubbiah100% (1)

- 8 Cotton - IEEE - Standards - Association - Battery - CommitteDocument28 pages8 Cotton - IEEE - Standards - Association - Battery - CommitteArun Harish KumarNo ratings yet

- 2022.11.30 TechnicalWebinar V1 WithRecording2 PDFDocument90 pages2022.11.30 TechnicalWebinar V1 WithRecording2 PDFAnggi AryantoNo ratings yet

- DFR and Sourcing of PCBsDocument214 pagesDFR and Sourcing of PCBsRobert MartosNo ratings yet

- Board - Assembly iNEMI China - Abril 09Document32 pagesBoard - Assembly iNEMI China - Abril 09lexsamothNo ratings yet

- CV-K C - ODonnellDocument3 pagesCV-K C - ODonnellSyed Abrar Ul HaqNo ratings yet

- LED Standards and Test Methods Development: DOE-PNNL Involvement and SupportDocument13 pagesLED Standards and Test Methods Development: DOE-PNNL Involvement and Supportsanjeevverma2001No ratings yet

- CV - Venkatesh Ramachandran - SWPCDocument14 pagesCV - Venkatesh Ramachandran - SWPChusam riadNo ratings yet

- Naukri SunilKumar (6y 0m)Document3 pagesNaukri SunilKumar (6y 0m)dodla.naiduNo ratings yet

- Petroleum Engineering Training and ConsultingDocument4 pagesPetroleum Engineering Training and ConsultingLeon21No ratings yet

- Eng Imtiaz Ahmed CVDocument4 pagesEng Imtiaz Ahmed CVAhmed Imtiaz RaoNo ratings yet

- Export Product Hand BookDocument94 pagesExport Product Hand Bookamit singhNo ratings yet

- Transformer Manufacturing Training Brochure PDFDocument8 pagesTransformer Manufacturing Training Brochure PDFNammavaru IT100% (1)

- Industry Guidance For: Integrity, Obsolescence and Avoidance of Fatigue FailureDocument33 pagesIndustry Guidance For: Integrity, Obsolescence and Avoidance of Fatigue FailureSnezana Vulovic100% (1)

- Education: Stanley NwaonuDocument8 pagesEducation: Stanley NwaonuChukwuma Emmanuel OnwufujuNo ratings yet

- CIGRE Study Committee D1 yDocument23 pagesCIGRE Study Committee D1 ykenlavie2No ratings yet

- Materials For Construction For Process Equipment and Piping Systems - Selection and In-Service PerformanceDocument7 pagesMaterials For Construction For Process Equipment and Piping Systems - Selection and In-Service PerformanceZoebairNo ratings yet

- Whelan Portfolio 2009Document7 pagesWhelan Portfolio 2009Whelan54No ratings yet

- NCRP - Sign 9Document1 pageNCRP - Sign 9anwarali1975No ratings yet

- Ansi Standard 90.1-2007 - BecuDocument226 pagesAnsi Standard 90.1-2007 - BecuAdministracion GeneralNo ratings yet

- Improving Fatigue Life Welds For HssDocument42 pagesImproving Fatigue Life Welds For Hssfle92No ratings yet

- Nationality India Year of Birth 23-JUNE-1968 Profession Specialisation Total Year of Experience 19 YearsDocument9 pagesNationality India Year of Birth 23-JUNE-1968 Profession Specialisation Total Year of Experience 19 YearsJanakiraman MalligaNo ratings yet

- 09 ThompsonDocument14 pages09 ThompsonKanishk KothariNo ratings yet

- Overview of An Integrated Research Facility For Advancing Hydrogen InfrastructureDocument22 pagesOverview of An Integrated Research Facility For Advancing Hydrogen InfrastructureDiego CamachoNo ratings yet

- d2t2 1400 Reverse Eng StudyDocument12 pagesd2t2 1400 Reverse Eng StudysantoshkryadavNo ratings yet

- 16 PTIRecommendationsforStayCableDesignTestingandInstallationDocument23 pages16 PTIRecommendationsforStayCableDesignTestingandInstallationBeratErtekin100% (1)

- PD-077 2018 Vegas - Antaki EsseDocument31 pagesPD-077 2018 Vegas - Antaki EsseSandro AraújoNo ratings yet

- 2.5 Technical Specifications For Hydro Mechanical WorksDocument62 pages2.5 Technical Specifications For Hydro Mechanical WorksAbhishek PandeyNo ratings yet

- SC B3-Terry KriegDocument80 pagesSC B3-Terry KriegKay KarthiNo ratings yet

- Quality and Reliability Aspects in Nuclear Power Reactor Fuel Engineering: Guidance and Best Practices to Improve Nuclear Fuel Reliability and Performance in Water Cooled ReactorsFrom EverandQuality and Reliability Aspects in Nuclear Power Reactor Fuel Engineering: Guidance and Best Practices to Improve Nuclear Fuel Reliability and Performance in Water Cooled ReactorsNo ratings yet

- Pap 567 Ver 1Document10 pagesPap 567 Ver 1ahmad exsanNo ratings yet

- Peraturan Skim Pemeriksaan Khas BIDocument56 pagesPeraturan Skim Pemeriksaan Khas BIahmad exsanNo ratings yet

- Wand System BrochureDocument10 pagesWand System Brochureahmad exsanNo ratings yet

- Knowledge Sharing - Corrosion Monitoring in PPTSB - 21st August 2011Document11 pagesKnowledge Sharing - Corrosion Monitoring in PPTSB - 21st August 2011ahmad exsanNo ratings yet

- Welding Module 1-6Document42 pagesWelding Module 1-6Init Bulan Bituin100% (1)

- Final Year Project PresentationDocument37 pagesFinal Year Project PresentationMuhammad Aqeel JadoonNo ratings yet

- TDS-BS 3262 ThermoplasticsDocument2 pagesTDS-BS 3262 Thermoplasticsmoktar albhlolyNo ratings yet

- The Materials Management Process Begins With The Supplier and EndsDocument30 pagesThe Materials Management Process Begins With The Supplier and EndssnehaNo ratings yet

- Gleitmo 605 Emülsiyon HazırlamaDocument7 pagesGleitmo 605 Emülsiyon HazırlamaErhan KüçükNo ratings yet

- Assembly Drawing ATLAS 1200 XL WS-FRDocument2 pagesAssembly Drawing ATLAS 1200 XL WS-FRBrian Stevens Escobar ReyesNo ratings yet

- Perma Bond A1046 - Technical Datasheet PDFDocument2 pagesPerma Bond A1046 - Technical Datasheet PDFsachin pradhanNo ratings yet

- Specs TARKETT - VCTIIDocument1 pageSpecs TARKETT - VCTIIFede PerezNo ratings yet

- C1.1.0 Ajiya - 2018 - Roofing Catalogue Clip Lock ProfileDocument8 pagesC1.1.0 Ajiya - 2018 - Roofing Catalogue Clip Lock ProfileFahmi YusoffNo ratings yet

- Sae Ams 4340G-2018Document6 pagesSae Ams 4340G-2018Hani YilmazNo ratings yet

- Elk FJM 30 630 1Document1 pageElk FJM 30 630 1kajian19 juniNo ratings yet

- Nondestructive Testing Standards More Commonly Used ASTM NDT Standards or Guidelines Standards ExplanationsDocument2 pagesNondestructive Testing Standards More Commonly Used ASTM NDT Standards or Guidelines Standards Explanationsenquiry info100% (1)

- Metal Putty Polyester PuttyDocument2 pagesMetal Putty Polyester PuttyabdullahNo ratings yet

- 'Identifying Basic Hand Tools and Test Equipment: General ClassificationDocument15 pages'Identifying Basic Hand Tools and Test Equipment: General ClassificationGaming AmbinNo ratings yet

- SMAW 9 Q1 W1 Mod1 PDFDocument18 pagesSMAW 9 Q1 W1 Mod1 PDFkim joshua galolo50% (2)

- WC338 Weiler CatalogDocument16 pagesWC338 Weiler CatalogGerai AchazaNo ratings yet

- Sprs CandyDocument12 pagesSprs CandyVinko MaričićNo ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- Sorting MachineDocument8 pagesSorting MachineRyan SrilaksonoNo ratings yet

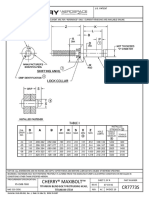

- CR7773SDocument5 pagesCR7773SYoNo ratings yet

- Company Name Address City State Zip Contact Email Phone Commodity Codes Average Gross Receipts Status Effective ExpirationDocument5 pagesCompany Name Address City State Zip Contact Email Phone Commodity Codes Average Gross Receipts Status Effective ExpirationSam ShaneNo ratings yet

- The Process of Paper Impregnation Is Known AsDocument2 pagesThe Process of Paper Impregnation Is Known AsAli RazaNo ratings yet

- Indian Export HousesDocument337 pagesIndian Export HousesUmakant PNo ratings yet

- Properties Pure-Substances MixturesDocument45 pagesProperties Pure-Substances MixturesJulie Maezar AparreNo ratings yet

- Krar Unit 60Document21 pagesKrar Unit 60Aman QaisarNo ratings yet

- HIMC Co., Ltd. Catalog enDocument12 pagesHIMC Co., Ltd. Catalog endenny saputraNo ratings yet

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil SorcaruNo ratings yet

- UNIT OF COMPETENCY: Weld Carbon Steel Plates MODULE TITLE: Performing Groove Welding On Carbon Steel PlatesDocument152 pagesUNIT OF COMPETENCY: Weld Carbon Steel Plates MODULE TITLE: Performing Groove Welding On Carbon Steel PlatesNaive Eilevor100% (2)

- Study Notes - Electricity and Circuits - Science Class 6 PDF DownloadDocument5 pagesStudy Notes - Electricity and Circuits - Science Class 6 PDF DownloadruchikaNo ratings yet