Professional Documents

Culture Documents

New Guideline Document From FSSC 22000 in July 2023

New Guideline Document From FSSC 22000 in July 2023

Uploaded by

ahmedCopyright:

Available Formats

You might also like

- Iso 14091 2021Document13 pagesIso 14091 2021ahmedNo ratings yet

- FSSC 2200 Scheme Version 5 - Audit Plan and Risk RatingDocument10 pagesFSSC 2200 Scheme Version 5 - Audit Plan and Risk RatingMidnight Rei100% (1)

- No. True/False: FSSC QuestionnaireDocument3 pagesNo. True/False: FSSC Questionnairechan5264100% (2)

- Eastern Project ReportDocument107 pagesEastern Project Reportremyasree9080% (5)

- Induction Training - 2021Document95 pagesInduction Training - 2021Fajar PrasetyoNo ratings yet

- COMESA Food Safety Training ManualDocument60 pagesCOMESA Food Safety Training ManualЕлена КоваленкоNo ratings yet

- Tesco PIU Guidelines On The Audit Process For Sites Supplying TescoDocument7 pagesTesco PIU Guidelines On The Audit Process For Sites Supplying TescoGourav TailorNo ratings yet

- Final - Rigid Plastic - May 6 2010Document30 pagesFinal - Rigid Plastic - May 6 2010Abdul Mueed100% (1)

- BRC Implementation Workbook SampleDocument24 pagesBRC Implementation Workbook SampleErki KippastoNo ratings yet

- GSO 1016-2000 STD Microbiological Criteria For Food Stuffs - Part 1Document25 pagesGSO 1016-2000 STD Microbiological Criteria For Food Stuffs - Part 1Mm. Sharaby100% (2)

- ISO 22005.2007 TraceabilityDocument15 pagesISO 22005.2007 TraceabilitySunil Girdhar100% (2)

- Critical Elements For EMPDocument54 pagesCritical Elements For EMPGaganpreet KaurNo ratings yet

- Food Safety Issue 8 Checklist EnglishDocument20 pagesFood Safety Issue 8 Checklist EnglishKSXNo ratings yet

- Methodology For Determination of Hazard Controls CCP S and OPRP SDocument4 pagesMethodology For Determination of Hazard Controls CCP S and OPRP SRosinanteNo ratings yet

- Primusgfs - Checklist - V 1.6: Module 2 - GMP Option (Sections 2.16 To To 2.31)Document10 pagesPrimusgfs - Checklist - V 1.6: Module 2 - GMP Option (Sections 2.16 To To 2.31)dendi,iloNo ratings yet

- BRC Training Guide SampleDocument22 pagesBRC Training Guide SampleOsman AitaNo ratings yet

- SQF Edition 9 Quick Start GuideDocument29 pagesSQF Edition 9 Quick Start GuideRemliw Ésoj Luap AobmagNo ratings yet

- Yum! GAP Guidelines1Document13 pagesYum! GAP Guidelines1shani31No ratings yet

- Requirements For The FSSC 22000 V5 Upgrade ProcessDocument3 pagesRequirements For The FSSC 22000 V5 Upgrade Processfiqrans100% (2)

- ISO 22000: Food Safety Management System (FSMS)Document19 pagesISO 22000: Food Safety Management System (FSMS)Muhammad ShahzadNo ratings yet

- Iso 22000 - Oprps Vs HaccpDocument47 pagesIso 22000 - Oprps Vs HaccpVina AfilianiNo ratings yet

- PAS 220 To 223 - PRPs ComparisonDocument1 pagePAS 220 To 223 - PRPs ComparisonMark Kwan100% (1)

- Pathogen Guidance - FINALDocument100 pagesPathogen Guidance - FINALmigNo ratings yet

- fssc22000 Features v3.2 2015 PDFDocument16 pagesfssc22000 Features v3.2 2015 PDFApple Sirinart ThaNo ratings yet

- Management: ProgramsDocument10 pagesManagement: ProgramsMike SajaNo ratings yet

- G65 BRC Checklist (1aug10)Document15 pagesG65 BRC Checklist (1aug10)almasofia3No ratings yet

- 12 HACCP ValidationDocument45 pages12 HACCP ValidationSartika MutiarasaniNo ratings yet

- BRC 8 Vs 9Document145 pagesBRC 8 Vs 9Marzia RossoNo ratings yet

- Better HACCP ImplementationDocument43 pagesBetter HACCP ImplementationMuhammad Asadullah100% (1)

- ISO/TS 22002:1-2009 Training Workshop: Presented To BDI October 31, 2012Document45 pagesISO/TS 22002:1-2009 Training Workshop: Presented To BDI October 31, 2012honabbieNo ratings yet

- Food Safety - SOP 14 - Prevention of Foreign Body ContaminationDocument4 pagesFood Safety - SOP 14 - Prevention of Foreign Body Contaminationopi akbarNo ratings yet

- Staff Training Slideshow 7-HACCPDocument20 pagesStaff Training Slideshow 7-HACCPHemen Sharadkumar UpadhyayaNo ratings yet

- BRCGS Standard For Packaging and Packaging MaterialsDocument6 pagesBRCGS Standard For Packaging and Packaging Materialshunain zafarNo ratings yet

- Vaccp and Taccp: Pratiksha SupekarDocument4 pagesVaccp and Taccp: Pratiksha SupekarcarlaNo ratings yet

- IV HaccpDocument52 pagesIV HaccpSiddharth SaxenaNo ratings yet

- Protocol For Validation of FSMS - FinalVersionDocument25 pagesProtocol For Validation of FSMS - FinalVersionChel Zalamea Domingo100% (1)

- Final - Print Adh Lam Slit - May 6 2010Document22 pagesFinal - Print Adh Lam Slit - May 6 2010cassilda_carvalho@hotmail.comNo ratings yet

- Codex Stan 1-1985 Labelling of Prepackaged GoodsDocument7 pagesCodex Stan 1-1985 Labelling of Prepackaged GoodsvabimhahNo ratings yet

- NBE HACCP Certification SchemeDocument47 pagesNBE HACCP Certification SchemereachrainbowNo ratings yet

- EMP Environmental Monitoring ProgramDocument10 pagesEMP Environmental Monitoring Programkiagus artaNo ratings yet

- Food Traceability Withdrawals and Recalls GuidanceDocument56 pagesFood Traceability Withdrawals and Recalls GuidanceQualidade SegurançaNo ratings yet

- FSSC Training ReportDocument6 pagesFSSC Training ReportGilbert AgudoNo ratings yet

- Saftey Culture: PrioritiesDocument8 pagesSaftey Culture: PrioritiesMutiara NadilaNo ratings yet

- Allergen PolicyDocument1 pageAllergen PolicyNarinder Pal Singh SokheyNo ratings yet

- TACCP Vs VACCPDocument17 pagesTACCP Vs VACCPMohamed AgrNo ratings yet

- Emergency PreparednessDocument14 pagesEmergency PreparednessV Subramanyam QCNo ratings yet

- Checklist ISO 22000Document27 pagesChecklist ISO 22000rbabar100% (1)

- Differences Between PRP, oPRP and CCPDocument5 pagesDifferences Between PRP, oPRP and CCPolotu_olaseindeNo ratings yet

- Application of Lean Six Sigma Tools To Minimize Length of Stay For Ophthalmology Day Case Surgery PDFDocument18 pagesApplication of Lean Six Sigma Tools To Minimize Length of Stay For Ophthalmology Day Case Surgery PDFM HNo ratings yet

- CanadaGAP Food Safety Manual AppendicesDocument108 pagesCanadaGAP Food Safety Manual AppendicesGaganpreetNo ratings yet

- Free Food Safety VideosDocument16 pagesFree Food Safety VideosMuhammad AtifNo ratings yet

- FMCQMS-002 Prerequisite ProgramDocument4 pagesFMCQMS-002 Prerequisite Programveejee tangalin100% (1)

- Introduction To 22000Document32 pagesIntroduction To 22000NakitawiernqNo ratings yet

- AIB HACCP Checklist2007Document9 pagesAIB HACCP Checklist2007m125esteban2003No ratings yet

- Guidebook For The Preparation of HACCP PlansDocument74 pagesGuidebook For The Preparation of HACCP Planslatog13No ratings yet

- BRC Implementation Workbook Issue 8 Plus FSMA SampleDocument31 pagesBRC Implementation Workbook Issue 8 Plus FSMA Samplearif shaikhNo ratings yet

- Food Processing Industry - CODEX Standards, FDI & DumpingDocument38 pagesFood Processing Industry - CODEX Standards, FDI & DumpingNarender YadavNo ratings yet

- HACCP Processed Meats Cop Part 4Document118 pagesHACCP Processed Meats Cop Part 4Arkham KhollyshulNo ratings yet

- Food Microbiology Quality Control Nov 14Document36 pagesFood Microbiology Quality Control Nov 14Harith AtrisNo ratings yet

- Case Studies On HaccpDocument28 pagesCase Studies On HaccpAnonymous OPix6Tyk5I100% (1)

- Bip 2078-2007Document236 pagesBip 2078-2007clive100% (1)

- SMETA Certification 1Document4 pagesSMETA Certification 1ahmedNo ratings yet

- FUSH 4-Pillar SMETA Audit ResultsDocument63 pagesFUSH 4-Pillar SMETA Audit ResultsahmedNo ratings yet

- Social Compliance - What About ItDocument5 pagesSocial Compliance - What About ItahmedNo ratings yet

- Responsible Sourcing Manager - IpswichDocument4 pagesResponsible Sourcing Manager - IpswichahmedNo ratings yet

- Iso CD Ts 22002 3 FarmingDocument31 pagesIso CD Ts 22002 3 FarmingAnibar PerezNo ratings yet

- Bip 2078-2007Document236 pagesBip 2078-2007clive100% (1)

- ISO 22000 Clause 9 10Document11 pagesISO 22000 Clause 9 10Thilina MadusankaNo ratings yet

- Document in NABCB Advt. For AssessorsDocument5 pagesDocument in NABCB Advt. For Assessorsatvenu16160No ratings yet

- Food Safety Management System Implementation Guide: GloballyDocument36 pagesFood Safety Management System Implementation Guide: GloballyGen100% (1)

- Iso Certification Consultants in MumbaiDocument13 pagesIso Certification Consultants in MumbaiSmita MalakaranNo ratings yet

- HACCP GMP Certification Criteria PDFDocument32 pagesHACCP GMP Certification Criteria PDFanon_417835525No ratings yet

- Agr 14 Haccp PDFDocument182 pagesAgr 14 Haccp PDFSerenityNo ratings yet

- Iso Awareness Weekend Staff Training Programme: RegistrationDocument12 pagesIso Awareness Weekend Staff Training Programme: RegistrationKakira Lions ClubNo ratings yet

- Iso 9001-2020Document27 pagesIso 9001-2020Wahid RasoolNo ratings yet

- Articulo 6 FS 22000Document13 pagesArticulo 6 FS 22000Meiler Karina TinocoNo ratings yet

- International University of Travnik Faculty of Polytechnic Sciences TravnikDocument12 pagesInternational University of Travnik Faculty of Polytechnic Sciences TravnikTiross DesignsNo ratings yet

- Resource 839-1549451075802582073 PDFDocument2 pagesResource 839-1549451075802582073 PDFmiz baigNo ratings yet

- SGS-CBE-PH Academy Makati Training Calendar H1 2020 PDFDocument4 pagesSGS-CBE-PH Academy Makati Training Calendar H1 2020 PDFben foldsNo ratings yet

- FSMS Action PlanDocument7 pagesFSMS Action Plan22000-Tools100% (7)

- Food Safety Management Systems: Based OnDocument23 pagesFood Safety Management Systems: Based Onekoimamp100% (2)

- HACCP Training GuideDocument42 pagesHACCP Training GuideSyed HamzaNo ratings yet

- 0211 SlideDocument22 pages0211 SlideRama Krishna RaoNo ratings yet

- What Is A Food Safety AuditDocument8 pagesWhat Is A Food Safety AuditSONIA NABINo ratings yet

- FSSC 22000 Vers 5, Add Req, ISO 22000 2018 Shared PDFDocument80 pagesFSSC 22000 Vers 5, Add Req, ISO 22000 2018 Shared PDFSyahrizal MuhammadNo ratings yet

- July 2021 To Continue: Permanent AddressDocument2 pagesJuly 2021 To Continue: Permanent AddressMuhammad Ramzan MalickNo ratings yet

- Building The Entrepreneurial Mindset 28022023 031306pm PDFDocument7 pagesBuilding The Entrepreneurial Mindset 28022023 031306pm PDFtabassum manzoorshahNo ratings yet

- Pas 223Document28 pagesPas 223ivansitopapi100% (1)

- Pas 221 Draft 3 - 19072012 For DPCDocument25 pagesPas 221 Draft 3 - 19072012 For DPCMarcos FernandezNo ratings yet

- FSSC 22000-2017Document100 pagesFSSC 22000-2017dpamplona_nevilleclarke100% (5)

- OTOP Presentation-Localized - Towns UpdatedDocument20 pagesOTOP Presentation-Localized - Towns UpdatedStephen KintanarNo ratings yet

New Guideline Document From FSSC 22000 in July 2023

New Guideline Document From FSSC 22000 in July 2023

Uploaded by

ahmedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Guideline Document From FSSC 22000 in July 2023

New Guideline Document From FSSC 22000 in July 2023

Uploaded by

ahmedCopyright:

Available Formats

Guidance Document: Food Safety and Quality Culture

FOOD SAFETY SYSTEM

CERTIFICATION 22000

GUIDANCE DOCUMENT: FOOD SAFETY AND

QUALITY CULTURE

FSSC 22000 Version 6 | July 2023 0 of 19 Version 2 | July 2023

Guidance Document: Food Safety and Quality Culture

CONTENTS

REVISION HISTORY ......................................................................................................................... 1

1. INTRODUCTION ....................................................................................................................... 2

2. GFSI REQUIREMENT ................................................................................................................. 2

3. FSSC 22000 ADDITIONAL REQUIREMENT 2.5.8 ...................................................................... 2

4. GFSI GUIDING QUESTIONS ...................................................................................................... 3

5. FSSC 22000 GUIDANCE ............................................................................................................. 3

6. GUIDANCE FOR IMPLEMENTING FOOD SAFETY AND QUALITY CULTURE ........................... 4

7. ADDITIONAL GUIDANCE BASED ON PAS 320: DEVELOPING AND SUSTAINING A MATURE

FOOD SAFETY CULTURE GUIDE .................................................................................................... 17

8. REFERENCES ........................................................................................................................... 19

REVISION HISTORY

Date Published Issue Changes

November 2020 1 First publication

July 2023 2 Updates made in line with Version 6 of the FSSC 22000 Scheme and

to include reference to PAS 320:2023.

FSSC 22000 Version 6 | July 2023 1 of 19

Guidance Document: Food Safety and Quality Culture

1. INTRODUCTION

GFSI defines food safety culture as “shared values, beliefs and norms that affect mindset and

behavior toward food safety in, across and throughout an organization” (GFSI 2020.1).

The definition derives from existing literature on organizational and food safety culture and is

made practical and applicable through the group’s work.

A mature food safety culture is one in which the company vision and mission have been broken

down into the finer details of expectations for every department and person throughout the

organization.

2. GFSI REQUIREMENT

The GFSI benchmarking document contains the following requirement that shall be implemented

by GFSI-approved Certification Program Owners (CPO) and audited onsite.

Requirement: Evidence of the senior management’s commitment to establish, implement,

maintain, and continuously improve the Food Safety Management System

shall be provided. This shall include elements of food safety culture, at a

minimum consisting of:

• Communication,

• Training,

• Feedback from employees and

• Performance measurement on food safety-related activities.

3. FSSC 22000 ADDITIONAL REQUIREMENT 2.5.8

Included in FSSC 22000 Version 6, under Part 2 of the Scheme, is the additional requirement 2.5.8

on Food Safety and Quality Culture. This requirement is applicable to all food chain categories.

The requirement is aligned with the requirement of GFSI. The additional requirement 2.5.8

indicates:

a) In accordance with and in addition to clause 5.1 of ISO 22000:2018, as part of the organization’s

commitment to cultivating a positive food safety and quality culture, senior management shall

establish, implement, and maintain a food safety and quality culture objective(s) as part of the

management system. The following elements shall be addressed as a minimum:

• Communication,

• Training,

• Employee feedback and engagement, and

• Performance measurement of defined activities covering all sections of the

organization’s impact on food safety and quality.

b) The objective(s) shall be supported by a documented food safety and quality culture plan, with

targets and timelines included in the management review and continuous improvement

processes of the management system.

FSSC 22000 Version 6 | July 2023 2 of 19

Guidance Document: Food Safety and Quality Culture

4. GFSI GUIDING QUESTIONS

GFSI has drafted a set of guiding questions that could be used when auditing an organization

against a GFSI-approved certification Scheme.

5. FSSC 22000 GUIDANCE

This FSSC 22000 guidance document includes guidance for auditors and organizations on

assessing food safety and quality culture within their organization in accordance with the FSSC

22000 Additional Requirement 2.5.8 as well as how the GFSI guiding questions link to ISO

22000:2018 and the overall FSMS.

FSSC 22000 Version 6 | July 2023 3 of 19

Guidance Document: Food Safety and Quality Culture

6. GUIDANCE FOR IMPLEMENTING FOOD SAFETY AND QUALITY CULTURE

FSSC 22000 VERSION 6 ADDITIONAL REQUIREMENT 2.5.8

In accordance with and in addition to clause 5.1 of ISO 22000:2018, as part of the organization’s commitment to cultivating a positive food safety and

quality culture, senior management shall establish, implement, and maintain a food safety and quality culture objective(s) as part of the management

system. The following elements shall be addressed as a minimum:

• Communication,

• Training,

• Employee feedback and engagement, and

• Performance measurement of defined activities covering all sections of the organization impacting food safety and quality.

GUIDANCE ON AUDITING THE COMMUNICATION ELEMENT

• Senior management can demonstrate their engagement with food safety by establishing expectations for every department and person

throughout the organization with regard to food safety and quality culture, e.g., establish whether this is included within job descriptions.

• Verify how food safety and quality culture aspects are communicated throughout the organization, e.g., establish if the organization has a

communication policy and communication matrix.

• Verify how top management has verified that all staff, e.g., understand food safety and quality culture expectations, verify whether this is included

within induction and annual training for personnel, and whether it included an assessment of personnel’s understanding.

• Interview personnel on the shop floor to determine whether employees know their responsibilities and what they are accountable for in relation

to food safety and quality-related tasks. Verify how personnel receive feedback on production performance and food safety/quality issues, e.g.,

verify if there are weekly or monthly production meetings and include feedback on production performance and food safety/quality issues.

• Assess during interviews with top management whether they can explain the organization’s food safety and quality expectations and how they

are used in the decision-making processes.

• Assess during interviews with the shop floor to which level personnel are informed on food safety and quality expectations. E.g., check the level

of comfort and ease with which the auditee explains or responds when asked about the expectations, such as whether they know what to do

when a non-conformance occurs. Can they describe for their section/area of work what non-conformance is?

FSSC 22000 Version 6 | July 2023 4 of 19

Guidance Document: Food Safety and Quality Culture

• Assess the capability of top management to react to, e.g., customer complaints or supplier issues, in a timely and effective manner whilst ensuring

the right decisions are made. This can be assessed during the interview with top management as well as when sampling customer complaints

and corrective actions.

• Assess whether food safety and quality-related expectations are communicated in a language understood by the personnel on the shop floor.

E.g., Look out for examples of translated materials either posted on the walls where employees work or other areas such as the canteen walls.

• Verify that training material is available and translations are in the local language and sample and examine answer sheets if written tests are

used for verification of competence.

COMMUNICATION

GFSI GUIDING QUESTION ISO 22000:2018 GUIDANCE

How do your senior leaders Clause 5.1, d) Assessment of this ISO 22000 clause shall

engage with food safety? Top management shall demonstrate leadership and commitment also include the expectations for every

with respect to the FSMS by communicating the importance of department and person throughout the

effective food safety management and conforming to the FSMS organization with regard to food safety

requirements, applicable statutory and regulatory requirements, culture.

and mutually agreed-on customer requirements related to food

safety.

How is your messaging used to Clause 5.2.2, a) and b) Assessment of this ISO 22000 clause shall

communicate food safety The food safety policy shall be: also include a detailed assessment of

expectations to all employees? how food safety culture aspects are

a) be available and maintained as documented information;

communicated throughout the

b) be communicated, understood, and applied at all levels

organization.

within the organization;

Is your company’s vision and Clause 5.2.2, b) Assessment of this ISO 22000 clause shall

mission clearly expressed so The food safety policy shall be communicated, understood, and also include how top management has

that all staff understands both? applied at all levels within the organization; verified that all staff understands food

safety culture expectations.

FSSC 22000 Version 6 | July 2023 5 of 19

Guidance Document: Food Safety and Quality Culture

COMMUNICATION

GFSI GUIDING QUESTION ISO 22000:2018 GUIDANCE

Are you confident that all Clause 5.3.1 The assessment shall be included in the

employees know their Top management shall ensure that the responsibilities and interview with personnel on the shop floor.

responsibilities and are held authorities for relevant roles are assigned, communicated, and Look for evidence that feedback personnel

accountable for their food understood within the organization. receives on production performance and food

safety-related tasks and that safety issues.

Clause 7.4.3

accountabilities are well-

connected? The organization shall establish, implement, and maintain an

effective system for communicating issues having an impact

on food safety. To maintain the effectiveness of the FSMS, the

organization shall ensure that the food safety team is informed

in a timely manner of changes in the following: a) – m).

Can you articulate your Clause 4.2 This shall be addressed when interviewing top

company’s food safety To ensure that the organization has the ability to consistently management.

expectations and how they are provide products and services that meet applicable statutory, Also, check when interviewing personnel at the

applied to every decision? regulatory, and customer requirements with regard to food shop floor to assess to which level personnel is

safety, the organization shall determine: informed on food safety expectations.

c) the interested parties that are relevant to the FSMS;

d) the relevant requirements of the interested parties of

the FSMS.

The organization shall identify, review and update information

related to the interested parties and their requirements.

Clause 6.2

The organization shall establish objectives for the FSMS at

relevant functions and levels.

FSSC 22000 Version 6 | July 2023 6 of 19

Guidance Document: Food Safety and Quality Culture

COMMUNICATION

GFSI GUIDING QUESTION ISO 22000:2018 GUIDANCE

Does your strategy enable you Clause 4.1 The top management decision-making

to respond quickly and The organization shall determine external and internal issues that process determines this and should be

effectively, with appropriate are relevant to its purpose and that affect its ability to achieve the addressed during an interview with top

oversight, to ensure the right intended result(s) of its FSMS. management. Specifically, look at the

decisions are made? capability of top management to react to,

The organization shall identify, review and update information

e.g., customer complaints or supplier

related to these external and internal issues.

issues.

Clause 6.3

When the organization determines the need for changes to the

FSMS, including personnel changes, the changes shall be carried out

and communicated in a planned manner.

The organization shall consider:

e) the purpose of the changes and their potential

consequences;

f) the continued integrity of the FSMS;

g) the availability of resources to effectively implement the

changes;

h) the allocation or re-allocation of responsibilities and

authorities.

Clause 9.3

Top management shall review the organization’s FSMS at planned

intervals to ensure its continuing suitability, adequacy, and

effectiveness.

FSSC 22000 Version 6 | July 2023 7 of 19

Guidance Document: Food Safety and Quality Culture

Can you identify examples of Clause 4.1 Specifically, address NOTE 2 to this clause

where using industry The organization shall determine external and internal issues that when interviewing top management.

intelligence has helped identify are relevant to its purpose and that affect its ability to achieve the Industry intelligence is also part of

potential hazards or risks to intended result(s) of its FSMS. understanding the context.

your business?

The organization shall identify, review and update information

related to these external and internal issues.

FSSC 22000 VERSION 6 ADDITIONAL REQUIREMENT 2.5.8

In accordance with and in addition to clause 5.1 of ISO 22000:2018, as part of the organization’s commitment to cultivating a positive food safety and

quality culture, senior management shall establish, implement, and maintain a food safety and quality culture objective(s) as part of the management

system. The following elements shall be addressed as a minimum:

• Communication,

• Training,

• Employee feedback and engagement, and

• Performance measurement of defined activities covering all sections of the organization impacting on food safety and quality.

GUIDANCE ON AUDITING THE TRAINING ELEMENT

• Assess the overall training program of the organization, including the content, e.g., evaluate the ’organization's training procedure, training

matrix, and records of training, and determine whether it addressed relevant topics.

• Assessment of competency during the interview of personnel on the shop floor. E.g., Check for level of comfort in having a conversation on

the topic directed at any person along the production line, not just the team leaders or Supervisors.

• Verify evidence that personnel have participated in food safety training, including whether personnel undertaking activities related to CCPs

and OPRPs have been trained in this regard and whether they were assessed and found competent. E.g., request retained evidence of

training such as attendance registers and written tests/signed-off records of on-the-task observation and allow sufficient time to stand and

observe employees at work during production and look out for good practices. This also applies to training on quality control parameters.

• Verify that the organization’s training program addresses hazard and risk management controls in personnel’s area of work and what actions

would be taken in the case they were not adhered to. Evaluate documented evidence that this training was undertaken.

FSSC 22000 Version 6 | July 2023 8 of 19

Guidance Document: Food Safety and Quality Culture

TRAINING

GFSI GUIDING QUESTION ISO 22000:2018 GUIDANCE

When was your last food Clause 7.2, b) Assess the overall training program of the

safety training, and what did The organization shall ensure that these persons, including the food organization.

you learn? safety team and those responsible for the operation of the hazard The assessment shall also be included in

control plan, are competent on the basis of appropriate education, the interview with personnel on the shop

training, and/or experience. floor. Look for evidence that personnel

have participated in food safety training.

How do you educate staff to Clause 7.3 This should be addressed in the

understand why the hazard The organization shall ensure that all relevant persons doing work organization’s training program. Assess

and risk management controls under the organization’s control shall be aware of their individual the content of the training program and

in their areas are so important, contribution to the effectiveness of the FSMS, including the benefits training.

and what would be the of improved food safety performance and the implications of not

consequences of not following conforming with the FSMS requirements.

them?

FSSC 22000 Version 6 | July 2023 9 of 19

Guidance Document: Food Safety and Quality Culture

FSSC 22000 VERSION 6 ADDITIONAL REQUIREMENT 2.5.8

In accordance with and in addition to clause 5.1 of ISO 22000:2018, as part of the organization’s commitment to cultivating a positive food safety and

quality culture, senior management shall establish, implement, and maintain a food safety and quality culture objective(s) as part of the management

system. The following elements shall be addressed as a minimum:

• Communication,

• Training,

• Employee feedback and engagement, and

• Performance measurement of defined activities covering all sections of the organization impacting on food safety and quality.

GUIDANCE ON AUDITING THE FEEDBACK FROM EMPLOYEES’ ELEMENT

• Assess when last the organization raised a food safety or quality concern whilst interviewing the food safety team (leader) and/or personnel

on the shop floor. E.g., Refer to their defined process for internal communication regarding food safety and quality issues and use it to check

if it is followed, confirm the target recipients and what feedback was received from them.

• Assess the specific food safety and quality concerns raised by personnel and how this has been managed by the food safety team and top

management, including a review of documented evidence. Determine whether the organization has a confidential reporting system in place

for employees to communicate these issues in a confidential manner. E.g., Check for what platforms have been set up by the organization

to ensure open lines of communication through online chatting platforms created specifically for food safety-related issues, anonymous tip-

off email or telephone numbers for employees to use, and so on.

• Assess how personnel contribute to food safety and quality in the organization whilst interviewing personnel on the shop floor. E.g., ask

personnel how they communicate suggestions, whom they speak to, and when.

• Assess whether personnel are actively involved in safeguarding food safety. E.g., taking pride in their own workspace, taking accountability

for themselves and one another, and looking out for following rules set per department or area of work by observing during the audit.

• Observe whether personnel are committed and adhere to the food safety and quality expectations of the organization whilst on the shop

floor, e.g., observe employees entering the facility and assess whether they have followed the correct entering procedures, including hand

washing and proper wearing of PPE.

• Assess whether the FSMS documentation is designed to support employees’ food safety and quality decisions and behaviors. E.g., check that

instructions are available and clear in a simple step-by-step guide/format and check that the latest updated information is made available at

the point of use.

• Assess whether personnel are included in the design and improvement of food safety and quality-related protocols and instructions. Verify

that the food safety team is involved in this and whether the food safety team and top management include personnel in this process. Assess

how their feedback is received and evaluated.

FSSC 22000 Version 6 | July 2023 10 of 19

Guidance Document: Food Safety and Quality Culture

• Assess how protocols and instructions are validated on the shop floor.

FEEDBACK FROM EMPLOYEES

GFSI GUIDING QUESTION ISO 22000:2018 GUIDANCE

When was the last time you or Clause 5.3.3 The assessment shall be done when

someone on your team raised All persons shall have the responsibility to report the interviewing the food safety team (leader)

a food safety concern? problem(s) with regard to the FSMS to identified person(s). and/or personnel on the shop floor. Look

specifically for food safety concerns raised by

personnel and how the food safety team and

top management have managed this.

How do you contribute to food Clause 7.3, c) The assessment shall be included in the

safety in your organization? The organization shall ensure that all relevant persons doing interview with personnel on the shop floor.

work under the organization’s control shall be aware of their Look for evidence that personnel are actively

individual contribution to the effectiveness of the FSMS, involved in safeguarding food safety.

including the benefits of improved food safety performance.

To what level are people Clause 7.1.2 The assessment shall be done by interviewing

committed and acting in The organization shall ensure that the persons necessary to personnel on the shop floor. Look for evidence

accordance with food safety operate and maintain an effective FSMS are competent (see that personnel are actively involved in

expectations? 7.2). safeguarding food safety.

Is your documentation Clause 7.5.1, b) Specifically, address the NOTE to this clause

designed to support The organization’s FSMS shall include documented information when assessing.

employees’ food safety determined by the organization as being necessary for the NOTE: The extent of documented information

decisions and behaviors? effectiveness of the FSMS; for an FSMS can differ from one organization to

another due to:

• the size of the organization and its type of

activities, processes, products, and services;

• the complexity of processes and their

interactions;

the competence of persons.

FSSC 22000 Version 6 | July 2023 11 of 19

Guidance Document: Food Safety and Quality Culture

FEEDBACK FROM EMPLOYEES

GFSI GUIDING QUESTION ISO 22000:2018 GUIDANCE

Are employees engaged in the Clause 5.3.2 In principle, personnel are represented by the

design and improvement of The food safety team leader shall be responsible for: food safety team.

food safety-related protocols Look for evidence of how the food safety team

i) ensuring the FSMS is established, implemented,

and instructions? and top management involve personnel or

maintained, and updated;

j) managing and organizing the work of the food safety personnel representative group when

team; developing protocols and instructions.

k) ensuring relevant training and competencies for the How are protocols and instructions validated

food safety team (see 7.2); on the shop floor?

l) reporting to top management on the effectiveness and

suitability of the FSMS.

FSSC 22000 Version 6 | July 2023 12 of 19

Guidance Document: Food Safety and Quality Culture

FSSC 22000 VERSION 6 ADDITIONAL REQUIREMENT 2.5.8

In accordance with and in addition to clause 5.1 of ISO 22000:2018, as part of the organization’s commitment to cultivating a positive food safety and

quality culture, senior management shall establish, implement, and maintain a food safety and quality culture objective(s) as part of the management

system. The following elements shall be addressed as a minimum:

• Communication,

• Training,

• Employee feedback and engagement, and

• Performance measurement of defined activities covering all sections of the organization impacting on food safety and

quality.

GUIDANCE ON AUDITING THE PERFORMANCE MEASUREMENT ELEMENT

• Assess how the organization’s food safety and quality performance is measured, e.g., are food safety and quality performance targets

established and monitored?

• Assessment shall be included in the interview with personnel on the shop floor, e.g., check to see if departmental targets have been set,

ask how they are monitored and how often they are reported on, and request evidence.

• Verify how personnel receive feedback on production performance and food safety/quality issues, e.g., an overall company dashboard

clearly showing the food safety/quality performance.

• Assess how top management evaluates food safety/quality performance. E.g., a personnel survey that is executed periodically, specifically

related to food safety/quality, including the food safety and quality culture of the organization.

• Assess how complaints and nonconformance issues are managed by the organization and top management, including a review of corrective

action reports. E.g., check to see if trends of similar complaints are identified and select a few reports to follow the trail of what actions have

been taken, verify the level of cause analysis and sufficiency of actions taken to correct each of the issues, verify the effectiveness of the

actions taken by asking if any further complaints or non-conformances of similar nature have been received.

• Assess how increased productivity affects the food safety and quality culture of the organization. E.g., are there more NCs during peak

production?

• Evaluate how the organization plans for changes and manages changes, including reviewing documented evidence thereof. Assess the

capability of top management to react to, e.g., customer complaints or supplier issues, by sampling customer complaints and non-

conformances.

• Evaluate how the organization implements changes based on trending results, e.g., verify the output from management reviews.

FSSC 22000 Version 6 | July 2023 13 of 19

Guidance Document: Food Safety and Quality Culture

• Assess the organization’s management of near misses and the actions taken from near misses to drive continuous improvement, e.g., where

trended data indicates the results are nearing an unacceptable level, what action is taken by the organization prior to the limit being

exceeded?

PERFORMANCE MEASUREMENT ON FOOD SAFETY-RELATED ACTIVITIES

GFSI GUIDING QUESTION ISO 22000:2018 GUIDANCE

How is your food safety performance Clause 9.1.2 The assessment shall be included in the

measured? interview with personnel on the shop floor.

The organization shall analyze and evaluate

appropriate data and information arising from Look for evidence as to which feedback

monitoring and measurement, including the personnel receive on production performance

results of verification activities related to PRPs and food safety issues. E.g., an overall

and the hazard control plan (see 8.8 and 8.5.4), company dashboard clearly showing the food

internal audits (see 9.2), and external audits. safety performance.

Clause 9.3.2 Also, assess how top management evaluates

food safety performance. E.g., a personnel

Management review input.

survey that is executed periodically.

How do you anticipate, manage, and respond Clause 6.1.1 The top management decision-making process

to change, learn from the past, and prepare for determines this and should be addressed

When planning for the FSMS, the organization

the future? during the interview with top management.

shall consider the issues referred to in 4.1 and

the requirements referred to in 4.2 and 4.3 and Specifically, look at the capability of top

determine the risks and opportunities that management to react to, e.g., customer

need to be addressed to: complaints or supplier issues.

m) give assurance that the FSMS can

achieve its intended result(s);

n) enhance desirable effects;

o) prevent or reduce undesired effects;

achieve continual improvement.

FSSC 22000 Version 6 | July 2023 14 of 19

Guidance Document: Food Safety and Quality Culture

PERFORMANCE MEASUREMENT ON FOOD SAFETY-RELATED ACTIVITIES

GFSI GUIDING QUESTION ISO 22000:2018 GUIDANCE

How does what you measure (e.g., customer Clause 9.1.2 Assess how the organization and top

complaints, compliance to procedures, management manage complaints and non-

The organization shall analyze and evaluate

productivity, etc.) influence your food safety conformance issues.

appropriate data and information arising from

culture? monitoring and measurement, including the

Are your measurements related to results of verification activities related to PRPs

volume/efficiency at the expense of food safety and the hazard control plan (see 8.8 and 8.5.4),

measures? internal audits (see 9.2), and external audits.

Clause 10.2

The organization shall continually improve the

suitability, adequacy, and effectiveness of the

FSMS.

Top management shall ensure that the

organization continually improves the

effectiveness of the FSMS through the use of

communication (see 7.4), management review

(see 9.3), internal audit (see 9.2), analysis of

results of verification activities (see 8.8.2),

validation of control measure(s) and

combination(s) of control measure(s) (see

8.5.3), corrective actions (see 8.9.3) and FSMS

updating (see 10.3).

FSSC 22000 Version 6 | July 2023 15 of 19

Guidance Document: Food Safety and Quality Culture

PERFORMANCE MEASUREMENT ON FOOD SAFETY-RELATED ACTIVITIES

GFSI GUIDING QUESTION ISO 22000:2018 GUIDANCE

How do you review your “near-misses” and use Clause 8.9.1 Also included is the management of near misses

this information to drive improvements in your in the assessment of this clause.

The organization shall ensure that data derived

food safety system?

from the monitoring of OPRPs and at CCPs are

evaluated by designated persons who are

competent and have the authority to initiate

corrections and corrective actions.

Clause 10.3

Top management shall ensure that the FSMS is

continually updated. To achieve this, the food

safety team shall evaluate the FSMS at planned

intervals. The team shall consider whether it is

necessary to review the hazard analysis (see

8.5.2), the established hazard control plan (see

8.5.4), and the established PRPs (see 8.2). The

updating activities shall be based on:

p) input from communication, external as

well as internal (see 7.4);

q) input from other information

concerning the suitability, adequacy,

and effectiveness of the FSMS;

r) output from the analysis of results of

verification activities (see 9.1.2);

s) output from management review (see

9.3).

System updating activities shall be retained as

documented information and reported as input

to the management review (see 9.3).

FSSC 22000 Version 6 | July 2023 16 of 19

Guidance Document: Food Safety and Quality Culture

7. ADDITIONAL GUIDANCE BASED ON PAS 320:

DEVELOPING AND SUSTAINING A MATURE FOOD

SAFETY CULTURE GUIDE

The British Standards Institution (BSI) has developed a publicly available standard for use as

guidance and advisory recommendations that provide further clarity for implementing food safety

and quality culture.

Below are aspects to consider as established by PAS 3203, however, in addition, the below also

indicates where these aspects can be integrated within your FSMS via cross-reference to the

relevant ISO 22000:2018 clauses and the inclusion of quality:

• Understanding the fundamentals of a food safety (and quality) culture and the context of

the organization: (Integrate with clause 4 of ISO 22000:2018)

- Defining the concept of a food safety (and quality) culture

- Establishing the relationship between food safety (and quality) culture and the

organizational culture

- Understanding the organization’s internal and external issues

• Establishing the governance for a food safety (and quality) culture: (Integrate with clause 5

of ISO 22000:2018)

- Top management commitment, accountability, and consistency;

- Defining the organization’s vision, mission, and values;

- Establishing the policy for a food safety (and quality) culture;

- Establishing and managing organizational structure, responsibilities,

accountabilities, and authorities.

• Understanding the organization’s food safety (and quality) culture: (Integrate with clause 4

of ISO 22000:2018)

- Determining the current maturity level of the organization’s food safety (and

quality) culture,

- Determining the desired food safety (and quality) culture.

• Designing a strategic change plan to achieve the desired food safety (and quality) culture:

(Integrate with clause 6 of ISO 22000:2018)

- Identifying the drivers of change,

- Establishing the organization’s readiness to drive change to achieve the desired

food safety (and quality) culture,

- Mapping the needs, behaviors, expectations, and changes to the existing FSMS

against the culture maturity gaps,

- Determining food safety (and quality) risks and opportunities,

- Setting priorities for positive food safety (and quality) culture change,

- Establishing a change plan for the organization’s food safety (and quality) culture.

• Preparing the key functions towards a food safety (and quality) culture: (Integrate with

clause 7 of ISO 22000:2018)

- Resources,

- Developing competence and awareness,

- Communicating and nudging,

FSSC 22000 Version 6 | July 2023 17 of 19

Guidance Document: Food Safety and Quality Culture

- Documentation.

• Embedding the change plan of the organization’s food safety (and quality) culture into the

existing FSMS: (Integrate with clause 8.1 of ISO 22000:2018)

- Managing and embedding change

- Managing disruptions and crises

• Evaluating the performance of the organization’s food safety (and quality) culture:

(Integrate with clause 9 of ISO 22000:2018)

- Monitoring and measuring

- Verifying

- Analyzing, evaluating, and reporting

- Management review

• Sustaining the continual improvement of the organization’s food safety (and quality)

culture: (Integrate with clause 10 of ISO 22000:2018)

- Continual improvement

- Reporting near misses

- Applying interventions

- Recognizing people and celebrating gains

- Updating

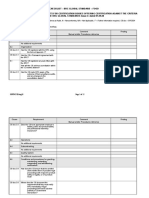

Figure 1 – PDCA (Plan-Do-Check-Act) cycle for Food Safety Culture3

PAS 320 is freely available for download from the BSI website.

FSSC 22000 Version 6 | July 2023 18 of 19

Guidance Document: Food Safety and Quality Culture

8. REFERENCES

1. FSSC 22000 V6 Additional requirement

2. ISO 22000:2018 Food safety management systems – Requirements for any organization in the

food chain

3. PAS 320:2023 Developing and sustaining a mature food safety culture – Guide.

FSSC 22000 Version 6 | July 2023 19 of 19

You might also like

- Iso 14091 2021Document13 pagesIso 14091 2021ahmedNo ratings yet

- FSSC 2200 Scheme Version 5 - Audit Plan and Risk RatingDocument10 pagesFSSC 2200 Scheme Version 5 - Audit Plan and Risk RatingMidnight Rei100% (1)

- No. True/False: FSSC QuestionnaireDocument3 pagesNo. True/False: FSSC Questionnairechan5264100% (2)

- Eastern Project ReportDocument107 pagesEastern Project Reportremyasree9080% (5)

- Induction Training - 2021Document95 pagesInduction Training - 2021Fajar PrasetyoNo ratings yet

- COMESA Food Safety Training ManualDocument60 pagesCOMESA Food Safety Training ManualЕлена КоваленкоNo ratings yet

- Tesco PIU Guidelines On The Audit Process For Sites Supplying TescoDocument7 pagesTesco PIU Guidelines On The Audit Process For Sites Supplying TescoGourav TailorNo ratings yet

- Final - Rigid Plastic - May 6 2010Document30 pagesFinal - Rigid Plastic - May 6 2010Abdul Mueed100% (1)

- BRC Implementation Workbook SampleDocument24 pagesBRC Implementation Workbook SampleErki KippastoNo ratings yet

- GSO 1016-2000 STD Microbiological Criteria For Food Stuffs - Part 1Document25 pagesGSO 1016-2000 STD Microbiological Criteria For Food Stuffs - Part 1Mm. Sharaby100% (2)

- ISO 22005.2007 TraceabilityDocument15 pagesISO 22005.2007 TraceabilitySunil Girdhar100% (2)

- Critical Elements For EMPDocument54 pagesCritical Elements For EMPGaganpreet KaurNo ratings yet

- Food Safety Issue 8 Checklist EnglishDocument20 pagesFood Safety Issue 8 Checklist EnglishKSXNo ratings yet

- Methodology For Determination of Hazard Controls CCP S and OPRP SDocument4 pagesMethodology For Determination of Hazard Controls CCP S and OPRP SRosinanteNo ratings yet

- Primusgfs - Checklist - V 1.6: Module 2 - GMP Option (Sections 2.16 To To 2.31)Document10 pagesPrimusgfs - Checklist - V 1.6: Module 2 - GMP Option (Sections 2.16 To To 2.31)dendi,iloNo ratings yet

- BRC Training Guide SampleDocument22 pagesBRC Training Guide SampleOsman AitaNo ratings yet

- SQF Edition 9 Quick Start GuideDocument29 pagesSQF Edition 9 Quick Start GuideRemliw Ésoj Luap AobmagNo ratings yet

- Yum! GAP Guidelines1Document13 pagesYum! GAP Guidelines1shani31No ratings yet

- Requirements For The FSSC 22000 V5 Upgrade ProcessDocument3 pagesRequirements For The FSSC 22000 V5 Upgrade Processfiqrans100% (2)

- ISO 22000: Food Safety Management System (FSMS)Document19 pagesISO 22000: Food Safety Management System (FSMS)Muhammad ShahzadNo ratings yet

- Iso 22000 - Oprps Vs HaccpDocument47 pagesIso 22000 - Oprps Vs HaccpVina AfilianiNo ratings yet

- PAS 220 To 223 - PRPs ComparisonDocument1 pagePAS 220 To 223 - PRPs ComparisonMark Kwan100% (1)

- Pathogen Guidance - FINALDocument100 pagesPathogen Guidance - FINALmigNo ratings yet

- fssc22000 Features v3.2 2015 PDFDocument16 pagesfssc22000 Features v3.2 2015 PDFApple Sirinart ThaNo ratings yet

- Management: ProgramsDocument10 pagesManagement: ProgramsMike SajaNo ratings yet

- G65 BRC Checklist (1aug10)Document15 pagesG65 BRC Checklist (1aug10)almasofia3No ratings yet

- 12 HACCP ValidationDocument45 pages12 HACCP ValidationSartika MutiarasaniNo ratings yet

- BRC 8 Vs 9Document145 pagesBRC 8 Vs 9Marzia RossoNo ratings yet

- Better HACCP ImplementationDocument43 pagesBetter HACCP ImplementationMuhammad Asadullah100% (1)

- ISO/TS 22002:1-2009 Training Workshop: Presented To BDI October 31, 2012Document45 pagesISO/TS 22002:1-2009 Training Workshop: Presented To BDI October 31, 2012honabbieNo ratings yet

- Food Safety - SOP 14 - Prevention of Foreign Body ContaminationDocument4 pagesFood Safety - SOP 14 - Prevention of Foreign Body Contaminationopi akbarNo ratings yet

- Staff Training Slideshow 7-HACCPDocument20 pagesStaff Training Slideshow 7-HACCPHemen Sharadkumar UpadhyayaNo ratings yet

- BRCGS Standard For Packaging and Packaging MaterialsDocument6 pagesBRCGS Standard For Packaging and Packaging Materialshunain zafarNo ratings yet

- Vaccp and Taccp: Pratiksha SupekarDocument4 pagesVaccp and Taccp: Pratiksha SupekarcarlaNo ratings yet

- IV HaccpDocument52 pagesIV HaccpSiddharth SaxenaNo ratings yet

- Protocol For Validation of FSMS - FinalVersionDocument25 pagesProtocol For Validation of FSMS - FinalVersionChel Zalamea Domingo100% (1)

- Final - Print Adh Lam Slit - May 6 2010Document22 pagesFinal - Print Adh Lam Slit - May 6 2010cassilda_carvalho@hotmail.comNo ratings yet

- Codex Stan 1-1985 Labelling of Prepackaged GoodsDocument7 pagesCodex Stan 1-1985 Labelling of Prepackaged GoodsvabimhahNo ratings yet

- NBE HACCP Certification SchemeDocument47 pagesNBE HACCP Certification SchemereachrainbowNo ratings yet

- EMP Environmental Monitoring ProgramDocument10 pagesEMP Environmental Monitoring Programkiagus artaNo ratings yet

- Food Traceability Withdrawals and Recalls GuidanceDocument56 pagesFood Traceability Withdrawals and Recalls GuidanceQualidade SegurançaNo ratings yet

- FSSC Training ReportDocument6 pagesFSSC Training ReportGilbert AgudoNo ratings yet

- Saftey Culture: PrioritiesDocument8 pagesSaftey Culture: PrioritiesMutiara NadilaNo ratings yet

- Allergen PolicyDocument1 pageAllergen PolicyNarinder Pal Singh SokheyNo ratings yet

- TACCP Vs VACCPDocument17 pagesTACCP Vs VACCPMohamed AgrNo ratings yet

- Emergency PreparednessDocument14 pagesEmergency PreparednessV Subramanyam QCNo ratings yet

- Checklist ISO 22000Document27 pagesChecklist ISO 22000rbabar100% (1)

- Differences Between PRP, oPRP and CCPDocument5 pagesDifferences Between PRP, oPRP and CCPolotu_olaseindeNo ratings yet

- Application of Lean Six Sigma Tools To Minimize Length of Stay For Ophthalmology Day Case Surgery PDFDocument18 pagesApplication of Lean Six Sigma Tools To Minimize Length of Stay For Ophthalmology Day Case Surgery PDFM HNo ratings yet

- CanadaGAP Food Safety Manual AppendicesDocument108 pagesCanadaGAP Food Safety Manual AppendicesGaganpreetNo ratings yet

- Free Food Safety VideosDocument16 pagesFree Food Safety VideosMuhammad AtifNo ratings yet

- FMCQMS-002 Prerequisite ProgramDocument4 pagesFMCQMS-002 Prerequisite Programveejee tangalin100% (1)

- Introduction To 22000Document32 pagesIntroduction To 22000NakitawiernqNo ratings yet

- AIB HACCP Checklist2007Document9 pagesAIB HACCP Checklist2007m125esteban2003No ratings yet

- Guidebook For The Preparation of HACCP PlansDocument74 pagesGuidebook For The Preparation of HACCP Planslatog13No ratings yet

- BRC Implementation Workbook Issue 8 Plus FSMA SampleDocument31 pagesBRC Implementation Workbook Issue 8 Plus FSMA Samplearif shaikhNo ratings yet

- Food Processing Industry - CODEX Standards, FDI & DumpingDocument38 pagesFood Processing Industry - CODEX Standards, FDI & DumpingNarender YadavNo ratings yet

- HACCP Processed Meats Cop Part 4Document118 pagesHACCP Processed Meats Cop Part 4Arkham KhollyshulNo ratings yet

- Food Microbiology Quality Control Nov 14Document36 pagesFood Microbiology Quality Control Nov 14Harith AtrisNo ratings yet

- Case Studies On HaccpDocument28 pagesCase Studies On HaccpAnonymous OPix6Tyk5I100% (1)

- Bip 2078-2007Document236 pagesBip 2078-2007clive100% (1)

- SMETA Certification 1Document4 pagesSMETA Certification 1ahmedNo ratings yet

- FUSH 4-Pillar SMETA Audit ResultsDocument63 pagesFUSH 4-Pillar SMETA Audit ResultsahmedNo ratings yet

- Social Compliance - What About ItDocument5 pagesSocial Compliance - What About ItahmedNo ratings yet

- Responsible Sourcing Manager - IpswichDocument4 pagesResponsible Sourcing Manager - IpswichahmedNo ratings yet

- Iso CD Ts 22002 3 FarmingDocument31 pagesIso CD Ts 22002 3 FarmingAnibar PerezNo ratings yet

- Bip 2078-2007Document236 pagesBip 2078-2007clive100% (1)

- ISO 22000 Clause 9 10Document11 pagesISO 22000 Clause 9 10Thilina MadusankaNo ratings yet

- Document in NABCB Advt. For AssessorsDocument5 pagesDocument in NABCB Advt. For Assessorsatvenu16160No ratings yet

- Food Safety Management System Implementation Guide: GloballyDocument36 pagesFood Safety Management System Implementation Guide: GloballyGen100% (1)

- Iso Certification Consultants in MumbaiDocument13 pagesIso Certification Consultants in MumbaiSmita MalakaranNo ratings yet

- HACCP GMP Certification Criteria PDFDocument32 pagesHACCP GMP Certification Criteria PDFanon_417835525No ratings yet

- Agr 14 Haccp PDFDocument182 pagesAgr 14 Haccp PDFSerenityNo ratings yet

- Iso Awareness Weekend Staff Training Programme: RegistrationDocument12 pagesIso Awareness Weekend Staff Training Programme: RegistrationKakira Lions ClubNo ratings yet

- Iso 9001-2020Document27 pagesIso 9001-2020Wahid RasoolNo ratings yet

- Articulo 6 FS 22000Document13 pagesArticulo 6 FS 22000Meiler Karina TinocoNo ratings yet

- International University of Travnik Faculty of Polytechnic Sciences TravnikDocument12 pagesInternational University of Travnik Faculty of Polytechnic Sciences TravnikTiross DesignsNo ratings yet

- Resource 839-1549451075802582073 PDFDocument2 pagesResource 839-1549451075802582073 PDFmiz baigNo ratings yet

- SGS-CBE-PH Academy Makati Training Calendar H1 2020 PDFDocument4 pagesSGS-CBE-PH Academy Makati Training Calendar H1 2020 PDFben foldsNo ratings yet

- FSMS Action PlanDocument7 pagesFSMS Action Plan22000-Tools100% (7)

- Food Safety Management Systems: Based OnDocument23 pagesFood Safety Management Systems: Based Onekoimamp100% (2)

- HACCP Training GuideDocument42 pagesHACCP Training GuideSyed HamzaNo ratings yet

- 0211 SlideDocument22 pages0211 SlideRama Krishna RaoNo ratings yet

- What Is A Food Safety AuditDocument8 pagesWhat Is A Food Safety AuditSONIA NABINo ratings yet

- FSSC 22000 Vers 5, Add Req, ISO 22000 2018 Shared PDFDocument80 pagesFSSC 22000 Vers 5, Add Req, ISO 22000 2018 Shared PDFSyahrizal MuhammadNo ratings yet

- July 2021 To Continue: Permanent AddressDocument2 pagesJuly 2021 To Continue: Permanent AddressMuhammad Ramzan MalickNo ratings yet

- Building The Entrepreneurial Mindset 28022023 031306pm PDFDocument7 pagesBuilding The Entrepreneurial Mindset 28022023 031306pm PDFtabassum manzoorshahNo ratings yet

- Pas 223Document28 pagesPas 223ivansitopapi100% (1)

- Pas 221 Draft 3 - 19072012 For DPCDocument25 pagesPas 221 Draft 3 - 19072012 For DPCMarcos FernandezNo ratings yet

- FSSC 22000-2017Document100 pagesFSSC 22000-2017dpamplona_nevilleclarke100% (5)

- OTOP Presentation-Localized - Towns UpdatedDocument20 pagesOTOP Presentation-Localized - Towns UpdatedStephen KintanarNo ratings yet