Professional Documents

Culture Documents

Handling Ropes and Wires

Handling Ropes and Wires

Uploaded by

Seaman Navigator0 ratings0% found this document useful (0 votes)

54 views22 pagesRopes and wires must be properly handled and maintained to prevent damage and ensure safety. Key precautions for ropes include protecting them from chemicals and sunlight, and regularly inspecting for wear. Wires require proper installation, lubrication, and inspection of splices. Both ropes and wires should be replaced when inspections find unacceptable damage. Crew should be trained on safe mooring and inspection practices.

Original Description:

Original Title

4. Handling Ropes and Wires

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRopes and wires must be properly handled and maintained to prevent damage and ensure safety. Key precautions for ropes include protecting them from chemicals and sunlight, and regularly inspecting for wear. Wires require proper installation, lubrication, and inspection of splices. Both ropes and wires should be replaced when inspections find unacceptable damage. Crew should be trained on safe mooring and inspection practices.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

54 views22 pagesHandling Ropes and Wires

Handling Ropes and Wires

Uploaded by

Seaman NavigatorRopes and wires must be properly handled and maintained to prevent damage and ensure safety. Key precautions for ropes include protecting them from chemicals and sunlight, and regularly inspecting for wear. Wires require proper installation, lubrication, and inspection of splices. Both ropes and wires should be replaced when inspections find unacceptable damage. Crew should be trained on safe mooring and inspection practices.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 22

HANDLING ROPES AND WIRES

PRECAUTIONS WHEN HANDLING ROPES:

• Synthetic ropes in contact with chemicals, acids, alkalis,

solvents, etc. can deteriorate. They have varying resistance to

such materials and must be stowed away from them in

well-ventilated dry compartments. Natural fibre ropes may

also get affected by chemicals.

• Wash the rope with fresh water in the event of it being

splashed by corrosives.

• Stow on gratings to avoid inadvertent contamination.

• Do not stow wet fibre ropes in the store as they are

susceptible to rot and mildew.

• Exposure to direct sunlight can cause synthetic ropes to

deteriorate and therefore must preferably be stowed under

deck.

• In port, coils must be kept covered.

• Avoid stowage of ropes in areas which are prone to heat, e.g.

against engine room bulkheads.

• Synthetic ropes may look good externally but may exhibit

excessive powdering internally. Hence inspect regularly for

wear and tear. Overworked ropes may become stiff and hairy

and must be replaced.

• New coils of ropes shall be unwrapped in an anti-clockwise

direction from the centre of the coil.

• Ensure that all splices are intact as all the tucks recommended

by the rope makers are necessary for safety and the tapered

part of the splice should be securely wrapped.

• The eyes are vulnerable to abrasion and should preferably be

protected by leather sheaths.

• When using stoppers use like for like(i.e. synthetic for

synthetic rope, fibre for fibre rope).

Fibre Rope Protection against

Chaffing :

• Avoid ropes making contact with sharp angles or from

snagging on quays.

• Ensure that the surface condition of winch barrels is good,

and that they are free from rust and paint.

• Ensure that fairleads are in good condition and that they

rotate properly and are lubricated regularly.

• Never allow a wire rope to cross a fibre rope on a bollard.

• Synthetic ropes have low melting points, hence do not surge

on drum ends.

• To avoid chafing, do not lead wires and ropes from the same

pedestal rollers and mooring leads.

• Never put strain on a kink as it can cause permanent damage.

• Synthetic ropes unlike fibre ropes do not provide any audible

warning when nearing its breaking point. Seamen to be wary

off severe whiplash.

• Owing to the design of mooring decks, the entire area should be

considered a potential snap-back zone.

• When mooring operations are taking place, all seafarers should be

correctly dressed in appropriate personal protective equipment

including full sleeved coveralls, safety helmet, safety shoes and

gloves.

• Have as few men as possible in the vicinity of all ropes under

strain. Never stand in the bight of a rope.

PRECAUTIONS WHEN HANDLING WIRE ROPES:

• When using steel wire ropes, it is important that they are properly

installed, maintained and lubricated as appropriate to their use.

Manufacturers’ guidelines and recommendations for use should be

strictly followed.

• The weight lifted by a wire rope shall be commensurate with the

permitted size and with a sufficient margin of safety as per the

relevant regulations.

• When eyes are formed, they should be made by eye-splicing or

using appropriate compression fittings (using swages or

ferrules). The use of bulldog grips is discouraged, and they must

not be used on lifting wires or mooring wires.

• A thimble or loop splice in any wire rope should have at least

three tucks, with a whole strand of rope and two tucks, with one

half of the wires cut out of each strand.

• Mooring and lifting wires are to be in good condition. Wire

ropes should be inspected frequently for wear corrosion and

damage. Splices in wire ropes should be inspected regularly to

check that they are intact.

• Wire ropes should be regularly inspected and treated with

suitable lubricants. These should be thoroughly applied so as to

prevent internal corrosion as well as corrosion on the outside.

The ropes should never be allowed to dry out.

• Wire ropes rove on drums should preferably be kept covered

with tarpaulin or other material on a voyage to avoid salt

deposits and corrosion.

• The intended use of a wire rope must be clearly stated on the

Certificate of Test & Thorough Examination and the wire rope shall

be used only for that purpose.

• Where wire rope is joined to fibre rope, a thimble or other device

should be inserted in the eye of the fibre rope. Both wire and fibre

rope should have the same direction of lay.

• When moorings are to be heaved on a drum end, the winch

operator must have a full view of all activity. The lead angle of the

wire rope onto the drum should be no more than a few degrees.

After being hauled tight, a chain stopper is to be used to allow the

wire rope to be removed from the warping drum and then placed

on a bollard or bitts by using figure of eight turns. At least the top

three lays of the figure of eight must be secured by a fibre rope to

prevent jumping.

• Avoid wire ropes making contact with sharp angles or from

snagging on quays as that would damage the wire rope

considerably.

• Ensure that fairleads are in good condition and that they rotate

properly and are lubricated regularly.

Wire to Rope Connection :

A rope mooring line should

never join a wire mooring line

without the use of a thimble.

The condition of the rope and

wire in this photo is a poor

example and the lack of a

thimble increases the

likelihood of the rope

breaking.

Connection of Mooring Tail Lines

to Wire Mooring Ropes :

The use of mooring tails is highly

recommended with low

elongation lines, such as steel

wire ropes for mooring of the

tankers. Synthetic tails provide

the necessary elasticity and

safety in the mooring system and

therefore lower the peak loads

on the main mooring line. This

elasticity provides protection

from surging and shock loading

to the main mooring rope and

deck equipment and safer

operation especially in exposed

mooring berths.

Forming a Eye Using Bulldog

Grips :

If it is necessary to create an

eye in the end of a wire, do

not use bulldog grips for

creating an eye in the end of a

wire rope.

• A wire should never be led across a fibre rope on a bollard.

Wires and ropes should be kept in separate fairleads or

bollards.

• When mooring and lifting operations are taking place, all

seafarers should be correctly dressed in appropriate personal

protective equipment including full sleeved coveralls, safety

helmet, safety shoes and gloves.

• Have as few men as possible in the vicinity of all wire ropes

under strain. Never stand in the bight of a wire rope.

Mooring Line Care and Maintenance:

FROM STEAMSHIP MUTUAL (P&I CLUB:

Recently the Club has experienced two large claims for injuries

sustained by linesmen and crew due to rope mooring lines

parting and striking personnel in the vicinity. In the first

incident a mooring line parted and struck two linesmen who

were on the wharf adjacent to the hull. It would seem that

the mooring line was worn at a point where it regularly

rubbed against on the ships hull whilst in use. The rope was

worn down to such a degree that it failed catastrophically

when being used to heave the vessel into position. The

second incident involved another rope mooring breaking

resulting in serious head arm and leg injuries to a

crewmember who was standing by in the vicinity.

• Members, their Masters and crew need to ensure that ropes

are cared for, utilised and maintained in line with industry

best practice. A planned maintenance system should also be

in place ensuring periodic thorough visual inspection of all

mooring lines, and that these are replaced promptly when

unacceptable damage is found.

Mooring Rope Inspection :

Apart from a visual inspection by crew prior to berthing and

periodic inspections by the Deck watch officer and seaman on

duty, whilst alongside, mooring ropes should be periodically

inspected along their entire length at least once a month. The

wear along the rope should be externally examined and areas

of wear and fusing on man made fibre ropes closely checked

to assess the integrity of the rope at these points.

• Areas of actinic degradation should also be inspected closely to

assess the rope’s integrity. Eye splice integrity and eye wear needs

to be checked and the strands of the rope opened up to check for

internal wear, the pilling of the internal surfaces on a man made

fibre rope is an indication of hard use. Mooring ropes, both loose

coils used on the bitts and those on winch drums should be

cropped and the eye re-spliced or end for ended once the working

end becomes worn. It is recommended that major damage should

not be cropped out from within the rope’s length and replaced

with a short splice as this will reduce the strength of the rope. If

there is any doubt as to the strength or integrity of a rope then it

should be replaced

{Definition of actinic}

• : of, relating to, resulting from, or exhibiting chemical changes

produced by radiant energy especially in the visible and ultraviolet

parts of the spectrum}

Mooring Wire Inspection:

Again, apart from visual inspection prior to use, wire ropes should be

subject to periodic inspection by the Deck watch officer and

seaman on duty, whilst the vessel is alongside and periodically

examined along their entire length at least once a month. Discard

criteria should be in place for removal of the wire rope from

service based on a recognised international standard. Normally the

discard criteria are based upon the percentage of the number of

individual wires within the rope which are broken within a length

equal to a multiple of the diameter of the rope. For example one

discard criterion is if more than 10% of the wires in the rope are

broken over a length of 10 diameters, then the wire should be

discarded. Another is if more than 8% of the wires are broken over

a length equal to 6 rope diameters. If the broken wires are

concentrated in one strand then the wire discard criterion

becomes stricter. If an individual wire within a strand has worn

down such that its’ diameter has been reduced by, for example,

33%, then it should be considered broken for the sake of

evaluating whether to discard the wire rope.

• If the wire rope is worn such that the diameter has decreased then

it should be discarded. Again various standards specify different

limits on allowable loss of rope diameter, stating that the rope

should be discarded if between 6 and 10% of the original diameter

of the rope has been lost. Defects which distort the wire rope, such

as bird caging, kinking, corrosion, flattening or crush damage

should be examined and their effect on the strength of the wire

evaluated.

Rope Care and Use:

In order to ensure that ropes remain in satisfactory condition and

free of damage the following points should be borne in mind by

crew members:

• Fibre ropes should not be left exposed to sunlight whilst at sea; they

should either be covered or stored below deck.

• Ropes need to be kept clear of the deck to ensure they do no come

into contact with any chemicals which may be detrimental to their

strength.

• It should be ensured that all mooring rollers are free turning and are

free from damage or corrosion on their surfaces which could cause

rope wear.

• Ropes should be stored clear of sources of heat.

• Winch drum ends, bollards and Panama leads need to be free

of damage or rust which could cause rope wear.

• Ropes should not be surged on winch drum ends or slacked

away by rendering; ropes should be walked back so far as

possible.

• Sharp angles in the lead of the rope are to be avoided as much

as possible. It must be remembered that these may exist in

spring lines when the rope runs alongside the hull between

the fairlead and the mooring bollard on the wharf.

• Fibre and wire ropes should not be led such that they cross

and touch other ropes, be they either fibre or wire, which

could lead to wear during the mooring period.

• Wire ropes are to be periodically dressed with an appropriate

grease to help maintain their condition.

WIRE ROPES

DAMAGED CONDITION OF MOORING

ROPES

You might also like

- Vsip - Info Mitsubishi Fuso Canter Repair Manual 5 PDF FreeDocument2 pagesVsip - Info Mitsubishi Fuso Canter Repair Manual 5 PDF FreeGuillermo lima50% (2)

- Tow LinesDocument11 pagesTow Linesbill baileyNo ratings yet

- Technical Bulletin: Mooring PracticesDocument3 pagesTechnical Bulletin: Mooring PracticeshoangductuanNo ratings yet

- Anchoring EquipmentDocument9 pagesAnchoring EquipmentPratama ZetoNo ratings yet

- Anchoring CiiDocument13 pagesAnchoring CiiDelando CoriahNo ratings yet

- Resolution MSC.137Document6 pagesResolution MSC.137Alexandre Gonçalves da RochaNo ratings yet

- Seam 213Document8 pagesSeam 213John Gonzaga EscuadroNo ratings yet

- Rudders: Semi Balanced RudderDocument10 pagesRudders: Semi Balanced RudderAurvin SinghNo ratings yet

- Mooring Snspool Version 1Document9 pagesMooring Snspool Version 1Alonso Olaya RuizNo ratings yet

- TTM 2000 RezeoDocument403 pagesTTM 2000 RezeoFlo FloNo ratings yet

- Guia de Naval II 2011 MARZO JULIO 2011 ORIGINAL 16 DE ABRILDocument94 pagesGuia de Naval II 2011 MARZO JULIO 2011 ORIGINAL 16 DE ABRILGermán Cristian Camacho SilvaNo ratings yet

- MSC 137 PDFDocument8 pagesMSC 137 PDFSandipan DNo ratings yet

- Forces On Ship: OE 1010 Introduction To Ocean EngineeringDocument62 pagesForces On Ship: OE 1010 Introduction To Ocean EngineeringdhruvbhagtaniNo ratings yet

- Investigation Report of The Capsizing of The Convoy "Norsul 12 and Norsul Vitória"Document25 pagesInvestigation Report of The Capsizing of The Convoy "Norsul 12 and Norsul Vitória"dudu666No ratings yet

- Trials and MonitoringDocument49 pagesTrials and MonitoringFabio TemporiniNo ratings yet

- VIRTUE BPG Integrated Final PDFDocument233 pagesVIRTUE BPG Integrated Final PDFsplicosakiNo ratings yet

- Imo Circ/resDocument20 pagesImo Circ/rescarmenNo ratings yet

- Student Centred ActivityDocument3 pagesStudent Centred ActivityakmalNo ratings yet

- Adobe Scan 03 Mei 2023Document1 pageAdobe Scan 03 Mei 2023Deli MejunNo ratings yet

- Shallow Water PDCDocument15 pagesShallow Water PDCsunusukuNo ratings yet

- 6 Common Mooring Methods Used For ShipsDocument5 pages6 Common Mooring Methods Used For ShipsGiorgi KandelakiNo ratings yet

- Pilot Card Tank09L: Ship'S ParticularsDocument2 pagesPilot Card Tank09L: Ship'S ParticularsAngga PurwantoNo ratings yet

- Aplicacion de Helices CicloidalesDocument51 pagesAplicacion de Helices CicloidalesMerrel RossNo ratings yet

- Marine Engineering System Course Briefing - 2014Document23 pagesMarine Engineering System Course Briefing - 2014hairuddinNo ratings yet

- Rate of Turn IndicatorDocument2 pagesRate of Turn Indicatorbandar2No ratings yet

- Sea Trial GuidanceDocument7 pagesSea Trial GuidanceStathis MoumousisNo ratings yet

- SA015 - Loss Prevention Safety Alert - Snap-Back ZonesDocument2 pagesSA015 - Loss Prevention Safety Alert - Snap-Back ZonesMuhammad Nadzri Noorhayatuddin100% (1)

- Manoeuvring 2nd Grade Handout Blocki PDFDocument27 pagesManoeuvring 2nd Grade Handout Blocki PDFIuri DudinovNo ratings yet

- Philsin College: Midterm ExamDocument45 pagesPhilsin College: Midterm ExamDarrel DilaoNo ratings yet

- Pivot PointDocument10 pagesPivot PointsanuNo ratings yet

- Tugs, Work Boats and Coastal FerriesDocument9 pagesTugs, Work Boats and Coastal FerriesVaruna Shantha100% (1)

- Marine Power PlantsDocument25 pagesMarine Power PlantsVinz VizenNo ratings yet

- The Ultimate Actionable Guide of Anchoring A Ship: Written by On February 13, 2016Document19 pagesThe Ultimate Actionable Guide of Anchoring A Ship: Written by On February 13, 2016Panagiotis MouzenidisNo ratings yet

- Shiphandling/Watchstanding Seminar IIDocument64 pagesShiphandling/Watchstanding Seminar IIJeen BerlinNo ratings yet

- Port Hedland Mooring Management Standard FINALDocument2 pagesPort Hedland Mooring Management Standard FINALJeongheeseokNo ratings yet

- Rudder Theory: Mohd. Hanif Dewan, Chief Engineer and Maritime Lecturer and Trainer, BangladeshDocument27 pagesRudder Theory: Mohd. Hanif Dewan, Chief Engineer and Maritime Lecturer and Trainer, BangladeshRAMSINGH CHAUHAN100% (1)

- Schilling Rudder - Wikipedia, The Free EncyclopediaDocument3 pagesSchilling Rudder - Wikipedia, The Free EncyclopediaAhmad HajivandNo ratings yet

- Fundamentals of Naval ArchitectureDocument18 pagesFundamentals of Naval Architecturevivek singh100% (1)

- Estimating Principal DimensionsDocument26 pagesEstimating Principal DimensionsgksahaNo ratings yet

- 1-Oil and Gas Hoisting Winch Split Drum Design and Finite Element AnalysisDocument24 pages1-Oil and Gas Hoisting Winch Split Drum Design and Finite Element AnalysisKevin armstrongNo ratings yet

- Presentation AnchorDocument35 pagesPresentation AnchorHan Thu WynnNo ratings yet

- Winter Navigation ST - Lawrence 2011Document61 pagesWinter Navigation ST - Lawrence 2011moe_htwe_1No ratings yet

- ch1 Framing SystemDocument12 pagesch1 Framing Systemموبليات حسين المصريNo ratings yet

- Full Scale Meas Sea TrialDocument30 pagesFull Scale Meas Sea TrialLukman Tarigan Sumatra100% (1)

- Mooring (Watercraft) : Not To Be Confused WithDocument19 pagesMooring (Watercraft) : Not To Be Confused WithDODDI PRASADNo ratings yet

- Manoeuvrability Final EditedDocument12 pagesManoeuvrability Final EditedSaptarshi BasuNo ratings yet

- Mooring and Anchor Handling EquipmentDocument38 pagesMooring and Anchor Handling EquipmentTee Jay GarcesNo ratings yet

- Analysis of Ship Hull Girder VibrationDocument10 pagesAnalysis of Ship Hull Girder VibrationLucas Barrozo BrunNo ratings yet

- Sustainable Marine Structures - Volume 05 - Issue 01 - March 2023Document52 pagesSustainable Marine Structures - Volume 05 - Issue 01 - March 2023Bilingual PublishingNo ratings yet

- RudderDocument18 pagesRudderT VigneshwarNo ratings yet

- Describe The Anchor Handling Arrangements From Hawse Pipe To Spurling PipeDocument13 pagesDescribe The Anchor Handling Arrangements From Hawse Pipe To Spurling PipeMirico Demegillo100% (1)

- Unit 4 Anchor and Cable WorkDocument5 pagesUnit 4 Anchor and Cable WorkRazvan RaduNo ratings yet

- Notes On Anchoring - EdwinDocument6 pagesNotes On Anchoring - EdwinEnrique BarajasNo ratings yet

- Mooring Ropes 22-03 Document1Document2 pagesMooring Ropes 22-03 Document1Cesar RodriguezNo ratings yet

- Mooring & Wire RopesDocument14 pagesMooring & Wire RopesAlexNo ratings yet

- Basic Rigging BookDocument156 pagesBasic Rigging BookAhmed ElzamlyNo ratings yet

- RiggerDocument156 pagesRiggerFasil Paruvanath100% (6)

- important points on wires and ropes - копияDocument2 pagesimportant points on wires and ropes - копияВлад РайлиNo ratings yet

- Inspection & Maintenance of SlingsDocument58 pagesInspection & Maintenance of SlingsMohammad Abubakar Siddiq100% (2)

- Wire RopeDocument4 pagesWire RopedobricovekNo ratings yet

- Mx-Mty-Mty: Express Easy TRCDocument2 pagesMx-Mty-Mty: Express Easy TRCFrancisco MezaNo ratings yet

- Installation Instructions Owner'S Guide &: StructurescanDocument8 pagesInstallation Instructions Owner'S Guide &: StructurescanOlegNo ratings yet

- 2020-2021 Truck & Bus Radials: Tyre Selection GuideDocument12 pages2020-2021 Truck & Bus Radials: Tyre Selection GuidesiritapeNo ratings yet

- 3484 Magazine Spring 2023Document36 pages3484 Magazine Spring 20233484 MagazineNo ratings yet

- Sunesta 216Document45 pagesSunesta 216elsalenNo ratings yet

- Injection Pump Model I! Specification O'577: BGVC431-3AJDocument2 pagesInjection Pump Model I! Specification O'577: BGVC431-3AJjohnny sabinNo ratings yet

- THE System: Pprroottoo - SsoouunnddDocument43 pagesTHE System: Pprroottoo - SsoouunnddAndré Toga Machado CoelhoNo ratings yet

- Catalogo Luces R M BZ 3 PDFDocument3 pagesCatalogo Luces R M BZ 3 PDFCesarLimaNo ratings yet

- Nissan Navara D22 Service Manual Supplement (2000 November)Document29 pagesNissan Navara D22 Service Manual Supplement (2000 November)johnywicked1234No ratings yet

- Air-To-Air Aftercooling Systems LEXH6521-02Document8 pagesAir-To-Air Aftercooling Systems LEXH6521-02Jose MoralesNo ratings yet

- 1 Vehicular Connectivity: C-V2X & 5G - September 2021Document34 pages1 Vehicular Connectivity: C-V2X & 5G - September 2021dn007No ratings yet

- Volkswagen Service Training Engine Management SystemsDocument10 pagesVolkswagen Service Training Engine Management Systemsrichard100% (57)

- Maintenance Training Manual Md369ffDocument338 pagesMaintenance Training Manual Md369ffM S SNo ratings yet

- Booking Confirmation On IRCTC, Train: 02344, 25-Jul-2021, 3A, NJP - SDAHDocument1 pageBooking Confirmation On IRCTC, Train: 02344, 25-Jul-2021, 3A, NJP - SDAHAnand Lal RoyNo ratings yet

- Engines Parts - Cimex GlobeDocument1 pageEngines Parts - Cimex GlobeAbm Faruk E MonjurNo ratings yet

- 8436 s06 QP 1Document28 pages8436 s06 QP 1Rishi Maha100% (1)

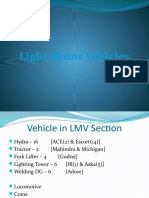

- Light Motor VehiclesDocument27 pagesLight Motor VehiclesPRANAY JOSHINo ratings yet

- Ten Mile Day-SummaryDocument1 pageTen Mile Day-SummaryPsic. Ó. Bernardo Duarte B.100% (1)

- Sibiu "Liqui Moly" Rally Official FIA Stage Classification Stage Ss 16 'Ss Liqui Moly Ii' Lenght 4 KmsDocument2 pagesSibiu "Liqui Moly" Rally Official FIA Stage Classification Stage Ss 16 'Ss Liqui Moly Ii' Lenght 4 KmsIvanBillNo ratings yet

- SKODA KUSHAQ Brochure With GNCAP 20 Oct 22Document34 pagesSKODA KUSHAQ Brochure With GNCAP 20 Oct 22Partha PainNo ratings yet

- Circular - Enhanced Safe Management Measures at Psa Singapore Terminals - Contactless (Segregated) Cargo Ops (SHD01052021)Document4 pagesCircular - Enhanced Safe Management Measures at Psa Singapore Terminals - Contactless (Segregated) Cargo Ops (SHD01052021)EricNo ratings yet

- Taefi Policy 2016 PDFDocument20 pagesTaefi Policy 2016 PDFwajidali454No ratings yet

- Polymer Technology: Geoplus and TerrabestDocument30 pagesPolymer Technology: Geoplus and Terrabestsuchita PatilNo ratings yet

- Oasi540 EngDocument26 pagesOasi540 EngManuel VisoNo ratings yet

- Models of Daily Life in Ancient EgyptDocument214 pagesModels of Daily Life in Ancient EgyptNona ANo ratings yet

- BCA Annual Testing Report (Full Load)Document3 pagesBCA Annual Testing Report (Full Load)Shen WeijianNo ratings yet

- India Warehousing and Cold Chain Market Size and Forecast 2018-2030Document153 pagesIndia Warehousing and Cold Chain Market Size and Forecast 2018-2030p23pallavNo ratings yet

- sg11 Sci 1st TP Sbaragamu 2 2018Document12 pagessg11 Sci 1st TP Sbaragamu 2 2018Muhammed IfkazNo ratings yet

- Spare Parts Documentation: TD10004553 EN 00Document69 pagesSpare Parts Documentation: TD10004553 EN 00Emon Sharma100% (1)