Professional Documents

Culture Documents

To

To

Uploaded by

SIL PROJECTSOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

To

To

Uploaded by

SIL PROJECTSCopyright:

Available Formats

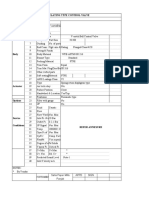

Date:-11-06-2011

President (works)

the undersigned reached site at 3.0PM on 10-06-2011, visited the plant &

observed following point as follow:-

1:- 8” vent line to be provided in main air header.

2:- N0-2 air blower suction & delivery line & motor to be restored.

3:-Pellets discharge metering screw –bucket elevator –silo to be re-engineering.

4:- HBL pump no-1 is not available, suction & delivery pipe to be restored.

5:- pit pump to be restored.

6:- venture circulation delivery line 6” valve to be provided.

7:- Venture discharge control valve to be restored.

8:- P.C inlet cooling water inlet manual valve to be restored.

9:- All manual valve to be made free.

10:-HBL line suction strainer drain valve to be restored.

11:-One HBL pump having flow 15 m3 /hr & H-50M to be provided as existing

pump is not suitable.

13:-3” line is cooling system to be restored.

14:-Grit cyclone screw feed conveyor & charcoal educator to be re-engineering.

15:- jacketed cooling water funnel to be provided & discharge to be given in

cooling tower.

16:-4” fresh water inlet line to be provided.

17:- Pit delivery line to WBL tank & drain to be provided.

18:-PLC to be restored.

19:-Firing gun to be lowered.

20:- All auto control valves to be checked.

21:- Although chloride level of WBL is very high we can attempt five times to

stabilize the operating parameters.

22 HP steam to be provided for charcoal educator for better creating vacuum.

23:- Auto diesel burner to be reset.

24:-After re stabilization of plant additional six effects LTV to be installed for

running the plant conveniently.

25:- Blower having 8700 m3/hr (5116 SCFM) & other is 6000 m3/hr (3528 SCFM)

which will create obstacle while running both the blowers. So same capacity of

(5116 SCFM) of blower to be provided for uniform pressure & volume.

S.K SINGH

Consultant

You might also like

- Cameron BOP Control SystemsDocument38 pagesCameron BOP Control SystemsAshok Suresh100% (3)

- 06 Hydraulic PumpingDocument71 pages06 Hydraulic PumpingAZDOLMANNo ratings yet

- Diesel Engineering HandbookDocument14 pagesDiesel Engineering Handbookmartin.ruben100% (1)

- Selection of Artificial Lift TypesDocument43 pagesSelection of Artificial Lift TypesAngel NgoNo ratings yet

- Chapter Three Liquid Piping SystemDocument51 pagesChapter Three Liquid Piping SystemMelaku TamiratNo ratings yet

- 3 CsDocument14 pages3 CsRavindra PawarNo ratings yet

- Controlled Circulation PumpDocument5 pagesControlled Circulation PumpLakshminarayanNo ratings yet

- Troubleshooting Boiler OperationDocument5 pagesTroubleshooting Boiler OperationRahul ChandrawarNo ratings yet

- Delay in Opening of LP Bypass ValveDocument94 pagesDelay in Opening of LP Bypass ValveCharu ChhabraNo ratings yet

- Monthly Report (May'19) : Static & FabricationDocument2 pagesMonthly Report (May'19) : Static & FabricationRavi ShankarNo ratings yet

- 1101 The Facility FilesDocument1 page1101 The Facility FilessajuhereNo ratings yet

- Shutdown Job at Rawmill Line-A (22!6!2016)Document2 pagesShutdown Job at Rawmill Line-A (22!6!2016)salman saleemNo ratings yet

- 1104 The Facility FilesDocument1 page1104 The Facility FilessajuhereNo ratings yet

- GDocument34 pagesGjuanca_eduNo ratings yet

- GGS-GAS FILTERING Process Decription DetailsDocument6 pagesGGS-GAS FILTERING Process Decription DetailsdasubhaiNo ratings yet

- Lünerseewerk HPP - Investigations To Maximize Power and Working Capacity by Means of Model TestsDocument7 pagesLünerseewerk HPP - Investigations To Maximize Power and Working Capacity by Means of Model TestsPeter MeusburgerNo ratings yet

- tentativeBoilerCleanUp 230509 112910Document2 pagestentativeBoilerCleanUp 230509 112910sarojdubey0107No ratings yet

- Circulating Water System and Station Alternative CoolingDocument6 pagesCirculating Water System and Station Alternative CoolingAdetunji TaiwoNo ratings yet

- Chapter 3 Mine PumpsDocument29 pagesChapter 3 Mine PumpsOolasyar KhattakNo ratings yet

- C-08.a-Intro To Hydraulic LiftDocument6 pagesC-08.a-Intro To Hydraulic Liftamitk8045No ratings yet

- ZA5D Installation in Lotus-Mugen-Honda Type 109BDocument7 pagesZA5D Installation in Lotus-Mugen-Honda Type 109BDeepak MurthyNo ratings yet

- Dynamic Simulation - Steam SystemDocument11 pagesDynamic Simulation - Steam SystemDicky Wahyu PerdianNo ratings yet

- A Case StudyDocument10 pagesA Case StudynourooziNo ratings yet

- Shutdown JobsDocument3 pagesShutdown Jobshafiz azamNo ratings yet

- Case Study - Finding System BottlenecksDocument5 pagesCase Study - Finding System BottlenecksDasilfa RinaldyNo ratings yet

- Z Purlin Data SheetDocument17 pagesZ Purlin Data SheetErshadNo ratings yet

- Harvest VFD Application On Boiler Feed Water PumpDocument5 pagesHarvest VFD Application On Boiler Feed Water PumpArini RizalNo ratings yet

- PROJECT 5. Problems at The Cumene Production Facility, Unit 800Document14 pagesPROJECT 5. Problems at The Cumene Production Facility, Unit 800migelNo ratings yet

- SH Usa 6 SeiterDocument6 pagesSH Usa 6 Seiterusa11No ratings yet

- Boiler Feed Pump Sizing CalculationDocument18 pagesBoiler Feed Pump Sizing CalculationArun Kumar Dey100% (2)

- Progress ReportDocument7 pagesProgress ReportTharindu WimalasekaraNo ratings yet

- Solved Problem 4.1 - Steam Power Plant For Athens - Ohio (4!21!10Document5 pagesSolved Problem 4.1 - Steam Power Plant For Athens - Ohio (4!21!10Andhika SiraitNo ratings yet

- States of Factory Equipment TodayDocument3 pagesStates of Factory Equipment TodayUmar DarNo ratings yet

- Dunbar Field Life Extended Using Sulzer Multiphase Pumps PDFDocument4 pagesDunbar Field Life Extended Using Sulzer Multiphase Pumps PDFAttabik AwanNo ratings yet

- Sobha Chrysanthemum STP ReportDocument13 pagesSobha Chrysanthemum STP Reportudupiganesh3069No ratings yet

- SIEMENS The H Class To Korea BrochureDocument8 pagesSIEMENS The H Class To Korea Brochurelink2u_007No ratings yet

- OHI Web Broch107Document18 pagesOHI Web Broch107Carlos Chico MoreiraNo ratings yet

- KPCL - Steam Blowing ProcedureDocument7 pagesKPCL - Steam Blowing ProcedureAtiqur RahmanNo ratings yet

- The Condensate, The Boiler Feed, and Their Auxiliary SystemsDocument70 pagesThe Condensate, The Boiler Feed, and Their Auxiliary Systemsbabis1980100% (1)

- 01 System Notes Part - IDocument162 pages01 System Notes Part - IDebnath DeNo ratings yet

- Fluxopump Retrofit (Uk)Document2 pagesFluxopump Retrofit (Uk)Mohamed Shehata0% (1)

- Accumulator (Koomey)Document26 pagesAccumulator (Koomey)Martin ToledoNo ratings yet

- Vacuum Excavator Truck DesignDocument8 pagesVacuum Excavator Truck DesignajcapetillogNo ratings yet

- OHI - PumpSystems (Bombeo Hidráulico - Oilwell Hyd)Document18 pagesOHI - PumpSystems (Bombeo Hidráulico - Oilwell Hyd)Adamec PachecoNo ratings yet

- BFW PumpsDocument3 pagesBFW PumpsMohammad Ali ZamanNo ratings yet

- LL Mit: B C ", ,, EnceDocument5 pagesLL Mit: B C ", ,, EnceKOWSHIK 4310No ratings yet

- Ic Engine Lab ManualDocument24 pagesIc Engine Lab ManualBanwari Lal Prajapat100% (1)

- BFP & AuxiliriesDocument70 pagesBFP & AuxiliriesVivek Painkra100% (1)

- Hydraulics Hydraulics: B.S.Pyromatic India (P) LTD.Document6 pagesHydraulics Hydraulics: B.S.Pyromatic India (P) LTD.dressfeet100% (2)

- Afiq 1 HKGHKDocument18 pagesAfiq 1 HKGHKCrystal MatthewsNo ratings yet

- 5 HRSG 11 12Document7 pages5 HRSG 11 12M Moarraf Naeem100% (1)

- Section 15540 Hvac Pumps PDFDocument6 pagesSection 15540 Hvac Pumps PDFkdpmansiNo ratings yet

- Piping Scope:: Upgrade Electrical Sytsms at Aindar-03, 06 & Shedgum-01 Gosp'SDocument2 pagesPiping Scope:: Upgrade Electrical Sytsms at Aindar-03, 06 & Shedgum-01 Gosp'Sjkrifa1702No ratings yet

- Gas and Oil Engines, Simply Explained: An Elementary Instruction Book for Amateurs and Engine AttendantsFrom EverandGas and Oil Engines, Simply Explained: An Elementary Instruction Book for Amateurs and Engine AttendantsNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Banking InformationDocument1 pageBanking InformationSIL PROJECTSNo ratings yet

- Ippta JournalDocument83 pagesIppta JournalSIL PROJECTSNo ratings yet

- IBR - 1950 - Reg. 43Document2 pagesIBR - 1950 - Reg. 43SIL PROJECTSNo ratings yet

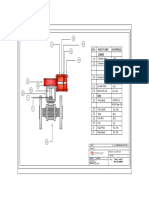

- Knife Gate Valve 12 INCH 10Document1 pageKnife Gate Valve 12 INCH 10SIL PROJECTSNo ratings yet

- IBR - 1950 - Reg. 56 ADocument3 pagesIBR - 1950 - Reg. 56 ASIL PROJECTSNo ratings yet

- PIPE Vs TUBEDocument3 pagesPIPE Vs TUBESIL PROJECTSNo ratings yet

- 50 V-Notch Valve2Document1 page50 V-Notch Valve2SIL PROJECTSNo ratings yet

- HV 1212Document4 pagesHV 1212SIL PROJECTSNo ratings yet

- Envelop Cover Address Print FormatDocument1 pageEnvelop Cover Address Print FormatSIL PROJECTSNo ratings yet

- HV 1013Document4 pagesHV 1013SIL PROJECTSNo ratings yet

- TM1M42742 ModelDocument1 pageTM1M42742 ModelSIL PROJECTSNo ratings yet

- 100 V-Notch (Pulp)Document1 page100 V-Notch (Pulp)SIL PROJECTSNo ratings yet

- V Notch Ball ValveDocument1 pageV Notch Ball ValveSIL PROJECTSNo ratings yet

- 11 - Vibrating Screens VSTDocument2 pages11 - Vibrating Screens VSTSIL PROJECTSNo ratings yet

- Butterfly Valve With DiaphragmDocument1 pageButterfly Valve With DiaphragmSIL PROJECTSNo ratings yet

- Ball Valve On-Off TypeDocument1 pageBall Valve On-Off TypeSIL PROJECTSNo ratings yet

- PR 4 ExamplesDocument12 pagesPR 4 ExamplesSIL PROJECTSNo ratings yet

- 18 (1) .03.08 Satia LTI MailDocument2 pages18 (1) .03.08 Satia LTI MailSIL PROJECTSNo ratings yet

- For Paper Industry: Approach Flow Screen SPCDocument2 pagesFor Paper Industry: Approach Flow Screen SPCSIL PROJECTSNo ratings yet

- Soda Converstion To CausticDocument1 pageSoda Converstion To CausticSIL PROJECTSNo ratings yet

- Screw Thickeners - CAD - PrintDocument2 pagesScrew Thickeners - CAD - PrintSIL PROJECTSNo ratings yet

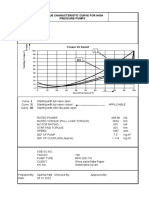

- TS Curve RPHDocument2 pagesTS Curve RPHSIL PROJECTS0% (1)

- UntitledDocument27 pagesUntitledSIL PROJECTSNo ratings yet

- UntitledDocument5 pagesUntitledSIL PROJECTSNo ratings yet

- Uttam U: EnergyDocument1 pageUttam U: EnergySIL PROJECTSNo ratings yet

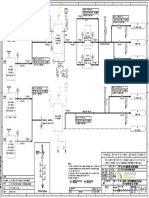

- E20 Green Fuel - Single Line Diagram (22.02.22)Document1 pageE20 Green Fuel - Single Line Diagram (22.02.22)SIL PROJECTSNo ratings yet

- 16 - Chest and TowerDocument2 pages16 - Chest and TowerSIL PROJECTSNo ratings yet

- 19 - Rectifier RollsDocument2 pages19 - Rectifier RollsSIL PROJECTSNo ratings yet

- Preliminary: DescriptionDocument1 pagePreliminary: DescriptionSIL PROJECTSNo ratings yet

- For Paper Industry: Deflakers DSTDocument2 pagesFor Paper Industry: Deflakers DSTSIL PROJECTSNo ratings yet