Professional Documents

Culture Documents

Design Knowhow - Low Voltage Substation Layouts, Earthing, Fire Protection and Tests - EEP

Design Knowhow - Low Voltage Substation Layouts, Earthing, Fire Protection and Tests - EEP

Uploaded by

Mohamed Abou El hassanCopyright:

Available Formats

You might also like

- W Hotel A&C StandardsDocument407 pagesW Hotel A&C StandardsKasinadh KarraNo ratings yet

- CBLM Final1Document115 pagesCBLM Final1Victor Rosales89% (72)

- ArtsDocument2 pagesArtsMohamed Abou El hassanNo ratings yet

- Jones NCTI Training KitDocument129 pagesJones NCTI Training Kitjonesncti0% (1)

- 3900 Series & 5900 Series Base Station Installation Guides-Wireless Network Info Community-Huawei ConnectDocument7 pages3900 Series & 5900 Series Base Station Installation Guides-Wireless Network Info Community-Huawei ConnectDavid TombeNo ratings yet

- EIT Course Substation Design Control Protection Facility Planning CEY2 BrochureDocument4 pagesEIT Course Substation Design Control Protection Facility Planning CEY2 Brochuregendoabdoul120No ratings yet

- Electrical Design Engineer & Protection EngineerDocument2 pagesElectrical Design Engineer & Protection EngineerAyansh patnaikNo ratings yet

- RFP 288-01-16 Fiber Man Services Attachment C Commscope RequirementsDocument4 pagesRFP 288-01-16 Fiber Man Services Attachment C Commscope RequirementsNguyễn Minh NhựtNo ratings yet

- EIT Course Electrical Power Protection CPS BrochureDocument3 pagesEIT Course Electrical Power Protection CPS BrochureAtabat AduduNo ratings yet

- MB PV Rooftop EN WebDocument20 pagesMB PV Rooftop EN WebLambert LambrintoNo ratings yet

- Faw1 PDFDocument2 pagesFaw1 PDFSavita BhabhiNo ratings yet

- CCNA 1.3: Describe The Impact of Infrastructure Components in An Enterprise Network (Firewalls, Access Points, Wireless Controllers)Document2 pagesCCNA 1.3: Describe The Impact of Infrastructure Components in An Enterprise Network (Firewalls, Access Points, Wireless Controllers)Savita BhabhiNo ratings yet

- Abb Furse Earthing A4 8pp Brochure FinalDocument8 pagesAbb Furse Earthing A4 8pp Brochure FinalTony BombataNo ratings yet

- 11 Deadliest Mistakes in A Power Substation Made by Young and Unmindful Electrical EngineersDocument2 pages11 Deadliest Mistakes in A Power Substation Made by Young and Unmindful Electrical EngineersArafat Lomangcolob BauntoNo ratings yet

- How To Use This ModuleDocument4 pagesHow To Use This ModuleHarold Vernon MartinezNo ratings yet

- Resume Olajide IdowuDocument3 pagesResume Olajide IdowuRupinder JeetNo ratings yet

- Weld Training Solutions: RealweldDocument4 pagesWeld Training Solutions: RealweldNenad MilosevicNo ratings yet

- Substations Design Guide PDFDocument16 pagesSubstations Design Guide PDFM Alim Ur RahmanNo ratings yet

- High Voltage Electrical Compliance and Safety Operating ProceduresDocument4 pagesHigh Voltage Electrical Compliance and Safety Operating ProcedurespkumarmysNo ratings yet

- EIT Course Power Distribution CPD BrochureDocument3 pagesEIT Course Power Distribution CPD BrochureKatamba RogersNo ratings yet

- Advanced-Power-System-Protection-Webinar-Aug-2020Document4 pagesAdvanced-Power-System-Protection-Webinar-Aug-2020nooralhudNo ratings yet

- Safari - 20 Nov 2022 20.55Document1 pageSafari - 20 Nov 2022 20.55denny yusufNo ratings yet

- Wavetra Energy Academy Course CatalogueDocument5 pagesWavetra Energy Academy Course CatalogueWavetra EnergyNo ratings yet

- STC Calender Apr 2014-Mar 15 Page by Page PDFDocument14 pagesSTC Calender Apr 2014-Mar 15 Page by Page PDFShubhankar KunduNo ratings yet

- Model Curriculum - Electrician Domestic Solutions PDFDocument30 pagesModel Curriculum - Electrician Domestic Solutions PDFnassarkiNo ratings yet

- Basics of Load CentersDocument98 pagesBasics of Load Centersvda0904No ratings yet

- CBLM KimDocument34 pagesCBLM KimVALDEZ, MELVINE G.No ratings yet

- Substations PDFDocument16 pagesSubstations PDFsorry2qaz100% (1)

- ResumeDocument4 pagesResumeAnil Prashanth MendoncaNo ratings yet

- Woodward Canbus To FO 37598 - ADocument11 pagesWoodward Canbus To FO 37598 - AAnonymous yugocxnNo ratings yet

- Branch Circuits - Part One - Code Basics Content From Electrical Construction & Maintenance (EC&M) MagazineDocument5 pagesBranch Circuits - Part One - Code Basics Content From Electrical Construction & Maintenance (EC&M) MagazineJessica LombanaNo ratings yet

- Grounding and ShieldingDocument16 pagesGrounding and ShieldingHaithem BrebishNo ratings yet

- Basic-Power-System-Protection-Webinar-Sep-2020Document4 pagesBasic-Power-System-Protection-Webinar-Sep-2020nooralhudNo ratings yet

- 000.265.9300 Grounding, Lightning Protection and EMC System DesignDocument29 pages000.265.9300 Grounding, Lightning Protection and EMC System Designvladimir rosas ayalaNo ratings yet

- Consulting - Specifying Engineer - NFPA 20 - Fire Pump Design 1Document15 pagesConsulting - Specifying Engineer - NFPA 20 - Fire Pump Design 1HSEI Jatim - NSU 2020No ratings yet

- CHP131 - Protection in Power Plants - ApplicationsDocument2 pagesCHP131 - Protection in Power Plants - ApplicationsMichael Parohinog GregasNo ratings yet

- TermoflexDocument56 pagesTermoflexAbner Said Rodriguez AlonzoNo ratings yet

- Chemin Profile PDFDocument146 pagesChemin Profile PDFElectrical CheminNo ratings yet

- Baumer QuickStart-VeriSens ML 11156853Document76 pagesBaumer QuickStart-VeriSens ML 11156853Kanapot RitthapNo ratings yet

- TUV SUD - Nuclear Training Infographic v14Document1 pageTUV SUD - Nuclear Training Infographic v14Anurag Kumar Singh SinghNo ratings yet

- Competency Based Learning Materials: Electrical and Installation Maintenance NC IiDocument3 pagesCompetency Based Learning Materials: Electrical and Installation Maintenance NC Iielmer olmedilloNo ratings yet

- Power Electronics, Switch Mode Power Supplies and Variable Speed DrivesDocument3 pagesPower Electronics, Switch Mode Power Supplies and Variable Speed DrivesMuhammad ImranNo ratings yet

- Electrical Power System Protection: Certificate inDocument4 pagesElectrical Power System Protection: Certificate innvchinaiNo ratings yet

- Conduit Sizing Ss Voltimum UKDocument6 pagesConduit Sizing Ss Voltimum UKOjog Ciprian AlinNo ratings yet

- SiemensPowerAcademyTD TrainingProgram EN 2020 PDFDocument12 pagesSiemensPowerAcademyTD TrainingProgram EN 2020 PDFgian93No ratings yet

- Radiant Architecture Class LADocument1 pageRadiant Architecture Class LAaialosangelesNo ratings yet

- Cop101 Version 14 Black LettersDocument49 pagesCop101 Version 14 Black LettersEdouard LiangNo ratings yet

- Dla-Nx9 Dla-Nx7 Dla-Nx5: InstructionsDocument99 pagesDla-Nx9 Dla-Nx7 Dla-Nx5: InstructionsDaltonist OggyNo ratings yet

- CBLM Final1 PDFDocument115 pagesCBLM Final1 PDFGlenn Etnomla100% (3)

- Substation Design & Operation Training Seminar - GLOMACS PDFDocument4 pagesSubstation Design & Operation Training Seminar - GLOMACS PDFmarkerNo ratings yet

- DWA-A1-HS-MS-GNF-0003-00A WMSRA For LV DC AC Cable Laying Works Rev-00ADocument22 pagesDWA-A1-HS-MS-GNF-0003-00A WMSRA For LV DC AC Cable Laying Works Rev-00AAnandu AshokanNo ratings yet

- E-Mobility CSS Solution SheetDocument2 pagesE-Mobility CSS Solution SheetGanapathy SadayanNo ratings yet

- Broucher Beyond BasicsDocument2 pagesBroucher Beyond BasicsVishwas Venkatesh PaiNo ratings yet

- Building Fire Protection SupplementDocument32 pagesBuilding Fire Protection SupplementReinhart85No ratings yet

- 2CSC000004D0201 - Enclosures and DIN-Rail Products Compact HomeDocument374 pages2CSC000004D0201 - Enclosures and DIN-Rail Products Compact HomeEverton Soares PivottoNo ratings yet

- Projector Manual 10626Document92 pagesProjector Manual 10626Arun P KrishnanNo ratings yet

- Competency Based Learning Material - ToRRES (FINAL)Document32 pagesCompetency Based Learning Material - ToRRES (FINAL)j4240300No ratings yet

- Cisco Network Professional's Advanced Internetworking Guide (CCNP Series)From EverandCisco Network Professional's Advanced Internetworking Guide (CCNP Series)No ratings yet

- New Age Cyber Threat Mitigation for Cloud Computing NetworksFrom EverandNew Age Cyber Threat Mitigation for Cloud Computing NetworksNo ratings yet

- Desktop Support Crash Course: Technical Problem Solving And Network TroubleshootingFrom EverandDesktop Support Crash Course: Technical Problem Solving And Network TroubleshootingNo ratings yet

- CCNA Cisco Certified Network Associate A Practical Study Guide on Passing the ExamFrom EverandCCNA Cisco Certified Network Associate A Practical Study Guide on Passing the ExamNo ratings yet

- What You Need To Know About Color Theory For PaintingDocument1 pageWhat You Need To Know About Color Theory For PaintingMohamed Abou El hassanNo ratings yet

- Oil Color Chart Exercises For Artists (Master Your Paint Pallette)Document1 pageOil Color Chart Exercises For Artists (Master Your Paint Pallette)Mohamed Abou El hassanNo ratings yet

- 27 05 00 Common Work Results For CommunicationsDocument16 pages27 05 00 Common Work Results For CommunicationsMohamed Abou El hassanNo ratings yet

- Chemistry-Hail - 2023 09 07Document24 pagesChemistry-Hail - 2023 09 07Mohamed Abou El hassanNo ratings yet

- Complete Guide On Color and The Effect of LightDocument1 pageComplete Guide On Color and The Effect of LightMohamed Abou El hassanNo ratings yet

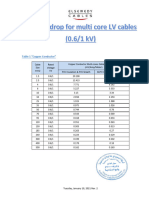

- Voltage Drop Rev. 2Document2 pagesVoltage Drop Rev. 2Mohamed Abou El hassanNo ratings yet

- MOS For The Installation of Water Supply SystemDocument16 pagesMOS For The Installation of Water Supply SystemMohamed Abou El hassanNo ratings yet

- Choosing Between 3-Pole and 4-Pole Transfer Switches - Consulting - Specifying EngineerDocument1 pageChoosing Between 3-Pole and 4-Pole Transfer Switches - Consulting - Specifying EngineerMohamed Abou El hassanNo ratings yet

- Engineering Appendix Three Pumping Stations Version 12 November 2012Document16 pagesEngineering Appendix Three Pumping Stations Version 12 November 2012Mohamed Abou El hassanNo ratings yet

- Calculation, Pump, Hydraulic, NPSH, Suction, Fluid, Water, NetDocument1 pageCalculation, Pump, Hydraulic, NPSH, Suction, Fluid, Water, NetMohamed Abou El hassanNo ratings yet

- NK 125315326 Aa1f2besbaqerw3Document11 pagesNK 125315326 Aa1f2besbaqerw3Mohamed Abou El hassanNo ratings yet

- Alworood - Power - Lighting-ModelDocument1 pageAlworood - Power - Lighting-ModelMohamed Abou El hassanNo ratings yet

- 2 1 1 Grinder Mechanical PDFDocument3 pages2 1 1 Grinder Mechanical PDFMohamed Abou El hassanNo ratings yet

- 2 2 2 Electrical In-FillDocument14 pages2 2 2 Electrical In-FillMohamed Abou El hassanNo ratings yet

- 27 41 32 Ip-Based Television System (Iptv)Document30 pages27 41 32 Ip-Based Television System (Iptv)Mohamed Abou El hassanNo ratings yet

- IWS STRONG Small Pumping Stations ENGDocument12 pagesIWS STRONG Small Pumping Stations ENGMohamed Abou El hassanNo ratings yet

- ID1000 Underground Tank 1 10m3 - ENDocument1 pageID1000 Underground Tank 1 10m3 - ENMohamed Abou El hassanNo ratings yet

- Collection Chamber Structural-Rev4Document1 pageCollection Chamber Structural-Rev4Mohamed Abou El hassanNo ratings yet

- Water Hammer - What Is It and How Does It Impact FirefightingDocument1 pageWater Hammer - What Is It and How Does It Impact FirefightingMohamed Abou El hassanNo ratings yet

- ID700 Small Pumping Station Wilo MTC40 Plastic Cover ENGDocument1 pageID700 Small Pumping Station Wilo MTC40 Plastic Cover ENGMohamed Abou El hassanNo ratings yet

- CATL Battery Datasheet FinalDocument2 pagesCATL Battery Datasheet FinalMohamed Abou El hassan100% (1)

- Fire Pump Settings - NFPA 20 - Fire Protection SpecialistsDocument1 pageFire Pump Settings - NFPA 20 - Fire Protection SpecialistsMohamed Abou El hassanNo ratings yet

- FIRE PUMP MINIMUM FLOW REQUIREMENTS - LinkedInDocument1 pageFIRE PUMP MINIMUM FLOW REQUIREMENTS - LinkedInMohamed Abou El hassanNo ratings yet

- How To Match Colors in A PaintingDocument1 pageHow To Match Colors in A PaintingMohamed Abou El hassanNo ratings yet

- Tm-90-21-Ul (R-03/30/22)Document20 pagesTm-90-21-Ul (R-03/30/22)Mohamed Abou El hassanNo ratings yet

- 22-Light ColorDocument12 pages22-Light ColorMohamed Abou El hassanNo ratings yet

- Relief Valves For Centrifugal Pumps According To NFPA 20 - Fire Protection SpecialistsDocument1 pageRelief Valves For Centrifugal Pumps According To NFPA 20 - Fire Protection SpecialistsMohamed Abou El hassanNo ratings yet

- Lumens Calculator - How Many Lumens Do I Need For A Room - InsightsDocument1 pageLumens Calculator - How Many Lumens Do I Need For A Room - InsightsMohamed Abou El hassanNo ratings yet

- Eaton-30A-3P-N1-Indoor-240V DisconnectorspdfDocument5 pagesEaton-30A-3P-N1-Indoor-240V DisconnectorspdfMohamed Abou El hassanNo ratings yet

- Gerapid Configuration Tool - Rev03 - 0812Document14 pagesGerapid Configuration Tool - Rev03 - 081201666754614No ratings yet

- Training Module For NGCP External Customers - MTDDocument285 pagesTraining Module For NGCP External Customers - MTDMary Grace BonaobraNo ratings yet

- Power Plant EmergencyDocument22 pagesPower Plant Emergencysekhar_ntpc75% (4)

- IEC 60364 - 5!52!2001 - Electrical Installation of BuildingsDocument136 pagesIEC 60364 - 5!52!2001 - Electrical Installation of BuildingsRebeca MancillaNo ratings yet

- ABB GOE - Тип Масло-ВоздухDocument4 pagesABB GOE - Тип Масло-Воздухdaniel_sa2011No ratings yet

- BF C275DDocument7 pagesBF C275DLebahMaduNo ratings yet

- AmfDocument5 pagesAmfJeffrey TeoNo ratings yet

- Principle Operation of Synchronous MotorDocument9 pagesPrinciple Operation of Synchronous MotorGideon MoyoNo ratings yet

- FM2203-167Q - R2 TechDocument17 pagesFM2203-167Q - R2 Techmohamed mahdiNo ratings yet

- Boq ElectricalDocument22 pagesBoq ElectricalMohammed SajjadNo ratings yet

- SWOT Analysis For Solar PV-Technology: Dr. Chandani Sharma and Dr. Anamika JainDocument4 pagesSWOT Analysis For Solar PV-Technology: Dr. Chandani Sharma and Dr. Anamika JainManish VaswaniNo ratings yet

- Pap LoosDocument23 pagesPap LoosSimplicio Goncalves100% (1)

- Power Liquid Filled Three Phase Padmounted Transformers: IndustrialDocument11 pagesPower Liquid Filled Three Phase Padmounted Transformers: Industrialwilliamdw40No ratings yet

- Perancangan Pelaksanaan Dea 3333Document49 pagesPerancangan Pelaksanaan Dea 3333Roger JohnNo ratings yet

- Manual Sepam Serie60 enDocument486 pagesManual Sepam Serie60 enfayssal salvadorNo ratings yet

- M49SP 1Document2 pagesM49SP 1ivandevelNo ratings yet

- Ti33j01j10-01en 004Document232 pagesTi33j01j10-01en 004Cappu CinoNo ratings yet

- Smart Grid & WAMS: Women in Engineering/ Young Professional Opening Talk 26/01/2016Document33 pagesSmart Grid & WAMS: Women in Engineering/ Young Professional Opening Talk 26/01/2016Feodor RadilovNo ratings yet

- Power Power Factor TransformerDocument36 pagesPower Power Factor Transformerme22b193No ratings yet

- Industrial Ups 3phase Enertonic I 01Document8 pagesIndustrial Ups 3phase Enertonic I 01kylegazeNo ratings yet

- Cal. P.U.C. Sheet No. Cancelling Revised Cal. P.U.C. Sheet NoDocument9 pagesCal. P.U.C. Sheet No. Cancelling Revised Cal. P.U.C. Sheet NoshadabNo ratings yet

- CyberPower OLS6000-10000ERT6U User ManualDocument42 pagesCyberPower OLS6000-10000ERT6U User ManualKhách Sạn Hoàng Phố100% (2)

- Battery Charger FSFTModelDocument4 pagesBattery Charger FSFTModelsunthron somchaiNo ratings yet

- Three-Phase Transformer Modeling Using Symmetrical ComponentsDocument7 pagesThree-Phase Transformer Modeling Using Symmetrical ComponentsSatish MoupuriNo ratings yet

- GEK90211C ML18H Powervac Breaker Manual PDFDocument48 pagesGEK90211C ML18H Powervac Breaker Manual PDFManuel L LombarderoNo ratings yet

- Cag 1737Document5 pagesCag 1737AONLANo ratings yet

- Thesis On Uninterruptible Power SupplyDocument5 pagesThesis On Uninterruptible Power Supplyjeanarnettrochester100% (1)

- Transformer Bushing MonitoringDocument8 pagesTransformer Bushing Monitoringabes1234100% (1)

- Electric Machines LaboratoryDocument44 pagesElectric Machines Laboratory11mustafa.mNo ratings yet

- BEHA M31. All ModelsDocument3 pagesBEHA M31. All ModelsDavison da Silva BarbosaNo ratings yet

Design Knowhow - Low Voltage Substation Layouts, Earthing, Fire Protection and Tests - EEP

Design Knowhow - Low Voltage Substation Layouts, Earthing, Fire Protection and Tests - EEP

Uploaded by

Mohamed Abou El hassanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Knowhow - Low Voltage Substation Layouts, Earthing, Fire Protection and Tests - EEP

Design Knowhow - Low Voltage Substation Layouts, Earthing, Fire Protection and Tests - EEP

Uploaded by

Mohamed Abou El hassanCopyright:

Available Formats

Home Premium Membership Video Courses Technical Articles Literature Schneider Forums EE Tools

Save 50% on all Video Courses with Enterprise Membership Plan and study

Premium Membership ♕ specialized LV/MV/HV technical articles and guides.

MORE INFORMATION »

advertisement

Power Substation / Premium Content / Testing and Commissioning

Design Knowhow: Low voltage substation layouts, earthing,

fire protection and tests

By Mohammed Ayman | Apr, 3rd 2023 | No comments | Translate | Save to PDF Subscribe | Share!

Home / Technical Articles / Design Knowhow: Low voltage substation layouts, earthing, fire protection and tests

advertisement

Subscribe to Weekly Newsletter

Subscribe to our Weekly Digest newsletter

and receive free updates on new technical

articles, video courses and guides (PDF).

SUBSCRIBE

11kV/415V Substation Design

The design of a low-voltage substation is a pretty complex and quite exciting job to do. If the

designer would have complete freedom to make decisions regarding the substation layout,

equipment, or cable routes, the job will be even more challenging! Well, this article will try to

shed some light on the main design aspects of the 11kV/415V substation layout, structure,

advertisement

earthing and fire suppression systems.

Design

Design Knowhow:

Knowhow: Low

Low voltage

voltage substation

substation layouts,

layouts, earthing,

earthing, fire

fire protection

protection and

and tests

tests

Since this type of substation is implemented to feed and distribute power to an entire project,

learning about the major design considerations and the required clearances inside the room

becomes necessary.

The design of a substation inside a building may have different design layouts that need to

be studied to know more about how electrical equipment, such as transformers, LV panels,

RMUs etc., are installed inside the room.

Different layouts are elaborated on in this article. The equipment inside the substations

MUST be protected from potential fire incidents, which means that a substation must contain

different types of firefighting and fire alarm systems that are interfaced together to provide

full protection in case of fire.

This article will reveal the interfacing between these systems inside the substation.

Although understanding the interior of a substation and how it should be protected

from fire incidents is vital, learning more about the required testing procedures

that will be performed for the panels before energizing a new substation is just as

important.

This article explains the major tests that need to be carried out step by step to deliver a

safe, reliable and protected substation.

Table of Contents:

1. Structure of an LV Substation

2. How to Start With the Design?

1. Equipment Clearances You MUST NOT Be Wrong About

2. Dozen of Layouts Available: How to Choose

1. BONUS! Most Common LV substation layouts (PDF)

3. Fire protection Interfacing Inside an LV substation

4. Earthing System inside an LV Substation

5. Requirements Before Testing LV Panels

1. General Notes

2. Pre-Commissioning Procedures

6. Tests After Erection of LV Panels

1. Insulation Resistance Test (IR)

2. Cable Continuity and Polarity Check

3. Phase Rotation Check

4. Functional Test

1. Structure of an LV Substation

An LV substation or an LV room typically contains standing switchboards and other

equipment required for the room to function, such as bus ducts and cable containments,

panel boards, capacitor banks, air conditioning system, fire alarm system, firefighting system,

lighting, small power etc. The latter systems are required to build a typical indoor LV

substation.

However, before indulging into more details about the LV substation’s structure, it is crucial

to have a brief on how the medium voltage substations, including the MV switchgear and the

transformer, supply an LV substation.

To comprehensively understand how electric power is delivered to LV substations,

you will need to track the source of electricity going through the stages of its

delivery. Electricity passes through three stages: generation, transmission and

distribution.

Electricity is first generated in power plants or stations with a voltage of 11kV, then stepped

up using step-up transformers to increase the voltage to between 100 kV to 700kV

depending on the distance it will be transferred to; the longer the distance, the higher the

voltage.

After that, electricity is transmitted via overhead electrical lines, which you can see when you

drive between cities (see bottom for ‘Commercial load’).

Figure 1 – A 24-bus system, showing generation, transmission, subtransmission, industrial,

and commercial loads

Figure

Figure 11 –– A

A 24-bus

24-bus system,

system, showing

showing generation,

generation, transmission,

transmission, subtransmission,

subtransmission, industrial,

industrial, and

and commercial

commercial loads

loads

The transmission of these lines is aimed at reaching several receiving HV substations. When

electrical power reaches a receiving station, the voltage decreases to 33kV and 66kV. It is

then sent to transmission lines from this receiving station to electrical substations close to

cities, villages, and urban areas. When electrical power reaches a substation, it is stepped

down once more by a step-down transformer to voltages closer to what it was generated at,

usually around 11kV.

From here, the transmission phase graduates to the distribution phase, and electrical power

is used to meet demand from primary and secondary consumers. This is done by installing

an MV voltage switchgear/ RMU (Ring Main Unit) that can supply several low-voltage

transformers that decrease this voltage to 500V or less for distribution and utilization

purposes.

This article will focus on the LV substation connected to the LV transformer

substation. LV substation is implemented to distribute low voltage power to the

consumer with a voltage between 100V to 500V for single and three-phase

loads.

By looking at the figure below, we can understand more what makes up an LV substation.

Figure 2 – Low voltage substation

Figure

Figure 22 –– Low

Low voltage

voltage substation

substation

Go back to the Contents Table ↑

2. How to Start With the Design?

Designing the LV part of an LV substation can only be done by taking some considerations

in mind. The 11kV/0.45kV substation can either be located indoors or outdoors. The most

likely type of LV substation used for supplying customers with less than 500V is located

inside the building and distributes power to the entire project, and should be designed to

meet the safety requirements to avoid any dangerous situations.

The LV substation MUST be designed to provide a reliable service, facilitate maintenance

and allow for future expansions.

In other words, at least 20% spare capacity should be provided for every equipment inside

the room, including cable trays, trunks, LV switchboards, etc. Below are some major

requirements that must be complied with inside an LV substation.

1. Access for personnel (normal and emergency).

2. Access for equipment (installation, operation and maintenance).

3. Regulatory compliance and approvals.

4. Cable containment and entries.

5. Earthing and grounding.

6. Water sealing (if below ground).

7. Air conditioning, lighting & small power.

8. Fire detection, alarm and suppression.

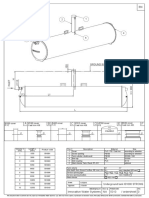

Figure 3 – Inside an LV/MV Substation

Figure

Figure 33 –– MV/LV

MV/LV substation

substation installation

installation layout

layout (all

(all dimensions

dimensions are

are in

in millimeters)

millimeters)

Go back to the Contents Table ↑

2.1. Equipment Clearances You MUST NOT Be Wrong About

The internal clearances of an low voltage room must always follow international standards

like NEMA, BS and NFPA. Equipment such as trays, LV switchgear, capacitor banks etc., are

usually located and placed following these standards. In many countries, LV substation

design drawings are be approved by the main electrical authority before building

construction.

This is why dimension considerations must be made during the design stage.

Electrical authorities might only supply the building with power if the requirements are met.

In a typical LV substation, cable trays are installed to facilitate the outgoing and incomer

cables. These trays should be designed to be located with sufficient clearances around them

to permit adequate access for the installation and maintenance of cables.

Premium Membership Required

This technical article/guide requires a Premium Membership. You can choose an annually

based Plus, Pro, or Enterprise membership plan. Subscribe and enjoy studying specialized

technical articles, online video courses, electrical engineering guides, and papers. With

EEP’s premium membership, you get additional essence that enhances your knowledge and

experience in low- medium- and high-voltage engineering fields.

Check out each plan’s benefits and choose the membership plan that works best for you or

your organization.

Good to know 💥 – Get 50% discount on all video courses by purchasing Enterprise plan.

Log In » Purchase »

advertisement

Related electrical guides & articles

Dos and don’ts in creating Earthing system for a Technical specification of

operation logic diagrams for complex project: Analysis, switchyard equipment in a

LV and MV switchgear calculation and installation nutshell (how-to guidelines

feeders (XLSX, DWG) and advice)

Three-phase basics and How to design the power Learn how to interpret and

terms that students often mix supply for data centres and design single-line diagrams

airports while megawatts of (SLD) for complex projects

loads rise fast

Premium Membership

Get access to premium HV/MV/LV technical articles, electrical engineering guides, research

studies and much more! It helps you to shape up your technical skills in your everyday life

as an electrical engineer.

MORE INFORMATION

Mohammed Ayman

I earned my degree from Eastern Mediterranean University (Turkey,

North Cyprus) in B.S Electrical & Electronic Engineering; shortly after,

I began my career as an electrical site engineer in a mega-scale

project in Qatar which allowed me to monitor and supervise electrical

site installations. I indulged in the design field of the electrical low

voltage distribution systems and have accomplished more than 10 projects with the

compliance of the national codes & international standards.

Leave a Comment

Tell us what you're thinking. We care about your opinion! Please keep in mind that

comments are moderated and rel="nofollow" is in use. So, please do not use a spammy

keyword or a domain as your name, or it will be deleted. Let's have a professional and

meaningful conversation instead. Thanks for dropping by!

YOUR REAL NAME *

EMAIL ADDRESS *

Prove That You Are Not R2-D2. Solve Some Math:

+ 87 = Eighty Eight

SUBMIT COMMENT

© 2023 EEP - Electrical Engineering Portal. All Rights Reserved | Privacy Policy | Terms and Conditions The content is copyrighted to EEP and may not be reproduced on other websites.

You might also like

- W Hotel A&C StandardsDocument407 pagesW Hotel A&C StandardsKasinadh KarraNo ratings yet

- CBLM Final1Document115 pagesCBLM Final1Victor Rosales89% (72)

- ArtsDocument2 pagesArtsMohamed Abou El hassanNo ratings yet

- Jones NCTI Training KitDocument129 pagesJones NCTI Training Kitjonesncti0% (1)

- 3900 Series & 5900 Series Base Station Installation Guides-Wireless Network Info Community-Huawei ConnectDocument7 pages3900 Series & 5900 Series Base Station Installation Guides-Wireless Network Info Community-Huawei ConnectDavid TombeNo ratings yet

- EIT Course Substation Design Control Protection Facility Planning CEY2 BrochureDocument4 pagesEIT Course Substation Design Control Protection Facility Planning CEY2 Brochuregendoabdoul120No ratings yet

- Electrical Design Engineer & Protection EngineerDocument2 pagesElectrical Design Engineer & Protection EngineerAyansh patnaikNo ratings yet

- RFP 288-01-16 Fiber Man Services Attachment C Commscope RequirementsDocument4 pagesRFP 288-01-16 Fiber Man Services Attachment C Commscope RequirementsNguyễn Minh NhựtNo ratings yet

- EIT Course Electrical Power Protection CPS BrochureDocument3 pagesEIT Course Electrical Power Protection CPS BrochureAtabat AduduNo ratings yet

- MB PV Rooftop EN WebDocument20 pagesMB PV Rooftop EN WebLambert LambrintoNo ratings yet

- Faw1 PDFDocument2 pagesFaw1 PDFSavita BhabhiNo ratings yet

- CCNA 1.3: Describe The Impact of Infrastructure Components in An Enterprise Network (Firewalls, Access Points, Wireless Controllers)Document2 pagesCCNA 1.3: Describe The Impact of Infrastructure Components in An Enterprise Network (Firewalls, Access Points, Wireless Controllers)Savita BhabhiNo ratings yet

- Abb Furse Earthing A4 8pp Brochure FinalDocument8 pagesAbb Furse Earthing A4 8pp Brochure FinalTony BombataNo ratings yet

- 11 Deadliest Mistakes in A Power Substation Made by Young and Unmindful Electrical EngineersDocument2 pages11 Deadliest Mistakes in A Power Substation Made by Young and Unmindful Electrical EngineersArafat Lomangcolob BauntoNo ratings yet

- How To Use This ModuleDocument4 pagesHow To Use This ModuleHarold Vernon MartinezNo ratings yet

- Resume Olajide IdowuDocument3 pagesResume Olajide IdowuRupinder JeetNo ratings yet

- Weld Training Solutions: RealweldDocument4 pagesWeld Training Solutions: RealweldNenad MilosevicNo ratings yet

- Substations Design Guide PDFDocument16 pagesSubstations Design Guide PDFM Alim Ur RahmanNo ratings yet

- High Voltage Electrical Compliance and Safety Operating ProceduresDocument4 pagesHigh Voltage Electrical Compliance and Safety Operating ProcedurespkumarmysNo ratings yet

- EIT Course Power Distribution CPD BrochureDocument3 pagesEIT Course Power Distribution CPD BrochureKatamba RogersNo ratings yet

- Advanced-Power-System-Protection-Webinar-Aug-2020Document4 pagesAdvanced-Power-System-Protection-Webinar-Aug-2020nooralhudNo ratings yet

- Safari - 20 Nov 2022 20.55Document1 pageSafari - 20 Nov 2022 20.55denny yusufNo ratings yet

- Wavetra Energy Academy Course CatalogueDocument5 pagesWavetra Energy Academy Course CatalogueWavetra EnergyNo ratings yet

- STC Calender Apr 2014-Mar 15 Page by Page PDFDocument14 pagesSTC Calender Apr 2014-Mar 15 Page by Page PDFShubhankar KunduNo ratings yet

- Model Curriculum - Electrician Domestic Solutions PDFDocument30 pagesModel Curriculum - Electrician Domestic Solutions PDFnassarkiNo ratings yet

- Basics of Load CentersDocument98 pagesBasics of Load Centersvda0904No ratings yet

- CBLM KimDocument34 pagesCBLM KimVALDEZ, MELVINE G.No ratings yet

- Substations PDFDocument16 pagesSubstations PDFsorry2qaz100% (1)

- ResumeDocument4 pagesResumeAnil Prashanth MendoncaNo ratings yet

- Woodward Canbus To FO 37598 - ADocument11 pagesWoodward Canbus To FO 37598 - AAnonymous yugocxnNo ratings yet

- Branch Circuits - Part One - Code Basics Content From Electrical Construction & Maintenance (EC&M) MagazineDocument5 pagesBranch Circuits - Part One - Code Basics Content From Electrical Construction & Maintenance (EC&M) MagazineJessica LombanaNo ratings yet

- Grounding and ShieldingDocument16 pagesGrounding and ShieldingHaithem BrebishNo ratings yet

- Basic-Power-System-Protection-Webinar-Sep-2020Document4 pagesBasic-Power-System-Protection-Webinar-Sep-2020nooralhudNo ratings yet

- 000.265.9300 Grounding, Lightning Protection and EMC System DesignDocument29 pages000.265.9300 Grounding, Lightning Protection and EMC System Designvladimir rosas ayalaNo ratings yet

- Consulting - Specifying Engineer - NFPA 20 - Fire Pump Design 1Document15 pagesConsulting - Specifying Engineer - NFPA 20 - Fire Pump Design 1HSEI Jatim - NSU 2020No ratings yet

- CHP131 - Protection in Power Plants - ApplicationsDocument2 pagesCHP131 - Protection in Power Plants - ApplicationsMichael Parohinog GregasNo ratings yet

- TermoflexDocument56 pagesTermoflexAbner Said Rodriguez AlonzoNo ratings yet

- Chemin Profile PDFDocument146 pagesChemin Profile PDFElectrical CheminNo ratings yet

- Baumer QuickStart-VeriSens ML 11156853Document76 pagesBaumer QuickStart-VeriSens ML 11156853Kanapot RitthapNo ratings yet

- TUV SUD - Nuclear Training Infographic v14Document1 pageTUV SUD - Nuclear Training Infographic v14Anurag Kumar Singh SinghNo ratings yet

- Competency Based Learning Materials: Electrical and Installation Maintenance NC IiDocument3 pagesCompetency Based Learning Materials: Electrical and Installation Maintenance NC Iielmer olmedilloNo ratings yet

- Power Electronics, Switch Mode Power Supplies and Variable Speed DrivesDocument3 pagesPower Electronics, Switch Mode Power Supplies and Variable Speed DrivesMuhammad ImranNo ratings yet

- Electrical Power System Protection: Certificate inDocument4 pagesElectrical Power System Protection: Certificate innvchinaiNo ratings yet

- Conduit Sizing Ss Voltimum UKDocument6 pagesConduit Sizing Ss Voltimum UKOjog Ciprian AlinNo ratings yet

- SiemensPowerAcademyTD TrainingProgram EN 2020 PDFDocument12 pagesSiemensPowerAcademyTD TrainingProgram EN 2020 PDFgian93No ratings yet

- Radiant Architecture Class LADocument1 pageRadiant Architecture Class LAaialosangelesNo ratings yet

- Cop101 Version 14 Black LettersDocument49 pagesCop101 Version 14 Black LettersEdouard LiangNo ratings yet

- Dla-Nx9 Dla-Nx7 Dla-Nx5: InstructionsDocument99 pagesDla-Nx9 Dla-Nx7 Dla-Nx5: InstructionsDaltonist OggyNo ratings yet

- CBLM Final1 PDFDocument115 pagesCBLM Final1 PDFGlenn Etnomla100% (3)

- Substation Design & Operation Training Seminar - GLOMACS PDFDocument4 pagesSubstation Design & Operation Training Seminar - GLOMACS PDFmarkerNo ratings yet

- DWA-A1-HS-MS-GNF-0003-00A WMSRA For LV DC AC Cable Laying Works Rev-00ADocument22 pagesDWA-A1-HS-MS-GNF-0003-00A WMSRA For LV DC AC Cable Laying Works Rev-00AAnandu AshokanNo ratings yet

- E-Mobility CSS Solution SheetDocument2 pagesE-Mobility CSS Solution SheetGanapathy SadayanNo ratings yet

- Broucher Beyond BasicsDocument2 pagesBroucher Beyond BasicsVishwas Venkatesh PaiNo ratings yet

- Building Fire Protection SupplementDocument32 pagesBuilding Fire Protection SupplementReinhart85No ratings yet

- 2CSC000004D0201 - Enclosures and DIN-Rail Products Compact HomeDocument374 pages2CSC000004D0201 - Enclosures and DIN-Rail Products Compact HomeEverton Soares PivottoNo ratings yet

- Projector Manual 10626Document92 pagesProjector Manual 10626Arun P KrishnanNo ratings yet

- Competency Based Learning Material - ToRRES (FINAL)Document32 pagesCompetency Based Learning Material - ToRRES (FINAL)j4240300No ratings yet

- Cisco Network Professional's Advanced Internetworking Guide (CCNP Series)From EverandCisco Network Professional's Advanced Internetworking Guide (CCNP Series)No ratings yet

- New Age Cyber Threat Mitigation for Cloud Computing NetworksFrom EverandNew Age Cyber Threat Mitigation for Cloud Computing NetworksNo ratings yet

- Desktop Support Crash Course: Technical Problem Solving And Network TroubleshootingFrom EverandDesktop Support Crash Course: Technical Problem Solving And Network TroubleshootingNo ratings yet

- CCNA Cisco Certified Network Associate A Practical Study Guide on Passing the ExamFrom EverandCCNA Cisco Certified Network Associate A Practical Study Guide on Passing the ExamNo ratings yet

- What You Need To Know About Color Theory For PaintingDocument1 pageWhat You Need To Know About Color Theory For PaintingMohamed Abou El hassanNo ratings yet

- Oil Color Chart Exercises For Artists (Master Your Paint Pallette)Document1 pageOil Color Chart Exercises For Artists (Master Your Paint Pallette)Mohamed Abou El hassanNo ratings yet

- 27 05 00 Common Work Results For CommunicationsDocument16 pages27 05 00 Common Work Results For CommunicationsMohamed Abou El hassanNo ratings yet

- Chemistry-Hail - 2023 09 07Document24 pagesChemistry-Hail - 2023 09 07Mohamed Abou El hassanNo ratings yet

- Complete Guide On Color and The Effect of LightDocument1 pageComplete Guide On Color and The Effect of LightMohamed Abou El hassanNo ratings yet

- Voltage Drop Rev. 2Document2 pagesVoltage Drop Rev. 2Mohamed Abou El hassanNo ratings yet

- MOS For The Installation of Water Supply SystemDocument16 pagesMOS For The Installation of Water Supply SystemMohamed Abou El hassanNo ratings yet

- Choosing Between 3-Pole and 4-Pole Transfer Switches - Consulting - Specifying EngineerDocument1 pageChoosing Between 3-Pole and 4-Pole Transfer Switches - Consulting - Specifying EngineerMohamed Abou El hassanNo ratings yet

- Engineering Appendix Three Pumping Stations Version 12 November 2012Document16 pagesEngineering Appendix Three Pumping Stations Version 12 November 2012Mohamed Abou El hassanNo ratings yet

- Calculation, Pump, Hydraulic, NPSH, Suction, Fluid, Water, NetDocument1 pageCalculation, Pump, Hydraulic, NPSH, Suction, Fluid, Water, NetMohamed Abou El hassanNo ratings yet

- NK 125315326 Aa1f2besbaqerw3Document11 pagesNK 125315326 Aa1f2besbaqerw3Mohamed Abou El hassanNo ratings yet

- Alworood - Power - Lighting-ModelDocument1 pageAlworood - Power - Lighting-ModelMohamed Abou El hassanNo ratings yet

- 2 1 1 Grinder Mechanical PDFDocument3 pages2 1 1 Grinder Mechanical PDFMohamed Abou El hassanNo ratings yet

- 2 2 2 Electrical In-FillDocument14 pages2 2 2 Electrical In-FillMohamed Abou El hassanNo ratings yet

- 27 41 32 Ip-Based Television System (Iptv)Document30 pages27 41 32 Ip-Based Television System (Iptv)Mohamed Abou El hassanNo ratings yet

- IWS STRONG Small Pumping Stations ENGDocument12 pagesIWS STRONG Small Pumping Stations ENGMohamed Abou El hassanNo ratings yet

- ID1000 Underground Tank 1 10m3 - ENDocument1 pageID1000 Underground Tank 1 10m3 - ENMohamed Abou El hassanNo ratings yet

- Collection Chamber Structural-Rev4Document1 pageCollection Chamber Structural-Rev4Mohamed Abou El hassanNo ratings yet

- Water Hammer - What Is It and How Does It Impact FirefightingDocument1 pageWater Hammer - What Is It and How Does It Impact FirefightingMohamed Abou El hassanNo ratings yet

- ID700 Small Pumping Station Wilo MTC40 Plastic Cover ENGDocument1 pageID700 Small Pumping Station Wilo MTC40 Plastic Cover ENGMohamed Abou El hassanNo ratings yet

- CATL Battery Datasheet FinalDocument2 pagesCATL Battery Datasheet FinalMohamed Abou El hassan100% (1)

- Fire Pump Settings - NFPA 20 - Fire Protection SpecialistsDocument1 pageFire Pump Settings - NFPA 20 - Fire Protection SpecialistsMohamed Abou El hassanNo ratings yet

- FIRE PUMP MINIMUM FLOW REQUIREMENTS - LinkedInDocument1 pageFIRE PUMP MINIMUM FLOW REQUIREMENTS - LinkedInMohamed Abou El hassanNo ratings yet

- How To Match Colors in A PaintingDocument1 pageHow To Match Colors in A PaintingMohamed Abou El hassanNo ratings yet

- Tm-90-21-Ul (R-03/30/22)Document20 pagesTm-90-21-Ul (R-03/30/22)Mohamed Abou El hassanNo ratings yet

- 22-Light ColorDocument12 pages22-Light ColorMohamed Abou El hassanNo ratings yet

- Relief Valves For Centrifugal Pumps According To NFPA 20 - Fire Protection SpecialistsDocument1 pageRelief Valves For Centrifugal Pumps According To NFPA 20 - Fire Protection SpecialistsMohamed Abou El hassanNo ratings yet

- Lumens Calculator - How Many Lumens Do I Need For A Room - InsightsDocument1 pageLumens Calculator - How Many Lumens Do I Need For A Room - InsightsMohamed Abou El hassanNo ratings yet

- Eaton-30A-3P-N1-Indoor-240V DisconnectorspdfDocument5 pagesEaton-30A-3P-N1-Indoor-240V DisconnectorspdfMohamed Abou El hassanNo ratings yet

- Gerapid Configuration Tool - Rev03 - 0812Document14 pagesGerapid Configuration Tool - Rev03 - 081201666754614No ratings yet

- Training Module For NGCP External Customers - MTDDocument285 pagesTraining Module For NGCP External Customers - MTDMary Grace BonaobraNo ratings yet

- Power Plant EmergencyDocument22 pagesPower Plant Emergencysekhar_ntpc75% (4)

- IEC 60364 - 5!52!2001 - Electrical Installation of BuildingsDocument136 pagesIEC 60364 - 5!52!2001 - Electrical Installation of BuildingsRebeca MancillaNo ratings yet

- ABB GOE - Тип Масло-ВоздухDocument4 pagesABB GOE - Тип Масло-Воздухdaniel_sa2011No ratings yet

- BF C275DDocument7 pagesBF C275DLebahMaduNo ratings yet

- AmfDocument5 pagesAmfJeffrey TeoNo ratings yet

- Principle Operation of Synchronous MotorDocument9 pagesPrinciple Operation of Synchronous MotorGideon MoyoNo ratings yet

- FM2203-167Q - R2 TechDocument17 pagesFM2203-167Q - R2 Techmohamed mahdiNo ratings yet

- Boq ElectricalDocument22 pagesBoq ElectricalMohammed SajjadNo ratings yet

- SWOT Analysis For Solar PV-Technology: Dr. Chandani Sharma and Dr. Anamika JainDocument4 pagesSWOT Analysis For Solar PV-Technology: Dr. Chandani Sharma and Dr. Anamika JainManish VaswaniNo ratings yet

- Pap LoosDocument23 pagesPap LoosSimplicio Goncalves100% (1)

- Power Liquid Filled Three Phase Padmounted Transformers: IndustrialDocument11 pagesPower Liquid Filled Three Phase Padmounted Transformers: Industrialwilliamdw40No ratings yet

- Perancangan Pelaksanaan Dea 3333Document49 pagesPerancangan Pelaksanaan Dea 3333Roger JohnNo ratings yet

- Manual Sepam Serie60 enDocument486 pagesManual Sepam Serie60 enfayssal salvadorNo ratings yet

- M49SP 1Document2 pagesM49SP 1ivandevelNo ratings yet

- Ti33j01j10-01en 004Document232 pagesTi33j01j10-01en 004Cappu CinoNo ratings yet

- Smart Grid & WAMS: Women in Engineering/ Young Professional Opening Talk 26/01/2016Document33 pagesSmart Grid & WAMS: Women in Engineering/ Young Professional Opening Talk 26/01/2016Feodor RadilovNo ratings yet

- Power Power Factor TransformerDocument36 pagesPower Power Factor Transformerme22b193No ratings yet

- Industrial Ups 3phase Enertonic I 01Document8 pagesIndustrial Ups 3phase Enertonic I 01kylegazeNo ratings yet

- Cal. P.U.C. Sheet No. Cancelling Revised Cal. P.U.C. Sheet NoDocument9 pagesCal. P.U.C. Sheet No. Cancelling Revised Cal. P.U.C. Sheet NoshadabNo ratings yet

- CyberPower OLS6000-10000ERT6U User ManualDocument42 pagesCyberPower OLS6000-10000ERT6U User ManualKhách Sạn Hoàng Phố100% (2)

- Battery Charger FSFTModelDocument4 pagesBattery Charger FSFTModelsunthron somchaiNo ratings yet

- Three-Phase Transformer Modeling Using Symmetrical ComponentsDocument7 pagesThree-Phase Transformer Modeling Using Symmetrical ComponentsSatish MoupuriNo ratings yet

- GEK90211C ML18H Powervac Breaker Manual PDFDocument48 pagesGEK90211C ML18H Powervac Breaker Manual PDFManuel L LombarderoNo ratings yet

- Cag 1737Document5 pagesCag 1737AONLANo ratings yet

- Thesis On Uninterruptible Power SupplyDocument5 pagesThesis On Uninterruptible Power Supplyjeanarnettrochester100% (1)

- Transformer Bushing MonitoringDocument8 pagesTransformer Bushing Monitoringabes1234100% (1)

- Electric Machines LaboratoryDocument44 pagesElectric Machines Laboratory11mustafa.mNo ratings yet

- BEHA M31. All ModelsDocument3 pagesBEHA M31. All ModelsDavison da Silva BarbosaNo ratings yet