Professional Documents

Culture Documents

PDF Ou220cucot040 DRW

PDF Ou220cucot040 DRW

Uploaded by

Deepak Bhanushali ifbOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDF Ou220cucot040 DRW

PDF Ou220cucot040 DRW

Uploaded by

Deepak Bhanushali ifbCopyright:

Available Formats

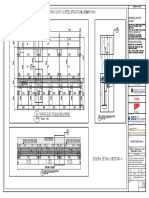

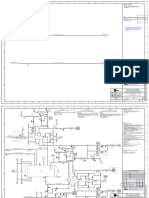

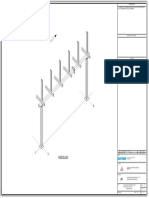

6 5 4 3 2 1

ISSUE INFORMATION CHANGE REF. DRAWN DATE CHECKED DATE APPROVED DATE

OU220CUCOT040 A1

1. MADE IN SINGLE PART.

2. SWAGING IS DONE KARTHI 17/09/2020 ABHISHEK 17/09/2020 N B PANTH 17/09/2020

ON ONE SIDE OF TUBE.

1. DIM 0102 CHANGED

A2 FROM 85 TO 80 mm KARTHI 21/09/2020 ABHISHEK 21/09/2020 N B PANTH 21/09/2020

59

12

1. MADE IN 2 PARTS.

A3 2. TOL. CHANGED FOR 0302 KARTHI 20/10/2020 ABHISHEK 20/10/2020 N B PANTH 20/10/2020

No.0202

E No.0203 A4 1. NO. 0103 ADDED

2. DETAIL VIEW A ADDED KARTHI 26/10/2020 ABHISHEK 26/10/2020 N B PANTH 26/10/2020 E

⌀5 -0.1(OD)

B DIM. 0103 CHANGED CN# 18821 KARTHI 29/12/2020 ABHISHEK 29/12/2020 N B PANTH 29/12/2020

No.0304

15 C ARROW POSITION

CHANGED FOR 0401

CN# 19161 KARTHI 07/01/2021 ABHISHEK 07/01/2021 N B PANTH 07/01/2021

0

No.0303 10

No.0205 POSITIONING CONCAVE

(ID)

POINT 1-SR 0.5-1

DEPTH 0.4-0.6

No.0204

No.0206

No.0201

+0.1

80

⌀50

⌀ 4.45 -0.1 (OD)

50

No.0301

D D

No.0302

0

+0.1

8.3 0 (ID)

No.0207

TUBE 2: ⌀5x0.41 TUBE 1: ⌀9.52x0.6

CUT LENGTH=50mm CUT LENGTH=130mm

VIEW 03 VIEW 02

NO 01 TO 04 NO 01 TO 07 NOTES:

1. THE WELDING SEAM SHALL BE FILLED WITH BRAZING FILLER METAL,

C AND NO DEFECTS SUCH AS INCLUDED SLAGS, CRACKS, SAND HOLES,

C

99 ETC. ARE ALLOWED.

2. THE WELDING SEAM SHALL BE TESTED FOR AIR TIGHTNESS UNDER AN

No.0101 WALL THICKNESS AFTER ATMOSPHERIC PRESSURE OF 3.0 MPa, THE PRESSURE SHALL BE

ROLLING CIRCLE SHALL MAINTAINED FOR 5 MIN, AND NO LEAKAGE SHALL OCCUR

NOT BE LESS THAN 0.5 mm IN ALL THE WELDING SEAMS.

No.0402 2

3. THE IMPURITY CONTENT OF THE INNER WALL IS LESS THAN 60 mg/m ,

2

AND THE WATER CONTENT IS LESS THAN 120 mg/m

4. THE NOZZLE SHALL BE FLAT AND FREE OF BURRS, AND THE

OUT-OF-ROUNDNESS SHALL BE NOT GREATER THAN 0.1.

5. THE BENDING RADIUS NOT NOTED IS R20, THE BEND SHALL BE ROUND

912 AND SMOOTH, AND THE FLATTENING RATE SHALL BE 15%.

0.3~0.4 C

6. THE FINISHED PRODUCTS SHALL BE PACKAGED WITH PLASTIC BAGS.

7. PART SHOULD COMPLY RoHs COMPLAINCE, SHOULD NOT CONTAIN

No.0102

No.0401 PROHIBITED SUBSTANCES (Pb, Cd, Hg, Cr+6, PBB, PBDE)

80

No.0103

B B

8

A

B

FOR PPAP

DETAIL A ROTATED BY 90°

DRAWN CHECKED APPROVED

NAME KARTHI ABHISHEK N B PANTH

VIEW 04 DATE 19/08/2020 19/08/2020 19/08/2020

NO 01 TO 02 C COPYRIGHT SCALE PROJECTION

GENERAL TOLERANCES

TUBING RAW MATERIAL VIEW 01 1:1

PIPE DIA TOL NO 01 TO 03

DWG. TYPE

TITLE

<12.7 ±0.08 CHARACTERISTIC SYMBOLS PART

A

12.71-22.2 ±0.09 GENERAL

TOLERANCES TUBING

THIS DRAWING IS OBTAINED DIRECTLY FROM 3D MODEL. CONDENSER OUT TUBE 1 CRITICAL [CC]

DWG. SIZE

A3 A

GENERAL

>22.21 ±0.12

LENGTH SIMPLE BLAZED ANGLE

TOLERANCES

TUBING

DON'T MODIFY MANUALLY.

FOR OTHER DIMENSIONS SEE 3D MODEL

- 728C - 1R SIGNIFICANT [SC]

MODEL TYPE

PART

THICKNESS TOL <30 ±0.8 ±1.5 BEND RADIUS ALL DIMENSIONS ARE IN MM MATERIAL [CC] WEIGHT SHEET

GEOMETRIC TOLERANCING STANDARD

<0.8 ±0.10 30-100 ±1 ±2 <30 ±0.5 REF. NO - 211244532 ANSI/ASME Y14.5M 1/1

±2°

0.81-1.09 ±0.13 101-300 ±2 ±3 31-100 ±1 DRAWING NO. REVISION

>1.1 ±0.15 >300 ±4 ±5 >100 ±2 PART NO. LEVEL REMARKS IFB Industries Limited, Goa. OU220CUCOT040 C

6 5 4 3 2 1

You might also like

- Ethylene Oxide Sterilization Validation ProtocolDocument25 pagesEthylene Oxide Sterilization Validation ProtocolUlisses V A Campos100% (5)

- AAR - M 107 - M 208 2009 Wheels, Carbon SteeLDocument36 pagesAAR - M 107 - M 208 2009 Wheels, Carbon SteeLUlises Quintana Carhuancho100% (1)

- Batch Reactor (Saponification) ExptDocument3 pagesBatch Reactor (Saponification) ExptVijay Prasad0% (1)

- CFX Multiphase 14.5 L03 Interphase Momentum Heat TransferDocument59 pagesCFX Multiphase 14.5 L03 Interphase Momentum Heat Transferedersalcedocastro100% (1)

- Dmso CoaDocument1 pageDmso CoaKarmpudi ChinnababuNo ratings yet

- PDF Ou321mxoaa010 DRWDocument1 pagePDF Ou321mxoaa010 DRWDeepak Bhanushali ifbNo ratings yet

- Btl-Ben-Shp-F 0020 Cotonou Port Line-Up - XDocument1 pageBtl-Ben-Shp-F 0020 Cotonou Port Line-Up - XStaff TrmOverseasNo ratings yet

- 110 20 GroutDocument1 page110 20 GroutAburvarajNo ratings yet

- 01-311 Range Main Electric Diagram - BG01473347 - BDocument17 pages01-311 Range Main Electric Diagram - BG01473347 - BJuan Angel Nava SanchezNo ratings yet

- 00 - l23d7754 Electric DiagramsDocument42 pages00 - l23d7754 Electric Diagramsgajass1984No ratings yet

- 220920-Architectural WorksDocument244 pages220920-Architectural WorksSimilikiti Weleh WelehNo ratings yet

- Power House-Rev2-Isometric 2Document1 pagePower House-Rev2-Isometric 2KelvinNo ratings yet

- One Plate Req'D As Drawn MK'D W102Document1 pageOne Plate Req'D As Drawn MK'D W102waleednazarNo ratings yet

- CD ADV VAT RAF FUL: Ebenezer Ebenco Trading AgentDocument2 pagesCD ADV VAT RAF FUL: Ebenezer Ebenco Trading AgentMoholi LithebeNo ratings yet

- Power House-Rev2-Isometric 1Document1 pagePower House-Rev2-Isometric 1KelvinNo ratings yet

- Power House-Rev2-Side ViewDocument1 pagePower House-Rev2-Side ViewKelvinNo ratings yet

- Exit Guide From ProperziDocument2 pagesExit Guide From Properzimuhammad kasyfuNo ratings yet

- Si Log-M1Document10 pagesSi Log-M1dilbertscottNo ratings yet

- Tri-Clamp: Item Qty. Description MaterialDocument2 pagesTri-Clamp: Item Qty. Description MaterialSivateja NallamothuNo ratings yet

- 729 PBM SD BR GD A103 ModelDocument1 page729 PBM SD BR GD A103 ModelAizhar John QuindozaNo ratings yet

- Fbos 5Document1 pageFbos 5JIHED PRIMA PHONESTORENo ratings yet

- Petronas Carigali: Shielded Metal Arc Welding (Smaw)Document13 pagesPetronas Carigali: Shielded Metal Arc Welding (Smaw)Hafizuddin PjoeNo ratings yet

- Schedule GIS MRSDocument1 pageSchedule GIS MRSbhuntoroNo ratings yet

- PDF Ou220brbrn030 DRWDocument1 pagePDF Ou220brbrn030 DRWDeepak Bhanushali ifbNo ratings yet

- T&M Synergy Limited: Purchase OrderDocument2 pagesT&M Synergy Limited: Purchase OrderMaina MathengeNo ratings yet

- Reportsumcount New Creati371 Data Chan8 Extention 91 Total 470Document23 pagesReportsumcount New Creati371 Data Chan8 Extention 91 Total 470carthi turboNo ratings yet

- STMT Ac 617255425Document2 pagesSTMT Ac 617255425srkmattaNo ratings yet

- Tender Documents List of ChangesDocument9 pagesTender Documents List of ChangesAnish MohanNo ratings yet

- Re-Installation Solar Panel Cable: NotesDocument5 pagesRe-Installation Solar Panel Cable: NotesTaufik HidayatullahNo ratings yet

- L3 - Static Structure FailureDocument35 pagesL3 - Static Structure FailureAnsh TyagiNo ratings yet

- InventoryDocument12 pagesInventoryjacky arciagaNo ratings yet

- Dokumen Operasional HINO SMALLDocument5 pagesDokumen Operasional HINO SMALLMTS EHSNo ratings yet

- MudmatDocument1 pageMudmatAhmad HaniifNo ratings yet

- D2 Bas21Document4 pagesD2 Bas21nelloNo ratings yet

- Rate List Supplier Mplun PDFDocument4 pagesRate List Supplier Mplun PDFyash100% (1)

- Laporan Pabean Pengeluaran AgustusDocument16 pagesLaporan Pabean Pengeluaran Agustusmutiara afsar maulanaNo ratings yet

- 174e-Boiler VFD Panel-01 (For Ib, FD and Pa Fan) - As BuiltDocument23 pages174e-Boiler VFD Panel-01 (For Ib, FD and Pa Fan) - As BuiltDharun KumarNo ratings yet

- CE DiagramDocument1 pageCE DiagramMaribeth AgubaNo ratings yet

- 1.5 X 45° CH TYP: Isometric ViewDocument1 page1.5 X 45° CH TYP: Isometric ViewChandru ChristurajNo ratings yet

- Data InvoiceDocument272 pagesData InvoiceSherlyana GunawanNo ratings yet

- Riocan Windfields Site PlanDocument4 pagesRiocan Windfields Site PlanChristian ParadisNo ratings yet

- Dma176n Installation Manual Kannad 406 AsDocument48 pagesDma176n Installation Manual Kannad 406 AsADT AvionicsNo ratings yet

- RPT Viewer 1Document1 pageRPT Viewer 1SAWERA TEXTILES PVT LTDNo ratings yet

- CSD Jalangi Feb22 ChecksheetDocument2 pagesCSD Jalangi Feb22 ChecksheetAnindya DeyNo ratings yet

- Power House Rev2 Plan ViewDocument1 pagePower House Rev2 Plan ViewKelvinNo ratings yet

- Power House-Rev2-Plan ViewDocument1 pagePower House-Rev2-Plan ViewKelvinNo ratings yet

- Binder 3Document7 pagesBinder 3qarayev.cavid91No ratings yet

- Calculation NoteDocument1 pageCalculation NoteonlyikramNo ratings yet

- The Best Diode MBR ds31413 ApplicationsDocument4 pagesThe Best Diode MBR ds31413 ApplicationsPopa Catalina-ElenaNo ratings yet

- ds12004 1164508Document5 pagesds12004 1164508Asantha Buddhi HerathNo ratings yet

- Pnumatic DrawingDocument12 pagesPnumatic Drawingtc_sundarNo ratings yet

- Otak International: Oil Storage Volume 2052 Ltr. Sludge Trap Volume 4000 Ltr. Total Capacity Volume 8553 LTRDocument1 pageOtak International: Oil Storage Volume 2052 Ltr. Sludge Trap Volume 4000 Ltr. Total Capacity Volume 8553 LTRnaveenNo ratings yet

- 9192-B000-A00000-0009-0903-0001 - 02 (Existing Cable Schedule)Document15 pages9192-B000-A00000-0009-0903-0001 - 02 (Existing Cable Schedule)Pottem VanithareddyNo ratings yet

- Procurement Tracking RegisterDocument3 pagesProcurement Tracking RegisterfeeeNo ratings yet

- PDF Metalcraft Espan 340 470 Similar Residential Vertical Claddingjan23Document22 pagesPDF Metalcraft Espan 340 470 Similar Residential Vertical Claddingjan23James GraveyNo ratings yet

- Work Balances/fluxwebberDocument1 pageWork Balances/fluxwebberJusto Tenero PocongNo ratings yet

- SPDR BIQ Tracker 2020 - Wheels India BIG EM 12.10.2020Document10 pagesSPDR BIQ Tracker 2020 - Wheels India BIG EM 12.10.2020Durai NaiduNo ratings yet

- SSGC Duplicate Bill20210123 090016Document1 pageSSGC Duplicate Bill20210123 090016Ghulam Baqir MazariNo ratings yet

- 1 - Isometric ViewDocument1 page1 - Isometric ViewVivek SathyaNo ratings yet

- Fatura Digital LighthdjakdndDocument1 pageFatura Digital Lighthdjakdnddaniel garecaNo ratings yet

- 3M0053 Y10 000 01 - Manual Hoist - DRAWINGDocument7 pages3M0053 Y10 000 01 - Manual Hoist - DRAWINGCaspian DattaNo ratings yet

- FW - 00172007 PDFDocument1 pageFW - 00172007 PDFJon DigNo ratings yet

- US20190295733A1 - Pasma Compression Fusion DeviceDocument8 pagesUS20190295733A1 - Pasma Compression Fusion DevicedaveklodavekloNo ratings yet

- Sand CatingDocument4 pagesSand CatingralbarakahNo ratings yet

- GM5340PRK enUS ASTMDocument2 pagesGM5340PRK enUS ASTMDuongthithuydungNo ratings yet

- Std07 Science EM 2Document114 pagesStd07 Science EM 2vijay_music88No ratings yet

- Analytical TechniquesDocument31 pagesAnalytical Techniquesapi-26041653No ratings yet

- MsDs Virkons Use DilutionDocument3 pagesMsDs Virkons Use DilutionAndy RenaisansNo ratings yet

- OIL AND FAT Technology Lectures III - Crude Oil ProductionDocument55 pagesOIL AND FAT Technology Lectures III - Crude Oil ProductionDavid Flores MolinaNo ratings yet

- Gas Absorption PDFDocument21 pagesGas Absorption PDFYash PagareNo ratings yet

- Chemistry Gas Laws AssignmentDocument6 pagesChemistry Gas Laws AssignmentHans Webster LabordoNo ratings yet

- 9701 m16 QP 33Document12 pages9701 m16 QP 33Imran MuhammadNo ratings yet

- Outotec Mineral Processing Solutions: BenefitsDocument12 pagesOutotec Mineral Processing Solutions: BenefitsAndi FaesalNo ratings yet

- Industrial Orientation ReportDocument34 pagesIndustrial Orientation ReportAlvin TeohNo ratings yet

- Pile Foundation Construction Problems and Solutions - Structural GuideDocument13 pagesPile Foundation Construction Problems and Solutions - Structural GuideJaimurugan KNo ratings yet

- 27-Piping Vibration and Stress - JCWDocument9 pages27-Piping Vibration and Stress - JCWpaivensolidsnake100% (1)

- 6 Organic ChiralityDocument7 pages6 Organic ChiralityThinaya JayarathneNo ratings yet

- Is 3589Document21 pagesIs 3589ajit singhNo ratings yet

- Inventaris Obat Dan BHPDocument14 pagesInventaris Obat Dan BHPElly FertianaNo ratings yet

- Capacitive Sensing Technology: 2.1 OverviewDocument28 pagesCapacitive Sensing Technology: 2.1 Overviewsdgpass2585No ratings yet

- MWC Testing and CommissioningDocument8 pagesMWC Testing and CommissioningladaojmNo ratings yet

- Syslab ProfileDocument39 pagesSyslab ProfileNurdiyantoAntNo ratings yet

- BS en 285:2006+a2:2009 Description: Sterilization. Steam SterilizersDocument21 pagesBS en 285:2006+a2:2009 Description: Sterilization. Steam SterilizersMykolaNo ratings yet

- Fatigue of MaterialsDocument40 pagesFatigue of MaterialsnitinNo ratings yet

- Experiment 11 1213Document8 pagesExperiment 11 1213MAYANKNo ratings yet

- Spent Acid From Chlorine DryingDocument2 pagesSpent Acid From Chlorine DryingacckypenrynNo ratings yet

- Https WWW - Archdaily.com 923614 RSV House ArkylabDocument7 pagesHttps WWW - Archdaily.com 923614 RSV House ArkylabNova Chandra adityaNo ratings yet

- Carlos Types of FuelDocument5 pagesCarlos Types of FuelDaiane LavrattiNo ratings yet

- Chemistry Class 11 Lecture 3 (Empirical and Molecular Formula)Document6 pagesChemistry Class 11 Lecture 3 (Empirical and Molecular Formula)allroundersaksham304No ratings yet