Professional Documents

Culture Documents

Us 5214237

Us 5214237

Uploaded by

lucas diz quintana0 ratings0% found this document useful (0 votes)

3 views5 pagesThis patent is for a bullet made of 100% fluorocarbon resin, specifically polytetrafluoroethylene (Teflon). The bullet has multiple annular grooves near the rear end to limit its effective range through air resistance. It also has a hollow point front end to cause it to pulverize on impact, delivering all of its energy within the first few inches of the target to generate significant hydrostatic shock. The goal is to quickly incapacitate targets, especially those under the influence of drugs, with minimal overpenetration risk at short ranges important for law enforcement situations.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent is for a bullet made of 100% fluorocarbon resin, specifically polytetrafluoroethylene (Teflon). The bullet has multiple annular grooves near the rear end to limit its effective range through air resistance. It also has a hollow point front end to cause it to pulverize on impact, delivering all of its energy within the first few inches of the target to generate significant hydrostatic shock. The goal is to quickly incapacitate targets, especially those under the influence of drugs, with minimal overpenetration risk at short ranges important for law enforcement situations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views5 pagesUs 5214237

Us 5214237

Uploaded by

lucas diz quintanaThis patent is for a bullet made of 100% fluorocarbon resin, specifically polytetrafluoroethylene (Teflon). The bullet has multiple annular grooves near the rear end to limit its effective range through air resistance. It also has a hollow point front end to cause it to pulverize on impact, delivering all of its energy within the first few inches of the target to generate significant hydrostatic shock. The goal is to quickly incapacitate targets, especially those under the influence of drugs, with minimal overpenetration risk at short ranges important for law enforcement situations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

US005214237A

United States Patent (19) (11 Patent Number: 5,214,237

McArthur (45) Date of Patent: May 25, 1993

(54) FLUOROCARBON RESIN BULLET AND 4,193,348 3/1980 Halverson. 02/509

METHOD OF MAKNG SAME 4,245,557 1/1981 Knappworst et al. .. ... 102/50

4,251,079 2/1981 Earl et al. ............... ... 102/501

75 Inventor: Bruce D. McArthur, 8735 Dixie 4,290,365 9/1981 Dreyer ............ . 102/532

Hwy., Clarkston, Mich. 48016 4,708,065 11/1987 Schilling et al. .................... 102/501

(73) Assignees: Bruce D. McArthur; Carolyn M. FOREIGN PATENT DOCUMENTS

McArthur, both of Clarkston, Mich. 784985 5/1968 Canada.

(21) Appl. No.: 847,862 1092349 11/1960 Fed. Rep. of Germany .

2551196 2/1976 France .

22) Filed: Feb. 28, 1992 243.676 7/1978 France.

OTHER PUBLICATIONS

Related U.S. Application Data

S. Tyles in Small Arms Projectiles, by Green, Army

(63) Continuation of Ser. No. 550,337, Jul. 9, 1990, aban Ordnance, May-Jun, 1932, pp. 395-401.

doned.

Primary Examiner-Harold J. Tudor

51 Int, C. ......................... F42B 8/14; F42B 12/34; Attorney, Agent, or Firm-Streich Lang

F42B 12/00

(52) U.S. C. .................................... 102/501; 102/506; (57) ABSTRACT

102/509; 102/529 A bullet is provided which is substantially 100% pure

(58) Field of Search ................ 102/501, 502,507-511, fluorocarbon resin. In the preferred embodiment a fluo

102/529, 532,506 rocarbon resin in the form of polytetrafluoroethylene,

(56) References Cited preferably Teflon from E.I. Dupont De Nemours Co.,

U.S. PATENT DOCUMENTS Inc. of New Jersey, also known as Dupont, is provided

with multiple annular grooves near the rear end and a

3,326, 133 6/1967 Stadler et al. ....................... 102/529 hollow point front end. The bullet in the preferred

3,580, 178 5/1971 Kopsch et al. . embodiment is characterized by having a high muzzle

3,802,345 4/1974 La Costa ............................. 102/522 velocity, a very short effective range, and pulverizes on

3,861,311 1/1975 Bilsbury . impact so as to deliver considerable hydrostatic shock

3,902,683 9/1975 Bilsbury . ing effect by delivery of all of its energy within the first

3,972,286 8/1976 Canon ................................. 102/507 two to three inches of target depth.

4,005,660 2/1977 Pichard ............................... 102/50

4,008,667 2/1977 Look .

4,063,511 12/1977 Bullard ................................ 102/501 4 Claims, 1 Drawing Sheet

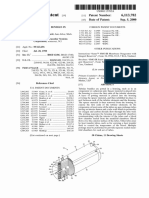

U.S. Patent May 25, 1993 5,214,237

5,214,237 2

1

mize ricochet. Stadler et al utilizes a blunt bullet end to

FLUOROCARBON RESIN BULLET AND METHOD increase air resistance and reduce effective range of the

OF MAKING SAME bullet.

Bilsbury U.S. Pat. No. 3,902,683 is a patent which

This is a continuation of application Ser, No. 5 further teaches use of plastic bullets for target practice

07/550,337 filed Jul. 9, 1990, abandoned. to reduce ricochet.

SUMMARY OF THE INVENTION

Bilsbury U.S. Pat. No. 3,861,311 teaches a combina

tion of a plastic bullet with an incendiary materialso as

A bullet is provided which is formed of a substan to create an armor piercing bullet which utilizes a plas

tially cylindrical core material which is substantially a O tic jacket which ruptures on impact and lets a metal

pure fluorocarbon resin that in the preferred embodi penetrator pierce the target with the assistance of the

ment is polytetrafluoroethylene manufactured by E.I. incendiary material.

Dupont De Nemours Co., Inc. of New Jersey, also Look U.S. Pat. No. 4,008,667 is a patent which

known as Dupont, under the trademark Teflon. teaches use of aerodynamic brakes in the bullet to mini

Several annular grooves are cut in the rear half of the 15 mize flight distances.

bullet, which is characterized by having extremely high Flight distances can also be reduced by providing a

muzzle exit velocity. The grooves provide air resistance bullet with annular grooves, such as taught in French

so as to limit the effective range of the bullet. Patent 2,551,196 and German Patent 1 092. 349 and

A hollow point is provided in the bullet in the pre French Patent 2,431,676.

ferred embodiment so as to cause the bullet to pulverize 20 However, none of these Patents teach the use of a

on impact and create considerable hydrostatic shock bullet which is manufactured of a pure fluorocarbon

effect in the target by delivery of substantially all of the resin for any purpose. The high melting point of a fluo

bullet energy within the first two to three inches of rocarbon resin, particularly the polytetrafluoroethylene

depth in the target, which generates a considerable used in the preferred embodiment which is commonly

shock wave in the target. 25 manufactured by Dupont under the trademark Teflon,

requires such high temperatures for molding that a

BACKGROUND OF THE INVENTION conventional mold has short lifetime.

Law enforcement personnel have considerable need None of the various prior art patents specifically

for an effective bullet which can deliver a tremendous address or solve the problem of such targets as a drug

hydrostatic shock effect to its target while having lim crazed dangerous human having to be stopped immedi

ited range. ately at short distances, which would require a bullet

When deadly force is used within close range, a law having minimal penetration and maximum hydrostatic

enforcement officer must be able to immediately stop a shock effect.

criminal. Some criminals, particularly those who have It is therefore a primary object of this invention to

been stimulated by mind altering drugs, continue to 35 provide a bullet which is characterized by:

function in an erratic manner when hit with conven A. Tremendous hydrostatic shock effect in a target.

tional bullets. Several conventional metal bullets having B. Tremendous muzzle velocity upon exiting a

high penetration characteristics may pass through the weapon.

body of such a criminal without bringing the criminal to C. Limited range.

a stop because such bullets do not provide sufficient D. Reasonable cost.

hydrostatic shock effect to such a target. DESCRIPTION OF THE DRAWINGS

Law enforcement officials in close quarters also have

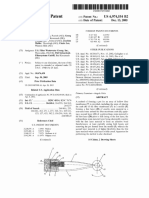

a need for a bullet which flies true at short range but FIG. 1 is a side perspective front view with parts

which has a limited range so as to minimize the danger removed of a bullet embodying the principles of the

to innocent persons outside the useful range of the bul 45 subject invention in the preferred embodiment.

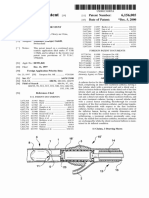

let. FIG. 2 is a perspective end view of the bullet in FIG.

Bullet inventors generally have attempted to maxi 1 showing the hollow point configuration.

mize penetration capability of their bullets. Bullets con FIG. 3 is a perspective end view of the rear end of the

ventionally are made to fly true by providing rifling in bullet in FIG. 1.

the barrel of a rifle or other weapon by using several DESCRIPTION OF THE PREFERRED

grooves down the barrel of the weapon to impart rota EMBOOMENT

tion spin to the bullet around its axis.

Bullets customarily are made of a metal and may be A bullet 10 which embodies the principles of the

coated with non-metal materials to reduce friction subject invention is shown in FIG. 1. In the preferred

when traveling down the rifling of a weapon barrel and 55 embodiment bullet 10 is made of a core material 21

to increase target penetration. Kopsch U.S. Pat. No. which the preferably comprises substantially a pure

3,580,178 is a patent which teaches the use of a fluoro fluorocarbon resin, preferably polytetrafluoroethylene.

carbon resin such as polytetrafluoroethylene, which is This material is commonly manufactured by Dupont as

most commonly manufactured by E.I. Dupont De Ne stated under the trademark Teflon.

mours Co., Inc. of New Jersey, also known as Dupont, Bullet 10, as shown, has a substantially cylindrical

under the trademark Teflon, as a low friction coating on body. More particularly, bullet 10 includes substantially

a bullet to reduce friction in the firing weapon and cylindrical exterior surface 14, a front end 16, and a rear

increase penetration in the target. end 18. Bullet 10 is symmetrical about an axis 20 which

Non-metal bullets have been occasionally invented defines the center of the bullet and the position of the

and used. Stadler et al 784,985 is a Canadian Patent cylindrical surface 14.

which teaches use of plastic bullets to make target an In FIG. 1 surface 14 of bullet 10 is partially removed

munition which is cheaper than metal bullets and which to show that the central portion of the front end 16

easily breaks upon impact with the target so as to mini preferably includes a cylindrical hole 22 drilled in front

3

5,214,237

4.

end 16 and a truncated conical interior surface 24. Sur groove. Side sections 42-44 between grooves 26-29 in a

face 24 may be made by countersinking on hole 22 so as bullet about 0.690 inches in length are each approxi

to provide a hollow point configuration in front end 16 mately 0.060 inches in length between grooves 26-29.

for reasons which will become apparent. Rear edges 34-37 of grooves 26-29 participate in pro

In FIG. 1 bullet 10 is also provided with several 5 ducing aerodynamic dragon surface 14 so as to limit the

annular grooves 26-29 which in the preferred embodi range of bullet 10, Bullet 10 will fly true for a range of

ment each are positioned in planes which are substan approximately 100 yards, but the aerodynamic drag

tially at right angles to axis 20. Grooves 26-29 have slows bullet 10 to a speed where a person could catch it

front edges 30-33 and rear edges 34-37. The respective in their bare hand at a range of approximately 200 feet.

front and rear edges of grooves 26-29 in the preferred 10 Bullet 10 is therefore especially suitable for use in inte

embodiment are connected by truncated conical bottom rior locations to minimize bystander risk. Persons

groove surfaces 38-41, respectively. versed in the art will appreciate that bystanders outside

In the preferred embodiment each line in each of the a building can be injured by weapons fired in the build

truncated conical bottom groove surfaces 38-41 which ing which penetrate the building wall in a wood frame

intersects the axis 20 does so at a about 60 degree angle. 5 building.

Persons versed in the art will appreciate that bullet 10 At a range of 10 feet the hydrostatic shock effect of

may be manufactured in various sizes and configura the bullet is so awesome that it will blast a four inch

tions for various caliber weapons without departing diameter hole four inches deep into a standard gelatin

from the spirit of the invention. w target designed to simulate a human body.

A typical 38 caliber metal bullet with a usual gun 20 Teflon has such a high melting temperature that it is

powder load propelling it has a muzzle exit velocity of impractical to manufacture a bullet through a molding

1,100 feet per second. Muzzle exit velocity will vary process. Efforts to do so resulted in a conventional mold

depending upon the size of the barrel in the weapon. being worn out after making only approximately 400

The Teflon bullet 10 in accordance with a preferred bullets.

embodiment of the invention weighs less than a metal 25 The preferred manufacturing steps for manufacture

bullet and the inherent slippery nature of Teflon mini of bullet 10 therefore include the steps of forming a core

mizes drag energy loss when traveling the rifling in the material 12 from a fluorocarbon resin cylinder, boring a

barrel of the weapon. hole in the front end 16 so as to form a hollow point,

Bullet 10 in a 38 caliber size therefore has been tested countersinking the hole, and cutting annular grooves in

to exit a four inch barrel with a muzzle velocity of 30 the cylinder side surface 14 so that each of the annular

approximately 2,800 feet per second. The muzzle exit grooves 26-29 are substantially defined by a plane at

velocity is in excess of 3,000 feet per second from a six right angles to axis 20.

inch barrel. Bullet 10 may be modified without departing from

Kinetic energy is demonstrated by the formula that the spirit of this invention for purposes of achieving a

kinetic energy is equal to the mass of the object times 35 bullet 10 having different flight and impact characteris

the square of the velocity divided by two. tics. Such modifications include but are not limited to

Therefore even though the mass of bullet 10 in accor the following suggestions.

dance with the present invention is less than the mass of If front end 16 is provided with the truncated conical

a similar metal bullet, bullet 10 has a greater kinetic surface 24 but does not have the cylindrical hole 22

energy than its counterpart metal bullet or metal bullet 40 extending deeper than surface 24, the bullet likely will

with Teflon coating such as that described in the not disintegrate upon impact but instead will penetrate

Kopsch U.S. Pat No. 3,580,178. farther and may even penetrate body armor. In accor

The hollow point configuration of bullet 10 in front dance with the preferred embodiment of the invention,

end 16 provides substantially instantaneous disintegra hole 22 is drilled deeper than interior surface 24 to

tion of bullet 10 upon impact with a target. Test firings 45 prevent penetration of bullet 10 into objects, such as

into standard masses which approximate the construc body armor.

tion of a human body have demonstrated that the bullet If truncated conical interior surface 24 has a smaller

10 on impact substantially disintegrates into particles diameter but the same depth, bullet 10 may not disinte

approximately the size of ordinary table salt and have grate upon impact and can penetrate body armor. In the

demonstrated that substantially all of the kinetic energy preferred embodiment if the outside diameter of side

of bullet 10 is dissipated within the first two or three surface 14 is 0.357 inches, a standard number 4 counter

inches of impacting the target. drill is used up to its shoulder to create interior surface

Bullet 10 at short range therefore has demonstrated a 24 at the appropriate diameter so as to prevent body

tremendous hydrostatic shock effect and creates a very armor penetration.

high surface wound on impact and is designed to imme 55 Annular grooves 26-29 are provided to maintain

diately stop an assailant, including persons functioning stability in flight by providing an exterior aerodynamic

under the influence of mind altering drugs which would drag which keeps bullet 10 pointed forward rather than

otherwise make then less susceptible to being stopped letting it tumble. Changing the groove width, depth,

by bullets which merely penetrate a target. spacing or configuration may cause bullet 10 to be un

The disintegration nature of the bullet 10 takes place stable in flight, resulting in tumbling and possible

upon impact with any object, including the target and breakup during flight. If grooves 26-29 are too shallow

background. Therefore if the target is missed, bullet 10 bullet 10 becomes rigid and won't fully disintegrate

disintegrates upon striking the background without upon impact and may ricochet. In the preferred em

ricochet resulting to threaten bystanders. bodiment for a 0.357 inch diameter side surface 14 the

Grooves 26 trough 29 have been developed so that in minimum diameter at the deepest part of grooves 26-29

a typical bullet measuring approximately 0.69 inches in is 0.307 inches.

length the grooves measure 0.10 inches from the rear The desirable flight characteristics of a Teflon bullet

edge of one groove to the rear edge of the adjacent are believed to be unique to Teflon. Tests have shown

5,214,237

5 6 -

that other common non-metallic materials are not ap each of said planes being substantially orthogonal

propriate for bullet 10 nor will they give the desired to said axis;

operating characteristics as described above. a generally cylindrical axial blind bore disposed

By way of example, if bullet 10 is made of a rigid within said front end of said body, wherein said

material such as nylon it becomes an armor piercing 5 blind bore has a substantially uniform diameter

device. If it is made of various plastic materials, the along the length thereof; and

structural integrity of bullet 10 is so weak that it disinte said blind bore terminating at a truncated conical

grates in flight. surface which extends from a front edge of said

Teflon provides the unique capacity for bullet 10 to bore to an outermost portion of said front end of

function as described herein because it permits tremen 10 said body, wherein the diameter of said conical

dous muzzle velocity due to its light weight and mini surface at said front end is larger than said uniform

mal friction in the firing weapon so as to provide tre diameter of said axial bore.

mendous hydrostatic shock effect at close range while 2. The bullet according to claim 1, wherein each of

preventing ricochet and long range hazard to bystand said grooves includes a front edge, a rear edge and a

es. 15 substantially frusto-conical surface extending therebe

I claim: tween, said frusto-conical surface having a front end

1. A bullet consisting of: mating with said groove front edge and a rear end mat

a polytetrafluoroethylene resin body disposed about a ing with said groove rear edge.

central axis, said body having a front end, a rear 3. The bullet according to claim 2, wherein the diam

end, and a generally cylindrical exterior surface 20 eter of each of said grooves at said rear end of said

extending therebetween, said rear end of said body frusto-conical surface is less than the diameter of said

being solid and having a planar rear face; groove at said groove front edge.

a plurality of annular grooves in said exterior surface 4. The bullet according to claim 2, wherein said frus

to facilitate disintegration of the bullet upon impact to-conical surface is disposed at about a 60-degree angle

with a target, said grooves being positioned only 25 from said central axis of the bullet.

proximate said rear end in a plurality of planes,

30

35

45

50

55

65

You might also like

- US5241749 Rod Baffle DesignDocument12 pagesUS5241749 Rod Baffle Designashish.itbhuNo ratings yet

- Geotechnical Characteristics of Copper Mine TailingsDocument12 pagesGeotechnical Characteristics of Copper Mine TailingsJamie CuttingNo ratings yet

- Patent Number 5194299Document11 pagesPatent Number 5194299Lope Nam-iNo ratings yet

- US6169135Document13 pagesUS6169135NidaNo ratings yet

- Us5844037 PDFDocument12 pagesUs5844037 PDFKelly GuerreroNo ratings yet

- United States Patent (10) Patent No.: US 6, 180,203 B1: Unkles (45) Date of Patent: Jan. 30, 2001Document8 pagesUnited States Patent (10) Patent No.: US 6, 180,203 B1: Unkles (45) Date of Patent: Jan. 30, 2001G DragonNo ratings yet

- US7827620Document9 pagesUS7827620Devansh ChhajlaniNo ratings yet

- United States Patent (191: Epperson, JRDocument6 pagesUnited States Patent (191: Epperson, JRAparnaNo ratings yet

- Us 5342560Document7 pagesUs 5342560Ghina Fatikah SalimNo ratings yet

- US7946356Document53 pagesUS7946356Ahmad Reza FarokhiNo ratings yet

- United States Patent: (75) Inventors: Franz-Josef Dietzen, Hassloch (DE)Document8 pagesUnited States Patent: (75) Inventors: Franz-Josef Dietzen, Hassloch (DE)Ghina Fatikah SalimNo ratings yet

- Us 7908972Document23 pagesUs 7908972Abas NjarkhatirNo ratings yet

- United States Patent (19) 11 Patent Number: 6,113,782Document22 pagesUnited States Patent (19) 11 Patent Number: 6,113,782Vansala GanesanNo ratings yet

- High Temperature Superconducting Cable US6794579Document10 pagesHigh Temperature Superconducting Cable US6794579Leon MutambalaNo ratings yet

- United States Patent (10) Patent No.: US 8,151,529 B2: Weidmann Et Al. (45) Date of Patent: Apr. 10, 2012Document9 pagesUnited States Patent (10) Patent No.: US 8,151,529 B2: Weidmann Et Al. (45) Date of Patent: Apr. 10, 2012Akshay GamreNo ratings yet

- United States Patent (19) 11 Patent Number: 5,935,885Document12 pagesUnited States Patent (19) 11 Patent Number: 5,935,885Yogesh KumarNo ratings yet

- United States Patent (10) Patent No.: US 6,412,231 B1Document10 pagesUnited States Patent (10) Patent No.: US 6,412,231 B1Sharvin ZacariasNo ratings yet

- United States Patent (19) 11 Patent Number: 5,997,619Document13 pagesUnited States Patent (19) 11 Patent Number: 5,997,619nooraaNo ratings yet

- US6156005Document7 pagesUS6156005Pardeep SharmaNo ratings yet

- United States Patent 19: Harth, II Et Al. 11 Patent Number: 5,661,241 45 Date of Patent: Aug. 26, 1997Document16 pagesUnited States Patent 19: Harth, II Et Al. 11 Patent Number: 5,661,241 45 Date of Patent: Aug. 26, 1997TYO WIBOWONo ratings yet

- US6110313Document12 pagesUS6110313Sayyed Abdul QayyumNo ratings yet

- US4802288 (Rotary Dryer) PDFDocument10 pagesUS4802288 (Rotary Dryer) PDFmitaNo ratings yet

- United States Patent (10) Patent No.: US 6,282,863 B1: Christian Et Al. (45) Date of Patent: Sep. 4, 2001Document20 pagesUnited States Patent (10) Patent No.: US 6,282,863 B1: Christian Et Al. (45) Date of Patent: Sep. 4, 2001Munir KadernaniNo ratings yet

- Halliburton Primary CementingDocument12 pagesHalliburton Primary CementingLara CitlalliNo ratings yet

- United States Patent (10) Patent No.: US 6,685,832 B2: Mahendran Et Al. (45) Date of Patent: Feb. 3, 2004Document31 pagesUnited States Patent (10) Patent No.: US 6,685,832 B2: Mahendran Et Al. (45) Date of Patent: Feb. 3, 2004Vansala GanesanNo ratings yet

- United States Patent: Osajda Et AlDocument9 pagesUnited States Patent: Osajda Et Almcx_123No ratings yet

- United States Patent (19) : Aerospatiale, FranceDocument7 pagesUnited States Patent (19) : Aerospatiale, Franceingeniomeca8800No ratings yet

- US6200692 (Container)Document8 pagesUS6200692 (Container)cliff hsuNo ratings yet

- Is So: (12) United States PatentDocument20 pagesIs So: (12) United States PatentСлэйтер Строительная компанияNo ratings yet

- Lapping Apparatus and Process With Two Opposed Lapping PlatensDocument33 pagesLapping Apparatus and Process With Two Opposed Lapping PlatensEduardo RazerNo ratings yet

- US6908288Document14 pagesUS6908288mohammad293No ratings yet

- US8069593Document9 pagesUS8069593PUVAN TSTNo ratings yet

- US6290739Document19 pagesUS6290739Loka ThaniNo ratings yet

- Brevet 2 Filetare VartejDocument11 pagesBrevet 2 Filetare VartejirinaNo ratings yet

- CC Relief DoorDocument7 pagesCC Relief DoorHim SatiNo ratings yet

- Detector PiezoelectricoDocument6 pagesDetector PiezoelectricoSalvador EscobarNo ratings yet

- United States Patent (10) Patent No.: US 6,293,107 B1: Kitagawa Et Al. (45) Date of Patent: Sep. 25, 2001Document19 pagesUnited States Patent (10) Patent No.: US 6,293,107 B1: Kitagawa Et Al. (45) Date of Patent: Sep. 25, 2001Burak PalaNo ratings yet

- United States Patent (10) Patent No.: US 6,343,550 B1: Feesler (45) Date of Patent: Feb. 5, 2002Document9 pagesUnited States Patent (10) Patent No.: US 6,343,550 B1: Feesler (45) Date of Patent: Feb. 5, 2002Quý Đình Mai MaiNo ratings yet

- Venova PatentDocument40 pagesVenova PatentJames PennNo ratings yet

- US7743601Document4 pagesUS7743601Alien GmpNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 6,933,430 B2 Oskorep (45) Date of Patent: Aug. 23, 2005Document14 pagesUnited States Patent: (12) (10) Patent N0.: US 6,933,430 B2 Oskorep (45) Date of Patent: Aug. 23, 2005Walied SamiNo ratings yet

- Grenzebach Patent 2005Document8 pagesGrenzebach Patent 2005Muhammed BALIKÇINo ratings yet

- US8398905Document9 pagesUS8398905Ator VastatinNo ratings yet

- United States Patent (19) 11 Patent Number: 5,937,665: Kiessel Et Al. (45) Date of Patent: Aug. 17, 1999Document9 pagesUnited States Patent (19) 11 Patent Number: 5,937,665: Kiessel Et Al. (45) Date of Patent: Aug. 17, 1999hussainNo ratings yet

- Armalite Bolt PatentDocument10 pagesArmalite Bolt PatentryNo ratings yet

- United States Patent (10) Patent No.: US 8.468,753 B2Document29 pagesUnited States Patent (10) Patent No.: US 8.468,753 B2Dhrubajyoti BoraNo ratings yet

- United States Patent (19) 11 Patent Number: 5,158,395Document17 pagesUnited States Patent (19) 11 Patent Number: 5,158,395Faris MuizNo ratings yet

- United States Patent: (10) Patent No.: US 6,974,554 B2Document8 pagesUnited States Patent: (10) Patent No.: US 6,974,554 B2Vansala GanesanNo ratings yet

- United States Patent: Pipkorn Et Al. Sep. 30, 2003Document16 pagesUnited States Patent: Pipkorn Et Al. Sep. 30, 2003Juan OrtegaNo ratings yet

- United States Patent (19) : (45) Date of Patent: Dec. 8, 1998Document6 pagesUnited States Patent (19) : (45) Date of Patent: Dec. 8, 1998nagy_andor_csongorNo ratings yet

- US8749333Document19 pagesUS8749333Anonymous GIIncAfLRNo ratings yet

- US6926223Document5 pagesUS6926223José Roberto LazoNo ratings yet

- US6257764Document16 pagesUS6257764waqargilllNo ratings yet

- United States Patent (19) 11 Patent Number: 6,124,044: Swidler (45) Date of Patent: Sep. 26, 2000Document7 pagesUnited States Patent (19) 11 Patent Number: 6,124,044: Swidler (45) Date of Patent: Sep. 26, 2000Alexander Franco CastrillonNo ratings yet

- United States Patent (10) Patent No.: US 8.454.296 B2Document18 pagesUnited States Patent (10) Patent No.: US 8.454.296 B2Yu YangNo ratings yet

- US5715763Document8 pagesUS5715763Fábio Henrique Lucas da CostaNo ratings yet

- Bolas Ver VerDocument6 pagesBolas Ver VerpatgabrielNo ratings yet

- US6840311Document11 pagesUS6840311Pardeep SharmaNo ratings yet

- United States Patent (10) Patent No.: US 7.624,666 B1: O'Neill Et Al. (45) Date of Patent: Dec. 1, 2009Document9 pagesUnited States Patent (10) Patent No.: US 7.624,666 B1: O'Neill Et Al. (45) Date of Patent: Dec. 1, 2009Turk SoloNo ratings yet

- Us5955039 PDFDocument8 pagesUs5955039 PDFMayur B NeveNo ratings yet

- STR-DA1200ES v1.1 PDFDocument125 pagesSTR-DA1200ES v1.1 PDFGomoiu BogdanNo ratings yet

- Electric Flight 1DB18ME040Document10 pagesElectric Flight 1DB18ME040Karthik NNo ratings yet

- National Programme For Control of Blindness PDFDocument23 pagesNational Programme For Control of Blindness PDFRabiu Hassan MusaNo ratings yet

- Samsung CLX-2160 (Service Manual)Document158 pagesSamsung CLX-2160 (Service Manual)info3551No ratings yet

- Glossary of Spirit TermsDocument6 pagesGlossary of Spirit TermssunwayjbNo ratings yet

- B31.1 Vs B31.3Document18 pagesB31.1 Vs B31.3Muhammed Ali Noureddeen100% (2)

- Sec eDocument2 pagesSec eVicter PaulNo ratings yet

- Homogeneous and Homothetic Functions PDFDocument8 pagesHomogeneous and Homothetic Functions PDFSatyabrota DasNo ratings yet

- RTVM 2014Document276 pagesRTVM 2014Che Amri Che AzmiNo ratings yet

- Two Separate WorldsDocument14 pagesTwo Separate WorldsmaryfeNo ratings yet

- Hosts and Guests - WorksheetDocument2 pagesHosts and Guests - WorksheetbeeNo ratings yet

- Project On UnileverDocument27 pagesProject On Unileverirfan103158100% (1)

- Jan W. Gooch, Biosketch - Jan. 2015Document15 pagesJan W. Gooch, Biosketch - Jan. 2015jan w goochNo ratings yet

- 104 Grammar-Test 1Document11 pages104 Grammar-Test 1Shwetha TpNo ratings yet

- Aristotle and Virtue Ethics 1Document3 pagesAristotle and Virtue Ethics 1Hyuna KimNo ratings yet

- Summary of Notice of Privact Practice Conditions of Admission andDocument3 pagesSummary of Notice of Privact Practice Conditions of Admission andShahho MustafaNo ratings yet

- Spermatogenesis & Sperm Maturation : Dr. Amin JanDocument33 pagesSpermatogenesis & Sperm Maturation : Dr. Amin JanSalman XahirNo ratings yet

- Models of Management in Socio-Political Environment..: Presented By.. The A' Factors. Roll No. 1-9Document13 pagesModels of Management in Socio-Political Environment..: Presented By.. The A' Factors. Roll No. 1-9amritaagarwal23No ratings yet

- Shark Finning Final DraftDocument11 pagesShark Finning Final Draftilana lutzNo ratings yet

- BELBIN Team Role Summary DescriptionsDocument1 pageBELBIN Team Role Summary DescriptionsashairwaysNo ratings yet

- Rahul 132Document67 pagesRahul 132gulatisrishti15No ratings yet

- Who Invented The Periodic TableDocument1 pageWho Invented The Periodic TableJny An AparenteNo ratings yet

- CinemaDocument9 pagesCinemaAlexNo ratings yet

- Douluo Dalu V18 - Three Spirit BonesDocument144 pagesDouluo Dalu V18 - Three Spirit Bonesenrico susantoNo ratings yet

- CSEC IT Study GuideDocument21 pagesCSEC IT Study GuideNaje CampbellNo ratings yet

- Medieval PhilosophyDocument52 pagesMedieval PhilosophyMelkamNo ratings yet

- Manual de Utilizare Sursa de Alimentare 27.6 V5 A Pulsar EN54-5A17 230 VAC50 HZ Montaj Aparent LEDDocument40 pagesManual de Utilizare Sursa de Alimentare 27.6 V5 A Pulsar EN54-5A17 230 VAC50 HZ Montaj Aparent LEDGabriel SerbanNo ratings yet

- DWIN LCD Display With ApplicationDocument23 pagesDWIN LCD Display With ApplicationcihanNo ratings yet

- Computer Methods and Programs in BiomedicineDocument9 pagesComputer Methods and Programs in BiomedicineAKSNo ratings yet