Professional Documents

Culture Documents

E 9018-B9 Product-Sheet

E 9018-B9 Product-Sheet

Uploaded by

juanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E 9018-B9 Product-Sheet

E 9018-B9 Product-Sheet

Uploaded by

juanCopyright:

Available Formats

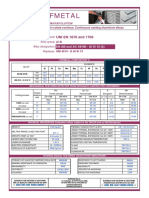

E 9018-B9

CATEGORY SMAW Stick Electrodes

TYPE Basic, Cr and Mo-alloyed electrode for heat resistant steels T/P91 and T/P92

APPLICATIONS Headers, main steam piping and turbine casings, in fossil fueled power generating plants. Oil refineries and coal liquefaction and gasification

plants. Preheat and Interpass temperature 200°C - 300°C.

PROPERTIES CEWELD E 9018-B9 is designed to weld equivalent ‘type T91’ T92 CrMo steels modified with small additions of niobium and Vanadium to give

improved long term creep properties. These consumables are specifically intended for high integrity structural service at elevated temperature so

the minor alloy additions responsible for its creep strength are kept above the minimum considered necessary to ensure satisfactory performance.

In this case, weldments will be weakest in the softened (intercritical) HAZ region of parent material, as indicated by so-called ‘type IV’ failure in

transverse weld creep tests.

CLASSIFICATION AWS A 5.5: E 9018-B9

EN ISO 3580-A: E CrMo91 B42 H5

F-nr 4

FM 3

SUITABLE FOR X11CrMo9-1, X12CrMo9.1, X20CrMoV11-1, X20CrMoV12-1, 1.7386, 1.4922, 1.4935 ASTM: A 199Gr.T9, A335Gr.P9, A351, A213/213M

Gr.T/P91Gr.T/P92

APPROVALS CE

WELDING POSITIONS:

TYPICAL WELD DEPOSIT WEIGHT %

C Si Mn P S Cr Ni Mo V Nb N

0.09 0.3 0.9 0.01 0.01 9 0.4 0.9 0.2 0.06 0.4

ALL WELD MECHANICAL PROPERTIES

Heat RP0,2 Rm A5 Impact Energy (J) ISO-V

Treatment MPa MPa (%) RT

As Welded / 550 700 21 55

WELDING PARAMETERS / PACKING

WELDING PARAMETERS WELDING PARAMETERS WELDING PARAMETERS PACKING PACKING PACKING

D (MM) LENGTH (MM) CURRENT (A) KG / CAN KG / 6PACK KG / 1000

2.5 300 65-85 2.5 15 19.8

3.2 350 100-130 2.6 15.6 36.4

4.0 450 140-180 3.1 18.6 66.7

5.0 450 180-230 3.1 18.6 101.9

REDRYING TEMPERATURE 400°C / 1 hr

GAS ACCORDING EN 14175

CERTILAS - THE FILLER METAL SPECIALIST Page 1 / 1 WWW.CERTILAS.COM/DISCLAIMER

You might also like

- Billy The Unicorn RainbowDocument5 pagesBilly The Unicorn Rainbowtheyjunky100% (1)

- Astm F714Document12 pagesAstm F714juan100% (1)

- Frecuencia de Ensayos Tabla 8.1 AWS D1.5Document1 pageFrecuencia de Ensayos Tabla 8.1 AWS D1.5juanNo ratings yet

- Tabla PDFDocument3 pagesTabla PDFjuanNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- Categorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBDocument1 pageCategorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBabhishekNo ratings yet

- AlMg 4.5Mn Product-SheetDocument1 pageAlMg 4.5Mn Product-SheetLuca MemoliNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocument2 pagesChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNo ratings yet

- B - Boehler DMO-IG - Ss - en - 5 PDFDocument1 pageB - Boehler DMO-IG - Ss - en - 5 PDFDimitris NikouNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Beryllium Nickel Strip: High Strength at Elevated TemperatureDocument4 pagesBeryllium Nickel Strip: High Strength at Elevated TemperatureImags GamiNo ratings yet

- Contact Material Beryllium Nickel Be NiStrip360 PDFDocument4 pagesContact Material Beryllium Nickel Be NiStrip360 PDFImags GamiNo ratings yet

- CWC-BookletF1 17Document1 pageCWC-BookletF1 17satnamNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- CWC-BookletF1 24Document1 pageCWC-BookletF1 24Jagannath SahuNo ratings yet

- RK1B7 A193b7m - A193b7 A193b7m EngDocument1 pageRK1B7 A193b7m - A193b7 A193b7m EngNarimane BentyNo ratings yet

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 pageAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNo ratings yet

- Midalloy ER410Document2 pagesMidalloy ER410Alessandro sergio de souzaNo ratings yet

- Union Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantDocument1 pageUnion Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantbrayanNo ratings yet

- Böhler Fox CM 5 KB: Classifi CationsDocument1 pageBöhler Fox CM 5 KB: Classifi CationsBranko FerenčakNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- Böhler CM 5-Ig: TIG Rod, High-Alloyed, Creep ResistantDocument1 pageBöhler CM 5-Ig: TIG Rod, High-Alloyed, Creep Resistantwesley59No ratings yet

- item22-LNT 502Document1 pageitem22-LNT 502VVan TanNo ratings yet

- BS en 1706 - En44100 PDFDocument2 pagesBS en 1706 - En44100 PDFDhamodaran RNo ratings yet

- En 44100Document2 pagesEn 44100hiren_mistry55No ratings yet

- Basic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660Document1 pageBasic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660mohamed AdelNo ratings yet

- Kaiser Aluminum 7075 Rod and BarDocument2 pagesKaiser Aluminum 7075 Rod and BarH VNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- Böhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantDocument1 pageBöhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantSerhii MishchenkoNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Document1 pageAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNo ratings yet

- Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument3 pagesMatmatch Is Trusted by 2 Million+ Engineers and Product Developers Each Yearhardeep SinghNo ratings yet

- Autrod 1264Document2 pagesAutrod 1264Anonymous yL7oldKNo ratings yet

- Carbo 4370 Mpr-E307Document1 pageCarbo 4370 Mpr-E307ali torabiNo ratings yet

- 02112015000000B - Boehler FOX EV 65 - CeDocument1 page02112015000000B - Boehler FOX EV 65 - CeMohamed AdelNo ratings yet

- Midalloy ER80S B6 EB6Document1 pageMidalloy ER80S B6 EB6joel cisnerosNo ratings yet

- TDS - Nimrod C276KSDocument1 pageTDS - Nimrod C276KSImmalatulhusnaNo ratings yet

- Ador Welding Cromoten D For c5 & f5 WeldingDocument1 pageAdor Welding Cromoten D For c5 & f5 WeldingShar MathewNo ratings yet

- Arcelormittal 9 Percent NickelDocument5 pagesArcelormittal 9 Percent NickelAdisak AumpiemNo ratings yet

- Alu MN: Description and ApplicationDocument1 pageAlu MN: Description and Applicationmohamed AdelNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- WG-WPS-0099 Rev 2Document1 pageWG-WPS-0099 Rev 2mb.pipingNo ratings yet

- Sandvik 254 Smo Tube and Pipe, Seamless: DatasheetDocument9 pagesSandvik 254 Smo Tube and Pipe, Seamless: DatasheetReadersmoNo ratings yet

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Datasheet Sandvik 2re69 enDocument9 pagesDatasheet Sandvik 2re69 enMuzammilNo ratings yet

- 308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsDocument1 page308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsFilipe CordeiroNo ratings yet

- Ati 2205 PDFDocument6 pagesAti 2205 PDFGetapo RaminNo ratings yet

- E 8018 B2Document1 pageE 8018 B2ElMacheteDelHuesoNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-MoDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-Mobaskaran ayyapparajNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Ceweld - 316h TigDocument1 pageCeweld - 316h TigFilipe CordeiroNo ratings yet

- Ceweld - 316H TigDocument1 pageCeweld - 316H TigFilipe CordeiroNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- Citorail OerlikonDocument1 pageCitorail OerlikonGiancarlo BlandinoNo ratings yet

- Automig 90S-G / Tigfil 90S-G: Classification: ApprovalsDocument1 pageAutomig 90S-G / Tigfil 90S-G: Classification: ApprovalsJagannath SahuNo ratings yet

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Document2 pagesAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNo ratings yet

- B - Boehler FOX CM 9 KB - Se - en - 5Document1 pageB - Boehler FOX CM 9 KB - Se - en - 5misthahNo ratings yet

- Böhler Fox CN 13/4 Supra: Classifi CationsDocument1 pageBöhler Fox CN 13/4 Supra: Classifi CationsBranko FerenčakNo ratings yet

- Stellite 6Document2 pagesStellite 6백승훈No ratings yet

- Grado 8Document2 pagesGrado 8juanNo ratings yet

- Certificado 01-09-2022Document1 pageCertificado 01-09-2022juanNo ratings yet

- PARTES DE CIMBRA ST-IV - Letra ADocument2 pagesPARTES DE CIMBRA ST-IV - Letra AjuanNo ratings yet

- Selección de Fuente de Poder para GMAWDocument1 pageSelección de Fuente de Poder para GMAWjuanNo ratings yet

- Certificado Per 22 X 70Document1 pageCertificado Per 22 X 70juanNo ratings yet

- Sección 8.7 Ensayos No Destructivos AWS D1.5Document3 pagesSección 8.7 Ensayos No Destructivos AWS D1.5juanNo ratings yet

- JU 001 06 0508 0000 08 02 0007 - AprovDocument2 pagesJU 001 06 0508 0000 08 02 0007 - AprovjuanNo ratings yet

- Cutech Arabia LLCDocument382 pagesCutech Arabia LLCjuanNo ratings yet

- Division 700: StructuresDocument301 pagesDivision 700: StructuresjuanNo ratings yet

- Standard Requirement For Visual Inspection of Welds: December 5, 2008Document1 pageStandard Requirement For Visual Inspection of Welds: December 5, 2008juanNo ratings yet

- Operator's Manual: Split HeaterDocument4 pagesOperator's Manual: Split HeaterjuanNo ratings yet

- Standard Requirement For Vacuum Testing of Tank Bottom Fillet WeldsDocument1 pageStandard Requirement For Vacuum Testing of Tank Bottom Fillet WeldsjuanNo ratings yet

- Magellan Pipeline Product SpecificationsDocument59 pagesMagellan Pipeline Product SpecificationsCuongNguyenNo ratings yet

- Hdpe Pipe InformationDocument21 pagesHdpe Pipe Informationprasadnn2001No ratings yet

- 919-Article Text-10875-1-10-20121101Document5 pages919-Article Text-10875-1-10-20121101Suyash KumarNo ratings yet

- Onis Brochure GB 2015Document16 pagesOnis Brochure GB 2015r_chulinNo ratings yet

- Experience With The Operation of A Test-RIG For 700 °C Power Plant MaterialsDocument5 pagesExperience With The Operation of A Test-RIG For 700 °C Power Plant MaterialsAnonymous lmCR3SkPrKNo ratings yet

- ECR - 120 Furnce Method of StatementDocument11 pagesECR - 120 Furnce Method of StatementMazhar choudharyNo ratings yet

- Durock Brand Cement Board With EdgeGuardDocument4 pagesDurock Brand Cement Board With EdgeGuardmdeenkNo ratings yet

- Effect of Flexural RFT On Punching Shear Strength of Flat SlabsDocument9 pagesEffect of Flexural RFT On Punching Shear Strength of Flat SlabsMichael ShawkyNo ratings yet

- Lewis Symbol ActivityDocument6 pagesLewis Symbol ActivityJessa EspirituNo ratings yet

- Mix Design M20, M25, M30Document2 pagesMix Design M20, M25, M30subedipurushottam112456071% (7)

- Via Afrika Agricultural Sciences: Grade 11 Study GuideDocument187 pagesVia Afrika Agricultural Sciences: Grade 11 Study GuideNicolars RamolopeNo ratings yet

- Termometro ViatDocument1 pageTermometro ViatANGEL STRAGLIATINo ratings yet

- Setting Time of ConcreteDocument1 pageSetting Time of ConcretemiyaeunchaeNo ratings yet

- Utp Af A7Document1 pageUtp Af A7VIRPOPNo ratings yet

- TOS 4 Unit 2 Concrete Technology & Standard R.C.C Section-1-1Document26 pagesTOS 4 Unit 2 Concrete Technology & Standard R.C.C Section-1-1revati chandakNo ratings yet

- Project Slide - 2ndDocument18 pagesProject Slide - 2ndFenil JoseNo ratings yet

- Cambridge IGCSE: CHEMISTRY 0620/43Document16 pagesCambridge IGCSE: CHEMISTRY 0620/43Hamza AnwarNo ratings yet

- 0901d19680063607 PDF Preview MediumDocument2 pages0901d19680063607 PDF Preview MediumMark EstilleroNo ratings yet

- Shear Strength and CBR Improvement of Lacustrine Soil Mixed With Waste Brick PowderDocument9 pagesShear Strength and CBR Improvement of Lacustrine Soil Mixed With Waste Brick PowderIJRASETPublicationsNo ratings yet

- Auto Thermal Reactor:: Secondary ReformerDocument6 pagesAuto Thermal Reactor:: Secondary ReformerAtif MehfoozNo ratings yet

- Brochure - Coloured EPSDocument6 pagesBrochure - Coloured EPSsara rafieiNo ratings yet

- Foam Top Pourer Set Mk5: Key Features Foam Tube LengthDocument4 pagesFoam Top Pourer Set Mk5: Key Features Foam Tube LengthLNo ratings yet

- PREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)Document5 pagesPREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)vinsmoke1No ratings yet

- EP Bearing & Chassis GreaseDocument2 pagesEP Bearing & Chassis Greasechem KhanNo ratings yet

- TipsDocument90 pagesTipsSagari IsukapalliNo ratings yet

- Astm A 20 20M - 00 PDFDocument31 pagesAstm A 20 20M - 00 PDFrc galinatoNo ratings yet

- THK Afb70Document2 pagesTHK Afb70K HNo ratings yet

- Design and Evaluation of Open Graded Hot Mix Asphalt Using Cement As A Grouting MaterialDocument9 pagesDesign and Evaluation of Open Graded Hot Mix Asphalt Using Cement As A Grouting MaterialijmremNo ratings yet

- 2000GSP r6Document10 pages2000GSP r6PNo ratings yet