Professional Documents

Culture Documents

R&R Eugene

R&R Eugene

Uploaded by

Phương Thanh TrịnhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R&R Eugene

R&R Eugene

Uploaded by

Phương Thanh TrịnhCopyright:

Available Formats

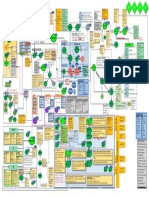

MAIN TASK FLOW @ Sourcing Team

Regular work Workload

Buyer

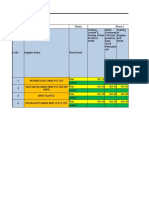

No Name Position Main Job Irregular work Report Channel Bottleneck point (if have) Improvement plan (In case H Remarks

(Division) daily weekly Monthly Measure

or L level)

Develop

-Receive quotation requests from sales and buyer. Carefully check detail and price, negotiate the cost and

shorten the lead time

- Update and record all detail of development into the folder to report and analyze and compare with the

previous season

- Check sample request and send to Mill (proto sample, LA sample, re-sample) refer ready date and update

to sales.

- Keeping record, check the awb# in the ready date of sample sending

Bulk

- Receive TPO --> check and share to Mill immediately (check price, RD, quality, color,...)

-Checking schedule of material in-house, discuss to get the best plan

- Receive PI from mill -> check and confirm to mill if all correct, share to saleteam

- Saleteam release OPO -> check with TPO and confirm on system. Team Manager

- Follow LD status, garment line and delivery status Assistant manager M

-'Request 5 sets of 1st BULK, keep 1 set. Request 2 sets of shade band, review color before pass to sales. Team Leader

- 1st lot checking and measuring. Check fabric quality (color shade, handfeel, weigh/width (with 1st bulk)) of

bulk to prevent quality issue in garment.

DEVELOP AND HANDLE BULK STAGE FOR GAP

-Update and record into order recap chart to follow and report

Division: GAP BOYS, TBK, MENS LOGO

- Follow and trouble shoot if any

'Ad/pp sample:

- Request sample yds for BULK sample submission: PPS, AD

- Receive and update recap and share to saleteam

Test report

--Request all related certifications or confirmation from Mill for special item Recycle poly, BCI cotton,

-Checking sample chart and following sample ready date.

shedding result,... - Summary and proceed payment once a

Keeping records and update to sales team

- Chase test report from mill after 1st shipment shipped (Mill internal test and 3rd test report). month for TT domestic payment term

-Weekly report update (new order, issue)

- Receive fabric test report and review the data if have problem or concern - Approve payment request - Any detail chart update if have request

12 EUGENE Associate Sourcing -Weekly sample chart update

-Request sewing check and update inspection report for bulk within 10 days to see any defect and call out to - Update Hand-carry list

-Weekly QA KR/CN chart update if have

mill. -Recap meeting wth team

-Internal recap update

- Conduct testing to Eins Lab if needed. -Order stationery for team

'Shipment

- Follow TNA for booking shipment and the recap

-Advise to sales and sawing if any change in shipment

- Confirm shipment with FWD, check booking sheet.

- Update schedule to Logistic team and Recap order

- Checking shipment and request mill share shipping docs

- Check or upload the shipment through SCM system, ensure this system data after shipment 2 days

- Proceed payment if all data correct

- Update recap

- Advise to Sales team and sewing if have any change in schedule.

Issue:

-Call out to Mill and discuss with sales team and fty if have any issue found out in BULK quality, color,

phyysical and chemical related

-Work with sewing fty to find out the reason and consider the solution

- Review the quality problem, color matching issue with manager

- Work with suppliers, advise options for solutions and discuss the best choice base on the current status of

quality level and time line of garment

- Record and advise claim if have and request deduct or plan for payment

Non-XPCC docs

-Ask mill to prepare and arrange all required documents from the time of order issuance. The documents

must be provided before fabric in-house.

-Review the updated document, fill in the chart with complete /missing elements.

-Ask logistic team help to upload docs on ERP system.

You might also like

- Strategic ManagementDocument15 pagesStrategic ManagementRamisa TasfiahNo ratings yet

- 06 5s Implementation Plan and Training Guide v20130618 PDFDocument16 pages06 5s Implementation Plan and Training Guide v20130618 PDFRamesh BabuNo ratings yet

- HỌC ONLINE 2022.11.12 CAP-Corrective Action Plan - Hướng Dẫn QA QC Làm Bảng Hành Động Khắc Phục LỗiDocument7 pagesHỌC ONLINE 2022.11.12 CAP-Corrective Action Plan - Hướng Dẫn QA QC Làm Bảng Hành Động Khắc Phục Lỗivuhien393No ratings yet

- SAP Lot Sizing Parameter PDFDocument1 pageSAP Lot Sizing Parameter PDFatungmu100% (1)

- 08 Mistake Proofing v20130529Document58 pages08 Mistake Proofing v20130529Adrian JoelNo ratings yet

- Production Part ApprovalDocument3 pagesProduction Part Approvalvidya410gmailcomNo ratings yet

- Work in Progress (WIP) Batch With Quality ManagementDocument4 pagesWork in Progress (WIP) Batch With Quality ManagementsowjanyaNo ratings yet

- Scorecard-APBM Construction of Waste Water r1Document78 pagesScorecard-APBM Construction of Waste Water r1Luigi Andrew MercadoNo ratings yet

- Overview of New ProjectDocument1 pageOverview of New ProjectIamIs NuchKornNo ratings yet

- Field Service Lightning Data Model Spring 19 v45.0Document1 pageField Service Lightning Data Model Spring 19 v45.0Victor TabuncicNo ratings yet

- VAVE资料讲义(部分) 领誉Document13 pagesVAVE资料讲义(部分) 领誉邓师傅No ratings yet

- Study GuideDocument2 pagesStudy GuideEmeli ReynosoNo ratings yet

- BP-5.1.2D OJT Effectiveness SHEET - Level-2Document1 pageBP-5.1.2D OJT Effectiveness SHEET - Level-2shinuNo ratings yet

- SAP Batch ManagementDocument6 pagesSAP Batch ManagementFernando AF100% (2)

- All FrameworksDocument1 pageAll FrameworksArnav RoyNo ratings yet

- Bill of Materials BOM ExampleDocument1 pageBill of Materials BOM ExampleMikalNo ratings yet

- Standard Operations ModuleDocument96 pagesStandard Operations ModuleNguyen Trac MinhNo ratings yet

- CP ProductionDocument7 pagesCP Productionsandeep.pantNo ratings yet

- Bài Tập Pivot - tham ChiếuDocument6 pagesBài Tập Pivot - tham ChiếuMinh MinhNo ratings yet

- Product Launch System: PLUS Action Plan (PAP)Document2 pagesProduct Launch System: PLUS Action Plan (PAP)Paula SilvaNo ratings yet

- 19 Measures v20130530Document48 pages19 Measures v20130530George SubaNo ratings yet

- FMEA Analysis MaintenanceDocument28 pagesFMEA Analysis MaintenanceBasit AliNo ratings yet

- Open SQL Editor: Saps'Word - We Sap For Your CauseDocument5 pagesOpen SQL Editor: Saps'Word - We Sap For Your CauseVinod NagarahalliNo ratings yet

- Layered Process Audit ChecksheetDocument3 pagesLayered Process Audit ChecksheetKevin Poore100% (1)

- Fifo Board - Rack "A" Example: Item Name: 0044 Needle Bearing SAP Code: B-NB-X050-0044-N0Document12 pagesFifo Board - Rack "A" Example: Item Name: 0044 Needle Bearing SAP Code: B-NB-X050-0044-N0Anonymous tv3qpx250% (2)

- Roadmap For Supplier Improvement Program 2020-21Document5 pagesRoadmap For Supplier Improvement Program 2020-21shobha shelarNo ratings yet

- 6W2H - Bulk Spill During Loading ScrapDocument3 pages6W2H - Bulk Spill During Loading Scrapsynyster92xNo ratings yet

- 11 Steps Capacity Enhacement LACV JSRDocument14 pages11 Steps Capacity Enhacement LACV JSRAmiya KumarNo ratings yet

- Natural Language Processing With Deep Learning CS224N/Ling284Document62 pagesNatural Language Processing With Deep Learning CS224N/Ling284dinhmanh hoangNo ratings yet

- Bench MarkDocument1 pageBench Markhow2beliveNo ratings yet

- Insulation Resistance Test FormDocument1 pageInsulation Resistance Test FormJohny AdvientoNo ratings yet

- Scmpe Marathon Notes May 23 by CA Sankalp Kanstiya-31!90!31-60Document30 pagesScmpe Marathon Notes May 23 by CA Sankalp Kanstiya-31!90!31-60Sangeetha NaharNo ratings yet

- VSM Imported MaterialDocument1 pageVSM Imported MaterialpranayNo ratings yet

- KRA Head of HRDocument2 pagesKRA Head of HRMostafizur RahmanNo ratings yet

- MP&L Organisation chartDocument4 pagesMP&L Organisation chartvishal.khalane9No ratings yet

- IE-114 MOST IntroductionDocument22 pagesIE-114 MOST IntroductionLahm NguyNo ratings yet

- Work FlowDocument1 pageWork FlowWaseem AshrafNo ratings yet

- Idris MM ClassesDocument3 pagesIdris MM ClassesmunafNo ratings yet

- Cost Management Cloud: Manufacturing CostingDocument20 pagesCost Management Cloud: Manufacturing Costinghaitham ibrahem mohmedNo ratings yet

- Per-Qf-33 Plantilla of Step IncrementDocument1 pagePer-Qf-33 Plantilla of Step IncrementMichelle O. MatiasNo ratings yet

- Retail Art Master DataDocument55 pagesRetail Art Master Datambraghumb9019No ratings yet

- P and G Revised - G2Document11 pagesP and G Revised - G2Sambit BehuraNo ratings yet

- IPCR July Dec 2020 FINAL Na KaauDocument7 pagesIPCR July Dec 2020 FINAL Na KaauCristina MelloriaNo ratings yet

- DDMRP OverviewDocument51 pagesDDMRP Overviewiamvignesh.sapNo ratings yet

- 2.5 Andon Board ExampleDocument2 pages2.5 Andon Board ExampleCarlos HernandezNo ratings yet

- PMP ChartDocument1 pagePMP Chartสมมาตร ปัญญาประทีปNo ratings yet

- High Level Building Blocks - DrawioDocument1 pageHigh Level Building Blocks - DrawioSumanta DuttaNo ratings yet

- SAP S4 HANA MM CertificationDocument1 pageSAP S4 HANA MM CertificationYong Benedict100% (4)

- 1.S4 MM Flow DetailedDocument1 page1.S4 MM Flow DetailedPrakash Praky100% (1)

- SOP Process Flow OverviewDocument2 pagesSOP Process Flow Overviewlorie lacNo ratings yet

- Mass Production (Capitalist-Profit Focused) Mass Customization (Consumer Focused) Mass-Impact On Planet-People-Community (Shareholder To StakeholderDocument4 pagesMass Production (Capitalist-Profit Focused) Mass Customization (Consumer Focused) Mass-Impact On Planet-People-Community (Shareholder To Stakeholdervaibhav kumar KhokharNo ratings yet

- 15 Jidoka v20130530 PDFDocument22 pages15 Jidoka v20130530 PDFbhnodarNo ratings yet

- ThetaGainer SepBatch ClassNotesDocument74 pagesThetaGainer SepBatch ClassNotesMovieMaster ZanNo ratings yet

- LP - Process MappingDocument47 pagesLP - Process MappingMugur AchiteiNo ratings yet

- Rework Processing (Stock-Manufactured Material) - 2GGDocument4 pagesRework Processing (Stock-Manufactured Material) - 2GGsowjanyaNo ratings yet

- Syndicate 5 - A3 Problem SolvingDocument1 pageSyndicate 5 - A3 Problem SolvingGalih IkhsanNo ratings yet

- SAP Service Management: Advanced ConfigurationFrom EverandSAP Service Management: Advanced ConfigurationRating: 4.5 out of 5 stars4.5/5 (3)

- TRF - Test Request FormDocument18 pagesTRF - Test Request FormPhương Thanh TrịnhNo ratings yet

- RD257581 (Parent RD 159179) - HOL22 BULK - YIG-06614Document14 pagesRD257581 (Parent RD 159179) - HOL22 BULK - YIG-06614Phương Thanh TrịnhNo ratings yet

- Invoice AjinDocument1 pageInvoice AjinPhương Thanh TrịnhNo ratings yet

- Special Garment WashDocument2 pagesSpecial Garment WashPhương Thanh TrịnhNo ratings yet

- Swot 2022 - EugeneDocument7 pagesSwot 2022 - EugenePhương Thanh TrịnhNo ratings yet

- Eins Fty Visit Report - EugeneDocument13 pagesEins Fty Visit Report - EugenePhương Thanh TrịnhNo ratings yet

- CPK Case AnalysisDocument8 pagesCPK Case AnalysisVikas MotwaniNo ratings yet

- Topic 8 Currency Derivatives FutureDocument26 pagesTopic 8 Currency Derivatives Futurecyrax 3000No ratings yet

- Group 11 - ( (Oscm1713)Document14 pagesGroup 11 - ( (Oscm1713)Rohit KarmakerNo ratings yet

- Thesis On Marketing Strategy of AirtelDocument7 pagesThesis On Marketing Strategy of Airtellucynaderfortwayne100% (2)

- Repayment of Term/Fixed Deposits in BanksDocument2 pagesRepayment of Term/Fixed Deposits in BanksMohammad Sazid AlamNo ratings yet

- Activity 4.1 Identify The Problem Solution and Customer Segments of Existing CompaniesDocument2 pagesActivity 4.1 Identify The Problem Solution and Customer Segments of Existing Companieszzrot1No ratings yet

- Premium-Liability Bafacr4x OnlineglimpsenujpiaDocument8 pagesPremium-Liability Bafacr4x OnlineglimpsenujpiaAga Mathew MayugaNo ratings yet

- Satisfaction Is Nice, But Value Drives LoyaltyDocument5 pagesSatisfaction Is Nice, But Value Drives LoyaltyVickram PersadNo ratings yet

- BEGIM Perfume Product LaunchDocument37 pagesBEGIM Perfume Product LaunchMuhammad Yoosuf ShahNo ratings yet

- What Role Did Tyco S Corporate Culture Play in The ScandalDocument1 pageWhat Role Did Tyco S Corporate Culture Play in The ScandalAmit PandeyNo ratings yet

- SALN Form BlankDocument3 pagesSALN Form BlankIrish GarciaNo ratings yet

- Basic Information About Business Environment:: Environment Analysis, and Strategy FormulationDocument29 pagesBasic Information About Business Environment:: Environment Analysis, and Strategy Formulationdyah_dewi_1No ratings yet

- The Hospitality Workforce During The Covid-19 Pandemic: Focus On Socioeconomic ConsequencesDocument11 pagesThe Hospitality Workforce During The Covid-19 Pandemic: Focus On Socioeconomic ConsequencesdsfasdfasdfNo ratings yet

- Project Management For ManagersDocument186 pagesProject Management For ManagersbanismNo ratings yet

- Experis Key InformationDocument11 pagesExperis Key InformationTahir SamadNo ratings yet

- Marketing AnalysisDocument26 pagesMarketing AnalysisRiya ChawlaNo ratings yet

- Reliance-Petroleum's-Triple-Option-Convertible-Debentures-BY AMIT AGARWALDocument20 pagesReliance-Petroleum's-Triple-Option-Convertible-Debentures-BY AMIT AGARWALAmit AgarwalNo ratings yet

- Balaji Annual Report 2014 15 PDFDocument280 pagesBalaji Annual Report 2014 15 PDFRahul AgrawalNo ratings yet

- Civic Welfare Training Service 2Document10 pagesCivic Welfare Training Service 2Mariz Rivera GonzalesNo ratings yet

- Research 2023Document52 pagesResearch 2023Logo KrdoNo ratings yet

- (CV) (Ngo Thi Thanh Truc) PDFDocument1 page(CV) (Ngo Thi Thanh Truc) PDFNguyen Phong DanhNo ratings yet

- Turban Dss9e Im Ch02Document15 pagesTurban Dss9e Im Ch02jennytan8970330% (1)

- CostsDocument8 pagesCostsTanjil Hasan TajNo ratings yet

- Project Excution and Control FourDocument40 pagesProject Excution and Control FourMohammad AbdullahNo ratings yet

- Century Textile ReportDocument4 pagesCentury Textile ReportAishwarya WakkarNo ratings yet

- Individual IntegratedDocument2 pagesIndividual IntegratedJayone LowNo ratings yet

- 10 Steps To Become A Game Composer PDFDocument2 pages10 Steps To Become A Game Composer PDFBig BomberNo ratings yet

- Credila Application Form PDFDocument2 pagesCredila Application Form PDFJag UnathNo ratings yet

- Accenture Digital Trust Technology Vision 2016Document12 pagesAccenture Digital Trust Technology Vision 2016J CanoNo ratings yet