Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

12 viewsCaseStudy Hot Tek Hot Vacuuming Service

CaseStudy Hot Tek Hot Vacuuming Service

Uploaded by

Omid LarkiHot-tek identified screen fouling on a plant's catalysts using a LanceScope inspection. They were able to clean 200 catalysts online without an emergency shutdown or production interruption. This returned the pressure drop across the catalysts to within 5% of design and provided a return on investment within less than a month by improving heater efficiency, increasing pre-heat and steam production, reducing stack temperature, and improving draft.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- InSaleh Blowdown IncidentDocument3 pagesInSaleh Blowdown IncidentHandriansyah DoelNo ratings yet

- SENTRO Technologies Online Chemical Cleaning PresentationDocument53 pagesSENTRO Technologies Online Chemical Cleaning Presentation조기현No ratings yet

- Conference Paper Gvpi Rewind Geno 02082018externalforweb LegallyDocument21 pagesConference Paper Gvpi Rewind Geno 02082018externalforweb LegallySISWANTONo ratings yet

- AUTOMATIC LAMINATION MACHINE ReportDocument59 pagesAUTOMATIC LAMINATION MACHINE Reportsabareesh91mechNo ratings yet

- Flyer Chem Clean 190722Document2 pagesFlyer Chem Clean 190722Sudhanshu DashNo ratings yet

- CaseStudy Hot Tek Hot Convection CleaningDocument2 pagesCaseStudy Hot Tek Hot Convection CleaningOmid LarkiNo ratings yet

- Date: Location: Data Set: Work Function: Incident Category: Activity: Date: Location: Data Set: Work Function: Incident Category: ActivityDocument1 pageDate: Location: Data Set: Work Function: Incident Category: Activity: Date: Location: Data Set: Work Function: Incident Category: Activityberry MikeNo ratings yet

- BRK Electronic Descaling SystemDocument5 pagesBRK Electronic Descaling SystemSuresh DNo ratings yet

- Catalogue Vulcanic English 2015Document155 pagesCatalogue Vulcanic English 2015raja raniNo ratings yet

- Flyer Steam Trap Testing Sonotec (1 2)Document2 pagesFlyer Steam Trap Testing Sonotec (1 2)march cobainNo ratings yet

- C - D High Rate SeriesDocument6 pagesC - D High Rate SeriesFelix MorenoNo ratings yet

- Octene Decontamination - Cleaning Final ReportDocument18 pagesOctene Decontamination - Cleaning Final ReportArie PanjunanNo ratings yet

- Power Quality: Amcor Flexibles Benefit From ABB 1MVA Voltage ConditionerDocument4 pagesPower Quality: Amcor Flexibles Benefit From ABB 1MVA Voltage ConditioneranksyeteNo ratings yet

- AOGV Presentation Nov 2018Document25 pagesAOGV Presentation Nov 2018Jose BijoyNo ratings yet

- Fire On An Electrostatic Paint Line - pp29-30Document2 pagesFire On An Electrostatic Paint Line - pp29-30Soeryanto SlametNo ratings yet

- Minggu 3Document37 pagesMinggu 3kevin candraNo ratings yet

- Applications Features & Benefits: Valve Regulated Lead Acid Battery Designed For UPS Standby Power ApplicationsDocument6 pagesApplications Features & Benefits: Valve Regulated Lead Acid Battery Designed For UPS Standby Power ApplicationsDaniel ArgumedoNo ratings yet

- Alternator Cleaning PDFDocument2 pagesAlternator Cleaning PDFjosielalves2910No ratings yet

- Vulcanic Liquid HeatingDocument65 pagesVulcanic Liquid HeatingJavier Conesa OutedaNo ratings yet

- Best Practice For Steam TracingDocument4 pagesBest Practice For Steam TracingCarlos SopasNo ratings yet

- Aurelia MA., Kharaini LD. & Yasmin AOADocument13 pagesAurelia MA., Kharaini LD. & Yasmin AOASavage YNo ratings yet

- AI01081C - EN - COD Measurement in Diary EffluentDocument2 pagesAI01081C - EN - COD Measurement in Diary EffluentA GlaumNo ratings yet

- C TECH BrochureDocument4 pagesC TECH BrochureBinayak AichNo ratings yet

- Installation Instructions: Aquaforce 30XW150-400 Water-Cooled Liquid ChillersDocument44 pagesInstallation Instructions: Aquaforce 30XW150-400 Water-Cooled Liquid ChillersphlxuNo ratings yet

- April 2011 IssueDocument70 pagesApril 2011 IssueMunicipal Sewer & Water MagazineNo ratings yet

- Presentation For INDUSTRIAL Cleaning Services PHRCDocument26 pagesPresentation For INDUSTRIAL Cleaning Services PHRCMOSES EDWINNo ratings yet

- Aquionics UV - Inline BrochureDocument2 pagesAquionics UV - Inline Brochuremiguel_vera6592No ratings yet

- Cfdesign V10: Saket ChaudharyDocument49 pagesCfdesign V10: Saket Chaudharymatteo_1234No ratings yet

- Issue No. 4 - 11-6-2022 - Grindings Sparks Lead To FireDocument1 pageIssue No. 4 - 11-6-2022 - Grindings Sparks Lead To Firehilal ahmadNo ratings yet

- Caso de Estudio COWAN ActuadoresDocument4 pagesCaso de Estudio COWAN ActuadoresGabrielNo ratings yet

- Coker ArticleDocument6 pagesCoker Articlepersonalmail_20011078100% (1)

- UPS Dynasty BatteriesDocument6 pagesUPS Dynasty BatteriesbandarbadhonNo ratings yet

- Clean in Place: Process Heating Solutions WorldwideDocument1 pageClean in Place: Process Heating Solutions WorldwidenitantharaniNo ratings yet

- 2kg KATS Design New HFC & FK-5-1-12.cdrDocument1 page2kg KATS Design New HFC & FK-5-1-12.cdrAhmed ElSabbanNo ratings yet

- Valve MagazineDocument52 pagesValve MagazineAhmed Ibrahim Ahmed EissaNo ratings yet

- SoniTech Capabilities StatementDocument1 pageSoniTech Capabilities StatementTim FrederickNo ratings yet

- Case Study Reducing Downtime by 12 Hours With Proactive Fault Detection 1712939403Document6 pagesCase Study Reducing Downtime by 12 Hours With Proactive Fault Detection 1712939403Ranu BaranwalNo ratings yet

- JPT 2017-FebreroDocument84 pagesJPT 2017-Febreroabraham dominguezNo ratings yet

- Polyurathane Resin HardnerDocument32 pagesPolyurathane Resin HardnerPritpal SinghNo ratings yet

- Track: One Point SolutionsDocument6 pagesTrack: One Point SolutionsKandeepanNo ratings yet

- Ups12-410, 830 & 1000MRXFDocument4 pagesUps12-410, 830 & 1000MRXFEfitZanifNo ratings yet

- June 2011 IssueDocument70 pagesJune 2011 IssueMunicipal Sewer & Water Magazine0% (1)

- Catalogue enDocument155 pagesCatalogue enworkingNo ratings yet

- PDA: A Global Association: Glass Vials - Laser Coding Case StudyDocument24 pagesPDA: A Global Association: Glass Vials - Laser Coding Case StudyRichard ShiNo ratings yet

- Safe Operating ProcessDocument22 pagesSafe Operating ProcessMahesh MunratiwargoudNo ratings yet

- Zonecheck BrochureDocument4 pagesZonecheck Brochuresai3942No ratings yet

- Case Study - Poe Impact On Patient SafetyDocument3 pagesCase Study - Poe Impact On Patient Safetyapi-329236128No ratings yet

- Temperature Control Solutions: June 2017 - Volume 24, Number 6Document48 pagesTemperature Control Solutions: June 2017 - Volume 24, Number 6Cristian SNo ratings yet

- UV 700 Rack - Sterilizer ManualDocument18 pagesUV 700 Rack - Sterilizer ManualfloreabanciuNo ratings yet

- Greece VDU ZF Picture DigitalDocument1 pageGreece VDU ZF Picture Digitalsaleh4060No ratings yet

- Controlling Coupling Guard Leakage: Rotating Equipment/MaintenanceDocument3 pagesControlling Coupling Guard Leakage: Rotating Equipment/MaintenanceinterveiwNo ratings yet

- SpaceVac ROW Catalogue Aug 22Document33 pagesSpaceVac ROW Catalogue Aug 22SivonildoNo ratings yet

- RVAC - RMU Catalog - June-2018Document4 pagesRVAC - RMU Catalog - June-2018PhaniNo ratings yet

- Ice BlastingDocument20 pagesIce BlastingshervinyNo ratings yet

- The Solution For The Solution For Processes ProcessesDocument1 pageThe Solution For The Solution For Processes Processeskeyur1109No ratings yet

- Envicool Station Climate Control (Brochure D) - 20150520Document10 pagesEnvicool Station Climate Control (Brochure D) - 20150520Renzo VelardeNo ratings yet

- Datasheet JNS60MB295 310 1Document2 pagesDatasheet JNS60MB295 310 1ISGENo ratings yet

- CurrentDocument12 pagesCurrentkrbakesline onlineNo ratings yet

- Rapid Thermal Processing: Science and TechnologyFrom EverandRapid Thermal Processing: Science and TechnologyRichard B. FairNo ratings yet

- Engineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeFrom EverandEngineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeNo ratings yet

- AP Physics1 Student Workbook AppendixDocument11 pagesAP Physics1 Student Workbook AppendixcarlosNo ratings yet

- Curriculum Vitae: Muhammad AlamDocument3 pagesCurriculum Vitae: Muhammad Alammuhammad arifNo ratings yet

- KarachiDocument2 pagesKarachiBaran ShafqatNo ratings yet

- What Is Corona?Document28 pagesWhat Is Corona?JaleesNo ratings yet

- Electrical Diagrams1Document55 pagesElectrical Diagrams1Youssef BoulaghlaNo ratings yet

- Alternating Current FundamentalsDocument49 pagesAlternating Current Fundamentalsvontedj100% (2)

- SuSD.1.F.008-Electrical Data SheetDocument6 pagesSuSD.1.F.008-Electrical Data SheetHonnie Mae PaduaNo ratings yet

- 2016CompositeList Web 51Document1 page2016CompositeList Web 51AnuranjanNo ratings yet

- Ingles 4 - Monografia FinalDocument28 pagesIngles 4 - Monografia FinalCindy Vanessa PaucarNo ratings yet

- 15EE563/17EE563 IA-2: Question 01 (MC)Document9 pages15EE563/17EE563 IA-2: Question 01 (MC)Vasavi VaasuNo ratings yet

- First Law of Thermodynamics-Energy Analysis of Closed System PDFDocument61 pagesFirst Law of Thermodynamics-Energy Analysis of Closed System PDFMustafa Cuneyt GezenNo ratings yet

- Axial Compressor SheetDocument1 pageAxial Compressor SheetAyman AbazaNo ratings yet

- 15701A03B1Document20 pages15701A03B1Suri VijayNo ratings yet

- Classification of Coal Quality ManagementDocument41 pagesClassification of Coal Quality Managementmya tunNo ratings yet

- Hardware Implementation of Non Directional Over Current Relay On ArduinoDocument4 pagesHardware Implementation of Non Directional Over Current Relay On ArduinoMasgun Cyng MimiNo ratings yet

- A Criticism of Self Compacting ConcreteDocument7 pagesA Criticism of Self Compacting ConcreteAnonymous dHyxmDNo ratings yet

- Auto Blowdown ControlDocument2 pagesAuto Blowdown ControlIan B. YtomNo ratings yet

- THERMODYNAMICS 2 DAILY EXAM 4 (Answer Key) SET BDocument1 pageTHERMODYNAMICS 2 DAILY EXAM 4 (Answer Key) SET BJads CayabyabNo ratings yet

- Fesco Online Bill June 23Document2 pagesFesco Online Bill June 23Waqar AkramNo ratings yet

- Cashback Model ListDocument79 pagesCashback Model Listgixabat112No ratings yet

- Wind-Energy-Potential-Vietnam - Netherlands 2018 PDFDocument81 pagesWind-Energy-Potential-Vietnam - Netherlands 2018 PDFKen NgoNo ratings yet

- Plta MerangkumDocument21 pagesPlta MerangkumOksiil ShelaNo ratings yet

- Marelli GenDocument26 pagesMarelli GenMohsen100% (1)

- 11 Phy - Gravitation - QN BankDocument42 pages11 Phy - Gravitation - QN BankMohit DhaundiyalNo ratings yet

- Red 403 Red 503Document1 pageRed 403 Red 503mt1742k4No ratings yet

- Garioni Naval - Steam GeneratorsDocument24 pagesGarioni Naval - Steam GeneratorsgarioninavalNo ratings yet

- Mechanics Paper 1 Study GuideDocument6 pagesMechanics Paper 1 Study GuideJi Jing MengNo ratings yet

- Ground Fault Protection OverviewDocument34 pagesGround Fault Protection OverviewModisa TsamaaseNo ratings yet

- Diesel Generator Set Specifications Sheet-10 kVADocument2 pagesDiesel Generator Set Specifications Sheet-10 kVAvelu.gNo ratings yet

CaseStudy Hot Tek Hot Vacuuming Service

CaseStudy Hot Tek Hot Vacuuming Service

Uploaded by

Omid Larki0 ratings0% found this document useful (0 votes)

12 views1 pageHot-tek identified screen fouling on a plant's catalysts using a LanceScope inspection. They were able to clean 200 catalysts online without an emergency shutdown or production interruption. This returned the pressure drop across the catalysts to within 5% of design and provided a return on investment within less than a month by improving heater efficiency, increasing pre-heat and steam production, reducing stack temperature, and improving draft.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHot-tek identified screen fouling on a plant's catalysts using a LanceScope inspection. They were able to clean 200 catalysts online without an emergency shutdown or production interruption. This returned the pressure drop across the catalysts to within 5% of design and provided a return on investment within less than a month by improving heater efficiency, increasing pre-heat and steam production, reducing stack temperature, and improving draft.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

12 views1 pageCaseStudy Hot Tek Hot Vacuuming Service

CaseStudy Hot Tek Hot Vacuuming Service

Uploaded by

Omid LarkiHot-tek identified screen fouling on a plant's catalysts using a LanceScope inspection. They were able to clean 200 catalysts online without an emergency shutdown or production interruption. This returned the pressure drop across the catalysts to within 5% of design and provided a return on investment within less than a month by improving heater efficiency, increasing pre-heat and steam production, reducing stack temperature, and improving draft.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

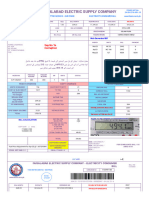

CASE STUDY

PROBLEM:

HOT VACUUMING PREVENTS The Plant was in danger of needing

an emergency shutdown to clean

their catalysts.

EMERGENCY SHUTDOWN

SOLUTION:

Hot-tek LanceScope inspection

identified screen fouling. Cleaning of

200 catalysts was then performed

online without interruption to

production.

before after

SMR Heater with Downstream SCR System Video: Hot Vacuuming Service

Production rate was being reduced and the pressure drop across

catalyst was increasing due to surface fouling hindering gas flow.

Hot Vacuuming Service

The IGS Hot-tek team created access ports upstream of the SCR

catalysts and performed a LanceScope inspection to identify

fouling. Cleaning was performed online without interruption to

production, on time and budget without safety issues.

Results and ROI

Pressure drop across the catalysts was returned to within 5%

of design. The plant recorded payback within less than a month.

As a result, the fired heater efficiency was improved, process SCR cleaning, watch this application in action

pre-heat and steam production increased, stack temperature

Scan QR

reduced, and draft improved. code to

watch video

W: integratedglobal.com E: info@integratedglobal.com T: +1 888 506 2669

You might also like

- InSaleh Blowdown IncidentDocument3 pagesInSaleh Blowdown IncidentHandriansyah DoelNo ratings yet

- SENTRO Technologies Online Chemical Cleaning PresentationDocument53 pagesSENTRO Technologies Online Chemical Cleaning Presentation조기현No ratings yet

- Conference Paper Gvpi Rewind Geno 02082018externalforweb LegallyDocument21 pagesConference Paper Gvpi Rewind Geno 02082018externalforweb LegallySISWANTONo ratings yet

- AUTOMATIC LAMINATION MACHINE ReportDocument59 pagesAUTOMATIC LAMINATION MACHINE Reportsabareesh91mechNo ratings yet

- Flyer Chem Clean 190722Document2 pagesFlyer Chem Clean 190722Sudhanshu DashNo ratings yet

- CaseStudy Hot Tek Hot Convection CleaningDocument2 pagesCaseStudy Hot Tek Hot Convection CleaningOmid LarkiNo ratings yet

- Date: Location: Data Set: Work Function: Incident Category: Activity: Date: Location: Data Set: Work Function: Incident Category: ActivityDocument1 pageDate: Location: Data Set: Work Function: Incident Category: Activity: Date: Location: Data Set: Work Function: Incident Category: Activityberry MikeNo ratings yet

- BRK Electronic Descaling SystemDocument5 pagesBRK Electronic Descaling SystemSuresh DNo ratings yet

- Catalogue Vulcanic English 2015Document155 pagesCatalogue Vulcanic English 2015raja raniNo ratings yet

- Flyer Steam Trap Testing Sonotec (1 2)Document2 pagesFlyer Steam Trap Testing Sonotec (1 2)march cobainNo ratings yet

- C - D High Rate SeriesDocument6 pagesC - D High Rate SeriesFelix MorenoNo ratings yet

- Octene Decontamination - Cleaning Final ReportDocument18 pagesOctene Decontamination - Cleaning Final ReportArie PanjunanNo ratings yet

- Power Quality: Amcor Flexibles Benefit From ABB 1MVA Voltage ConditionerDocument4 pagesPower Quality: Amcor Flexibles Benefit From ABB 1MVA Voltage ConditioneranksyeteNo ratings yet

- AOGV Presentation Nov 2018Document25 pagesAOGV Presentation Nov 2018Jose BijoyNo ratings yet

- Fire On An Electrostatic Paint Line - pp29-30Document2 pagesFire On An Electrostatic Paint Line - pp29-30Soeryanto SlametNo ratings yet

- Minggu 3Document37 pagesMinggu 3kevin candraNo ratings yet

- Applications Features & Benefits: Valve Regulated Lead Acid Battery Designed For UPS Standby Power ApplicationsDocument6 pagesApplications Features & Benefits: Valve Regulated Lead Acid Battery Designed For UPS Standby Power ApplicationsDaniel ArgumedoNo ratings yet

- Alternator Cleaning PDFDocument2 pagesAlternator Cleaning PDFjosielalves2910No ratings yet

- Vulcanic Liquid HeatingDocument65 pagesVulcanic Liquid HeatingJavier Conesa OutedaNo ratings yet

- Best Practice For Steam TracingDocument4 pagesBest Practice For Steam TracingCarlos SopasNo ratings yet

- Aurelia MA., Kharaini LD. & Yasmin AOADocument13 pagesAurelia MA., Kharaini LD. & Yasmin AOASavage YNo ratings yet

- AI01081C - EN - COD Measurement in Diary EffluentDocument2 pagesAI01081C - EN - COD Measurement in Diary EffluentA GlaumNo ratings yet

- C TECH BrochureDocument4 pagesC TECH BrochureBinayak AichNo ratings yet

- Installation Instructions: Aquaforce 30XW150-400 Water-Cooled Liquid ChillersDocument44 pagesInstallation Instructions: Aquaforce 30XW150-400 Water-Cooled Liquid ChillersphlxuNo ratings yet

- April 2011 IssueDocument70 pagesApril 2011 IssueMunicipal Sewer & Water MagazineNo ratings yet

- Presentation For INDUSTRIAL Cleaning Services PHRCDocument26 pagesPresentation For INDUSTRIAL Cleaning Services PHRCMOSES EDWINNo ratings yet

- Aquionics UV - Inline BrochureDocument2 pagesAquionics UV - Inline Brochuremiguel_vera6592No ratings yet

- Cfdesign V10: Saket ChaudharyDocument49 pagesCfdesign V10: Saket Chaudharymatteo_1234No ratings yet

- Issue No. 4 - 11-6-2022 - Grindings Sparks Lead To FireDocument1 pageIssue No. 4 - 11-6-2022 - Grindings Sparks Lead To Firehilal ahmadNo ratings yet

- Caso de Estudio COWAN ActuadoresDocument4 pagesCaso de Estudio COWAN ActuadoresGabrielNo ratings yet

- Coker ArticleDocument6 pagesCoker Articlepersonalmail_20011078100% (1)

- UPS Dynasty BatteriesDocument6 pagesUPS Dynasty BatteriesbandarbadhonNo ratings yet

- Clean in Place: Process Heating Solutions WorldwideDocument1 pageClean in Place: Process Heating Solutions WorldwidenitantharaniNo ratings yet

- 2kg KATS Design New HFC & FK-5-1-12.cdrDocument1 page2kg KATS Design New HFC & FK-5-1-12.cdrAhmed ElSabbanNo ratings yet

- Valve MagazineDocument52 pagesValve MagazineAhmed Ibrahim Ahmed EissaNo ratings yet

- SoniTech Capabilities StatementDocument1 pageSoniTech Capabilities StatementTim FrederickNo ratings yet

- Case Study Reducing Downtime by 12 Hours With Proactive Fault Detection 1712939403Document6 pagesCase Study Reducing Downtime by 12 Hours With Proactive Fault Detection 1712939403Ranu BaranwalNo ratings yet

- JPT 2017-FebreroDocument84 pagesJPT 2017-Febreroabraham dominguezNo ratings yet

- Polyurathane Resin HardnerDocument32 pagesPolyurathane Resin HardnerPritpal SinghNo ratings yet

- Track: One Point SolutionsDocument6 pagesTrack: One Point SolutionsKandeepanNo ratings yet

- Ups12-410, 830 & 1000MRXFDocument4 pagesUps12-410, 830 & 1000MRXFEfitZanifNo ratings yet

- June 2011 IssueDocument70 pagesJune 2011 IssueMunicipal Sewer & Water Magazine0% (1)

- Catalogue enDocument155 pagesCatalogue enworkingNo ratings yet

- PDA: A Global Association: Glass Vials - Laser Coding Case StudyDocument24 pagesPDA: A Global Association: Glass Vials - Laser Coding Case StudyRichard ShiNo ratings yet

- Safe Operating ProcessDocument22 pagesSafe Operating ProcessMahesh MunratiwargoudNo ratings yet

- Zonecheck BrochureDocument4 pagesZonecheck Brochuresai3942No ratings yet

- Case Study - Poe Impact On Patient SafetyDocument3 pagesCase Study - Poe Impact On Patient Safetyapi-329236128No ratings yet

- Temperature Control Solutions: June 2017 - Volume 24, Number 6Document48 pagesTemperature Control Solutions: June 2017 - Volume 24, Number 6Cristian SNo ratings yet

- UV 700 Rack - Sterilizer ManualDocument18 pagesUV 700 Rack - Sterilizer ManualfloreabanciuNo ratings yet

- Greece VDU ZF Picture DigitalDocument1 pageGreece VDU ZF Picture Digitalsaleh4060No ratings yet

- Controlling Coupling Guard Leakage: Rotating Equipment/MaintenanceDocument3 pagesControlling Coupling Guard Leakage: Rotating Equipment/MaintenanceinterveiwNo ratings yet

- SpaceVac ROW Catalogue Aug 22Document33 pagesSpaceVac ROW Catalogue Aug 22SivonildoNo ratings yet

- RVAC - RMU Catalog - June-2018Document4 pagesRVAC - RMU Catalog - June-2018PhaniNo ratings yet

- Ice BlastingDocument20 pagesIce BlastingshervinyNo ratings yet

- The Solution For The Solution For Processes ProcessesDocument1 pageThe Solution For The Solution For Processes Processeskeyur1109No ratings yet

- Envicool Station Climate Control (Brochure D) - 20150520Document10 pagesEnvicool Station Climate Control (Brochure D) - 20150520Renzo VelardeNo ratings yet

- Datasheet JNS60MB295 310 1Document2 pagesDatasheet JNS60MB295 310 1ISGENo ratings yet

- CurrentDocument12 pagesCurrentkrbakesline onlineNo ratings yet

- Rapid Thermal Processing: Science and TechnologyFrom EverandRapid Thermal Processing: Science and TechnologyRichard B. FairNo ratings yet

- Engineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeFrom EverandEngineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeNo ratings yet

- AP Physics1 Student Workbook AppendixDocument11 pagesAP Physics1 Student Workbook AppendixcarlosNo ratings yet

- Curriculum Vitae: Muhammad AlamDocument3 pagesCurriculum Vitae: Muhammad Alammuhammad arifNo ratings yet

- KarachiDocument2 pagesKarachiBaran ShafqatNo ratings yet

- What Is Corona?Document28 pagesWhat Is Corona?JaleesNo ratings yet

- Electrical Diagrams1Document55 pagesElectrical Diagrams1Youssef BoulaghlaNo ratings yet

- Alternating Current FundamentalsDocument49 pagesAlternating Current Fundamentalsvontedj100% (2)

- SuSD.1.F.008-Electrical Data SheetDocument6 pagesSuSD.1.F.008-Electrical Data SheetHonnie Mae PaduaNo ratings yet

- 2016CompositeList Web 51Document1 page2016CompositeList Web 51AnuranjanNo ratings yet

- Ingles 4 - Monografia FinalDocument28 pagesIngles 4 - Monografia FinalCindy Vanessa PaucarNo ratings yet

- 15EE563/17EE563 IA-2: Question 01 (MC)Document9 pages15EE563/17EE563 IA-2: Question 01 (MC)Vasavi VaasuNo ratings yet

- First Law of Thermodynamics-Energy Analysis of Closed System PDFDocument61 pagesFirst Law of Thermodynamics-Energy Analysis of Closed System PDFMustafa Cuneyt GezenNo ratings yet

- Axial Compressor SheetDocument1 pageAxial Compressor SheetAyman AbazaNo ratings yet

- 15701A03B1Document20 pages15701A03B1Suri VijayNo ratings yet

- Classification of Coal Quality ManagementDocument41 pagesClassification of Coal Quality Managementmya tunNo ratings yet

- Hardware Implementation of Non Directional Over Current Relay On ArduinoDocument4 pagesHardware Implementation of Non Directional Over Current Relay On ArduinoMasgun Cyng MimiNo ratings yet

- A Criticism of Self Compacting ConcreteDocument7 pagesA Criticism of Self Compacting ConcreteAnonymous dHyxmDNo ratings yet

- Auto Blowdown ControlDocument2 pagesAuto Blowdown ControlIan B. YtomNo ratings yet

- THERMODYNAMICS 2 DAILY EXAM 4 (Answer Key) SET BDocument1 pageTHERMODYNAMICS 2 DAILY EXAM 4 (Answer Key) SET BJads CayabyabNo ratings yet

- Fesco Online Bill June 23Document2 pagesFesco Online Bill June 23Waqar AkramNo ratings yet

- Cashback Model ListDocument79 pagesCashback Model Listgixabat112No ratings yet

- Wind-Energy-Potential-Vietnam - Netherlands 2018 PDFDocument81 pagesWind-Energy-Potential-Vietnam - Netherlands 2018 PDFKen NgoNo ratings yet

- Plta MerangkumDocument21 pagesPlta MerangkumOksiil ShelaNo ratings yet

- Marelli GenDocument26 pagesMarelli GenMohsen100% (1)

- 11 Phy - Gravitation - QN BankDocument42 pages11 Phy - Gravitation - QN BankMohit DhaundiyalNo ratings yet

- Red 403 Red 503Document1 pageRed 403 Red 503mt1742k4No ratings yet

- Garioni Naval - Steam GeneratorsDocument24 pagesGarioni Naval - Steam GeneratorsgarioninavalNo ratings yet

- Mechanics Paper 1 Study GuideDocument6 pagesMechanics Paper 1 Study GuideJi Jing MengNo ratings yet

- Ground Fault Protection OverviewDocument34 pagesGround Fault Protection OverviewModisa TsamaaseNo ratings yet

- Diesel Generator Set Specifications Sheet-10 kVADocument2 pagesDiesel Generator Set Specifications Sheet-10 kVAvelu.gNo ratings yet