Professional Documents

Culture Documents

Carboxane 2000 Product Performance Summary 092619

Carboxane 2000 Product Performance Summary 092619

Uploaded by

BERSE MAJU INDONESIACopyright:

Available Formats

You might also like

- 922 Water ActivityDocument8 pages922 Water ActivityRajib Kumar BaishnabNo ratings yet

- Envirolastic AR 425 Data PageDocument4 pagesEnvirolastic AR 425 Data PageYsmael Steel TeklaNo ratings yet

- Basf Masterprotect 300 SpecDocument2 pagesBasf Masterprotect 300 SpecWilfredoEnghoyNo ratings yet

- Carbozinc 11: Salt Fog PerformanceDocument2 pagesCarbozinc 11: Salt Fog PerformanceDemetrio RodriguezNo ratings yet

- Ancamide 261a UsDocument11 pagesAncamide 261a UsdamiendamNo ratings yet

- Carbozinc 859: Selection & Specification DataDocument5 pagesCarbozinc 859: Selection & Specification DataFrancis BautistaNo ratings yet

- Ancamide 261A: Curing AgentDocument11 pagesAncamide 261A: Curing AgentBERKAT RAJA SEMESTANo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Interface AE311 Greige SpecDocument2 pagesInterface AE311 Greige SpecNT Bích ThảoNo ratings yet

- Interface AE315 Granite - Azure SpecDocument2 pagesInterface AE315 Granite - Azure SpecNT Bích ThảoNo ratings yet

- Interface AE315 Mushroom - Grass Spec 24112023Document2 pagesInterface AE315 Mushroom - Grass Spec 24112023NT Bích ThảoNo ratings yet

- Carbozinc 859 (Organic Zinc-Rich Epoxy)Document4 pagesCarbozinc 859 (Organic Zinc-Rich Epoxy)helioxavier2No ratings yet

- Ceilcote 2000 Flakeline+td+engDocument2 pagesCeilcote 2000 Flakeline+td+engMohamed NouzerNo ratings yet

- Especificaciones Pintura Macropoxi NavalDocument4 pagesEspecificaciones Pintura Macropoxi NavalVicenteRojasLeonNo ratings yet

- New Product Developed-IndustrialsDocument6 pagesNew Product Developed-IndustrialshpclslroNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- Interface AE310 Iron Spec 24112023Document2 pagesInterface AE310 Iron Spec 24112023NT Bích ThảoNo ratings yet

- Interface - AE310 Fog - Spec - 18012024Document2 pagesInterface - AE310 Fog - Spec - 18012024NT Bích ThảoNo ratings yet

- PDS - GacoFlex S20 Series - Silicone CoatingDocument3 pagesPDS - GacoFlex S20 Series - Silicone Coatingwassaadi95No ratings yet

- ALUBOND SpecificationsDocument2 pagesALUBOND SpecificationssoosanantonyNo ratings yet

- Spectrasyn™ 10: Polyalphaolefin (Pao) FluidDocument2 pagesSpectrasyn™ 10: Polyalphaolefin (Pao) FluidMaram YasserNo ratings yet

- PDS GacoFlexS2100 SiliconeCoating 1Document2 pagesPDS GacoFlexS2100 SiliconeCoating 1wassaadi95No ratings yet

- Carboxane 2000 PDSDocument4 pagesCarboxane 2000 PDSBERSE MAJU INDONESIANo ratings yet

- ReportDocument21 pagesReportFaisal AkhterNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- Carbotherm 3300 PDSDocument4 pagesCarbotherm 3300 PDS이선엽No ratings yet

- John Chan _ Sun AceDocument24 pagesJohn Chan _ Sun AceDario MendezNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Hexane Polymerisation: Data SheetDocument3 pagesHexane Polymerisation: Data SheetHamid Vahedi LarijaniNo ratings yet

- Sabic® Ldpe 2201H0Document2 pagesSabic® Ldpe 2201H0Berkosan BalkansNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Reactamine 760: Selection & Specification DataDocument4 pagesReactamine 760: Selection & Specification DataPrakashNo ratings yet

- Hempaline Defend 630: Product DescriptionDocument3 pagesHempaline Defend 630: Product DescriptionJorge Alberto MontalatNo ratings yet

- Isopentane Shell ChemicalsDocument3 pagesIsopentane Shell Chemicalsazrim02No ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- TarguardDocument4 pagesTarguardMariela Tabata Calizaya ChipanaNo ratings yet

- Targuard PDFDocument4 pagesTarguard PDFsofian juniardiNo ratings yet

- Isoparaffins Shellsolt EuropeDocument3 pagesIsoparaffins Shellsolt EuropeSaman ZehraNo ratings yet

- Sabic Fortify C5070D TDSDocument2 pagesSabic Fortify C5070D TDSmiya079127No ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Carboguard 890N PDSDocument5 pagesCarboguard 890N PDScorey jacobsNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- ACE 2010 - YL056F Akzo Powder CoatingDocument3 pagesACE 2010 - YL056F Akzo Powder CoatingNitin BalapureNo ratings yet

- Lexan Margard HLG5 2021Document3 pagesLexan Margard HLG5 2021Jessica RamosNo ratings yet

- Datasheet Isoparaffinsshellsoltdeurope PDFDocument3 pagesDatasheet Isoparaffinsshellsoltdeurope PDFmeNo ratings yet

- 1035 TD 20 Product Data Sheet ViscopasteDocument2 pages1035 TD 20 Product Data Sheet ViscopasteUrooj IlyasNo ratings yet

- Crystic Gelcoat 76 PA FRDocument3 pagesCrystic Gelcoat 76 PA FRmohamed rafiNo ratings yet

- SABIC® HDPE - C0549 - GlobalDocument2 pagesSABIC® HDPE - C0549 - Globaltechnical kmiNo ratings yet

- SQ1 Mogas95Document1 pageSQ1 Mogas95Basant Kumar SaxenaNo ratings yet

- Automotive TestsDocument1 pageAutomotive TestsMacNo ratings yet

- Pao 100Document2 pagesPao 100Антон СтепураNo ratings yet

- PaverDocument2 pagesPavershalini sivaNo ratings yet

- Mgo SpecsDocument1 pageMgo SpecsPhu HaoNo ratings yet

- Bulletin Abril 2005 B900 00092Document8 pagesBulletin Abril 2005 B900 00092tableman.test9000No ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Pmma 20HRDocument2 pagesPmma 20HRChu ChuNo ratings yet

- NYTRO® 11GBX-US (English) PDSDocument2 pagesNYTRO® 11GBX-US (English) PDSRHETT BUTLERNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- NC20B1NL 2 UsansiDocument7 pagesNC20B1NL 2 UsansiBERSE MAJU INDONESIANo ratings yet

- Sanitile Wall Coatings Brochure - 111616Document8 pagesSanitile Wall Coatings Brochure - 111616BERSE MAJU INDONESIANo ratings yet

- ISO 12944 Brochure - 011921Document16 pagesISO 12944 Brochure - 011921BERSE MAJU INDONESIANo ratings yet

- Marine Market Brochure - Letter - 0120-LoDocument5 pagesMarine Market Brochure - Letter - 0120-LoBERSE MAJU INDONESIANo ratings yet

- OEM Market Brochure - Letter - 0120-LoDocument5 pagesOEM Market Brochure - Letter - 0120-LoBERSE MAJU INDONESIANo ratings yet

- Food & Beverage Market Brochure - 0519-LoDocument8 pagesFood & Beverage Market Brochure - 0519-LoBERSE MAJU INDONESIANo ratings yet

- Rust Bullet Abs CertificationDocument3 pagesRust Bullet Abs CertificationBERSE MAJU INDONESIANo ratings yet

- 10 Year Limited WarrantyDocument2 pages10 Year Limited WarrantyBERSE MAJU INDONESIANo ratings yet

- Unr - Acid - Test Chemical Resistant Cert RBDocument1 pageUnr - Acid - Test Chemical Resistant Cert RBBERSE MAJU INDONESIANo ratings yet

- San241 - 2006za - Potable Water Cert RBDocument1 pageSan241 - 2006za - Potable Water Cert RBBERSE MAJU INDONESIANo ratings yet

- Certificate Rust Bullet - EPA - Drinking WaterDocument2 pagesCertificate Rust Bullet - EPA - Drinking WaterBERSE MAJU INDONESIANo ratings yet

- Chapt05 Lecture SsDocument48 pagesChapt05 Lecture SsLiky LeeNo ratings yet

- Determination of Plancks Constant From P PDFDocument10 pagesDetermination of Plancks Constant From P PDFFelipe CeregattiNo ratings yet

- Global Warming and Its EffectsDocument22 pagesGlobal Warming and Its EffectsHaseebAlisyedNo ratings yet

- Solid State Physics-2Document183 pagesSolid State Physics-2Tauseef AhmadNo ratings yet

- Electric HeatingDocument21 pagesElectric HeatingRao RaeesNo ratings yet

- Anand 04 PDFDocument488 pagesAnand 04 PDFPatikshita majhiNo ratings yet

- IOAA SyllabusDocument5 pagesIOAA SyllabusScience Olympiad Blog100% (5)

- Ce 1Document5 pagesCe 1Imran RazzaqNo ratings yet

- Physics Challenge For Teachers and Students: Solutions To January 2007 ChallengeDocument2 pagesPhysics Challenge For Teachers and Students: Solutions To January 2007 ChallengehenrykNo ratings yet

- Lecture 13Document41 pagesLecture 13Mohamad AsrulNo ratings yet

- Citizen JournalismDocument1 pageCitizen JournalismirineNo ratings yet

- Introduction To Reinforced Conrete: Prepared By: Engr. Christopher E. RodolfoDocument35 pagesIntroduction To Reinforced Conrete: Prepared By: Engr. Christopher E. RodolfoKristoff LorenzoNo ratings yet

- Electrochemical Cell: NameDocument12 pagesElectrochemical Cell: NameHarshit SinghNo ratings yet

- Fluid M1 G1 22.11.12Document2 pagesFluid M1 G1 22.11.12Riss EdullantesNo ratings yet

- Overview Fusion Welding StandardsDocument1 pageOverview Fusion Welding StandardspedroNo ratings yet

- 1 Laigle - Large and Deep Caverns FV2Document56 pages1 Laigle - Large and Deep Caverns FV2pawan paudelNo ratings yet

- PSLE Science 2020 AnswerDocument8 pagesPSLE Science 2020 Answersgdogman1212No ratings yet

- Distillation Lab Manual PDFDocument12 pagesDistillation Lab Manual PDFIdil DoreNo ratings yet

- Bituminous Soil StabilizationDocument30 pagesBituminous Soil StabilizationYathish14382% (11)

- Design of Ms Pipe:: - (40 MM NB, Class'b'Document4 pagesDesign of Ms Pipe:: - (40 MM NB, Class'b'Kancharla Naga Ratna KumarNo ratings yet

- HIPOTESIS DeBROGLIEDocument4 pagesHIPOTESIS DeBROGLIEYusup SetiawanNo ratings yet

- Unit - 1 MCQ'sDocument5 pagesUnit - 1 MCQ'srishavr2001No ratings yet

- Recirculating Air Conditioning Unit: Technical Teaching EquipmentDocument3 pagesRecirculating Air Conditioning Unit: Technical Teaching EquipmentLiya StaariNo ratings yet

- Bda31103 Lect02 - 1 Dof Part1Document20 pagesBda31103 Lect02 - 1 Dof Part1Ong Kok MengNo ratings yet

- ASTM A653 37 Rev 01Document1 pageASTM A653 37 Rev 01Vladimir Lopez ZamoraNo ratings yet

- MGD-GSP-OLV-DPR-024 - 02.10.2020 (Signed)Document3 pagesMGD-GSP-OLV-DPR-024 - 02.10.2020 (Signed)Mircea CaprarNo ratings yet

- Design of Wind Turbine Tower and Foundation Systems - Optimization PDFDocument71 pagesDesign of Wind Turbine Tower and Foundation Systems - Optimization PDFJUAN RULFONo ratings yet

- E04: Laws of Collision With Air TrackDocument3 pagesE04: Laws of Collision With Air TrackTạ HạnhNo ratings yet

Carboxane 2000 Product Performance Summary 092619

Carboxane 2000 Product Performance Summary 092619

Uploaded by

BERSE MAJU INDONESIACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carboxane 2000 Product Performance Summary 092619

Carboxane 2000 Product Performance Summary 092619

Uploaded by

BERSE MAJU INDONESIACopyright:

Available Formats

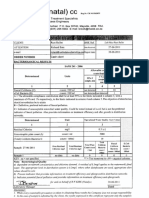

Carboxane® 2000

PRODUCT PERFORMANCE SUMMARY

WEATHERING PERFORMANCE

ASTM D4587 Cycle 2 per SSPC Coating Specification No. 36. *Level 3A is the highest level. It

Method requires minimum exposure time of 3,000 hours with color change ≤ 2.0 delta E and maximum gloss

reduction of 25% or less from the original reading.

Carboxane 2000, one coat applied DTM at 4 to 6 mils DFT. Color 1864 made with dry grind

System

pigments.

At 3,000 hours: Gloss Reduction -- 11%; Color Change – 0.32 delta E.

At 5,000 hours: Gloss Reduction – 11%; Color Change – 0.35 delta E.

Results

At 7,000 hours: Gloss Reduction – 22%; Color Change – 0.28 delta E.

At 10,000 hours: Gloss Reduction – 24%; Color Change – 0.26 delta E.

WEATHERING PERFORMANCE

Method EMMAQUA - actual concentrated sunlight

System Carboxane 2000

25 months EMMAQUA exposure = 2866 MJ/m2

Average 12 months of actual south Florida weathering = 280 MJ/m2

Exposure Approximately 2.5 months of EMMAQUA exposure is equivalent to 12 months south Florida

weathering

Duration 32 months

At 12 months: 90% gloss retention

Results At 25 months: 73% gloss retention

At 32 months: 61% gloss retention

WEATHERING PERFORMANCE

Method South Florida Exposure

System Carboxane 2000: 3 different colors (Grey, White, and Black)

10 years South Florida

Exposure

Direct Inland; 45º Facing South

Panels evaluated for resistance to:

Evaluation Dirt Retention (ASTM D3274); Mildew (ASTM D3274); Chalking (ASTM D4214); Color Change

(dE) (ASTM D2616)

Color Dirt Retention* Mildew* Chalking* Color (dE)

Grey (C705) 10/10 10/10 10/10 2.02

Results

White (0895) 10/10 9.75/10 10/10 1.16

Black (C900) 10/10 10/10 10/10 0.80

*Rating out of 10 (10 being highest/best)

WEATHERING PERFORMANCE

Method ASTM G53 Method D; QUV-A340 bulbs

System Carboxane 2000

Exposure Cycle: 8 hours UV/60 ºC followed by 4 hours condensation @ 45 ºC

At 4,779 hours: Gloss Reduction 2%

At 7,967 hours: Gloss Reduction 3.5%

Results

At 12,157 hours: Gloss Reduction 19%

At 11,000 hours: Color Change 0.46 delta E

September 2019 www.carboline.com Page 1 of 3

Carboxane® 2000

PERFORMANCE DATA SUMMARY

WEATHERING PERFORMANCE

Method ASTM G53 Method D; QUV-B313 bulbs

System Carboxane 2000

Cycle: 8 hours UV/60ºC followed by 4 hours condensation A@ 45ºC

Exposure

Duration: 1500 hours total

Results At 1,500 hours: Gloss Reduction 35%; Color Change 1.25 delta E

CORROSION PROTECTION OVER GRIT BLASTED CARBON STEEL

Method ISO 12944-6: 2018

System Carboxane 2000, one coat applied DTM at 5 to 7 mils DFT.

Results Meets Corrosivity Category C3 High

CORROSION PROTECTION OVER GRIT BLASTED CARBON STEEL

Method ISO 20340

Duration 25 cycles (4200 hours)

Carbozinc 859

System

Carboxane 2000

Surface Prep SSPC-SP10

Corrosion Undercutting: 0 mm

Results Plane Area: No effects

Adhesion: 853 psi (5.9 MPa)

CORROSION PROTECTION OVER GRIT BLASTED CARBON STEEL

Method ASTM D5894 Cyclic Salt Fog/UV Exposure

Duration 6,048 hours

Carbozinc 859

System

Carboxane 2000

Surface Prep SSPC-SP10

Corrosion Undercutting: 3 mm

Results

Plane Area: No effects

CORROSION PROTECTION OVER GRIT BLASTED CARBON STEEL

Method ASTM B117 Slat Spray

Duration 6,000 hours

Carbozinc 859

System

Carboxane 2000

Surface Prep SSPC-SP10

Corrosion Undercutting: 0 mm

Results

Plane Area: No effects

September 2019 www.carboline.com Page 2 of 3

Carboxane® 2000

PRODUCT PERFORMANCE SUMMARY

CHEMICAL SPOT TESTING

Method ASTM D1308 (Chemical spot test)

System Carboxane 2000

Exposure 1 hour @ 75ºF followed by 1 hour recovery

Deionized water: Resistant; no effect

Methyl ethyl ketone: Resistant; no effect

Mineral spirits: Resistant; no effect

5% Sulfuric acid: Resistant; no effect

Results

5% Hydrochloric acid: Resistant; no effect

Glacial acetic acid: Resistant; no effect

5% Sodium hydroxide: Resistant; no effect

Deionized water: Resistant; no effect

HARDNESS

Method ASTM D3363 – Pencil Hardness

System Carboxane 2000

Results Pencil Hardness: 3H

ADHESION (WET)

Method Total immersion in water at 75ºF for 7 days; followed by X-cut” test

System Carboxane 2000

Results No failure after 7 days in liquid or vapor phases

FLEXIBILITY

Method ASTM D522 – Conical mandrel

System Carboxane 2000

a. 3 week ambient cure

Cure

b. 24 hour cure at 140ºF

a. >3/8”

Results

b. >9/16”

NOTE

The technical data presented in this document is accurate to the best of Carboline’s knowledge based on laboratory testing of the

product(s) or system(s) described. Actual results in the field may vary depending on field conditions and application methods. The

performance characteristics stated do not constitute a guarantee or warranty that the products will meet the stated results under all

circumstances. Contact Carboline technical staff with questions. 425, 03748-1, 03873,06299T, 09564, 09665, 096666.

September 2019 www.carboline.com Page 3 of 3

You might also like

- 922 Water ActivityDocument8 pages922 Water ActivityRajib Kumar BaishnabNo ratings yet

- Envirolastic AR 425 Data PageDocument4 pagesEnvirolastic AR 425 Data PageYsmael Steel TeklaNo ratings yet

- Basf Masterprotect 300 SpecDocument2 pagesBasf Masterprotect 300 SpecWilfredoEnghoyNo ratings yet

- Carbozinc 11: Salt Fog PerformanceDocument2 pagesCarbozinc 11: Salt Fog PerformanceDemetrio RodriguezNo ratings yet

- Ancamide 261a UsDocument11 pagesAncamide 261a UsdamiendamNo ratings yet

- Carbozinc 859: Selection & Specification DataDocument5 pagesCarbozinc 859: Selection & Specification DataFrancis BautistaNo ratings yet

- Ancamide 261A: Curing AgentDocument11 pagesAncamide 261A: Curing AgentBERKAT RAJA SEMESTANo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Interface AE311 Greige SpecDocument2 pagesInterface AE311 Greige SpecNT Bích ThảoNo ratings yet

- Interface AE315 Granite - Azure SpecDocument2 pagesInterface AE315 Granite - Azure SpecNT Bích ThảoNo ratings yet

- Interface AE315 Mushroom - Grass Spec 24112023Document2 pagesInterface AE315 Mushroom - Grass Spec 24112023NT Bích ThảoNo ratings yet

- Carbozinc 859 (Organic Zinc-Rich Epoxy)Document4 pagesCarbozinc 859 (Organic Zinc-Rich Epoxy)helioxavier2No ratings yet

- Ceilcote 2000 Flakeline+td+engDocument2 pagesCeilcote 2000 Flakeline+td+engMohamed NouzerNo ratings yet

- Especificaciones Pintura Macropoxi NavalDocument4 pagesEspecificaciones Pintura Macropoxi NavalVicenteRojasLeonNo ratings yet

- New Product Developed-IndustrialsDocument6 pagesNew Product Developed-IndustrialshpclslroNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- Interface AE310 Iron Spec 24112023Document2 pagesInterface AE310 Iron Spec 24112023NT Bích ThảoNo ratings yet

- Interface - AE310 Fog - Spec - 18012024Document2 pagesInterface - AE310 Fog - Spec - 18012024NT Bích ThảoNo ratings yet

- PDS - GacoFlex S20 Series - Silicone CoatingDocument3 pagesPDS - GacoFlex S20 Series - Silicone Coatingwassaadi95No ratings yet

- ALUBOND SpecificationsDocument2 pagesALUBOND SpecificationssoosanantonyNo ratings yet

- Spectrasyn™ 10: Polyalphaolefin (Pao) FluidDocument2 pagesSpectrasyn™ 10: Polyalphaolefin (Pao) FluidMaram YasserNo ratings yet

- PDS GacoFlexS2100 SiliconeCoating 1Document2 pagesPDS GacoFlexS2100 SiliconeCoating 1wassaadi95No ratings yet

- Carboxane 2000 PDSDocument4 pagesCarboxane 2000 PDSBERSE MAJU INDONESIANo ratings yet

- ReportDocument21 pagesReportFaisal AkhterNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- Carbotherm 3300 PDSDocument4 pagesCarbotherm 3300 PDS이선엽No ratings yet

- John Chan _ Sun AceDocument24 pagesJohn Chan _ Sun AceDario MendezNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Hexane Polymerisation: Data SheetDocument3 pagesHexane Polymerisation: Data SheetHamid Vahedi LarijaniNo ratings yet

- Sabic® Ldpe 2201H0Document2 pagesSabic® Ldpe 2201H0Berkosan BalkansNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Reactamine 760: Selection & Specification DataDocument4 pagesReactamine 760: Selection & Specification DataPrakashNo ratings yet

- Hempaline Defend 630: Product DescriptionDocument3 pagesHempaline Defend 630: Product DescriptionJorge Alberto MontalatNo ratings yet

- Isopentane Shell ChemicalsDocument3 pagesIsopentane Shell Chemicalsazrim02No ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- TarguardDocument4 pagesTarguardMariela Tabata Calizaya ChipanaNo ratings yet

- Targuard PDFDocument4 pagesTarguard PDFsofian juniardiNo ratings yet

- Isoparaffins Shellsolt EuropeDocument3 pagesIsoparaffins Shellsolt EuropeSaman ZehraNo ratings yet

- Sabic Fortify C5070D TDSDocument2 pagesSabic Fortify C5070D TDSmiya079127No ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Carboguard 890N PDSDocument5 pagesCarboguard 890N PDScorey jacobsNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- ACE 2010 - YL056F Akzo Powder CoatingDocument3 pagesACE 2010 - YL056F Akzo Powder CoatingNitin BalapureNo ratings yet

- Lexan Margard HLG5 2021Document3 pagesLexan Margard HLG5 2021Jessica RamosNo ratings yet

- Datasheet Isoparaffinsshellsoltdeurope PDFDocument3 pagesDatasheet Isoparaffinsshellsoltdeurope PDFmeNo ratings yet

- 1035 TD 20 Product Data Sheet ViscopasteDocument2 pages1035 TD 20 Product Data Sheet ViscopasteUrooj IlyasNo ratings yet

- Crystic Gelcoat 76 PA FRDocument3 pagesCrystic Gelcoat 76 PA FRmohamed rafiNo ratings yet

- SABIC® HDPE - C0549 - GlobalDocument2 pagesSABIC® HDPE - C0549 - Globaltechnical kmiNo ratings yet

- SQ1 Mogas95Document1 pageSQ1 Mogas95Basant Kumar SaxenaNo ratings yet

- Automotive TestsDocument1 pageAutomotive TestsMacNo ratings yet

- Pao 100Document2 pagesPao 100Антон СтепураNo ratings yet

- PaverDocument2 pagesPavershalini sivaNo ratings yet

- Mgo SpecsDocument1 pageMgo SpecsPhu HaoNo ratings yet

- Bulletin Abril 2005 B900 00092Document8 pagesBulletin Abril 2005 B900 00092tableman.test9000No ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Pmma 20HRDocument2 pagesPmma 20HRChu ChuNo ratings yet

- NYTRO® 11GBX-US (English) PDSDocument2 pagesNYTRO® 11GBX-US (English) PDSRHETT BUTLERNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- NC20B1NL 2 UsansiDocument7 pagesNC20B1NL 2 UsansiBERSE MAJU INDONESIANo ratings yet

- Sanitile Wall Coatings Brochure - 111616Document8 pagesSanitile Wall Coatings Brochure - 111616BERSE MAJU INDONESIANo ratings yet

- ISO 12944 Brochure - 011921Document16 pagesISO 12944 Brochure - 011921BERSE MAJU INDONESIANo ratings yet

- Marine Market Brochure - Letter - 0120-LoDocument5 pagesMarine Market Brochure - Letter - 0120-LoBERSE MAJU INDONESIANo ratings yet

- OEM Market Brochure - Letter - 0120-LoDocument5 pagesOEM Market Brochure - Letter - 0120-LoBERSE MAJU INDONESIANo ratings yet

- Food & Beverage Market Brochure - 0519-LoDocument8 pagesFood & Beverage Market Brochure - 0519-LoBERSE MAJU INDONESIANo ratings yet

- Rust Bullet Abs CertificationDocument3 pagesRust Bullet Abs CertificationBERSE MAJU INDONESIANo ratings yet

- 10 Year Limited WarrantyDocument2 pages10 Year Limited WarrantyBERSE MAJU INDONESIANo ratings yet

- Unr - Acid - Test Chemical Resistant Cert RBDocument1 pageUnr - Acid - Test Chemical Resistant Cert RBBERSE MAJU INDONESIANo ratings yet

- San241 - 2006za - Potable Water Cert RBDocument1 pageSan241 - 2006za - Potable Water Cert RBBERSE MAJU INDONESIANo ratings yet

- Certificate Rust Bullet - EPA - Drinking WaterDocument2 pagesCertificate Rust Bullet - EPA - Drinking WaterBERSE MAJU INDONESIANo ratings yet

- Chapt05 Lecture SsDocument48 pagesChapt05 Lecture SsLiky LeeNo ratings yet

- Determination of Plancks Constant From P PDFDocument10 pagesDetermination of Plancks Constant From P PDFFelipe CeregattiNo ratings yet

- Global Warming and Its EffectsDocument22 pagesGlobal Warming and Its EffectsHaseebAlisyedNo ratings yet

- Solid State Physics-2Document183 pagesSolid State Physics-2Tauseef AhmadNo ratings yet

- Electric HeatingDocument21 pagesElectric HeatingRao RaeesNo ratings yet

- Anand 04 PDFDocument488 pagesAnand 04 PDFPatikshita majhiNo ratings yet

- IOAA SyllabusDocument5 pagesIOAA SyllabusScience Olympiad Blog100% (5)

- Ce 1Document5 pagesCe 1Imran RazzaqNo ratings yet

- Physics Challenge For Teachers and Students: Solutions To January 2007 ChallengeDocument2 pagesPhysics Challenge For Teachers and Students: Solutions To January 2007 ChallengehenrykNo ratings yet

- Lecture 13Document41 pagesLecture 13Mohamad AsrulNo ratings yet

- Citizen JournalismDocument1 pageCitizen JournalismirineNo ratings yet

- Introduction To Reinforced Conrete: Prepared By: Engr. Christopher E. RodolfoDocument35 pagesIntroduction To Reinforced Conrete: Prepared By: Engr. Christopher E. RodolfoKristoff LorenzoNo ratings yet

- Electrochemical Cell: NameDocument12 pagesElectrochemical Cell: NameHarshit SinghNo ratings yet

- Fluid M1 G1 22.11.12Document2 pagesFluid M1 G1 22.11.12Riss EdullantesNo ratings yet

- Overview Fusion Welding StandardsDocument1 pageOverview Fusion Welding StandardspedroNo ratings yet

- 1 Laigle - Large and Deep Caverns FV2Document56 pages1 Laigle - Large and Deep Caverns FV2pawan paudelNo ratings yet

- PSLE Science 2020 AnswerDocument8 pagesPSLE Science 2020 Answersgdogman1212No ratings yet

- Distillation Lab Manual PDFDocument12 pagesDistillation Lab Manual PDFIdil DoreNo ratings yet

- Bituminous Soil StabilizationDocument30 pagesBituminous Soil StabilizationYathish14382% (11)

- Design of Ms Pipe:: - (40 MM NB, Class'b'Document4 pagesDesign of Ms Pipe:: - (40 MM NB, Class'b'Kancharla Naga Ratna KumarNo ratings yet

- HIPOTESIS DeBROGLIEDocument4 pagesHIPOTESIS DeBROGLIEYusup SetiawanNo ratings yet

- Unit - 1 MCQ'sDocument5 pagesUnit - 1 MCQ'srishavr2001No ratings yet

- Recirculating Air Conditioning Unit: Technical Teaching EquipmentDocument3 pagesRecirculating Air Conditioning Unit: Technical Teaching EquipmentLiya StaariNo ratings yet

- Bda31103 Lect02 - 1 Dof Part1Document20 pagesBda31103 Lect02 - 1 Dof Part1Ong Kok MengNo ratings yet

- ASTM A653 37 Rev 01Document1 pageASTM A653 37 Rev 01Vladimir Lopez ZamoraNo ratings yet

- MGD-GSP-OLV-DPR-024 - 02.10.2020 (Signed)Document3 pagesMGD-GSP-OLV-DPR-024 - 02.10.2020 (Signed)Mircea CaprarNo ratings yet

- Design of Wind Turbine Tower and Foundation Systems - Optimization PDFDocument71 pagesDesign of Wind Turbine Tower and Foundation Systems - Optimization PDFJUAN RULFONo ratings yet

- E04: Laws of Collision With Air TrackDocument3 pagesE04: Laws of Collision With Air TrackTạ HạnhNo ratings yet