Professional Documents

Culture Documents

Fall Prevention Plan

Fall Prevention Plan

Uploaded by

Hitoshi KatoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fall Prevention Plan

Fall Prevention Plan

Uploaded by

Hitoshi KatoCopyright:

Available Formats

ADDITION & ALTERATION WORKS TO EXISTING FIRE PROTECTION SYSTEM AT 20 BIOPOLIS WAY

LOCATION: STALLITE LAB AT BASEMENT 1

FALL PREVENTION PLAN

Disclaimer

The details provided in this example method statement are intended as a guide only, the hazards and control

procedures listed are not a comprehensive list. Must ensure that carry out a risk assessment to determine and

control the significant hazards that will be present circumstance. All information and advice are given in good

faith. We cannot accept any responsibility for your subsequent acts or omissions. If have any doubts queries or

concerns should refer to the relevant regulations and take further professional advice.

The Landlord, its representative and its agent reserve the right to impose any additional work procedures or make

changes to the contents herein as may be required by the Authorities or as it deems fit without prior notice to the

Applicants.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 1 of 40

Document No: TL_FP_FPP-00

Effective Date: 01/01/2023

Revision No: 0

Name Title Signature Date

Document Author(s) Islam Md Bulbul WSHC 01/01/2023

Authorised By Kenneth Lee Executive Director 01/01/2023

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 2 of 40

Description

The Fall Prevention Plan is a site-specific plan that provides a systematic approach towards eliminating or

reducing the risk of falling from height by ensuring that all reasonable fall prevention measures and methods are

being taken prior to the commencement of the work or reducing the severity of injury to a person in the event of

a fall such as safety harness systems. Reducing or eliminating the risk of falls by ensuring that all reasonable fall

prevention measures and methods have been implemented, prior to the commencement of work.

The plan should be customized to address the unique conditions at individual workplaces. All workplaces

engaged in activities that require workers to work at height shall develop and implement FPP to ensure the safety

of the workers during their course of work.

The following Fall Protection Plan is a program prepared for the prevention of injuries associated with falls. A Fall

Protection Plan must be developed and evaluated on a site-by-site basis. It is recommended that builders discuss

the written Fall Protection Plan with their OSHA Area prior to going on a jobsite.

Workers must be provided with suitable personal protective equipment such as safety harness with lanyard

attached to a suitable anchor point or lifeline. Where there are no obvious anchors points such as fixed steel

railings, employers must devise alternative means such as installing brackets onto the structure or use

extendable bars equipped with an eye-lug. Workers must be trained in the proper usage of such equipment

including the need to maintain 100% tie-off. This means that at any one point in time, one of two lanyards of the

worker must be secured to the anchor point. This is particularly important when the work involves moving from

one location to another.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 3 of 40

TONG LOONG ENGINEERING PTE LTD

Fall Prevention Policy

The Top Management of TONG LOONG ENGINEERING PTE. LTD. recognizes the importance of providing all

our employees, sub-contractors, and visitors with a safe and healthy work environment. Our goal is to prevent all

occupational injuries and illness.

The company will seek to achieve this by:

➢ Identifying and reducing the risks of all types of work activities that have the potential to produce

personal injury,

➢ Commitment to prevention of injury of persons from incident of falling from height and objects falling

from height.

➢ Commitment to comply with applicable legal and other requirements whilst carrying out working at height

of 2m and above.

➢ This policy shall be communicated, understood, implemented, and maintained at all levels of

organization and to all interested parties.

➢ To prevent workplace fatalities and injuries arising from working at height in our workplace premise, in

compliance to the WSH Act and other relevant regulations.

➢ To ensure our workplace premise is safe and without risks for everyone working at height in our

workplace premises.

Tong Loong Engineering Pte Ltd shall reviewed this policy annually to ensure that it remains relevant and

appropriate to the organization and will make amendment as and when necessary.

All managers and supervisors are responsible and accountable for the safety and health of our employees, sub-

contractors, and company property under their control. Managers and supervisors are responsible for ensuring

compliance to all regulations, procedures and safe work practices in all workplaces, worksites at all times.

NAME: Lee Shih Tong Kenneth

SIGN:

DESIGNATION: Executive Director

DATE: 01/01/2023

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 4 of 40

Responsibilities

Project Manager

➢ Overall responsibilities in implementing Safety and Health at the site.

➢ To actively participate in the Company’s Occupational, Health & Safety Management programmes and

provides support to the safety personnel at site for the implementation of OHS.

➢ To ensure that risk assessment is carried out for all work activities prior to the work commencement.

➢ To monitor the implementation of the FPP.

➢ To carry out incident investigation on all incidents relating to fall.

➢ Review all working methods and process, both new and existing to see that all safety precautions are

met.

➢ Establish an emergency plan for all emergency situations relating to working at height.

➢ Take prompt corrective actions to remove any unsafe or unhealthy work conditions and to maintain

effectively such corrections made.

➢ Liaise with all authorities on safety matters

Project Engineer

➢ Familiarize himself with the Company’s Occupational, Health and Safety Management System and

ensure its effective implementation.

➢ Review any new or changes in the processes, equipment, and materials to ensure that safety is taken

into consideration.

➢ To ensure safe work procedure and the control measures are being carried out for the activities identify

with possible falling hazards and all work related to height activities.

➢ Establish and maintain a programmed for the identification and assessment of falling hazards.

➢ To ensure training is being carried out for all work involve in work at height.

➢ Assists in the investigation of every serious or fatal accident and dangerous occurrence and recommend

preventive measures.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 5 of 40

Safety Manager

➢ Manage and oversee the day-to-day construction management of the project.

➢ Prepares, supervises, and approves the development of PEP [from construction point of view], and its

implementation plus ensuring Lessons Learned are properly documented throughout the life of the

project including Project Close-out.

➢ Manage the construction effort and be the construction representative of our company with Client. To

plan, develop and organize the construction effort to formulate the most cost-effective plan to timely

completion within budget and to implement the execution of that plan.

➢ Responsible for implementation of the scope of work as related to construction/ fabrication, pre

commissioning, load-out and offshore installation hook-up and offshore pre-commissioning and

commissioning of the facilities in conformance with project specifications, Scope of Work, and in

accordance with the approved Project Schedule.

➢ Monitor and report to Project Manager / Manager of project details, including progress, risks and

opportunities in a timely manner.

➢ Ensures all changes to specifications, work scope and drawings are documented.

➢ Define clear roles & responsibilities and deliverable requirements in terms of both scope and schedule to

all the team members.

➢ Review man-hours and duration forecasts to completion for onshore construction and man-hours,

duration and manning forecasts for offshore hook-up and offshore installation durations and resource

requirements.

➢ Monitor construction productivity and schedule performance and investigate reasons for less than

satisfactory performance. Provide recommendations and institute measures for improvement by

modification to operating procedures/work instructions.

➢ Adhere to Company Safety Standards and promote safety culture among the ranks throughout the

Company.

➢ Any other ad-hoc projects and duties as required by the management.

WAH Assessor

➢ Have successfully completed a training course acceptable to the commissioner to equip you to become

a Working at Height assessor.

➢ Implementation of the FPP in accordance with WSH Approved Code of Practice working safety at

height issued by the Workplace Safety and Health (WSH) Council.

➢ Implementation of the PTW to ensure all safety measures are in place before any hazardous Work at

Height (WAH) can commence.

➢ Training requirements for Workers, Supervisors, and other WAH personnel to ensure effective conduct

and oversight of work performed at heights.

➢ Implementation of safety measures while working on roof, near fragile surfaces and by using the

industrial rope access system.

➢ To ensure all reasonably practicable measures and methods are taken to eliminate potential falling from

height.

➢ To implement emergency response procedures and to investigation all falls from height incidents.

➢ To ensure compliance with all applicable regulatory requirement.

➢ To brief all workers on the risk Assessment and Safe Work Procedures for any work at height activities.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 6 of 40

Safety Officer

➢ Assist with the preparation of a construction health and safety plan.

➢ Confirm necessary documentation was submitted to the relevant authorities.

➢ Attend project planning meetings.

➢ Assessments and approval of contractor(s) health and safety plans.

➢ Attend the contractor’s site handover.

➢ Attend regular site, technical and progress meetings.

➢ Facilitate site health and safety meetings.

➢ Identification of the hazards and risks relevant to the construction project through regular coordinated

site inspections.

➢ Establish and maintain health and safety communication structures and systems, distribution of health

and safety specific documents to sub-contractors.

➢ Compiling project specific emergency response and preparedness plans.

➢ Testing the effectiveness of the emergency response plans.

➢ Conduct site safety inductions.

➢ Evaluate the levels of compliance of subcontractors to the project specific health and safety plan and

client specifications through inspections and audits.

➢ Oversee the reporting and investigation of project related incidents.

➢ Oversee the maintenance of all records.

➢ Participation in management reviews of the health and safety systems.

➢ Use of trends analysis to identify system deficiencies and incident trends, outline relevant improvements.

➢ Incorporation of changes into a health and safety management system.

➢ Review and update the health and safety plan.

➢ Development of technical reports in relation to health and safety issues and communicate through

presentations to diverse groups of decision makers.

Safety Coordinator

➢ Conduct periodic safety and health walk-through inspections of all workplace facilities.

➢ Ensure that quarterly safety training and all other specifically required training is provided for all

employees.

➢ Ensure that occupational injuries and illnesses is maintained. Post the annual summary at each work

location.

➢ Conduct accident/injury investigations and illness exposure monitoring.

➢ Establish and monitor a program for reporting and investigating “near-miss” situations.

➢ Conduct investigations into employee inquiries, suggestions, and complaints.

➢ Maintain required safety and health documents/files.

➢ Ensure periodic inspections of all motorized vehicles.

➢ Designate an employee who shall coordinate all safety programs of the employer.

➢ Provide safety classes to each type or class of employee no less than quarterly.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 7 of 40

Scaffold Supervisor

➢ Shall discharge his duties as relevant in the WSH Act and WSH (Construction) Regulations 2007.

➢ Ensure that every scaffold and every component thereof shall be of sound material, good construction,

adequate strength, free from patent defects, and shall be suitable and safe for the purpose for which it is

intended.

➢ Shall ensure that the scaffold is erected, added to, altered, or dismantled in Accordance with the WSH

Act, Factories (Scaffolds) Regulations 2004, CP 14: Code of Practice for Scaffold and the CP 20: Code

of Practice for Suspended Scaffolds.

➢ Shall inspect the scaffold within the immediately preceding 7 days and after inclement weather with

record.

➢ Shall enter the results of inspections in a register containing details as required by the Chief Inspector

and the register shall keep available at the site for the inspection by an inspector.

➢ Shall ensure that the scaffold is displayed with appropriate sign as regard to safe or unsafe use of

scaffold.

➢ To ensure fall related risk assessment control measures are implemented for their activities.

➢ To stop work and rectify or notify safety Dept if any safety & health deviation is observed.

Scaffold Erector

To attend the proper Scaffold Erector course by approved training providers.

➢ Strictly follow the safe work procedure during erection and dismantling.

➢ Make full and proper use of PPE including harness and lifeline.

➢ Check physical condition before start work.

➢ Report all unsafe conditions to scaffold supervisor immediately.

➢ To maintain good Housekeeping in their work area.

➢ To ensure fall related risk assessment control measures are implemented for their activities.

➢ To stop all activity and rectify or notify Safety dept if any falling hazards or unsafe condition is observed.

Safety Supervisor

➢ To carry out approved safe work procedures and control measures at workplace for all working at height

activities.

➢ To inspect and maintain all workers personal fall prevention equipment by submitting weekly checklist.

➢ To carry out training to all workers on risk assessment/safe work procedure for all work related to

working at height activities with proper documentation.

➢ To facilitate the conduct of risk assessment.

➢ Investigate accidents, put up reports and recommend remedial actions.

➢ Compile all safety records and reports.

➢ Conduct all safety audits and put-up reports.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 8 of 40

Work-At-Height Supervisor

➢ Use Scissor lift, Boom lift and scaffold, work platforms and work access points provided.

➢ Implement the Fall Protection Plan; Brief to workers to prevent falling from height & Falling objects.

➢ Ensuring that the person at work has adequate instruction, information, training, and supervision as is

necessary for that person to perform his work.

➢ Ensure to carry out regular maintenance and inspection of equipment and tools.

➢ Avoid overloading any equipment.

➢ Ensure that both hands are kept free when climbing ladders.

➢ Avoid climbing or leaning over or sitting on guardrail.

➢ Ensure that safety harness is properly strapped on and securely anchored.

➢ Ensure that safety harness is properly strapped on and securely anchored.

➢ Wear safety harness for worker's fall protection and ensure that the lanyard is correct length for height

that the worker is carried out.

➢ Train personnel in the correct use of equipment and the procedures that should be followed.

➢ Put in place emergency procedures.

Sub-Contractor

➢ Familiarize them with the Main Contractor’s Fall Protection Plan.

➢ Take prompt corrective actions to remove any fall related unsafe work conditions.

➢ Ensure all fall protection equipment’s brought into site are in good and safe working conditions.

➢ Conduct daily toolbox, SWP to his employee to ensure that they are fully aware of their responsibilities

towards fall safety issues.

➢ Ensure good housekeeping is practiced on site.

➢ Promptly report and investigate all fall related incidents / accidents forward a copy of such investigation

report to the site Project Manager / Project Engineer.

➢ To carry out fall related risk assessment for their activities and submit work method statement and safe

work procedures to the main contractor.

➢ Brief their men/worker on the fall safety risk and hazard pertaining to them job and conduct training to

their workers.

➢ To ensure risk assessment control measures are implemented for them activities,

➢ To ensure that their employee does not oversee or supervise any work in the worksite unless the person

has received adequate fall safety training.

➢ To stop all activity and rectify or notify Safety Dept if any falling hazards are observed.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 9 of 40

Workers

➢ Obey all fall safety instructions, signage and adhere to safe working procedures.

➢ To involve Falling hazards identification; risk assessment and determination of controls (e.g., risk

assessment session).

➢ To assist in fall incident investigation.

➢ Should not tamper with any safety device or undertake any will full or reckless acts.

➢ Make full and proper use of all falls protective equipment and safety devices provided at work.

➢ Report any unsafe condition, openings or any other falling hazards, injuries, and incidents to site WSH

Coordinator / Supervisor immediately.

➢ Practice good housekeeping on site always.

➢ Ask your immediate supervisor if you are in dugth. Do not risk yourself; report any unsafe condition to

your supervisor.

➢ To ensure fall related risk assessment control measures are implemented for their activities.

➢ To stop all activity and notify Safety Dept if any falling hazards are observed.

➢ To use all PPE issued to them correctly when carrying out their work.

➢ To observe all safety precautions and report all unsafe conditions.

➢ To attend all safety training.

➢ To comply with the company in-house safety rules and regulations.

➢ Must not do any act to harm or endanger him or others.

➢ To report on any unsafe act or condition immediate supervisor.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 10 of 40

Checklist for Work-at-Height

This checklist provides the basic requirements for working safely at heights. Occupiers and employers should

ensure and maintain a safe working environment for working at heights. This checklist is non-exhaustive, and

users are recommended to make the necessary customisation to suit the work processes and conditions at the

workplace.

➢ Every open side or opening into or through which a person may fall is covered or guarded by an

effective barrier to prevent falls.

➢ Where covers are used for openings, are these covers securely fixed to prevent accidental

displacement?

➢ Every open side of a staircase is provided with a substantial handrail and lower rail or other effective

means and maintained.

➢ Secure handhold and foothold are provided for any person who must work at a place from which he

would be liable to fall:

(a) More than 2m; or

(b) Into any substance which is likely to cause drowning or asphyxiation.

➢ If item 1 is not practicable, other suitable means such as travel restraint systems or fall arrest systems

should be provided.

➢ Where any work at height is to be carried out, is safe means of access to and egress provided?

➢ Is there a Fall Prevention Plan (FPP) developed and implemented?

➢ Where hazardous work at height is carried out, is a permit-to-work (PTW) for hazardous work at height

available and implemented?

➢ Has risk assessment (RA) been conducted and are safe work procedures (SWP) developed for the

works?

➢ Are the hazards and risk control measures communicated to all workers?

➢ Have all workers received the necessary instruction, information, and training for them to perform work

at heights?

➢ Is there adequate supervision to ensure that safe work practices for working at heights are in place?

➢ Is the condition of the workplace suitable for implementation of a fall arrest or travel restraint system?

(i.e., sufficient height clearance for fall arrest, distance from anchorage point or static line to the edge of

opening and length of safety harness or restraint belt etc.)

➢ Is sufficient and secured anchorage provided?

➢ Is the anchorage point or lifeline being used by the workers who are working at height?

➢ Are workers instructed on the proper method to wear and use the safety harness or restraint belt, as well

as attach it to the lifeline or anchorage point?

➢ Are the anchorage and anchorage line of the travel restraint system or fall arrest system inspected by a

competent person before use by the workers?

➢ Is every ladder and stepladder used of good construction, sound material and adequate strength for the

purpose for which it is used?

➢ Where a ladder is used for access or as a working place, are adequate handholds provided to a height

of at least one metre above the place of landing of the highest rung to be reached by the feet of any

person on the ladder?

➢ Does the ladder or stepladder have level and firm footing?

➢ Is the ladder or stepladder secured so as to prevent undue swaying?

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 11 of 40

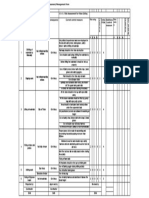

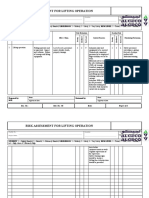

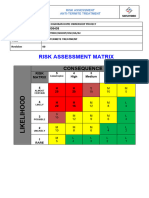

Hazard Identification & Risk Assessment

➢ Hazard identification and risk assessment/safe work procedure for all working at height activities shall be

conducted prior to commencement of the work.

➢ All workers / Sub-contractor is to meet up with the site safety team weekly to discuss and review the

control measures put in place for working at height.

➢ All safety documents shall be review, amend as and when necessary and field reference and

inspections.

Control Measure/Method

Control measures adopted shall be according to the hierarchy of control beginning with elimination, Substitution

engineering control, and administrative control like safe work procedure and permit to work system and lastly

personal protective equipment.

Use of the Ladder, mobile elevated work platform like scissor lift and boom lift to access to high working places.

Proper design of working platform with guard rail and mid rail for mobile scaffold.

Mobile tower scaffold to be erected by qualified erectors, supervised with scaffold supervisor. Those more than 4

meters in height scaffold must be carried out by approved scaffold contractor.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 12 of 40

Safe Work Procedure

➢ Safe work procedures for all activities working at height must be presented with the risk assessment.

➢ Safety belt, harness or lifeline shall be used and securely anchored to a strong structure when working

at position liable to fall 2m or more.

➢ Safe work platform shall be provided for person to work at height. Proper means of access and egress

such as stairs, ladder and ramp must be provided.

➢ Working platform shall be constructed in compliance with WSH (Scaffold) Regulation 2011.

➢ Where work is to be performed at any open side or floor opening which a person is liable to fall 2m or

more, effective barrier able to withstand 50kgf or more, or opening cover must be installed to prevent

falling from height.

➢ Safety nets shall be provided below the area of work where platform or use of safety belt or lifeline is not

practically feasible. The safety net shall be of sufficient size and strength to catch any person for whose

protection it is used and so located as to cover the areas of possible fall.

➢ Overhead protection must be provided to protect other workers at lower levels against falling tools and

equipment, where overhead protection is not practical, the work area exposed to possible falling objects

shall be demarcated.

➢ Climbing and descending of ladders shall be done using both hands.

➢ Ladders are not to be placed where they are liable to be struck by doors, vehicles, and passer-by unless

other effective means of protection are provided.

➢ Tools and equipment shall be raised or lowered by a rope or other approved means.

➢ Assume a person is working on 3 closely deck aluminium work platform in a single bay. Then the

maximum weight for material or equipment not to overload the platform.

➢ Assume 2 workers is working on 3 closely deck aluminium work platform in a single bay. Then the

maximum weight for material or equipment not to overload.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 13 of 40

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 14 of 40

➢ When working at height more than 2m, with no access and space constrain, a mobile elevated, work

platform will be used.

➢ The user must have received training on safe operation and inspection of the mobile elevated work

platform.

➢ The user must anchor their safety harness to the guardrail of the mobile elevated work platform.

When working at height 2m or more, with no access to mobile elevated work platform or scaffold, the last resort is

using the ladder. The ladder is used for light work (e.g., install cover panel, bracing, angle bar, tighten bolt & nuts)

and for short duration (preferable least than 30 minutes per location).

Step’s platform is preferred to be used. In event, there is space constraint and then alternate type of ladder can

be considered.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 15 of 40

The user shall comply with the safe work procedure for workings at height involve using ladder.

Ladders are probably the most used and misused pieces of work equipment within a workplace, without

completing without all necessary check on a ladder before its use can be fatal, work should only be carried out

from a ladder when the job is of short duration and can be carried out safety. Below outline what to do and what

not to do whilst using the ladder.

Do Ensure That

➢ Before you use a ladder, you have considered if the work can be carried out by a safe method.

➢ All ladders are inspected before and after use, especially rungs, treads, and stiles. Do not use any ladder if

it is defective, obtain a replacement.

➢ The ladder is significantly strong and long enough for it intended use.

➢ There are at least three rungs extending beyond a roofs edge.

➢ The ladder is secured at the top, wherever practicable.

➢ The ladder is positioned so that the base wont slip outwards.

➢ The base of the ladder s placed on a firm, level, and dry surface.

➢ If the ladder needs to be placed on grass, that is has a large board place underneath it to prevent it from

slipping.

➢ The bottom of the ladder is secured by stabilisers or ties, to a stable, fixed object.

➢ If this is not possible, that there is another person around to “foot’’ the ladder.

➢ When is use, the ladder rests against a solid surface?

➢ You always keep your body always facing the ladder with your feet in the

Middle of the ladder rungs.

➢ When climbing up or down, use both hands on the stiles.

➢ When working from a ladder you should always have 3 points of contact, i.e. Both feet and at least one

hand.

➢ You should use a shoulder bag, belt holster or belt hooks for carrying tools up and down the ladder.

➢ If the ladder has been loaned, that it has been checked on return as safe for Further use.

➢ If using a ladder over a doorway always ensure that the door is looked, or egress Prevented and

appropriately singed to warn of men at work.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 16 of 40

Don’t Ever:

➢ Use a ladder for work at height other than for short duration work or inspection.

➢ Use a ladder in heavy rain.

➢ Use a ladder near any power lines.

➢ Overreach when using a ladder

➢ Have more than one person on a ladder at any one time

➢ Try to carry a long ladder on your own. Always get assistance

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 17 of 40

Developing and Implementing of Plan

This plan is established for the sole purpose of allowing employers and employees in recognizing the importance

of fall protection, implement procedure and to address falling hazard.

Each personnel who are involved in work at height operation must be trained and to adhere to this plan.

This plan is established in the best knowledge from the team. In the event where this plan has not address on any

special scenario found on site, it must be bought out to the attention of the site manager and together, decide

upon the safest method of fall protection, with record documented, before proceeding.

This plan cannot be administered, implemented, monitored, and enforced by one individual or total reliance on

the site workplace safety and health team alone.

It is the responsibility of respective site managers to spearhead this Fall Prevention Plan, through education,

regular monitoring, and enforcement. The site engineers, supervisors, coordinators and workplace safety and

health personnel are also responsible to correct any unsafe acts or conditions immediately.

All personnel from this project have the responsibility to understand and adhere to the procedures of this plan and

to follow the instructions of their immediate supervisors. It is also their responsibility to bring to management’s

attention on any unsafe or hazardous conditions that may cause injury to either themselves or any other

stakeholder.

Protection from Falling Objects

When working on a site where the potential for falling objects exist the employer needs to provide adequate

warning for both the employee and other people who may enter the site. Ways to do this include verbally

communicating the hazards and by placing of signage tat states beware of falling equipment. Another way to

ensure safety of guest on the site is to have an employee in charge of escorting them who is aware of areas that

have potential for falling objects. The employee can then try to navigate the guest’s route around those hazards.

When workers are exposed to falling object, we ensure they wear all necessary PPE and implement one of the

following measures.

➢ Erect the fire protection pipe to prevent object from falling from higher level.

➢ Barricade the area to which objects could fall, prohibit workers from entering the barricaded area, and

keep objects that may fall far enough away from the edge of a higher level so that those objects would

not go over the edge if they were accidentally moved.

➢ When moving a load, it is important to never lift, lower or swing a load over anyone’s head. In areas

where loads are being placed on high shelves with the potential to tumble over the other side ensure you

have a spotter in place that keeps employees from entering the backside hazard and that can help

instruct the employee placing the load. Restrict these stacking and heavy moving operations to hours

when fewer people are present.

➢ Tools and debris are one of the main causes of falling objects. To mitigate this hazard employees, need

to ensure the work areas is clean and tidy. When a worker is done using a tool, they need to put it in the

proper storage area, if they have made a mess or created debris, they need to clean it up immediately.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 18 of 40

➢ Use toe boards or guardrails on scaffolds to prevent objects from falling. Alternately, use debris nets or

catch platforms to grab falling objects.

➢ When working with machines or power tools that can produce flying particles, wear safety glasses,

goggles, or face shields.

➢ Inspect tools prior to use and be sure all guards are in place and in good working condition.

➢ Allow only properly trained workers to use power-actuated tools.

➢ Administrative controls are a great way to prevent or stop falling objects in the workplace. Examples of

these types of controls include the installation of boards on the sides of elevated work areas or scaffolds

to prevent objects from falling over the edge, the usage of bars across storage areas to keep material

from tumbling out, the usage of nets to capture falling object, the implementation of fences or other

barricades to keep workers and guest out of fall zones and scheduling work for a time when the amount

of people at lower levels is at a minimum.

➢ When all else fails the last line of defense is personal protective equipment. Anyone who is going to be

in an area where to potential for falling object hazards exists needs to wear a hard hat and steel toed

shoes. Both pieces of equipment must be inspected before use and be in proper working condition and

fit properly. All employers are required to provide employees with Personal Protective Equipment.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 19 of 40

Type of Fall Prevention System

When a system provides fall arrest, it protects the worker who is already in the process of falling by stopping

the fall after it has happened. A system provides fall restraint; it is preventing the worker from accessing the

potential hazard. Fall arrest is the form of fall protection which involves the safe stopping of a person

already falling.

Two types of fall protection equipment are used in power generation, transmission, and distribution work

positioning and fall arrest equipment. Fall arrest equipment comes in many forms. For power generation,

transmission, and distribution work, workers commonly use a body harness with a shock-absorbing lanyard.

A fall protection plan is required whenever a worker is working at height. Government regulations require

written plans be available to all workers. The plan must be available at the work site before work where there is a

potential for a fall.

A personal fall arrest system is one option of protection that OSHA requires for workers on construction sites who

are exposed to vertical drops. Attachment Location. Body Harness. Vertical Lifeline/Lanyard. Articulation man lifts

provided with a restraint system and full body harness to an anchor point. Guardrails with toe boards.

Personal fall arrest systems

Anchor points

A path is the black line that appears when you draw a line in Adobe Illustrator. A path is made up of a series

of points called “anchor points” and line segments between these points. The anchor points on the either end of a

path have “control handles” and these can be used to control the direction of the curved path.

Anchor points are a vital part of a fall protection system. Fall protection anchor points are usually installed on the

roof and are used to connect lanyards, lifelines and other forms of tie-off which prevent a worker from falling. Roof

anchors can be as simple as a D-ring connection or as complex as a complete lifeline system. Both permanent

and temporary fall protection anchors are available.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 20 of 40

Full body harness

Fall protection harnesses and other fall arrest and restraint equipment for virtually any application. A harness is

an integral part of any personal fall arrest system and is an important choice. While many of our harnesses can

be used on most jobs, we also manufacture harnesses for specific uses within different industries. Safety

harnesses are a necessity in fall protection. These lightweight, durable harnesses meet OSHA standards.

Choose from different sizes, styles and materials that work for construction, arc flash, wind energy, and more.

Safety harnesses provide comfort and confidence, and directly affects the user's productivity, as well as gives

them flexibility to do what needs to be done on the site. The latest in full body harness protection have earned a

reputation as top full body harnesses for maximum comfort, freedom of movement and ease-of-use.

Restraint line or Lanyard

Self-retracting lanyard/lifelines are popular devices among professionals who work at height. These fall arrest

systems can save lives, but they can also be dangerous if used improperly. The use of an SRL can seem easy,

as its basic functions are just like a seat belt, but it is important to pay attention to proper use. They are the edges

of floors, roofs, decks, or other walking-working surfaces which move or change location as additional sections

are constructed. For example, each time a piece of plywood is placed on floor joists, the relative position of the

unprotected edge changes. "Unprotected sides and edges." Each employee on a walking/working surface

(horizontal and vertical surface) with an unprotected side or edge which is more above a lower level shall be

protected from falling using guardrail systems, safety net systems, or personal fall arrest systems.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 21 of 40

Shock Absorbing Lanyard

The result of a fall in a body belt is never pretty - the fall forces applied in a concentrated area of the body can

bring about severe internal injuries. So much so that belts were removed from recognition in fall arrest

applications, along with the polyester rope lanyards without energy absorbers.

They were replaced with full body harnesses and fall arrest lanyards or self-retracting lifelines with energy-

absorbing systems, both of which offer a higher degree of user safety during and after the fall, as well as lower

impact on the body because of the fall itself.

Retractable Lanyard

A Retractable Lifeline works a lot like a seat belt. Pull it out slowly, and it will follow you. If you run, you'll end up

on your ass. These self retracting lifelines come in various sizes, lengths, material. Use a web retractable for

concrete, and steel retractable for welding.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 22 of 40

Rope grabs

The rope grab is the device that allows the worker to move up and down a vertical lifeline. It's like a bus pass.

Without it, you're an idiot with a rope tied around your waist. One of the first things to consider while using a rope

grab is to find where your rope meets the roof edge and tie a knot. This is just an added safety precaution you

can make in case the unforeseeable happens.

The manual rope grab is basically a metal hand trigger. When you hold the rope grab down, you can move freely

up and down the rope. Once you let go, the rope grab latches to the rope and will no longer move up and down.

This way you won't fall any further. If you do fall, do not grab onto the rope grab, and pull the trigger! You'll just

keep sliding down the rope, which is not good. This would be one of reasons you would want to tie that knot in the

end of your lifeline.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 23 of 40

Connectors (Self-locking snap hooks)

Snap hooks and carabineers are to be used as anchorage connectors or connectors for fall arrest, restraint, work

positioning, suspension, or rescue systems. Fall arrest systems typically include a full body harness and a

connecting subsystem, such as a self retracting lifeline. Maximum permissible free fall. This type of system is

used where a free fall is possible before the fall is arrested.

Restraint systems typically include a full body harness and a lanyard or restraint line used to restrain the user

from reaching a hazard (leading edge roof work). This type of system is used where no vertical free fall is

possible. Work positioning systems typically include a full body harness and lanyard to position or support the

user at the work position.

Rescue systems typically include a full body harness, and a connecting subsystem, such as a lanyard, that is

used to retrieve a victim in a rescue application.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 24 of 40

Engineered Lifelines

An engineered horizontal lifeline is a completely different animal than the lifeline in the bucket. Systems designed

by a qualified person have end anchors rated to withstand two times the applied load in the event of a fall. In this

case, a fall protection engineer uses professional training and knowledge to determine the anchor points and

connections are strong enough to arrest a fall and to reduce required fall distances. A permanently

installed horizontal lifeline is made from stainless steel cable rather than a reinforced, synthetic nylon rope. Most

importantly, the system is Permanent.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 25 of 40

Warning lines

The warning line must be erected around all sides of the roofing work area. Determine if mechanical equipment

will be used for the work. If so, the warning line must be erected no less than 6 feet from the roof edge parallel to

the direction of the mechanical equipment’s operation and no less than 10 feet from the roof edge perpendicular

to the direction of the mechanical equipment’s operation.

If mechanical equipment is not being used, the warning line must be erected no less than 6 feet from the roof

edge. Employees who are not performing roofing work in the designated work area must remain outside the work

area between the roof edge and the warning line. Points of access, material-handling areas, storage areas and

hoisting must be connected to the work area by an access path formed by two warning lines. When these areas

are not in use, a warning line must be placed across the path at the point where the path intersects the warning

line erected around the work area, or the path must be offset in a manner that a person cannot walk directly into

the work area.

All warning lines must be flagged with high-visibility material at no more than 6-feet intervals. Warning lines must

be rigged and supported so the lowest point (including sag) is no less than 34 inches from the walking/working

surface and the highest point is no more than 39 inches from the walking/working surface. After being rigged with

warning lines, stanchions shall be capable of resisting (without tipping over) a force of at least 16 pounds applied

horizontally against the stanchion, 30 inches above the walking/working surface perpendicular to the warning line

and in the direction of the floor, roof or platform edge. The rope, wire or chain serving as the warning line must

have a minimum tensile strength of 500 pounds and, after being attached to the stanchions, must support

(without breaking) the load applied to the stanchions.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 26 of 40

Safety nets

As a passive fall safety and debris containment device, safety netting systems provide your crew and the public

below the protection they need, without requiring their active involvement. Construction safety nets must be

heavy-duty and incorporate a UV coating to stand up to the elements outdoors. They provide debris containment,

personnel fall protection or both and are available for various commercial construction builds. Industrial safety

nets are typically lighter but just as strong and often include a flame-retardant protection for added safety. They

are ideal for many material handling applications and available in pre-packaged or custom configurations.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 27 of 40

Safety monitory systems

The safety monitor system is a method of preventing workers from falling when they are working, without other

types of fall protection, on a leading edge or roof perimeter, or in other instances where there is a fall hazard.

Safety monitoring of a clinical trial is conducted by an independent physician with relevant expertise. This is

accomplished by review of adverse event, immediately after they occur, with timely follow-up through resolution.

A fall protection plan is required whenever a worker is working at height. Government regulations require

written plans be available to all workers. The plan must be available at the work site before work where there is a

potential for a fall.

Appropriate FPP will be determined by the task to be performed. Fall protection training is an important part of a

worker's overall safety training. Identifying fall hazards and deciding how best to protect workers is the first step in

reducing or eliminating fall hazards. Occupational fatalities caused by falls remain a serious public health

problem.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 28 of 40

Inspection of Fall Prevention System

After completing installation of any fall arrest system or fall protection equipment, all components are inspected

and certified. Certification documents that your fall protection system and all related personal protection

equipment (PPE) meets OSHA regulations. Proper signage verifies the system’s tested capabilities and

operational limits and informs outside inspectors that the system has been designed and tested by an OSHA-

defined “Qualified Person.” DFP also provides all clients with a complete systems installation manual and binder.

The following criteria will be utilized to maintain all equipment in good working condition.

Full Body Harness

Inspect before each use

➢ Closely examine all the nylon webbing to ensure there are no burn marks, which could weaken the

material.

➢ Verify there are no torn, frayed, broken fibbers, pulled stitches, or frayed edges anywhere on the

harness.

➢ Examine D-ring for excessive wear, pits, deterioration, or cracks.

➢ Verify that buckles are not deformed, cracked, and will operate correctly.

➢ Check to see that all grommets (if presents) are secure and not deformed from abuse or a fall.

➢ Harness should never have additional punched holes.

➢ All rivets should be tight, not deformed.

➢ Check tongue / straps for excessive wear from repeated buckling.

Inspect after each use

➢ Annual inspection of all harness will be completed by a competent person, documentation will be

maintained on file.

➢ Storage will consist of hanging in an enclosed cabinet, to protect from damage.

➢ All harness that are involved in a fall will be destroyed.

Lanyards/Shock Absorbing Lanyards

Inspect before each use

➢ Check lanyard material for cuts, burns, abrasions, kinks, knots, broken stitches, and excessive wear.

➢ Inspect the snap hooks for hook, locks, and eyes distortion.

➢ Check carabineer for excessive wear, distortion, and lock operation.

➢ Ensure that all locking mechanisms seat and lock properly.

➢ Once locked, locking mechanism should prevent hook from opening.

➢ Visually inspect absorber attaches to the lanyard.

➢ Verify that points where the lanyard attaches to the snap hooks are free of detects.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 29 of 40

Inspect after each use

➢ Annual inspection of all harness will be completed by a competent person, documentation will be

maintained on file.

➢ Storage will consist of hanging in an enclosed cabinet, to protect from damage.

➢ All harness that involved in a fall will be destroyed.

Tie-off Adaptors/Anchorages

➢ Inspect for integrity and attachment to solid surface.

➢ Annual inspection of all tie-off and anchorages by a competent person with documentation.

➢ All tie-offs and anchorages will be destroyed and replaced after a fall.

Boom Lift / Scissors Lift

The safe use of a boom lift requires a rigorous application of the rules. This training course gives workers all the

techniques and knowledge required to drive, access, and operate boom lifts by demonstrating the operational

limits of these devices and the best maintenance practices for them.

Inspect before each use

➢ Inspect/service per manufacturer guidelines. Boom lift, scissors lifts, and safety nets will be inspected at

the beginning of each shift in use. Structural integrity or forklift basket will be checked per same

schedule.

➢ Annual inspection of forklift basket will be completed by competent person with documentation

maintained.

➢ Operating and emergency controls are in proper working condition, EMO button or Emergency Stop

Device.

➢ Functional upper drive control interlock (i.e., foot pedal, spring lock, or two hand controls).

➢ Lower operating controls successfully override the upper controls.

➢ Both upper and lower controls are adequately protected from inadvertent operation.

➢ Work platform extension slides in and out freely with safety locking pins in place to lock setting on

models with extension platforms.

➢ Inspect for defects such as cracked welds, fuel leaks, hydraulic leaks, damaged control cables or wire

harness, etc.

➢ Floor conditions: Drop offs, holes, uneven surfaces, and sloped floors.

➢ Housekeeping: Debris, floor obstructions, cords, construction material and supplies.

➢ Electrical power cables or panels, (minimum 10 feet away). If larger lines or wet conditions, contact

EH&S or the Electrical shop for guidance. Insolated small lines in dry conditions 3 feet away.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 30 of 40

Horizontal Lifelines

➢ Inspect all screw, bolts, nuts, and any other fastening devices to ensure they are not loose or missing.

Also make sure they haven’t been altered in any way.

➢ Look for rust, corrosion, or any other deterioration of the metal components.

➢ Inspect your rope for broken wires (wire rope), broken threads (synthetic rope), or any other obvious

damage.

➢ Inspect all screw, bolts, nuts, and any other fastening devices to ensure they are not loose or missing.

Also make sure they haven’t been altered in any way.

➢ Look for rust, corrosion, or any other deterioration of the metal components.

➢ Inspect your rope for broken wires (wire rope), broken threads (synthetic rope), or any other obvious

damage.

➢ Lean it as directed by the manufacturer. This should be periodically and is usually with warm water and

mild soap. Make sure any casings are clean as well as the ropes. Make sure your labels are clean so

that they are legible. Let the equipment air dry.

➢ As with other fall protection, store the equipment in a cool dry place. While it is in use, ensure your

inspections are frequent enough for the type of weather exposure it is getting, but when not in use, make

sure you store it properly.

➢ Any issues contact your manufacturer or distributor. Do not let problems or even suspected problems

go unchecked. Your employees are counting on this equipment to protect their lives.

Guardrails

Guardrail should be inspected at least every 12 months. There are many reasons why guardrails may not be

compliant and may not provide the collective protection they were intended to provide. The weather can have a

big impact on the stability of guardrail systems, i.e., excessive high winds and snow may cause the rails to move

and become detached at points. Foliage can also cause guardrail to become unstable.

It is recommended to have Guardrail Edge Protection visually inspected every 12 months. This ensures that the

system still meets the manufacturer’s commendations and shows you have taken all the necessary steps to

provide the highest possible safety for anybody working at Height.

Height safe, install, inspect, and certify the following types of guardrail edge protection systems:

➢ Fixed

➢ Freestanding

➢ Parapet

➢ Collapsible

➢ Rivet fix

➢ Rail fixed to metal deck roofs

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 31 of 40

What to look for:

➢ Movement from the original installation location

➢ Damage to critical components and counterbalance weights

➢ Loose or missing components, fixing bolts, grub screws etc.

➢ Temporary systems - Daily visual inspection will be completed by a competent person.

➢ Temporary systems - Weekly, a complete structural inspection will be completed by a competent

person.

➢ Permanent Systems - Annual structural inspection will be completed by a competent person with

future frequency of inspection defined based on conditions/controls present.

Height safe Systems will tag the guardrail and provide you with a certificate of inspection for your records and

contact you’re a month prior to your next inspection due date. This will guarantee your system always remains

safe and fit for use. Should you require any repairs, Height safe Systems will provide you with a report explaining

any urgent repairs or recommendations which may help improve your system and your safety.

Storage and Maintenance Fall Prevention Equipment

➢ Never store the personal fall arrest equipment in the bottom of a tools box, on the ground, or outside

exposed to the elements (i.e., Sun, Rain, Snow, etc).

➢ Hang equipment in a cool dry location in a manner that retains its shape.

➢ Always follow manufacturer recommendations for inspection.

➢ Clean with a mild, nonabrasive soap, and hang to dry.

➢ Never force dry or use strong detergents in cleaning.

➢ Never store equipment near excessive heat, chemicals, moisture, or sunlight.

➢ Never store in an area with exposures to fumes or corrosives elements.

➢ Avoid dirt and build-up on equipment.

➢ Never use this equipment for any purpose other than personal fall arrest.

➢ Never use this equipment for any purpose other than personal fall arrest.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 32 of 40

Training

Under no circumstances shall workers work in areas where they might be exposed to fall hazards, do work

requiring fall prevention devices, or use fall prevention devices until they have. Successfully completed

company’s fall prevention training program. The training program includes operational training on recognition and

avoidance of unsafe conditions and the regulations applicable to their work environment for each specific fall

hazard the employee may encounter. The training program is given by a competent person qualified in each

aspect of the program, and must cover the following areas:

➢ Selection and use of personal fall arrest systems, including application limits, proper anchoring and tie-

off techniques, estimation of free fall distance (including determination of deceleration distance and total

fall distance to prevent striking a lower level), methods of use, and inspection and storage of the system.

➢ The correct procedures for erecting, maintaining, disassembling, and inspecting the FPP to be used.

➢ The use and operation of guardrail systems, personal fall arrest systems, safety net systems, warning

line systems, safety monitoring systems, controlled access zones, and other prevention to be used.

➢ The role of each employee in the safety monitoring system when this is used.

➢ The limitations on the use of mechanical equipment during the performance of roofing work on low-

sloped roofs.

➢ The correct procedures for the handling and storage of equipment and materials and the erection of

overhead prevention.

➢ The role of employee in fall prevention plan.

➢ The Safety Supervisor will identify all current and new workers who require training and schedule the

instruction for those workers. Training on the above components will occur on the job site, as

appropriate. Training will cover written policy/procedures on fall prevention and include training on the

subject. Job site instruction will include demonstration of and practice in wearing fall prevention

equipment and any instruction necessary for a specific job. The Safety Supervisor has overall

responsibility for the safety of workers and will verify training program, for each worker required to be

trained.

S/n Description of Training Training Conduct by

1 Use of Safety Belt/Harness Quarterly Supervisor

2 Use of Lifeline Anchorage Point Quarterly Safety Personnel

3 Use of Fall Arrestor Quarterly Safety Personnel

4 Use of Work Platform Monthly Supervisor

5 Use of Mobile Scaffold Monthly Safety Personnel

6 Use A Frame Ladder Monthly Supervisor

7 Scaffold Erection & Dismantling Monthly Scaffold Supervisor

8 Using Boon Lift & Scissor Lift Yearly Supplier

All the trainings will be carried out in phases to help the person who carries out any work at height to:

➢ Be aware of the risk involved.

➢ Understand and implement the control measures.

➢ Be acquainted with fall protection; and

➢ Respond to emergency where applicable.

All training will be documented and a list the personnel been trained will be tabulated onto the recorded.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 33 of 40

Incident Investigation

All accidents that result in injury to workers, regardless of their nature, are investigated and reported. It is an

integral part of any safety program that documentation takes place as soon as possible so that the cause and

means of prevention can be identified to prevent a reoccurrence.

If a worker falls or there is some other related, serious incident (e.g., a near miss) occurs, this plan will be

reviewed to determine if additional practices, procedures, or training need to be implemented to prevent similar

types of falls or incidents from occurring.

The person leading the investigation should be one with authority to put in place immediate corrective action

when the investigation is completed. The person carrying out the investigation must be neutral and not belong to

the team involved in the incident. Depending on the size and complexity of the incident, the investigation team

can include people from different levels of the company (e.g., worker, supervisor, engineer, etc.). The supervisor

needs to be involved because he knows the work area and processes well; he also represents the first-level

management of the company.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 34 of 40

Rescue & Emergency Preparedness

An emergency response plan for all emergency situations relating to work at height and object falling from height

must be established.

An emergency rescue team comprising of first aiders, emergency responders or rescuers should be appointed

and adequately trained to carry out rescue operation. Emergency drills and exercises must be conducted at least

once in every six months.

List of Emergency Contact Person

Name Designation Contact No Remark

Kenneth Lee Executive Director 9735 2108

A Jesu Project Engineer 9237 4605

Miah Akib Safety Coordinator 8698 8166

Ministry of Manpower 6438 5122

Police 999

SCDF / Ambulance 995

Power Grid 1800 752 6666

Power Gas 1800 752 1800

PUB (Water) 1800 284 6600

Singapore Telecoms 1800 288 4099/4900

Emergency contact numbers of relevant authorities (e.g., SCDF, PUB, MOM, Police) and contact numbers of

project management, safety personnel and first aiders should be made easily available Sufficient and suitable

first-aid facilities.

Emergency respond plan should be established and include:

➢ Evacuation route

➢ Emergency assembly point

➢ Formation of emergency team

➢ Raising of alarms

➢ Evacuation procedure

➢ First-aid measures (first aider, first aid facilities)

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 35 of 40

Emergency drill and exercise

A fire drill is a method of practicing how a building would be evacuated in the event of a fire or other emergency.

Usually, the building's existing fire alarm system is activated, and the building is evacuated as if

the emergency had occurred.

An emergency management plan is a course of action developed to mitigate the damage of potential events that

could endanger an organization's ability to function. Such a plan should include measures that provide for the

safety of personnel and, if possible, property and facilities.

All possible emergencies, consequences, required actions, written procedures, and the resources available.

Detailed lists of personnel including their home telephone numbers, their duties and responsibilities should be

conducted at least once a year review plan from lesson learnt

Nearest Hospital

Ng Teng Fong General Hospital

1 Jurong East Street 21, Singapore 609606

Suspension Trauma

➢ Effect on the Blood circulation system due to suspended for too long.

➢ Blood is pulled into the legs by gravity, reducing the flow to the heart.

➢ Unable to maintain supply to the brain, heartbeats increase faster and breathing becomes faster.

➢ Eventually hear slows and becomes unconscious.

Important

➢ When hanging in a fall harness, the leg straps support the body's weight. During this time, the

leg straps of the fall protection harness crush the femoral arteries on the inside of the legs,

cutting off blood circulation. This results in nausea, unconsciousness, and a drop in blood

pressure and heart rate.

➢ Blood supply to the brain falls below critical level.

➢ Death can occur within 20minutes or insufficient blood circulation to the legs that might lead to

amputation.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 36 of 40

Prevention Method

➢ Both hands raise upward to hold onto the suspended lanyards and raise both legs toward our

chest to form an arc.

➢ Try and brace your legs against a solid object or building structure to support our body,

releasing the suspension loading.

➢ Create a temporary support to relive tension at the straps while waiting for rescuers.

➢ Rescue the casualty ASAP.

➢ If the victim is conscious, communicate with the victim and assure the victim help is on the way

Inform the Project Manager or Safety Officer.

Rescue Plan

➢ The site supervisor (or alternate foreperson) takes control of the situation.

➢ The site supervisor sounds the emergency alarm—two long blasts from a horn. All workers in

the immediate vicinity of the incident stop working. The site supervisor quickly evaluates the

situation and identifies any further hazards that could arise.

➢ The site supervisor or their designate goes to get help if workers are close by. If no one is close

enough, the site supervisor calls for help.

➢ Attend first aid if you are competence

➢ The site supervisor calls SCDF to notify local police, fire, and ambulance if required.

➢ The site supervisor (or a worker assigned to the task) isolates the accident zone and its

perimeter to limit further exposure.

➢ The site supervisor (or a worker assigned to the task) moves all non-affected personnel to a

safe zone or directs them to remain where they are.

➢ The site supervisor sends a designated worker to the site gate to meet the response team

(police, medical, fire, etc.) and ensure that they have a safe access path to the accident scene.

➢ The site supervisor assembles the emergency rescue team at the accident site as quickly as

possible to determine the best rescue procedure for the situation.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 37 of 40

Post-Rescue Procedure

All non-affected workers should remain in the designated safe gathering zone until the site supervisor

notifies them to do otherwise.

The site supervisor and health and safety representative should

➢ Begin the accident investigation.

➢ Quarantine all fall-arrest equipment that may have been subjected to fall fatigue effects

and/or shock loading for further investigation.

➢ Secure the area (the WSH (Incident Reporting) Regulation requires that an accident scene

not be disturbed where a fatal or critical injury has occurred).

➢ Determine whether the jobsite-specific rescue and evacuation plans were followed as

designed.

➢ Record modifications or additions to the plans that the rescue team deems necessary.

➢ Record all documented communications with fire, police, MOM, and other contractors

involved. (When a fall occurs and is arrested, you must notify the MOL in writing.)

➢ Record all documented statements from employees, witnesses, and others.

➢ Save all photographs of the incident.

➢ Record all key information such as dates, time, weather, general site conditions, and

specific accident locales including sketches of the immediate incident area, complete with

measurements if applicable.

After Rescue

➢ If an individual is unconscious. Do not lay him down immediately.

➢ Sudden increase in blood flow to the heart can seriously affect the heart.

➢ Suggested that patient gradually goes from kneeling, sitting to lying over 30 min periods.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 38 of 40

Always keep the following items for the rescue.

Depending on the type of work that is carried out, as well as the height of the building or site-specific

circumstances, you might need to use rescue equipment as simple as a ladder or as complicated as a

crane. In some situations, you may have to consider MEWP (mobile elevating platforms), man-riding

baskets for cranes or proprietary rescue system. If someone has fallen over an edge, you need to think

of the additional friction encountered when trying to raise the fallen worker, the anchor line being at a

risk of cutting and generally be aware of the edge interfering with the rescue equipment.

In any case, make sure that the equipment that you will use for a rescue are properly serviced before being use.

Do not use the equipment for purposes other than which it was intended. Whatever happens, make sure that

there are other trained individuals on the ground that can assist with the rescue plan.

➢ First-aid kit.

➢ Three lanyards equipped with shock absorbers.

➢ One full-body harness.

➢ Tag line always attached to the basket.

➢ Descent controller rescue device in good working condition.

➢ Secondary safety line to tie the basket above the headache ball of the crane.

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 39 of 40

Fall Prevention Plan Revision Date: 17 Jan 2023

TONG LOONG | Haskell | Rev 00 | Jan 2023 Prepared by: ISLAM MD BULBUL Page 40 of 40

You might also like

- 2.1 - CR 10 (1) (A) Fall Protection PlannerDocument1 page2.1 - CR 10 (1) (A) Fall Protection PlannerSusan LouwNo ratings yet

- Steel FixingDocument5 pagesSteel Fixingrishanmulky89% (9)

- Fall Prevention Plan: Client Logo Project NameDocument17 pagesFall Prevention Plan: Client Logo Project NameNestor Mijares100% (6)

- Method Statements For Eskom Substations - Stringing, Erection, Earthing and Cabling PDFDocument27 pagesMethod Statements For Eskom Substations - Stringing, Erection, Earthing and Cabling PDFTreenel TradingNo ratings yet

- Portable Electrical Equipment InspectorDocument2 pagesPortable Electrical Equipment InspectorAmukelaniNo ratings yet

- Hirarc FormDocument2 pagesHirarc FormAus100% (1)

- Ladders, Hop Ups Risk AssessmentDocument8 pagesLadders, Hop Ups Risk AssessmentRebecca Winter100% (2)

- Partsbook SDT85 T58506-A1000000Document94 pagesPartsbook SDT85 T58506-A1000000BE 073No ratings yet

- RISK ASSESSMENT REPORT - George Municipality - Tender ENG0042016 Installation of Perimeter Concrete Palisade FeDocument10 pagesRISK ASSESSMENT REPORT - George Municipality - Tender ENG0042016 Installation of Perimeter Concrete Palisade FeemmyNo ratings yet

- Job Hazard Analysis For Cementitious GroutingDocument8 pagesJob Hazard Analysis For Cementitious Groutingaloysius akpanNo ratings yet

- Ladder Log Ladder Inspection ChecklistDocument2 pagesLadder Log Ladder Inspection Checklistkhalis100% (1)

- Risk Assess Plastering 2006 Tcm17 26368Document2 pagesRisk Assess Plastering 2006 Tcm17 26368Anonymous QGHbz92u100% (1)

- SWP - Formwork ConstructionDocument1 pageSWP - Formwork ConstructionSiti Norsyazana Abd Majid100% (1)

- Risk Assessment For Partition MarkingDocument5 pagesRisk Assessment For Partition Markingkhalid14No ratings yet

- 8.11. CR 29.H. Firefighting Equipment InspectorDocument3 pages8.11. CR 29.H. Firefighting Equipment InspectorGasa Security100% (2)

- Fencing, Installation and Repair.: Activity DescriptionDocument6 pagesFencing, Installation and Repair.: Activity DescriptionVictor100% (1)

- Casting ConcreteDocument9 pagesCasting ConcreteNontobeko MkhizeNo ratings yet

- Emergency Plan For Rescue From HeightsDocument9 pagesEmergency Plan For Rescue From HeightsMuhammad Shamaran AbdullahNo ratings yet

- SWMS - PlumberDocument7 pagesSWMS - PlumberSiddiqueShaikhNo ratings yet

- Incident Investigation ProcedureDocument7 pagesIncident Investigation ProcedureJobaer100% (1)

- DEE EHU 2-2-1 OHS Activities CalendarDocument9 pagesDEE EHU 2-2-1 OHS Activities CalendarAndi Yanuar100% (1)

- Risk - Assessment - TelehandlerDocument11 pagesRisk - Assessment - TelehandlerCiaraNo ratings yet

- Safe Work Method StatementDocument11 pagesSafe Work Method StatementJNo ratings yet

- Assembling Electrical Wiring Support 021Document4 pagesAssembling Electrical Wiring Support 021goodlife26960% (1)

- Fall Protection Plan (Feb 2023)Document3 pagesFall Protection Plan (Feb 2023)Keong Chee TongNo ratings yet

- Anchor Bolt Setting - Rev 01Document26 pagesAnchor Bolt Setting - Rev 01Geherson AbustanNo ratings yet

- Thohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFDocument17 pagesThohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFbubele pamlaNo ratings yet

- Brick Masonry - EHS Risk AssessmentDocument2 pagesBrick Masonry - EHS Risk Assessmentnagarjuna100% (3)

- Risk Assessment - Site Establishment - 2021Document6 pagesRisk Assessment - Site Establishment - 2021Asakundwi Mukhwa100% (3)

- Risk AssessmetDocument9 pagesRisk AssessmetAshoka Indunil WickramapalaNo ratings yet

- Safe Work Method Statement WorksheetDocument7 pagesSafe Work Method Statement WorksheetianllagasNo ratings yet

- Hand Tool InspectorDocument2 pagesHand Tool InspectorAmukelani100% (1)

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDocument1 pageRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- 007 Risk Assessment For Precast Construction & Installation of Street Lighting FoundationDocument5 pages007 Risk Assessment For Precast Construction & Installation of Street Lighting FoundationJahan Zaib50% (2)

- Risk Assessment IIIDocument1 pageRisk Assessment IIIJosh Booth100% (2)

- HSE Procedure For Garbage DisposalDocument4 pagesHSE Procedure For Garbage DisposalKhuda BukshNo ratings yet

- 19.DQ Working at Height Rescue PlanDocument3 pages19.DQ Working at Height Rescue Plankhurram0% (1)

- SWP Lifting Operations and Lifting Equipment 22-12-10 v1 06Document7 pagesSWP Lifting Operations and Lifting Equipment 22-12-10 v1 06Joozza MandaNo ratings yet

- Job Hazard AnalysisDocument10 pagesJob Hazard AnalysisDave ImpresoNo ratings yet

- Fall Protection - Sample Fall Protection Plan (OSHA)Document22 pagesFall Protection - Sample Fall Protection Plan (OSHA)bobjuan84No ratings yet

- Fall Prevention PlanDocument6 pagesFall Prevention PlanMohammed KhatibNo ratings yet

- Visitor Safety Orientation - IMPIDocument13 pagesVisitor Safety Orientation - IMPIHSE IMPICNo ratings yet

- Project Baseline Risk Assessment REF DIA61362019RFPDocument26 pagesProject Baseline Risk Assessment REF DIA61362019RFPThandabantu Magengelele100% (2)

- Job Safety Analysis (JSA) - Carpentry Works DateDocument1 pageJob Safety Analysis (JSA) - Carpentry Works DatenabeelNo ratings yet

- 25-Ra Use of Portable Pipe Threading MachineDocument4 pages25-Ra Use of Portable Pipe Threading MachineAsad Ayaz100% (1)

- 7-Block Work Risk Assessment ReportDocument7 pages7-Block Work Risk Assessment ReportSyed Ali Hassan100% (4)

- Excavation of RoadDocument7 pagesExcavation of RoadCharles LambNo ratings yet

- Demolition JhaDocument2 pagesDemolition JhaElvyn Fabellore HerreraNo ratings yet

- Rescue Plan For Maintenance Building Using Rope Access MethodDocument4 pagesRescue Plan For Maintenance Building Using Rope Access MethodCristlee TombokanNo ratings yet