Professional Documents

Culture Documents

AP2 Arm - 1035386A1

AP2 Arm - 1035386A1

Uploaded by

byjurpOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AP2 Arm - 1035386A1

AP2 Arm - 1035386A1

Uploaded by

byjurpCopyright:

Available Formats

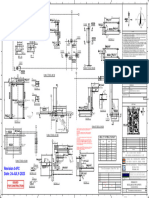

12 11 10 9 8 7 6 5 4 3 2 1

H H

Rz 12.5

52

109

21.9±0.15 50

20

0.1 A 49 71 70

A 51

17 17

37.67±0.1 108

7 3 48

0.1

13

A

81 R0.5 80

R12 69 R1 R1 79

B 86 M10 X 1.5P 30.70

R30.55 105

87 0.2 C

R1 78 (18 DEEP)

16 72 R1

52±0.25 14

24 17.00 68

16.65

G 15 ACROSS FLATS G

49±0.1 -DRAFT

107

104

E

PL

10.9 47 54 R1.5 77 44.5

67 88 2X 4 MIN

AN

73 R6

17 30.9

4X 4 R3 D

E

31.65 31.23° 2X R2

6

R4 46 89 45±0.25 106

18 4.2±0.1 82 53 R40.25 7.5 82 103

G

19 R0.5 MAX 30

C 35.43°

12X R1.5 34.48° 85 90 91

20 R0.3 MAX 4° 25.5°

55 3±0.1

6±0.1 E SECTION G-G

R1.5 31 45

22 21 33 74 92

23 19 R3 76.5±0.2 80.5

21 35

R2 32 18 43 56 R43.75±0.2

44 +DRAFT R2 66 93 R45±0.1

R40.25±0.2 102

-DRAFT

R3 65 -DRAFT

1 42

F 24 26±0.1 26

33 49±0.1 57 45°

84

R48

R2 101

F

-DRAFT 27 0.5 R5 94 R23

25 0.2 B 2X R6 64 82

PCD 60 95

41 6.6 C 2X R3 63 76.5

RAMP UP 96

13° 0.5 MAX 100

28 30° R2 INDICATOR MARK,

62 DIRECTION NO RADIUS, NO BURR,

75 R3

R6.3 A 83 90° 20°

97

99 G SHARP CORNER PERMISSIBLE

29 5.5±0.2 ZONE 'X'

2.5 58 2X R2

34 76 R1.5 M P

6.4

0.5 X 45° 40 61 6.3 D RA

36.3°

6.2 OF 6

T E

+ DRAFT 47 T AR LAN 98

S P

35 27±0.2 7

0.1 39

36.3° 59

35° 60 AT

54.57°

F

0.15 A 38

36

SECTION D-D

37

48.8±0.2

E SECTION A-A

130

5 137 E

34.57°

136

27 5

7.2

131 7.0

110 53°±5° 135

-DRAFT

10

111 8 168

0.1 134

6.2 76.5±0.25

132 AT PLANE 2

112 5.5 6.0 VIEW F

71.22±0.1

113 1 167 AT PLANE 2

R1 129 166 0.1

165 0.2 B

114 10° R3 128

D 32 133 164

70.46±0.1

D

SURFACE FINISH MEASUREMENTS AT PLANE 3

C R3 127 TO BE TAKEN ALONG THIS 9

SURFACE (REFER TO DIM #9, TABLE 2) 163

R2 126

138 0.00

32.53-0.20 B

AXIAL L Ra0.1

10 AT PLANE 4

117 U Ra0.5

16.88±0.1 116 SECTION C-C 0.1 A

L Ra1.6

90° 124 162 160

-1° MAX DRAFT 12 8.5 125 U Ra3.2

139

0.25 A B 7 161 MEASURED WITHIN ZONE 'X'

115 RADIAL L Ra0.25 0.00

118 10 U Ra0.4 31.21-0.20

AT PLANE 1

16 159

5 158

119 2X R0.5 MAX

123

13 7.5 140 155

PLANE 1 18±0.2

22 PLANE 2 30 157

120 2X R3 2 154 27±0.2

141

143 40 37.3±0.25 156

C 121 142 PLANE 3

2 153 47 C

45°

R5 PLANE 4

145

146

122 TABLE 1: GENERAL NOTES PLANE 5 10°

25 MIN

ITEM DIM FEATURE DESCRIPTION

1.8 152

1 MATERIAL ADC12 PER JIS H5302 DIE CAST ALUMINUM 144 R31.65±0.25

1 OPTIONAL: SAE J452, UNS A03800 OR KSD 6006 ALDC12. AT PLANE 5

DETAIL B 2 2 FINISH AS CAST PER NADCA-G-6-6-15 GRADE 2.

147

26

SCALE 2:1

3 3 TRIM COMMERCIAL TRIM PER NADCA-G-6-5-15. 148

EJECTOR PIN 28

4 4 MARKS NO EJECTOR PIN MARKS ALLOWED ON DATUM -A- AND CUP AREA

149

FLASH AROUND CORNERS AND INSERTS NOT TO EXCEED 0.25 THICK X 44.4

5 5 FLASH 0.76 HIGH. NO FLASH PERMITTED ON DATUM -A-, DATUM -D- OR ON TOP

OF BEARING SEAT SURFACE. 150

48 A1 -- -- -- 2021-06-23 ECO# E-0048684 VV NP KP

CORNERS/ ALL AS CAST CORNERS TO BE R1.5 MAX AND FILLETS TO BE R3.0 MAX PRODUCTION RELEASE

6 6 FILLETS UNLESS OTHERWISE SPECIFIED 151 ( WAS 1035386 REV. 011 )

69.3±0.2

B B

DATE

REV CHG ZONE DIM DESCRIPTION OF CHANGE DRN CHK APR

DRAFT ANGLE TO BE 1.5° PER SIDE UNLESS SPECIFIED AND 5° MAX PER YYYY-MM-DD

7 7 DRAFT ANGLE SIDE IN SPECIFIED WEIGHT REDUCTION AREAS. CONFIDENTIAL - ALL RIGHTS RESERVED

REFER TO LITENS POROSITY GUIDE FILE G300P SECTION E-E DIE CASTING REPRODUCTION AND/OR DISCLOSURE TO THIRD PARTIES WITHOUT PRIOR WRITTEN

AUTHORIZATION BY LITENS AUTOMOTIVE GROUP IS STRICTLY PROHIBITED

8 8 POROSITY (or LITENS BRACKET GUIDE FILE G301 REV Bb.) GENERAL TOLERANCES LITENS SPECIAL CHARACTERISTICS LITENS SPECIAL GENERAL NOTES

PER LITENS CURRENT "GLOBAL SUPPLIER REQUIREMENTS DRAWING SYMBOLS UNLESS OTHERWISE

GRADE (JIS)

AND GUIDELINES" MANUAL & LITENS CURRENT "SPECIAL SPECIFIED

CHARACTERISTICS DESIGNATION" WORK INSTRUCTION

DIMENSION

FOR AS CAST PARTS

A 6 S = SIGNIFICANT 0 IDENTIFICATION # ALL LINEAR DIMENSIONS

ARE IN MILLIMETERS.

0 REVISION

TOTAL ON

DRAWING

= MAJOR

TABLE 2: ADDITION REQUIREMENTS

M

DIMENSION RANGE TOLERANCE IDENTIFICATION BURRS, SHARP EDGES,

M 100% = 100% INSPECTION 0 CORROSION, DIRT OR

REFER TO FOREIGN MATERIALS

10 ± 0.26 INDICATED NOTE (E.G., CHIPS, GREASE)

ITEM DIM FEATURE NOTE M PTC = PASS THROUGH 0

DETRIMENTAL TO

>10 TO 16 ± 0.27 GEOMETRIC TOLERANCES PER PROPOSED EJECTOR HANDLING, FUNCTION

188.496 a) RACK SHOTBLAST FINISH ON A VERTICAL HANGER USING

SS110 STAINLESS STEEL SHOT MEDIA AT 50 Hz FREQUENCY FOR A GENERAL TOLERANCES >16 TO 25 ± 0.29

ASME Y14.5-2009

SURFACE TEXTURE PER

PIN LOCATION OR APPEARANCE ARE

NOT PERMISSIBLE.

169 SURFACE (120) SECONDS CYCLE. EACH CYCLE TO HAVE 5 ARMS ON HANGER. CORNER FILLETS AND BLENDS PARTING LINE

9 ASME Y14.36M-1996 NO MANUAL CHANGES.

170 9 TREATMENT b) SURFACE FINISH: (Ra = 1.6 - 3.2 µm) (PER JIS B 405) >25 TO 40 ± 0.32

11.535 11.13 44.5 c) SURFACE FINISH TO BE AVERAGE OF 4 DIMENSIONS GENERAL TOLERANCES & FEATURE DIMENSIONS UNLESS OTHERWISE SPECIFIED

R0.5 48.8 >40 TO 63 ± 0.35

(PITCH = 7.235) TAKEN ON OUTSIDE SURFACE OF HUB CORE. ANGULAR DIMENSIONS DIMENSION RANGE TOLERANCE LINEAR DIMENSIONS (mm)

X ±1

ANGULAR ( ° )

±1°

FILLETS AND RADII

CASTINGS = R2.0

DRAFT ANGLES

2° / SIDE

4.56 CUTTING TOOL: DIAMOND TIP, SIZE: R0.4 1 ± 0.2 >63 TO 100 ± 0.39 X.X ± 0.5 STAMPINGS = 2X MATL

MACHINING MACHINE TIME: 1 TIME SHORTEST LENGTH TOLERANCE X.XX± 0.35 OTHER = R1.5

PLANE 6 10 OF TARGET ANGLE >R1 TO R4 ± 1.0 >100 TO 160 ± 0.44

10 PROCESS ROTATION SPEED: 1,800 RPM PRODUCTS TO COMPLY WITH CURRENT AND FUTURE SUBSTANCE

FEED RATE: 0.06 mm/REVOLUTION 10 mm ± 1.0° >R4 TO R8 ± 1.5 >160 TO 250 ± 0.50 OF CONCERN (SOC) REQUIREMENTS AND DIRECTIVES

A AFTER EACH OPERATION: SHOTBLASTING AND THREADING:

10 mm < X 50 mm ± 30' >R8 TO R16 ± 2.0 >250 TO 400 ± 0.55

LAST DIM# 172 TITLE

ARM

A

3.8 SURFACE a) ALL PARTS TO BE WASHED WITH HOT WATER (60 ±10°C) DRAWN VV

360°

340°

180°

13°

0°

CAD FILE LAST SAVED ON: 07/09/21 4:00:14 PM

172 171 11 11 CONDITIONING FOR 15 SECONDS. 50 mm < X 120 mm ± 20' >R16 TO R32 ± 3.0 >400 TO 630 ± 0.60 CHECKED

b) ALL PARTS TO BE IMMEDIATELY DRIED WITH HOT AIR NP

(80 ±10°C) FOR 60 SECONDS. >R32 TO R64 ± 5.0 >630 TO 1000 ± 0.70

(MM/DD/YY)

APPROVED DRAWING NUMBER

120 mm < X 400 mm ± 10' KP

ALL PARTS TO BE HANDLED WITH CARE. SCRATCHES, DENTS >R64 TO R128 ± 8.0 >1000 TO 1600 ± 0.80

DATE

1035386

UNWRAPPED RAMP > 400 mm ± 5' 2021-06-23

12 12 HANDLING AND SURFACE IMPERFECTIONS THAT INFLUENCE THE FUNCTION YYYY-MM-DD PER ISO 8601

PROJECTION SCALE 1:1

AND APPEARANCE OF THE PARTS ARE NOT PERMISSIBLE. PER JIS B 0405 GRADE F >R128 ± 10.0 >1600 TO 2500 TBD

(PER PCD 60) PART MASS

317 g

TOTAL REF. DO NOT

BY: verica.vuckovic

CAD DATA APPLICATION 1035394 SCALE

OWNER SITE

LAP CAD SYSTEM SOLIDWORKS 2020 STATUS PRODUCTION SHEET 1 OF 1

FILE C:\LitensGroup\PE\0080\HONDA\14958\CAD\1035394\1035386 SIZE A0

12 11 10 9 8 7 6 5 4 3 2 1

FRM-00377 / 2

You might also like

- Locação: Projeto Arquitetônico CompletoDocument1 pageLocação: Projeto Arquitetônico CompletoGuilherme DuarteNo ratings yet

- BourréeDocument1 pageBourréeVgh GoghNo ratings yet

- sk8072 RevaDocument1 pagesk8072 RevautkuNo ratings yet

- Amigos Traigan Cerveza - FlautaDocument2 pagesAmigos Traigan Cerveza - FlautaDavid MeloNo ratings yet

- Lluis Llach - L'EstacaDocument2 pagesLluis Llach - L'EstacaKaveh AnsariNo ratings yet

- Terrace Floor Plan: Scale 1:100Document1 pageTerrace Floor Plan: Scale 1:100Manish MishraNo ratings yet

- X Y Z U: Tube BundleDocument1 pageX Y Z U: Tube BundlerubenNo ratings yet

- Oolsgv MSP V3abm GF DR P 009601 c03 - 2023.05.16 Sections & DetailsDocument1 pageOolsgv MSP V3abm GF DR P 009601 c03 - 2023.05.16 Sections & DetailsNitin SeenauthNo ratings yet

- X0231 PDW Eut DG 20007 AaDocument1 pageX0231 PDW Eut DG 20007 AajianranrenNo ratings yet

- SP0793-6186-15-0020 - PVDC EXPANSION PROJECT LIME STONE MILLING BALL OFFLOADING CONCRETE LAYOUT AND DETAILS Rev.1Document1 pageSP0793-6186-15-0020 - PVDC EXPANSION PROJECT LIME STONE MILLING BALL OFFLOADING CONCRETE LAYOUT AND DETAILS Rev.1Hector HernandezNo ratings yet

- 穿越时空的思念Document2 pages穿越时空的思念仇怡No ratings yet

- Vendavais30 Flauta TransversalDocument2 pagesVendavais30 Flauta TransversalDeivid Cordeiro dos SantosNo ratings yet

- Cylinder Full ViewlargeDocument1 pageCylinder Full ViewlargeavinashNo ratings yet

- Sace-Sm-Seun-0006 - Mapa Iluminado - 03 - 08 - 2022Document1 pageSace-Sm-Seun-0006 - Mapa Iluminado - 03 - 08 - 2022rafaelengprodNo ratings yet

- Vendavais30-2 Clarineta BBDocument2 pagesVendavais30-2 Clarineta BBDeivid Cordeiro dos SantosNo ratings yet

- SCH - QD Amin 13en.01Document1 pageSCH - QD Amin 13en.01Christopher SotoNo ratings yet

- Always With Me Guitar ScoreDocument2 pagesAlways With Me Guitar ScoreAlisa OngNo ratings yet

- Control Board - Schematic v626Document1 pageControl Board - Schematic v626XuNo ratings yet

- Deepest Fog (Synth)Document2 pagesDeepest Fog (Synth)Pablo Mena VilchesNo ratings yet

- Área Administrativa: Contenedor ContenedorDocument1 pageÁrea Administrativa: Contenedor ContenedorPipesanchNo ratings yet

- 感謝妳 趙傳Document2 pages感謝妳 趙傳rachealNo ratings yet

- Vendavais30 Saxofone SopranoDocument2 pagesVendavais30 Saxofone SopranoDeivid Cordeiro dos SantosNo ratings yet

- Est-02 - Planta y Detalles Mampostería EstructuralDocument1 pageEst-02 - Planta y Detalles Mampostería EstructuralJESUS SEBASTIAN NARVAEZ ORTIZNo ratings yet

- Oolsgv MSP V6abm GF DR P 009601 c01 - 2023.05.03 Sections & DetailsDocument1 pageOolsgv MSP V6abm GF DR P 009601 c01 - 2023.05.03 Sections & DetailsNitin SeenauthNo ratings yet

- Bella Ciao Arr Fabio LimaDocument1 pageBella Ciao Arr Fabio LimaGerd Bauer100% (1)

- Bella Ciao Arr Fabio Lima PDFDocument1 pageBella Ciao Arr Fabio Lima PDFAdrian BlancoNo ratings yet

- BourreeDocument1 pageBourreeEmanuel GodêsNo ratings yet

- Bourree: J.S. BachDocument1 pageBourree: J.S. BachEmanuel GodêsNo ratings yet

- Hip Night Hop-PianoDocument1 pageHip Night Hop-Pianobluedragons199260No ratings yet

- Anchor Cage (Weight For Components) - 75921113 - R0Document1 pageAnchor Cage (Weight For Components) - 75921113 - R0Milena CabarcasNo ratings yet

- PreformDocument1 pagePreformsoudy salahNo ratings yet

- Sbdo Ppa 105 3011 00Document1 pageSbdo Ppa 105 3011 00Douglas de Melo FélixNo ratings yet

- Dancing in The Moonlight - Saxophone Quartet-Alto SaxophoneDocument2 pagesDancing in The Moonlight - Saxophone Quartet-Alto SaxophoneJoão SalcedasNo ratings yet

- Dancing in The Moonlight - Saxophone Quartet-Alto SaxophoneDocument2 pagesDancing in The Moonlight - Saxophone Quartet-Alto SaxophoneJoão SalcedasNo ratings yet

- Amigos Traigan Cerveza - SaxoDocument2 pagesAmigos Traigan Cerveza - SaxoDavid MeloNo ratings yet

- Circuito C3600 SCHDocument1 pageCircuito C3600 SCHChinomasin ChinoNo ratings yet

- Si Nous Nous Aimons Les Uns Les AutresDocument1 pageSi Nous Nous Aimons Les Uns Les AutresJacques DupontNo ratings yet

- Last Saved:: KEY VoltageDocument13 pagesLast Saved:: KEY VoltageDario Bessone100% (3)

- Mi Negrita Me Espera para La Cindy Con Amor PDFDocument2 pagesMi Negrita Me Espera para La Cindy Con Amor PDFCARLOS IVAN BONILLA OSPINA100% (1)

- Vendavais30 ViolinoDocument2 pagesVendavais30 ViolinoDeivid Cordeiro dos SantosNo ratings yet

- 4439 701 001 80Document20 pages4439 701 001 80Ahmed SalamaNo ratings yet

- NGL-REL-ELE-019-DAL-R0-012 - Switchyard Layout - R1 1Document1 pageNGL-REL-ELE-019-DAL-R0-012 - Switchyard Layout - R1 1Kiran TejaNo ratings yet

- Ice Load For This Floor 1.0Kn/M2: M/L DWG No. H-11400-1360-1209Document1 pageIce Load For This Floor 1.0Kn/M2: M/L DWG No. H-11400-1360-1209Chiều TànNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 01Document1 pageEpcc05 MDR 421 STR DWG 000 0072 01RANJEET PRATAP SINGHNo ratings yet

- Recorrido FibraDocument1 pageRecorrido FibraYuly Paola Gamboa FernandezNo ratings yet

- Bravo Full ScoreDocument1 pageBravo Full ScoreJair VazquezNo ratings yet

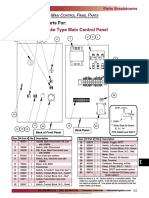

- p165 NI Main Control Panel PartsDocument1 pagep165 NI Main Control Panel PartsFRANCISCO JAVIER RUEDA LOPEZNo ratings yet

- Preliminary: GermanyDocument3 pagesPreliminary: GermanySonNguyenNo ratings yet

- P.HM5L 20-M0300 LAY001lDocument1 pageP.HM5L 20-M0300 LAY001lĐứcNo ratings yet

- General Notes:: Dhi Qar Combined Cycle Power Plant ProjectDocument1 pageGeneral Notes:: Dhi Qar Combined Cycle Power Plant Projectmustafa1989ocNo ratings yet

- Rice Field - Jay Chou Piano SheetDocument4 pagesRice Field - Jay Chou Piano SheetAnhNo ratings yet

- Proger Engenhar IA LTDA:0297 216300016 1Document1 pageProger Engenhar IA LTDA:0297 216300016 1web76280No ratings yet

- Adios Chico de Mi BarrioDocument2 pagesAdios Chico de Mi BarrioDavid MeloNo ratings yet

- TA22-24DEF-001 PNID D-400-24-50-0003 - REV - F4 - MarkupDocument1 pageTA22-24DEF-001 PNID D-400-24-50-0003 - REV - F4 - Markupjk.jackycheokNo ratings yet

- Flow Diagram - AQ37-55VSD Air Cooled Wuxi 9820543900Document1 pageFlow Diagram - AQ37-55VSD Air Cooled Wuxi 9820543900Kanisorn DonthogNo ratings yet

- Chasis Steering TrainningDocument2 pagesChasis Steering TrainningStency Villarroel PeñaNo ratings yet

- Transporte em MiamiDocument2 pagesTransporte em MiamiEmerson Jose de AlmeidaNo ratings yet

- Vendavais30 Saxofone TenorDocument2 pagesVendavais30 Saxofone TenorDeivid Cordeiro dos SantosNo ratings yet

- 03 07 2023Document2 pages03 07 2023byjurpNo ratings yet

- Master List of Pressure Gauge - 27.06.22Document25 pagesMaster List of Pressure Gauge - 27.06.22byjurpNo ratings yet

- Iap Comp Digital Operational Manual v1.3Document42 pagesIap Comp Digital Operational Manual v1.3byjurpNo ratings yet

- SPC 30 06 22Document111 pagesSPC 30 06 22byjurpNo ratings yet