Professional Documents

Culture Documents

Phantomatic X4.EN

Phantomatic X4.EN

Uploaded by

Nenad PavlovićOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Phantomatic X4.EN

Phantomatic X4.EN

Uploaded by

Nenad PavlovićCopyright:

Available Formats

en

Clamps 01 Electric head 02

Phantomatic X4

4-axis machining centre

03

01 05

04

Working capacity

Machining centre CNC with 4 controlled axes, used for working bars of aluminium, PVC, light

alloys in general and steel pieces up to 2 mm.

It has an 8 place tools storage, with the possibility of hosting an angular unit and a milling disc,

to perform machining on the 5 sides of the piece.

Works bars up to 4 m long. The 4th CN axis allows the electro spindle to continuously rotate to

from 0° to 180° to perform the work on the profile edge.

It also has a mobile work surface that facilitates the piece loading/unloading operation and

significantly increases the workable section.

Tool Magazine 03 Operator Interface 04 Pneumatic Stops 05

The images are only given for illustrative purposes

Phantomatic X4

4-axis machining centre

01 02 03 04 05

Clamps Electric head Tool Magazine Operator Interface Pneumatic Stops

The machine software, The 7 kW electrospindle in The tool holding storage is The new control version, The machine is fitted with

depending on the length of S1 with high torque power, integrated on the X axis, with suspended interface, sturdy stops that allow bar

the piece and the work to allows to carry out heavy- placed lower and in allows the operator to see reference, located one on

be carried out, is able to duty processing. backward position the screen from any the left side (standard) and

safely determine the The movement of the compared to the position, thanks to the one on the right side

positioning quota of every electrospindle along axis A electrospindle, allows a possibility to rotate the (optional).

clamp unit. The automatic allows to perform rotations drastic time reduction for monitor on the vertical Every stop, activated by

positioning allows to hook from 0° to 180°, allowing the tools change axis. The operator means of a pneumatic

every vice unit and move it to perform work on 3 sides operation. This function is interface has a 15" touch cylinder, is of retractable

by moving the truck. This of the profile, without particularly useful when screen display with all type and is automatically

operation happens with having to move it. working head and tail of USB connections selected by the machine

maximum speed and It can be used on certain the extruded material, necessary to remotely software according to the

precision, avoiding long types of extruded steel allowing to avoid the run to interface with PC and CN. work to be carried out. The

times and collision risks and on aluminium profiles, reach the storage, in that It also has a push button advantages of the double

and making the machine thanks to a lubrication the same moves together control unit, a mouse and stop can be summarised in

easy to use, also by system, settable from the with the electro spindle, in keyboard and is also the possibility to load more

operators with less software, whose twin tank the relative positioning. arranged for the profile pieces for work in

experience. allows to use both minimal The storage is able to connection of a barcode multipiece mode, as well

diffusion oil and oil contain up to 8 tool reader and remote push as the possibility to carry

emulsion mist. holders with respective button control unit. IT IS out the repositioning of the

tools, which can be equipped with a front USB bar or of the piece and

configured at the port for exchanging data. carry out work on

discretion of the operator. particularly long profiles.

A sensor detects the

correct positioning of the

cones.

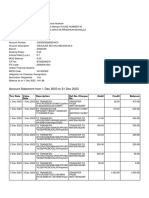

AXES TRAVEL

AXIS X (longitudinal) (mm) 4.000

AXIS Y (transversal) (mm) 270

AXIS Z (vertical) (mm) 420

AXIS A (spindle rotation) (°) 0 ÷ 180

ELECTRO SPINDLE

Maximum power in S1 (kW) 7

Maximum speed (revs/min) 16.500

Tool attachment cone HSK – 50F

AUTOMATIC TOOLS STORAGE ON TRUCK

Storage tools maximum number 8

Number of angular units that can be inserted in storage 1

Maximum diameter blade that can be inserted in storage (mm) Ø = 180

FUNCTIONALITY

Multipiece functioning ●

WORKABLE SIDES

With direct tool (upper side and lateral sides) 3

With angular unit (heads) 2

With blade tool (upper side, lateral sides and heads) 1 + 2 +2

TAPPING CAPACITY (with tap, on aluminium and through hole)

With compensator M8

Stiff (optional) M10

PROFILE POSITIONING

Piece reference left stop with pneumatic movement ●

Piece reference right stop with pneumatic movement ○

PIECE LOCKING

Vices standard number 4

Vices maximum number 6

Automatic vices positioning through axis X ●

SAFETY DEVICES AND PROTECTIONS

Machine integral protection booth ●

● included

○ available

2012/07/01 The pictures are provided by way of illustration only www.emmegi.com

You might also like

- Student Union Election Online Voting SystemDocument44 pagesStudent Union Election Online Voting SystemBullet AristoNo ratings yet

- Agiecharmilles Cut P Pro Serie - en PDFDocument52 pagesAgiecharmilles Cut P Pro Serie - en PDFdimasNo ratings yet

- Cincom L12Document8 pagesCincom L12asilka68No ratings yet

- Installation Guide For Aruba IAP-205 - IM - 5806655 - 1Document36 pagesInstallation Guide For Aruba IAP-205 - IM - 5806655 - 1Dante NuevoNo ratings yet

- Comet GB PDFDocument16 pagesComet GB PDFPelitamaju MsNo ratings yet

- 2018 - UMC-1000 2016 - NewDocument16 pages2018 - UMC-1000 2016 - NewAbhishek VelagaNo ratings yet

- RoboColumn - Brochure enDocument5 pagesRoboColumn - Brochure enJacintaShiNo ratings yet

- Speedline Abc: Production Turning MachineDocument12 pagesSpeedline Abc: Production Turning MachinebaumgconradoNo ratings yet

- Eumach - Umc - 5 Axis VMC Umc-1000Document16 pagesEumach - Umc - 5 Axis VMC Umc-1000Abhishek VelagaNo ratings yet

- DownloadDocument28 pagesDownloadmoonstarNo ratings yet

- Power Bend Pro EngDocument36 pagesPower Bend Pro EngmarcoNo ratings yet

- Series AX: High Precision Turning / Turn-Mill CentersDocument7 pagesSeries AX: High Precision Turning / Turn-Mill CentersRAJIV GandhiNo ratings yet

- 6" Chucker Horizontal Turning Center With Magazine & Y-AxisDocument14 pages6" Chucker Horizontal Turning Center With Magazine & Y-AxissunhuynhNo ratings yet

- And SelexxDocument12 pagesAnd SelexxKathe ReyesNo ratings yet

- 12 21 CNC Multitasking Machine Hyperturn200PM SEODocument13 pages12 21 CNC Multitasking Machine Hyperturn200PM SEOajoa60No ratings yet

- HELLER - 5 Axis Machining Centres F - ENDocument8 pagesHELLER - 5 Axis Machining Centres F - ENRajiv GandhiNo ratings yet

- Es CatDocument22 pagesEs Catwouter NeirynckNo ratings yet

- Vertical Milling Center MAXXMILL 400 630 750Document13 pagesVertical Milling Center MAXXMILL 400 630 750danielNo ratings yet

- 2013SG10A Brochure WebDocument5 pages2013SG10A Brochure WebWindi SyahputraNo ratings yet

- CNC Milling Center Training Purposes Concept MILL 55Document4 pagesCNC Milling Center Training Purposes Concept MILL 55Mez NacerNo ratings yet

- Stepcraft CNC - QTN1 PDFDocument3 pagesStepcraft CNC - QTN1 PDFA SNo ratings yet

- Metal Forming Solutions For The Aerospace Industry: Shaping A Better FutureDocument12 pagesMetal Forming Solutions For The Aerospace Industry: Shaping A Better Futuregk spra siaNo ratings yet

- D691en SHARK ResektoskopeDocument20 pagesD691en SHARK ResektoskopeVengatNo ratings yet

- Milling Machine Concept Mill 55 En-1Document4 pagesMilling Machine Concept Mill 55 En-1EmzyNo ratings yet

- Hydrostatic Vibratory Plates 365-712 Kilos AVH 5020 / 6020 / 7010Document6 pagesHydrostatic Vibratory Plates 365-712 Kilos AVH 5020 / 6020 / 7010Aurelian BogdanNo ratings yet

- Defender BrochureDocument12 pagesDefender BrochureWayne HoppeNo ratings yet

- P4 Abt: Range of Automatic Panel Benders. More Flexible, More Versatile, More ProductiveDocument16 pagesP4 Abt: Range of Automatic Panel Benders. More Flexible, More Versatile, More ProductiveNevres Gutic100% (1)

- Aph Series: Aph Hydrostatic Vibratory PlatesDocument24 pagesAph Series: Aph Hydrostatic Vibratory PlatesАнтон ЛазаровNo ratings yet

- CNC Vertical Type: Gear Form Grinding MachineDocument8 pagesCNC Vertical Type: Gear Form Grinding MachineKOMATSU SHOVELNo ratings yet

- Morbidelli M600 M800 - Ing - 3Document32 pagesMorbidelli M600 M800 - Ing - 3marco lopez perezNo ratings yet

- Catalog ErowaDocument46 pagesCatalog ErowafrdrfdederNo ratings yet

- Compact. Powerful. Flexible.: Our CNC Processing Center Centateq P-210Document44 pagesCompact. Powerful. Flexible.: Our CNC Processing Center Centateq P-210azhar ayupNo ratings yet

- CatRoverA Mag17 ENG LRDocument36 pagesCatRoverA Mag17 ENG LRcsontosbaluNo ratings yet

- Combidrive (R.wolf)Document20 pagesCombidrive (R.wolf)Denis100% (1)

- Datasheet CybTouch 8 PSe PS V2.x enDocument6 pagesDatasheet CybTouch 8 PSe PS V2.x enmajidsaee33No ratings yet

- Precision & Heavy Duty Limit SwitchesDocument6 pagesPrecision & Heavy Duty Limit Switchesbiswasdipankar05No ratings yet

- Catalogo Hermle - Brochure - C32 - ENDocument29 pagesCatalogo Hermle - Brochure - C32 - ENJUANNo ratings yet

- 6 Axes CNC Tool Grinding MachinesDocument12 pages6 Axes CNC Tool Grinding MachinesNguyễn Tấn Phước100% (1)

- mmc-Assetspdfslecturaammannaph5020AVH 5020 6020 7010 en (E94) PDFDocument6 pagesmmc-Assetspdfslecturaammannaph5020AVH 5020 6020 7010 en (E94) PDFMacNo ratings yet

- Yuasa International: Full 4 Axis vs. Programmable Indexer?Document4 pagesYuasa International: Full 4 Axis vs. Programmable Indexer?Pham LongNo ratings yet

- Schroder Brochure - PowerBend - Professional - ENDocument12 pagesSchroder Brochure - PowerBend - Professional - ENIlian AvramovNo ratings yet

- YCKT-Balancing Machine CEMBDocument7 pagesYCKT-Balancing Machine CEMBNguyễn Quốc PhượngNo ratings yet

- PRO SeriesDocument2 pagesPRO SeriesJani CoolNo ratings yet

- TurretPunches PDFDocument9 pagesTurretPunches PDFDamir F RastoderNo ratings yet

- CKD's ABSODEX Lineup Can Be Used For Any Application: All Absolute TypesDocument6 pagesCKD's ABSODEX Lineup Can Be Used For Any Application: All Absolute TypesngknhutNo ratings yet

- Ezeecut Plus: Wirecut Technology Made EasyDocument4 pagesEzeecut Plus: Wirecut Technology Made EasyMohit JainNo ratings yet

- VLC 500 800 1200 - enDocument20 pagesVLC 500 800 1200 - eneuan crozierNo ratings yet

- Forceturn 630.30 DatasheetDocument3 pagesForceturn 630.30 DatasheetLukasz PawellaNo ratings yet

- 2 PDFDocument24 pages2 PDFluis RYFNo ratings yet

- Fanuc 0ieDocument12 pagesFanuc 0ieangelNo ratings yet

- Morbidelli CX100 - Rev00 - Mag17 - Ing - 00L0367229ADocument12 pagesMorbidelli CX100 - Rev00 - Mag17 - Ing - 00L0367229AnewprintmNo ratings yet

- Umill Series - English - 2019 09Document8 pagesUmill Series - English - 2019 09Kiril AngelovNo ratings yet

- Surftest SV-3100Document12 pagesSurftest SV-3100صالح سميرNo ratings yet

- WR - Generale Filo enDocument9 pagesWR - Generale Filo enDarko MiladinovicNo ratings yet

- Update 20 01 SRB HA Leaflet 2019 09 MinDocument4 pagesUpdate 20 01 SRB HA Leaflet 2019 09 MinManish MohananNo ratings yet

- Power Bend Pro Rev.02 ENGDocument36 pagesPower Bend Pro Rev.02 ENGFabien ProuvezNo ratings yet

- Wohlenberg CuttersDocument16 pagesWohlenberg CuttersMOHAMEDELHELALYNo ratings yet

- Mill 55Document4 pagesMill 55Manuel XamanNo ratings yet

- EBA 7260 EnglDocument2 pagesEBA 7260 EnglRina RachmanNo ratings yet

- SBOX-Lite Operating Manual 220vDocument24 pagesSBOX-Lite Operating Manual 220vahmed desokyNo ratings yet

- Vehicular Ad-Hoc Network VanetDocument4 pagesVehicular Ad-Hoc Network VanetAgusurio AzmiNo ratings yet

- CMS X-Tools Analysis Library Release Notes - ENDocument6 pagesCMS X-Tools Analysis Library Release Notes - ENCesar SampaioNo ratings yet

- Social Media Brand Ambassador ContractDocument12 pagesSocial Media Brand Ambassador ContractMapro EntNo ratings yet

- Netys-Rt Catalogue Pages 2018-07 Dcg142033i En-IDocument4 pagesNetys-Rt Catalogue Pages 2018-07 Dcg142033i En-IFernando jose Torrico aguileraNo ratings yet

- Interesting Sudoku GameDocument48 pagesInteresting Sudoku GameВовчик БатяNo ratings yet

- Librarika GuideDocument5 pagesLibrarika GuideSouthwestern College Visual Resource CenterNo ratings yet

- Vhost Virtio Net Need For Speed 2Document27 pagesVhost Virtio Net Need For Speed 2Лиля БуторинаNo ratings yet

- Dot Permit Application-RenewalsDocument2 pagesDot Permit Application-Renewalsfrecy sanchezNo ratings yet

- MH241 Series Vs TTP-2410MTDocument1 pageMH241 Series Vs TTP-2410MTAna Lorena GayossoNo ratings yet

- 1.1 Deep Structural Enhanced Network For Document ClusteringDocument16 pages1.1 Deep Structural Enhanced Network For Document ClusteringAli Ahmed ShaikhNo ratings yet

- Quickspecs: HP Pro Tower 290 G9 Desktop PCDocument35 pagesQuickspecs: HP Pro Tower 290 G9 Desktop PCdeadliner11No ratings yet

- 22ECU403 Integrated LabDocument68 pages22ECU403 Integrated LabDayanand GKNo ratings yet

- 2 PBDocument5 pages2 PBJulianto SaputroNo ratings yet

- BVCCT-305 Advance Computing SkillsDocument76 pagesBVCCT-305 Advance Computing SkillsManisha khanNo ratings yet

- Department of Education: Republic of The PhilippinesDocument4 pagesDepartment of Education: Republic of The PhilippinesCharles AcieloNo ratings yet

- Ebook Storytelling For Interactive Digital Media and Video Games 1St Edition Nicholas B Zeman Online PDF All ChapterDocument69 pagesEbook Storytelling For Interactive Digital Media and Video Games 1St Edition Nicholas B Zeman Online PDF All Chaptertyron.rifenbark580100% (6)

- Masters Thesis TopicsDocument8 pagesMasters Thesis Topicskcaevuief100% (2)

- Information Security Maturity Model For Nist Cyber Security FrameworkDocument12 pagesInformation Security Maturity Model For Nist Cyber Security FrameworkCS & ITNo ratings yet

- Hotel Management System Using Python TkiDocument5 pagesHotel Management System Using Python Tkiyash bafnaNo ratings yet

- Samsung TV UE40D5520 ManualDocument297 pagesSamsung TV UE40D5520 ManualJames GodfreyNo ratings yet

- 54 Signature Verification System Using Python PY054Document7 pages54 Signature Verification System Using Python PY054VijayKumar Lokanadam100% (1)

- Ds 000347 Icm 42688 P v1.2Document109 pagesDs 000347 Icm 42688 P v1.2longcasey90No ratings yet

- TRILUX Smart Parking of The Future - ENDocument9 pagesTRILUX Smart Parking of The Future - ENAdham Mohamed EmarahNo ratings yet

- PPQHSWJ 3 WB78 Upd NDocument5 pagesPPQHSWJ 3 WB78 Upd NjbvcfygbkumarNo ratings yet

- NSX NEW Icon Library - CommunitiesDocument19 pagesNSX NEW Icon Library - CommunitiesElizabethNo ratings yet

- Bulletin Masoneilan SVI II AP - Aug 2020Document16 pagesBulletin Masoneilan SVI II AP - Aug 2020Raphael AndradeNo ratings yet

- 11 Measuring and Data Transmission: Software Documentation Page 11-1 EDC7 Keyword Protocol 2000Document20 pages11 Measuring and Data Transmission: Software Documentation Page 11-1 EDC7 Keyword Protocol 2000Lucía jandigNo ratings yet

- HMW 1 TextDocument5 pagesHMW 1 TextCaseyJ.Li0% (1)