Professional Documents

Culture Documents

Of-MF 08B - Preventive Maintenance Checklist

Of-MF 08B - Preventive Maintenance Checklist

Uploaded by

JBMMPL - QUALITYOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Of-MF 08B - Preventive Maintenance Checklist

Of-MF 08B - Preventive Maintenance Checklist

Uploaded by

JBMMPL - QUALITYCopyright:

Available Formats

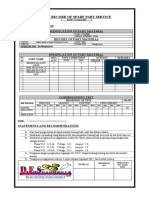

Doc No-QF/MF/08B

PREVENTIVE MAINTENANCE CHECKLIST Rev No-00/01.01.18

Page 1 of 2

Machine Name:- Machine Code:-

Date:-

Sr.No. Check Points Frequency Specified Maintenance Instructions First Quarter Second Quarter Third Quarter Forth Quarter Checked By Verified By Remarks

Mechanical

1 Check Machine limit s/w & 1 year Check travel of every axis & Perfomed zero

proximity sensor return.check proper working of limit s/w & proximity

sensor

2 Check Lubriction system, 1 year Check Lubrication Cartridge working condition

Ballscrew condition

Check Coolant pump impeller 6 months Check Coolant pump impeller for worn out

3

condition

4 X=0.01 Check Backlash of axis

Check Backlash of axis 1 year Y= 0.01

Z=0.01

5 X=0.005 Check X & Z axis Repeatability

Check Repeatability 1 year Y=0.005

Z=0.005

Check spindle belt,timmer belt Check spindle belt & timer belt condition

6 1 year

condition

7 Check seal of clamp/declamp Check cylinder for air leakage

6 months

and pot up/down cylinder

8 900-950

Check drawbar stroke 1 year Check proper drawbar stroke

kgf

0.01 max Check Spindle runout

9 Check Spindle runout 1 year

10 Check Spindle side & motor Check for worn out

1 year

Side pulley condition

11 Check all telescopic cover Check all telescopic cover noise &wiper condition

1 year

condition

12 Check proper working of chip conveyor

Check Chip conveyor condition 1 year

13 Change gear box oil 1 year EP- 170 Change gear box oil

14 Check all axis motor couplings 1 year Proper working of couplings

15 Check Counterweight Check for air leakage or oil leakage

6 months

balancing cylinder

16 Check ATC motor break 0.2mm Check for brake liner wornout & setting

6 months

setting

Check Magzine motor break 0.2mm Check for brake liner wornout & setting

17 6 months

setting

Check Greasing to cam & ATC Grease Apply Greas to cam & ATC Gear

20 6 months

Gear EP3

All Pneumatic Valve & Prssure Check proper working of Pneumatic Valve & Prssure

21 6 months

S/W S/W

Check Clamp/declamp cylinder 8.0 mm Proper working clamp /declamp cyl. Stroke

22 6 months

stroke

900-950 Proper clamping force

23 Tool Clamping Force 6 months

kgf

Electrical

Sr.No. Check Points Frequency Specified Maintenance Instructions First Quarter Second Quarter Third Quarter Forth Quarter Checked By Verified By Remarks

Check control voltage 24V DC

24 1 year Check proper control voltage o/p

Current drawn by Lubriction 0.63-1.0

25 motor 1 year Amp Check Lub Motor current drawn each phase

Current drawn Magzine motor 1.0-1.6

26 1 year Amp Check Mag.Motor current drawn each phase

Current drawn by ATC motor

27 1 year Check ATC Motor current drawn each phase

Current drawn by H.P.Coolant 4.0-6.3

28 motor 6 months Amp Check H.P.Coolant Motor current drawn each phase

Current drawn by Flood coolant 1.0-1.6

29 motor 6 months Amp Check Flood Coolant Motor current drawn each phase

Current drawn by Chip 1.0-1.6

30 conveyor motor 6 months Amp Check Chip conveyor Motor current drawn each phase

Current drawn by Spindle < 40%

31 motor 1 year Check Spindle Motor current drawn each phase

Current drawn by X,Y,Z axis < 40%

32 motor 1 year Check current drawn by x,y,z axis motor

Stabilizer I/P & O/P 415±10V

33 Voltages(R,Y,B) 6 months Check for proper Stabilizer I/P & O/P Voltages(R,Y,B)

Transformer O/P 220±10V Check for proper Transformer I/P & O/P

34 Voltages(R,Y,B) 6 months

Voltages(R,Y,B)

Check earth to Neutral supply 4V (Max)

35 3 months Check proper earth to Neutral supply

Check loose connection

36 1 year Check all loose wire connections

Current drawn by chiller unit 0.37Amp

37 motor 1 year Check Current drawn by chiller unit motor

Check All the Contactors for

38 proper working 6 months Clean the contacts By IPA or CRC Spray.

Check SMPS out put Supply 24 V DC

39 6 months Check SMPS out put Supply

Clean drive fan

40 6 months Check & clean drive fan

JAI BHAWANI

MATA ENGITECH PREVENTIVE MAINTENANCE CHECKLIST

PVT LTD

Machine Name:- Machine Code:-

Monthly :- Date:-

Checked Verified

Sr.No. Check Points Maintenance Instructions Ok Not Ok Remarks

By By

1 Check dust inside the stabilizer Clean by dry air

2 Check Input & Output Phase to Check Input & Output Phase to Phase &

Phase & Phase to Neutral Supply Phase to Neutral Supply

3 Check Input & Output connection Check input voltage & Output connection for

loosen

Check Carbon Brush Condition Check Carbon Brush Condition

4

Check Dimmer condition Check Dimmer working properly,clean by

5 polish paper

Check loose connection in the Check loose connection in the Stabilizer &

6 Stabilizer tighten it

Check control card condition Clean the control card by ISOPROFILE

7 ALCOHOL or Electronic Cleaner

Check High I/P & O/P Voltage trip to

8 all 3 phases

10

You might also like

- Maintenance - Terex Franna AT22Document6 pagesMaintenance - Terex Franna AT22FergiKalesaran0% (1)

- VMC Preventive Master Check ListDocument33 pagesVMC Preventive Master Check Listmugunthaa6686% (14)

- NC250 Engine ManualDocument60 pagesNC250 Engine ManualTallerSoldaduraAluminioInoxidable67% (3)

- MG ZS UK Maintenance Check Sheet V1.03 PDFDocument2 pagesMG ZS UK Maintenance Check Sheet V1.03 PDFyogapost100% (1)

- DIN&ISO GB标准紧固件号对照表Document32 pagesDIN&ISO GB标准紧固件号对照表Wei YaoNo ratings yet

- Reduction Gearbox 1500 AGSC KPDocument1 pageReduction Gearbox 1500 AGSC KPΣπύρος ΛελούδαςNo ratings yet

- Service Sheet ScaniaDocument2 pagesService Sheet Scaniamiswansabani86No ratings yet

- PMS预防维修prevent Maintenance System-30DTDocument40 pagesPMS预防维修prevent Maintenance System-30DTlinkangjun0621No ratings yet

- HINO FM 1000 HR Service SheetDocument7 pagesHINO FM 1000 HR Service SheetYudi AriantoNo ratings yet

- PM Schedule Plan For All MachinesDocument32 pagesPM Schedule Plan For All MachineskumaresanNo ratings yet

- Check Sheet PS Pc78uu-6 EditDocument3 pagesCheck Sheet PS Pc78uu-6 EditToko SerbaNo ratings yet

- Preventive Maintenance Check and Lubrication Frequency (YEAR)Document18 pagesPreventive Maintenance Check and Lubrication Frequency (YEAR)Anonymous h0yutV8No ratings yet

- Qa10 PS PC200-8 (3418)Document3 pagesQa10 PS PC200-8 (3418)Ridho RoihanNo ratings yet

- Form Mekanik AndrewDocument19 pagesForm Mekanik AndrewDoedoey ChNo ratings yet

- Periodical Service Scania P380: Maintenance SheetDocument2 pagesPeriodical Service Scania P380: Maintenance SheetWanda Panggih KurniawanNo ratings yet

- Qa10 PS GD535-5Document3 pagesQa10 PS GD535-5Andaru GunawanNo ratings yet

- Toyota Vitz Preventive Maintenance ScheduleDocument8 pagesToyota Vitz Preventive Maintenance Schedulealexberhane3No ratings yet

- PS Checklist Motor GraderDocument1 pagePS Checklist Motor Graderyogi ganda pratamaNo ratings yet

- S1 Maintenance DetailsDocument6 pagesS1 Maintenance DetailsHemanthNo ratings yet

- PS Checklist Motor GraderDocument1 pagePS Checklist Motor Graderyogi ganda pratamaNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- Toyota Platz Preventive Maintenance ScheduleDocument8 pagesToyota Platz Preventive Maintenance Schedulealexberhane3No ratings yet

- Checklist For Preventive Maintenance Machine: Rotary Cambering Machine Machine Code: Frequency: Monthly / Quarterly / Annually Checks M Q ADocument2 pagesChecklist For Preventive Maintenance Machine: Rotary Cambering Machine Machine Code: Frequency: Monthly / Quarterly / Annually Checks M Q ASanjay Malhotra100% (1)

- Jadwal Weekly MaintanaceDocument8 pagesJadwal Weekly Maintanaceardy ansyahNo ratings yet

- Motorcycle Service Bulletin 2023 04 BS VI E Carb Cleaning SOPDocument7 pagesMotorcycle Service Bulletin 2023 04 BS VI E Carb Cleaning SOPAkshay KumkarNo ratings yet

- EOT Crane ChecklistDocument3 pagesEOT Crane Checklistankit100% (1)

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- PC 1250 Initial 100 HR Service SheetDocument4 pagesPC 1250 Initial 100 HR Service SheetJamyansuren TseveendorjNo ratings yet

- Inspection Unit PC 200Lc - 8moDocument28 pagesInspection Unit PC 200Lc - 8moBima AditamaNo ratings yet

- Honda Maintenance ScheduleDocument1 pageHonda Maintenance ScheduletaylorNo ratings yet

- VMC Maintenance ScheduleDocument5 pagesVMC Maintenance Scheduleadel allamNo ratings yet

- Ex3202 - Grease Audit ReportDocument3 pagesEx3202 - Grease Audit ReportAndi OnggongNo ratings yet

- Wheeloader 980HDocument8 pagesWheeloader 980HAdie PranataNo ratings yet

- VMC Maintenance ScheduleDocument5 pagesVMC Maintenance ScheduleHải TạNo ratings yet

- PML 087a - PMS - EngineDocument70 pagesPML 087a - PMS - EngineFidriNo ratings yet

- Manual For Jackup Refrigeration SystemDocument134 pagesManual For Jackup Refrigeration Systemcastropedro2002No ratings yet

- Service Otoyol PM Check ListDocument6 pagesService Otoyol PM Check Listalexberhane3No ratings yet

- TA1 Test For Steering SystemDocument6 pagesTA1 Test For Steering SystemAyman EsaNo ratings yet

- Maintenance Interval CaymanDocument4 pagesMaintenance Interval CaymanJZM GulfNo ratings yet

- NO Spare Parts Service 10000 Hrs 20000 Hrs 30000 HrsDocument3 pagesNO Spare Parts Service 10000 Hrs 20000 Hrs 30000 HrsrandyNo ratings yet

- TFR MtnceDocument18 pagesTFR MtnceRajesh TKNo ratings yet

- Service Sheet Tadano Cto1Document4 pagesService Sheet Tadano Cto1ainul arifNo ratings yet

- Checklist PPM AircondDocument6 pagesChecklist PPM AircondsyahirahafiqahNo ratings yet

- PMS PER WAKTUDocument57 pagesPMS PER WAKTUAbdul BasitNo ratings yet

- Maintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesDocument2 pagesMaintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesCristiano DellazariNo ratings yet

- Turbine Over Hauling Procedure Siemens Recommendsbirkosit 111019222302 Phpapp01 PDFDocument75 pagesTurbine Over Hauling Procedure Siemens Recommendsbirkosit 111019222302 Phpapp01 PDFAnonymous wIPMQ5rh100% (3)

- Test Record of Spare Part Service: Spesification of Part Material History of Part MaterialDocument4 pagesTest Record of Spare Part Service: Spesification of Part Material History of Part MaterialKhalidperkasaNo ratings yet

- Service Manual: Tennant A80Document33 pagesService Manual: Tennant A80Павел КорчагинNo ratings yet

- Mooney M20 100hour PDFDocument2 pagesMooney M20 100hour PDFsplyn100% (1)

- LV Mitsubishi TritonDocument6 pagesLV Mitsubishi TritonAdie PranataNo ratings yet

- Recip. Compressor TestingDocument10 pagesRecip. Compressor TestingS DasNo ratings yet

- Siement Turbine Over Hauling ProcedureDocument75 pagesSiement Turbine Over Hauling Procedurerajurajangam100% (2)

- Pre-Delivery Inspection SB 4000 XF - Euro 2 - Training ...Document8 pagesPre-Delivery Inspection SB 4000 XF - Euro 2 - Training ...Павел ПогребнойNo ratings yet

- Gig-Service Bus PM Check ListDocument6 pagesGig-Service Bus PM Check Listalexberhane3No ratings yet

- Routine & Preventive MaintenanceDocument8 pagesRoutine & Preventive Maintenancevinay956No ratings yet

- Inspection and Preventive Maintenance: ServicereportDocument2 pagesInspection and Preventive Maintenance: ServicereportMoz KamalNo ratings yet

- MOL MOL Pakistan Oil & Gas Co. B.V. Makori Gas Processing FacilityDocument2 pagesMOL MOL Pakistan Oil & Gas Co. B.V. Makori Gas Processing FacilityJaadi 786No ratings yet

- Preventive Maintenance ServiceDocument1 pagePreventive Maintenance ServiceJenry JonathanNo ratings yet

- Hitachi Zx870: Schedule Service 250 / 750 HoursDocument5 pagesHitachi Zx870: Schedule Service 250 / 750 HourspojokbioNo ratings yet

- 82440Document2 pages82440Sandip NandyNo ratings yet

- LXP3-6K: SpecificationDocument1 pageLXP3-6K: SpecificationYopp MismoNo ratings yet

- Cwor-Brochure WebDocument8 pagesCwor-Brochure WebMartin McCaffreyNo ratings yet

- GS2 Series - Introduction: Features AccessoriesDocument13 pagesGS2 Series - Introduction: Features AccessoriesDavid NarvaezNo ratings yet

- Pilz RelayDocument11 pagesPilz RelayRavi SankarNo ratings yet

- KBM255 Series 2018Document4 pagesKBM255 Series 2018Lucian A MUșaNo ratings yet

- 6e1 BalenoDocument113 pages6e1 BalenoRizkyNo ratings yet

- CombinedCatalogs 100213Document32 pagesCombinedCatalogs 100213Cristobal LeonNo ratings yet

- MR E Xa KH003 - MITSUBISHIDocument350 pagesMR E Xa KH003 - MITSUBISHIdthi16088No ratings yet

- Track Roller Frames D&ADocument62 pagesTrack Roller Frames D&Anelson troncoso galdamesNo ratings yet

- UNV MW3243-F-V LED Monitor V2.0-ENDocument4 pagesUNV MW3243-F-V LED Monitor V2.0-ENCore LatAmNo ratings yet

- Comprehensive Product Catalogue: PressureDocument59 pagesComprehensive Product Catalogue: PressureAnonymous rpSGuQPNo ratings yet

- 2012 A7 On Board Power Supply and Networking PDFDocument44 pages2012 A7 On Board Power Supply and Networking PDFValentin NedeleaNo ratings yet

- Change Over SwitchDocument3 pagesChange Over SwitchPeter DindahNo ratings yet

- FPGA Technology: Carl LebsackDocument27 pagesFPGA Technology: Carl LebsackShrikant ChamlateNo ratings yet

- Quanta Y01 Shark Bay Power SequenceDocument1 pageQuanta Y01 Shark Bay Power SequenceJoselo LópezNo ratings yet

- Easy Resawing: The Fence. The FenceDocument2 pagesEasy Resawing: The Fence. The FenceBilAndersenNo ratings yet

- Adjustable Pitch Propellers Model AHX Catalog 524Document22 pagesAdjustable Pitch Propellers Model AHX Catalog 524AudasisNo ratings yet

- Руководство по ремонту. Двигатель Cummins KDSl 614 PDFDocument342 pagesРуководство по ремонту. Двигатель Cummins KDSl 614 PDFNick ENo ratings yet

- 4. Hướng dẫn sử dụng điều hòa tủ đứngDocument21 pages4. Hướng dẫn sử dụng điều hòa tủ đứngDuy ChuNo ratings yet

- Model Machine DrawingDocument15 pagesModel Machine Drawingசெல்வ குமார்No ratings yet

- Firekab Je H ST H BD Fe180 ph120Document2 pagesFirekab Je H ST H BD Fe180 ph120Azzeddine ZerroukNo ratings yet

- Computer Fundamental PDFDocument143 pagesComputer Fundamental PDFSudhir GulekarNo ratings yet

- Product Catalog: Packaged Rooftop Air Conditioners Voyager With E-Flex™ Technology Cooling & Gas/ElectricDocument76 pagesProduct Catalog: Packaged Rooftop Air Conditioners Voyager With E-Flex™ Technology Cooling & Gas/ElectricHéctor LombardiNo ratings yet

- War Field Spying Robot With Night Vision Wireless Camera: Submitted byDocument26 pagesWar Field Spying Robot With Night Vision Wireless Camera: Submitted byankita dhengaleNo ratings yet

- MP2550-3350 Ordering InfoDocument4 pagesMP2550-3350 Ordering InfoCheffley WhiteNo ratings yet

- IaamaxlogicDocument4 pagesIaamaxlogicAshly JosephNo ratings yet

- NVC LED New Products-201610Document23 pagesNVC LED New Products-201610sameera priyashanthaNo ratings yet

- IOT Home Automation: Block DiagramDocument4 pagesIOT Home Automation: Block Diagramসপ্তক মন্ডলNo ratings yet