Professional Documents

Culture Documents

Dim DMS000779284 en 20170904160759

Dim DMS000779284 en 20170904160759

Uploaded by

陈唐伟Copyright:

Available Formats

You might also like

- Structural Drawings 2Document9 pagesStructural Drawings 2Makenson MuscadinNo ratings yet

- Siemens TXR 320 Installation ManualDocument16 pagesSiemens TXR 320 Installation ManualRomel HufalarNo ratings yet

- EX1200-Electrical Circuit Diagram (Cummins Engine Specification)Document1 pageEX1200-Electrical Circuit Diagram (Cummins Engine Specification)Norman CoetzeeNo ratings yet

- Sap Open Text Imaging InstallationDocument8 pagesSap Open Text Imaging Installationkumudranjan100% (1)

- Information Sheet 3.1.2 Computer Specifications: 1.2 Obtain Correct Specifications From Relevant ResourcesDocument5 pagesInformation Sheet 3.1.2 Computer Specifications: 1.2 Obtain Correct Specifications From Relevant Resourcesapi-196541959100% (2)

- Ta 193114 001Document1 pageTa 193114 001Rene HebaNo ratings yet

- FJS 1923000149Document1 pageFJS 1923000149SHAHZAD LATIFNo ratings yet

- A29-K-HVA-VA-015028-001 - 01A Schematic Diagram For MOS-029 HVAC-Default-000Document1 pageA29-K-HVA-VA-015028-001 - 01A Schematic Diagram For MOS-029 HVAC-Default-000Muhammed ThanzeelNo ratings yet

- Lateral View (Left) : Detail ADocument14 pagesLateral View (Left) : Detail ARahul PatelNo ratings yet

- SCR 005075Document1 pageSCR 005075jeplgpbmcNo ratings yet

- Saudi Arabian Oil Company: 282 A BA-274759 006 0B2Document1 pageSaudi Arabian Oil Company: 282 A BA-274759 006 0B2Mohamed Wasim ShaikhNo ratings yet

- Mezzanine Level Fire AlarmDocument1 pageMezzanine Level Fire Alarmdanish0229No ratings yet

- PNG2023 Plumb 012 ADocument1 pagePNG2023 Plumb 012 ANoel MoronaNo ratings yet

- QGTL1 Pro 07 00002 001 - 10Document1 pageQGTL1 Pro 07 00002 001 - 10Muhammad Arham KhalilNo ratings yet

- ELEVATIONS (1:100) SECTION A-A (1:50) : NotesDocument2 pagesELEVATIONS (1:100) SECTION A-A (1:50) : NotesLubangakene BrianNo ratings yet

- B168082001P00 PDFDocument1 pageB168082001P00 PDFWaleed JaradatNo ratings yet

- P011-0002, Symbols & Legends (2,3)Document1 pageP011-0002, Symbols & Legends (2,3)Mubashir fareedNo ratings yet

- PB02-STG-001 Steam Turbine System (A10-P-2001)Document1 pagePB02-STG-001 Steam Turbine System (A10-P-2001)zhangNo ratings yet

- Ci PW 01 03 001Document1 pageCi PW 01 03 001harihfclNo ratings yet

- Saudi Arabian Oil Company: S61 S HA-004773 003 00Document1 pageSaudi Arabian Oil Company: S61 S HA-004773 003 00zarrar malikNo ratings yet

- Saudi Arabian Oil Company: S61 S HA-004773 003 00Document1 pageSaudi Arabian Oil Company: S61 S HA-004773 003 00zarrar malikNo ratings yet

- Issued For Construction: Hydrostatic Test ScheduleDocument1 pageIssued For Construction: Hydrostatic Test ScheduleMohamed HaleemNo ratings yet

- FINAL RAILWAY CROSSING PROPOSAL OF UER 2-ModelDocument1 pageFINAL RAILWAY CROSSING PROPOSAL OF UER 2-ModelSaurav KumarNo ratings yet

- B Block PitDocument1 pageB Block PitAPS DESIGN INFRA PVT.LTD.No ratings yet

- Attic Access - TguDocument5 pagesAttic Access - TgujhamiralexNo ratings yet

- DED-DIC-ARE&STR - CONCEPT DESIGN - 271023 - ModelDocument1 pageDED-DIC-ARE&STR - CONCEPT DESIGN - 271023 - ModelAnwar SalukiNo ratings yet

- Ven-002 - 1st Floor Plan Ventilation Layout (1) - Layout1Document1 pageVen-002 - 1st Floor Plan Ventilation Layout (1) - Layout1ᏗᎷᎥᏖᏕᎥᏁᎶᏂNo ratings yet

- LS Fence 1Document1 pageLS Fence 1jimNo ratings yet

- 03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrDocument1 page03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrD HOLNo ratings yet

- UNIT 11 - WORKING DRAWINGS - REV 1-Door & Window ScheduleDocument1 pageUNIT 11 - WORKING DRAWINGS - REV 1-Door & Window ScheduleD HOLNo ratings yet

- SIMON18012: Call Before You DigDocument1 pageSIMON18012: Call Before You DigBALAKRISHNANNo ratings yet

- 819-Tw-E-102 Electrical LT Block Diagram LT Block Diagram r1 (1) - OzoraDocument1 page819-Tw-E-102 Electrical LT Block Diagram LT Block Diagram r1 (1) - OzoraMichael NgoNo ratings yet

- SampleDocument1 pageSampleKYC BIM010No ratings yet

- Notes:: Saudi Arabian Oil CompanyDocument1 pageNotes:: Saudi Arabian Oil Companymohamed esmailNo ratings yet

- Captură de Ecran Din 2024-02-26 La 10.56.19Document1 pageCaptură de Ecran Din 2024-02-26 La 10.56.19samuelantonoviciNo ratings yet

- V A L L E Y: Saudi Arabian Oil CompanyDocument1 pageV A L L E Y: Saudi Arabian Oil CompanyThomas JohnNo ratings yet

- UWP 25418 001 Elevated Water Tank 5000L CR02 PDFDocument1 pageUWP 25418 001 Elevated Water Tank 5000L CR02 PDFer.praveenraj30No ratings yet

- 408 N.MAIN - FIRE SERVICE-Fire Service PlanDocument1 page408 N.MAIN - FIRE SERVICE-Fire Service PlanarielNo ratings yet

- Extracted Pages From PID BinderDocument15 pagesExtracted Pages From PID Bindermangesh patilNo ratings yet

- GDP - 2734 - Wakl - CD - 30-01-118 Diagramatic Section RWDP R0Document1 pageGDP - 2734 - Wakl - CD - 30-01-118 Diagramatic Section RWDP R0Mohd Khairul FitriNo ratings yet

- 522445-AUR901-DRG-BC-5600-CIVIL TYPICAL UNDERGROUND SERVICES DETAILS SHEET 1 OF 4油罐间Document1 page522445-AUR901-DRG-BC-5600-CIVIL TYPICAL UNDERGROUND SERVICES DETAILS SHEET 1 OF 4油罐间Gibson SitumorangNo ratings yet

- Notes:: Saudi Arabian Oil CompanyDocument1 pageNotes:: Saudi Arabian Oil Companymohamed esmailNo ratings yet

- A1700 Signage Location and DetailsDocument5 pagesA1700 Signage Location and DetailsJustMoveIt Trucking, OPCNo ratings yet

- TA2860 RHI SI ZZ DR N 3002 Temporary UtilitiesDocument1 pageTA2860 RHI SI ZZ DR N 3002 Temporary UtilitiesBack To SumateraNo ratings yet

- MOM Fortis, Kalyan 10.08.2022Document1 pageMOM Fortis, Kalyan 10.08.2022Mohd MustaqNo ratings yet

- SCHP53RD01 PDFDocument1 pageSCHP53RD01 PDFsnamprogNo ratings yet

- Mayfair LOTS 4 & 10 Buildings 4-6: Building 6 Roof PlanDocument1 pageMayfair LOTS 4 & 10 Buildings 4-6: Building 6 Roof PlanEric WilsonNo ratings yet

- Fire-Pump Room - Rev.cDocument1 pageFire-Pump Room - Rev.cwael72No ratings yet

- ODEC Ventilation Layout UKDocument1 pageODEC Ventilation Layout UKsondeepyadav4873No ratings yet

- 3Document1 page3tarique mohammedNo ratings yet

- Utilities Substation Ss-053: Saudi Arabian Oil CompanyDocument1 pageUtilities Substation Ss-053: Saudi Arabian Oil CompanyLino AbetoNo ratings yet

- Amphi TheatreDocument1 pageAmphi TheatreanzaniNo ratings yet

- 2084 CrawlspaceDocument7 pages2084 Crawlspacepatrick.estimatorsNo ratings yet

- 0415 RiserPoster 032315 Final.5cf68e0c62dee PDFDocument1 page0415 RiserPoster 032315 Final.5cf68e0c62dee PDFFernando Jimenez ChillonNo ratings yet

- Marked-Up P&ID For Hot Gas Bypass of J12-K-0613Document1 pageMarked-Up P&ID For Hot Gas Bypass of J12-K-0613nausheed123No ratings yet

- Meriton: Church AveDocument1 pageMeriton: Church AveIrfan SehovicNo ratings yet

- Binghati Powr Coordination DrawingDocument1 pageBinghati Powr Coordination Drawingzafrikhan875No ratings yet

- Cb-3 Mech'l Plans 05.06.22Document12 pagesCb-3 Mech'l Plans 05.06.22Mark Vincent MoraNo ratings yet

- DetailsDocument1 pageDetailstensiNo ratings yet

- Earthing Schematic Office R3 (04.01.2022) OUR ScopeDocument1 pageEarthing Schematic Office R3 (04.01.2022) OUR ScopeRZK AbbadonNo ratings yet

- 4355-Aa-Dc-22i10pr0900i - Checkprint For SquadDocument1 page4355-Aa-Dc-22i10pr0900i - Checkprint For Squadamit bagchiNo ratings yet

- Ta 680745 001Document1 pageTa 680745 001shahidNo ratings yet

- Mitsubishi PL-3GJB2.UK Service ManualDocument12 pagesMitsubishi PL-3GJB2.UK Service Manual陈唐伟No ratings yet

- 30RB B Series CatalogDocument16 pages30RB B Series Catalog陈唐伟No ratings yet

- Service Manual - Rav-Gp1101at8p-A Rav-Gp1401at8p-A Rav-Gp1601at8p-A-1632279104Document94 pagesService Manual - Rav-Gp1101at8p-A Rav-Gp1401at8p-A Rav-Gp1601at8p-A-1632279104陈唐伟No ratings yet

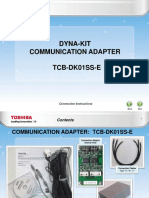

- Dynadr ConnectionDocument16 pagesDynadr Connection陈唐伟No ratings yet

- Master of Science (Engineering Geology) PDFDocument4 pagesMaster of Science (Engineering Geology) PDFMuhammad AzmanNo ratings yet

- Breaktor900 B4 - 0 Short Spec ENA Active Cooling - EB9DE-XX5BCDocument25 pagesBreaktor900 B4 - 0 Short Spec ENA Active Cooling - EB9DE-XX5BCHamza HammadiNo ratings yet

- Remplacement LVDT Valve 010310 (E)Document20 pagesRemplacement LVDT Valve 010310 (E)Arko RoosNo ratings yet

- Specification INPUT: 100-240V AC (50/60Hz)Document1 pageSpecification INPUT: 100-240V AC (50/60Hz)Federico UrquizaNo ratings yet

- Ta 062Document119 pagesTa 062ehj choNo ratings yet

- Axil FansDocument20 pagesAxil Fansjuberinamdar2465No ratings yet

- BMW Group Plant Debrecen Careers - 2Document2 pagesBMW Group Plant Debrecen Careers - 2Shivanshu PandeyNo ratings yet

- 5 Spark Kafka Cassandra Slides PDFDocument20 pages5 Spark Kafka Cassandra Slides PDFusernameusernaNo ratings yet

- Imad Khalfi CVDocument1 pageImad Khalfi CVImad KhalfiNo ratings yet

- DRX Influence - Compare Huawei DRX Parameter With Apple DRX ParameterDocument5 pagesDRX Influence - Compare Huawei DRX Parameter With Apple DRX ParameterAhmed GadNo ratings yet

- CH 16 Unix & Linux Operating SystemDocument36 pagesCH 16 Unix & Linux Operating SystemKumar HimanshuNo ratings yet

- Hybrid Cooler Project PresentationDocument13 pagesHybrid Cooler Project PresentationJK COTTONNo ratings yet

- Services As EmployeesDocument12 pagesServices As EmployeesCJ LNo ratings yet

- NDT One MarkDocument11 pagesNDT One MarkAnonymous 6SivdzjNo ratings yet

- Crimp Interchange: The Change in The Ratio of The Crimp of The Warp and Weft System Is Termed As Crimp InterchangeDocument12 pagesCrimp Interchange: The Change in The Ratio of The Crimp of The Warp and Weft System Is Termed As Crimp InterchangeAshutoshNo ratings yet

- 1974 Ski DooDocument292 pages1974 Ski DooVincent RoyNo ratings yet

- Bmo Beaconmedaes Psa Medical Oxygen Concentrator Plant SpecificationDocument13 pagesBmo Beaconmedaes Psa Medical Oxygen Concentrator Plant Specificationdiah131No ratings yet

- Fermi FET Technology Seminar ReportDocument21 pagesFermi FET Technology Seminar Reportimcoolsha999No ratings yet

- BS en 3452 3 Penetrant Testing Reference BlocksDocument15 pagesBS en 3452 3 Penetrant Testing Reference BlocksKresimir SimeonNo ratings yet

- Daag To Lirf b737Document76 pagesDaag To Lirf b737Abdel Hafid LahrecheNo ratings yet

- Sartorius Balance Cable Pinouts - TALtechDocument2 pagesSartorius Balance Cable Pinouts - TALtechWill CariasNo ratings yet

- Presentation Pavement Failures 1507355219 83810Document26 pagesPresentation Pavement Failures 1507355219 83810suraj shetNo ratings yet

- Seismic Design and Steel Connection DetailingDocument16 pagesSeismic Design and Steel Connection Detailingjose felix100% (1)

- Oracle9i Jdeveloper User's GuideDocument4,683 pagesOracle9i Jdeveloper User's Guidealvati85No ratings yet

- A Road AccidentDocument4 pagesA Road AccidentAiman FirdausNo ratings yet

- Electric Vehicle Machines and Drives - Design, Analysis and ApplicationDocument26 pagesElectric Vehicle Machines and Drives - Design, Analysis and Applicationmsssrinivas1No ratings yet

Dim DMS000779284 en 20170904160759

Dim DMS000779284 en 20170904160759

Uploaded by

陈唐伟Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dim DMS000779284 en 20170904160759

Dim DMS000779284 en 20170904160759

Uploaded by

陈唐伟Copyright:

Available Formats

For authorized service personnel only.

INSTALLATION WORK

AIR CONDITIONER WARNING

For the air conditioner to operate satisfactorily, install it as outlined in this installation instruction sheet.

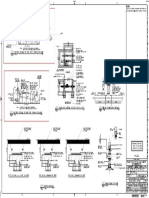

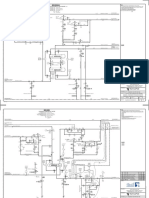

Install the air conditioner as follows: 2. BODY INSTALLATION

(1) Install special nut A, then special nut B onto the hanging bolt.

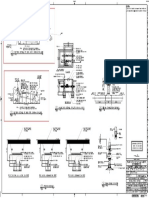

3 PIPE INSTALLATION 2. BENDING PIPES

The pipes are shaped by your hands. Be careful not to collapse them.

(2) Raise the body and mount its hooks onto the hanging bolt between the special nuts. Do not bend the pipes in an angle more than 90°.

(3) Turn special nut B to adjust the height of the body.

INDOOR UNIT (Compact cassette type)

Connect the indoor unit and outdoor unit with the air conditioner piping and cables available from our standards parts. This CAUTION

1

When pipes are repeatedly bend or stretched, the material will harden,

installation instruction sheet describes the correct connections using the installation set available from our standard parts. INSTALLATION THE UNIT WARNING Do not use mineral oil on flared part. Prevent mineral oil making it difficult to bend or stretch them any more. Do not bend or

INSTALLATION INSTRUCTION SHEET

Installation work must be performed in accordance with national wiring standards by authorized personnel only. from getting into the system as this would reduce the stretch the pipes more than three times.

Perform final tightening by tightening the double nut firmly.

If refrigerant leaks while work is being carried out, ventilate the area. If the refrigerant comes in contact with a flame, it produces a toxic gas. lifetime of the units.

Special nut A

While welding the pipes, be sure to blow dry nitrogen gas CAUTION

Do not use an extension cable. WARNING

After installing the through them. To prevent breaking of the pipe, avoid sharp bends.

Hook

Do not turn on the power until all installation work is complete. Install the air conditioner in a location which can withstand body, tighten the nuts.

(PART No. 9374318261-04)

Special nut B Bend the pipe with a radius of curvature of 150 mm or over.

a load of do at least five times the weight of the main unit

CAUTION and which will not amplify sound or vibration. If the instal- 30 mm

If the pipe is bent repeatedly at the same place, it will break.

lation location is not strong enough, the indoor unit may

Hanging bolt or more 1. FLARING

For authorized service personnel only. This installation instruction sheet describes how to install the indoor unit only. fall and cause injuries. (1) Cut the connection pipe to the necessary length with a pipe cutter.

To install the outdoor unit, refer to the installation instruction sheet included with the outdoor unit. (2) Hold the pipe downward so that cuttings will not enter the pipe and

If the job is done with the panel frame only, there is a risk remove the burrs.

Be careful not to scratch the air conditioner when handling it. that the unit will come loose. Please take care. 19 mm (3) Insert the flare nut (always use the flare nut attached to the indoor 3. PIPE CONNECTION

Ceiling

After installation, explain correct operation to the customer, using the operating manual. and outdoor units respectively) onto the pipe and perform the flare Indoor unit

Let the customer keep this installation instruction sheet because it is used when the air conditioner is serviced or moved. 3. LEVELING processing with a flare tool. (1) Detach the caps and plugs from the pipes.

This mark indicates procedures which, if improperly performed, are most likely to result in the death of 1. POSITION THE CEILING HOLE AND HANGING BOLTS Use the special R410A flare tool, or the conventional flare tool.

DANGER Using a level, or vinyl hose filled with water, fine adjust so that the body is level.

or serious injury to the user or service personnel. Ceiling openings and hanging bolt installation diagram Inclined installation so as the drain pipe side is higher may cause a mal-

Check if [L] is flared uniformly and CAUTION

This mark indicates procedures which, if improperly performed, might lead to the death or serious injury function of the float switch, and may cause water leakage.

WARNING WARNING is not cracked or scratched. B

of the user.

CONNECTION PIPE REQUIREMENT When fastening the hangers, make the bolt positions

Be sure to apply the pipe against the port on the indoor unit

correctly. If the centering is improper, the flare nut cannot

This mark indicates procedures which, if improperly performed, might possibly result in personal harm uniform. Die be tightened smoothly. If the flare nut is forced to turn, the

CAUTION

to the user, or damage to property. CAUTION A threads will be damaged.

Refer to the installation instruction sheet of the outdoor unit for description of the length of connecting pipe or for difference Pipe Do not remove the flare nut from the indoor unit pipe until

DANGER of its elevation. immediately before connecting the connection pipe.

530 mm (Hanging bolt position)

Never touch electrical components immediately after the power supply has been turned off. Electrical shock may occur. After 9,000/12,000 14,000/18,000 24,000

turning off the power, always wait 5 minutes or more before touching electrical components. MODEL Dimension A (mm)

BTU/h model BTU/h model BTU/h model Pipe outside diameter (2) Centering the pipe against port on the indoor unit, turn the flare nut

Flare tool for R410A, clutch type with your hand.

Liquid 6.35 mm (1/4 in.) 6.35 mm (1/4 in.) 6.35 mm (1/4 in.) Vinyl hose

This air conditioner uses new refrigerant HFC (R410A).

580 – 660 mm (Ceiling openings)

6.35 mm (1/4 in.)

540 mm (Hanging bolt position)

Diameter

700 mm (Cassette grille)

Gas 9.52 mm (3/8 in.) 12.70 mm (1/2 in.) 15.88 mm (5/8 in.) 9.52 mm (3/8 in.)

570 mm (Indoor unit)

The basic installation work procedures are the same as conventional refrigerant models.

However, pay careful attention to the following points:

Since the working pressure is 1.6 times higher than that of conventional refrigerant models, some of the piping and installation

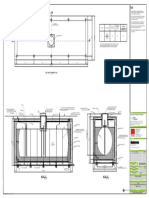

Use pipe with water-resistant heat insulation. 2 INSTALLING DRAIN PIPE 12.70 mm (1/2 in.)

15.88 mm (5/8 in.)

0 to 0.5 To prevent gas leakage, coat the flare

surface with alkylbenzene oil (HAB).

Do not use mineral oil.

and service tools are special. (See the table below.) 19.05 mm (3/4 in.)

CAUTION Note: Install the drain pipe.

Connection pipe

Especially, when replacing a conventional refrigerant model with a new refrigerant R410A model, always replace the conven- Install the drain pipe with downward gradient (1/50 to 1/100) and so

Install heat insulation around both the gas and liquid pipes. Failure to do so may cause water leaks. there are no rises or traps in the pipe.

Pipe outside diameter Dimension B -0.4

0

(mm) (Gas)

tional piping and flare nuts with the R410A piping and flare nuts.

Use heat insulation with heat resistance above 120 °C. (Reverse cycle model only)

75 mm

Use general hard polyvinyl chloride pipe (VP25) [outside diameter 32 mm (1-1/4”)] 6.35 mm (1/4 in.) 9.1

Models that use refrigerant R410A have a different charging port thread diameter to prevent erroneous charging with con- In addition, if the humidity level at the installation location of the refrigerant piping is expected to exceed 70%, install heat and connect it with adhesive (polyvinyl chloride) so that there is no leakage. 9.52 mm (3/8 in.) 13.2 Connection pipe

150 mm – 200 mm

ventional refrigerant and for safety. Therefore, check beforehand. [The charging port thread diameter for R410A is 1/2 UNF 20 insulation around the refrigerant piping. If the expected humidity level is 70-80%, use heat insulation that is 15 mm or thicker When the pipe is long, install supporters. (Liquid)

threads per inch.] and if the expected humidity exceeds 80%, use heat insulation that is 20 mm or thicker. Do not perform air bleeding. 12.70 mm (1/2 in.) 16.6

Indoor unit

Be more careful that foreign matter (oil, water, etc.) does not enter the piping than with refrigerant models. Also, when storing If heat insulation is used that is not as thick as specified, condensation may form on the surface of the insulation. Always heat insulate the indoor side of the drain pipe. 15.88 mm (5/8 in.) 19.7

135 mm 250 mm

In addition, use heat insulation with heat conductivity of 0.045 W/(m·K) or less (at 20 °C). When desiring a high drain pipe height, raise it up to 700 mm or less from the ceiling within

the piping, securely seal the openings by pinching, taping, etc. 19.05 mm (3/4 in.) 24.0

a range of 150 mm from the body. A rise dimension over this range will cause leakage.

When charging the refrigerant, take into account the slight change in the composition of the gas and liquid phases, and always Supporter

charge from the liquid phase side whose composition is stable. When using conventional flare tools to flare R410A pipes, the dimension (3) When the flare nut is tightened properly by your hand, use a torque

Min.450 mm

ELECTRICAL REQUIREMENT Maintenance NG

A should be approximately 0.5 mm more than indicated in the table (for

flaring with R410A flare tools) to achieve the specified flaring. Use a

wrench to finally tighten it.

Special tools for R410A Connection cord (mm2) space Rise thickness gauge to measure the dimension A. Holding spanner

NG

Tool name Contents of change Trap

MAX. MIN. Width across

150 mm or less

1.5 to 2.0 m Width across flats of Body side

Pressure is high and cannot be measured with a conventional gauge. To prevent erroneous mixing of other Air bleeding flats Pipe outside diameter

2.5 1.5 Flare nut

refrigerants, the diameter of each port has been changed.

Gauge manifold NG 6.35 mm (1/4 in.) 17 mm

It is recommended the gauge with seals –0.1 to 5.3 MPa (–76 cmHg to 53 kgf/cm2) for high pressure. –0.1 to Use conformed wire with Type 60245 IEC57. Min.450 mm

Max. 700 mm 9.52 mm (3/8 in.) 22 mm

3.8 MPa (–76 cmHg to 38 kgf/cm2) for low pressure. Install all electrical works in accordance to the standard. Drain pipe (O.D. ø25.4)

Install the disconnect device with a contact gap of at least 3 mm in all poles nearby the units. (Both indoor unit and outdoor unit) 102 mm 40 mm 99 mm Torque wrench

Charge hose To increase pressure resistance, the hose material and base size were changed. 12.70 mm (1/2 in.) 26 mm

NOTES:

15.88 mm (5/8 in.) 29 mm

114 mm

Vacuum pump A conventional vacuum pump can be used by installing a vacuum pump adapter. Check for drainage

Pour about 1 liter of water from the position shown in the diagram or from the airflow outlet to the dew 19.05 mm (3/4 in.) 36 mm CAUTION

30 mm

Gas leakage detector Special gas leakage detector for HFC refrigerant R410A. tray. Check for any abnormalities such as strange noises and whether the drain pump functions normally

262 mm

The drain pump operates when operating in the cooling mode.

Hold the torque wrench at its grip, keeping it in the

215 mm

Drain pipe Wire cover Screw

Copper pipes right angle with the pipe, in order to tighten the flare nut

It is necessary to use seamless copper pipes and it is desirable that the Thicknesses of Annealed Copper Pipes (R410A) correctly.

amount of residual oil is less than 40 mg/10 m. Do not use copper pipes Pipe outside diameter Thickness Flare nut Tightening torque

having a collapsed, deformed or discolored portion (especially on the interior

123 mm

6.35 mm (1/4 in.) 0.80 mm 6.35 mm (1/4 in.) dia. 16 to 18 N·m (160 to 180 kgf·cm)

58 mm

surface). Otherwise, the expansion valve or capillary tube may become

30 mm

Control box

blocked with contaminants. 9.52 mm (3/8 in.) 0.80 mm Ceiling Liquid pipe Gas pipe 9.52 mm (3/8 in.) dia. 30 to 42 N·m (300 to 420 kgf·cm)

As an air conditioner using R410A incurs pressure higher than when

12.70 mm (1/2 in.) 0.80 mm 12.70 mm (1/2 in.) dia. 49 to 61 N·m (490 to 610 kgf·cm)

using conventional refrigerant, it is necessary to choose adequate materials.

Thicknesses of copper pipes used with R410A are as shown in the table. 15.88 mm (5/8 in.) 1.00 mm Be sure to keep sufficient space in the designated position for 15.88 mm (5/8 in.) dia. 63 to 75 N·m (630 to 750 kgf·cm)

Never use copper pipes thinner than that in the table even when it is future maintenance.

19.05 mm (3/4 in.) 1.20 mm 19.05 mm (3/4 in.) dia. 90 to 110 N·m (900 to 1100 kgf·cm)

available on the market. Watering pot

STANDARD PARTS

The following installation parts are furnished.

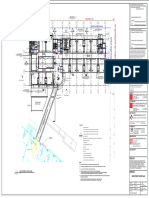

SELECTING AN INSTALLA- Discharge Direction Setting

• The discharge direction can be selected as shown below.

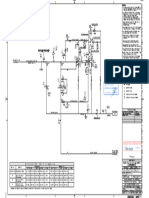

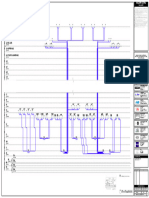

4 INSTALLING HEAT INSULATION 5 ELECTRICAL WIRING 1. CONNECTION DIAGRAMS

Connection wire (to outdoor unit)

(2) After wiring is complete, secure the remote controller cable, connection

cable, and power cable with the wire clamps.

Use them as required. TION LOCATION WARNING

Control line

Connection cable

Decide the mounting position with the customer as follows: 100 mm or more*

CAUTION 3 (to outdoor unit)

INDOOR UNIT ACCESSORIES OPTIONAL PARTS Electrical work must be performed in accordance with this

After checking for gas leaks (refer to the Installation Manual of the Manual by a person certified under the national or regional

2

WARNING * Please ensure sufficient outdoor unit), perform this section. regulations. Be sure to use a dedicated circuit for the unit.

1

Power line Wired remote controller

Name and Shape Q’ty Application Exterior Parts name Model No. Summary maintenance space during

Install heat insulation around both the large (gas) and small (liquid) An insufficient power supply circuit or improperly performed electrical cable (option)

Unit control is Select installation locations that can properly support the weight installation. work can cause serious accidents such as electric shock or fire.

Coupler heat For indoor side pipe joint pipes. Failure to do so may cause water leaks.

Wired remote performed by of the indoor unit. Install the units securely so that they do not Indoor

insulation UTB - UD topple or fall. Before starting work, check that power is not being supplied to the in-

2 controller wired remote Must fit tightly against body without any gap. unit side

door unit and outdoor unit.

controller Wired remote controller wire (option)

Use the included transmission cables and power cables or ones speci-

(4 directions) (3 directions) After checking for gas leaks, insulate by wrapping insulation around the

Special nut A For installing indoor unit Install the plate at fied by the manufacturer. Improper connections, insufficient insulation,

(large flange) Air outlet

UTR - YDZB

outlet when car-

rying out 3-way

CAUTION 2 parts (gas and liquid) of the indoor unit coupling, using the Coupler

Heat Insulation.

or exceeding the allowable current can cause electric shock or fire. *Black

4 shutter plate Do not install the indoor unit in the following areas: For wiring, use the prescribed type of wires, connect them securely, mak-

direction opera- • Area with high salt content, such as at the seaside. It will deteriorate After installing the Coupler Heat Insulation, wrap both ends with vinyl tape 3

White

ing sure that there are no external forces of the wires applied to the termi- 2

tion. metal parts, causing the parts to fail or the unit to leak water. * For a 3-way outlet, make sure to perform the Function Setting on the so that there is no gap. nal connections. Improperly connected or secured wires can cause seri- Red

remote controller. Also, make sure to use the optional shutter panel to 1

Ceiling dirt by dis- • Area filled with mineral oil or containing a large amount of splashed Coupler heat insulation ous accidents such as overheating the terminals, electric shock, or fire.

Special nut B For installing indoor unit oil or steam, such as a kitchen. It will deteriorate plastic parts, caus- block the outlet.

charged wind was Do not modify the power cables, use extension cables, or use any Indoor

(small flange) ing the parts to fail or the unit to leak water. Body

4 Cassette made difficult to No gap branches in the wiring. Improper connections, insufficient insulation, or unit side

UTG-UF*B-F • Area that generates substances that adversely affect the equipment, * The ceiling height cannot be set in the 3-way outlet mode. Therefore, do

grille cling by reviewing exceeding the allowable current can cause electric shock or fire.

the shape of the

such as sulfuric gas, chlorine gas, acid, or alkali. It will cause the

copper pipes and brazed joints to corrode, which can cause refriger-

not change the setting in the “Setting the Ceiling Height” at 8 FUNC-

TION SETTING.

Be sure to overlap

the insulation

Coupler heat

insulation

Match the terminal block numbers and connection cable colors with those of the out- * Ground the remote controller ip it has a ground wire

Template For ceiling openings cutting LOUVER. ant leakage. door unit or branch box. Erroneous wiring may cause burning of the electric parts.

(Carton top) Also used as packing It can be taken • Area that can cause combustible gas to leak, contains suspended No gap Securely connect the connection cables to the terminal blocks. In ad-

1 carbon fibers or flammable dust, or volatile inflammables such as * When the outlet is shut, be sure to install the optional Air outlet shut- dition, secure the cables with wiring holders. Improper connections, ei-

in fresh air of up 2. CONNECTION CABLE PREPARATION

paint thinner or gasoline. If gas leaks and settles around the unit, it ter plate kit. ther in the wiring or at the ends of the wiring, can cause a malfunction, Wire clamp Connection cable

to 10% of “high”

can cause a fire. For the details of installation, please refer to Installation Manual of kit. electric shock, or fire. Keep the earth (ground) wire longer than the other wires. (to outdoor unit)

air volume of the

Remote For air conditioner operation Fresh air • Area where animals may urinate on the unit or ammonia may be Always fasten the outside covering of the connection cable with the

UTZ-VXAA indoor unit by

intake kit generated. cable clamp. (If the insulator is chafed, electric leakage may occur.)

controller attaching Fresh

air intake kit to Do not install where there is the danger of combustible gas leakage. Securely install the electrical box cover on the unit. An improperly in- mm

1 stalled electrical box cover can cause serious accidents such as elec- 20

cassette type Do not install the unit near a source of heat, steam, or flammable gas.

indoor unit. tric shock or fire through exposure to dust or water.

Install the indoor unit, outdoor unit, power supply cable, transmission Install sleeves into any holes made in the walls for wiring. Otherwise, Power supply cable

Use to connect Earth (ground)

or connection cable

cable, and remote control cable at least 1 m away from a television or a short circuit could result. re G

with various pe- wire mo

For remote controller External con- radio receivers. The purpose of this is to prevent TV reception interfer- Install a earth (ground) leakage breaker. In addition, install the earth or

UTY-XWZX ripheral devices m

nect kit ence or radio noise. (Even if they are installed more than 1 m apart, (ground) leakage breaker so that the entire AC main power supply is 30m

Battery 2 and air condition- you could still receive noise under some signal conditions.) cut off at the same time. Otherwise, electric shock or fire could result.

er PC board.

If children under 10 years old may approach the unit, take preventive Always connect the earth (ground) wire. • Use a 4-core wire cable.

Install when the measures so that they cannot reach the unit.

Remote controller holder For installing the remote Improper earthing (grounding) work can cause electric shocks.

under roof condi-

controller holder installation Use the “Insulation kit for high humidity” (option), when the condition Install the remote controller cable and bus wire so as not to be direct

Insulation tion is expected

under the roof is over 80% in humidity and over 30°C in temperature. touched with your hand.

kit for high UTZ-KXGC to be the humidity

1 humidity Otherwise, there is a risk of condensation on the ceiling.

of over 80 % and (1) Use ring terminals with insulating sleeves as shown in the figure be- 3. CONNECTION OF WIRING Wired remote controller

Wire clamp

the temperature (1) Install the indoor unit in a location having sufficient strength to sup-

low to connect to the terminal block.

cable (option)

of over 30 °C. port the weight of the indoor unit.

(2) Securely clamp the ring terminals to the wires using an appropriate (1) Remove the control box cover and install each connection wire

tool so that the wires do not come loose.

(2) The inlet and outlet ports should not be obstructed; the air should be

(3) Use the specified wires, connect them securely, and fasten them so (3) Install control box cover.

Tapping screw For mounting the remote able to blow all over the room.

that there is no stress placed on the terminals. Screw Control box cover

(3) Leave the space required to service the air conditioner.

2 controller (4) Use an appropriate screwdriver to tighten the terminal screws. Do not

(4) Locate where the air can be distributed evenly throughout the room

by the unit.

use a screwdriver that is too small, otherwise, the screw heads may CAUTION

be damaged and prevent the screws from being properly tightened.

(5) Install the unit where connection to the outdoor unit is easy. Do not bundle the remote controller wire, or wire the remote

(5) Do not tighten the terminal screws too much, otherwise, the screws may break.

(6) Install the unit where the connection pipe can be easily installed.

CASSETTE GRILLE ACCESSORIES (6) See the table 1 for the terminal screw tightening torques. controller cord in parallel, with the indoor unit connection

(7) Install the unit where the drain pipe can be easily installed.

(8) Install the unit where noise and vibration is not amplified. wire (to the outdoor unit) and the power supply cord. It may

Name and Shape Q’ty Application (9) Take servicing, etc., into consideration and leave the spaces. Also mm cause erroneous operation.

install the unit where the filter can be removed. 10

ip

Connector cover For covering connector Str Ring terminal

1

Strong and durable ceiling Sleeve

Screw For mounting cassette

4 grille Screw with spe-

262 mm cial washer Screw with

or more special washer

Screw For mounting connector

Ring terminal

1 cover Wire

Ring ter-

Wire minal

Terminal

board

1,000 mm

Terminal block

or more

1,000 mm

1,800 mm

or more

or more

Table 1

Obstruction

Tightening torque

M4 screw 1.2 to 1.8 N·m (12 to 18 kgf·cm)

Floor

This product can be installed at a height of up to 3.0 m. Perform the Function

Setting on the remote controller in accordance with the installed height.

WARNING

(See 8 FUNCTION SETTING.) Use ring terminals and tighten the terminal screws to the specified

torques, otherwise, abnormal overheating may be produced and

possibly cause heavy damage inside the unit.

(Continued to the next page)

9374318261-04_IM_EN.indb 1 2017/8/29 9:43:37

6 CASSETTE GRILLE

INSTALLATION

2. INSTALLING THE GRILLE TO INDOOR UNIT

(1) Install the cassette grille on the indoor unit.

(2) Connect the connector.

Wire (display): WHITE

7 REMOTE CONTROLLER

SETTING

8 FUNCTION SETTING (6) After completing the FUNCTION SETTING, be sure to turn off the

power and turn it on again.

(5) Room temperature sensor control for heating

Depending on the installed environment, correction of the room tem-

perature sensor may be required.

Wire (louver): WHITE

Wire (louver): RED Select the appropriate control setting according to the installed environ-

1. REMOVE THE INTAKE GRILLE 1. Load Batteries (R03/LR03 2) CAUTION ment.

“DRAIN” mark “PIPE” mark (... Factory setting)

(1) Slide the 2 grille hook 1 Press and slide the battery compartment Confirm whether the wiring work for outdoor unit has been Function number

finished. Function number Setting value Setting description

lid on the reverse side to open it.

Slide in the direction of the arrow while

Setting value 00 Standard

Confirm whether the cap for electric control box on the out-

pressing the mark. door unit is close. 01 Lower control

31

2 Insert batteries.

02 Slightly higher control

Be sure to align the battery polarities 03 Higher control

This procedure changes to the function settings used to control the

( ) correctly. indoor unit according to the installation conditions. Incorrect settings (6) Auto restart

3 Close the battery compartment lid. can cause the indoor unit malfunction.

Enable or disable automatic restart after a power interruption.

After the power is turned on, perform the "FUNCTION SETTING" ac-

Indoor unit side (... Factory setting)

cording to the installation conditions using the remote controller.

* Align the stamped marks on the cassette grille against the pipe and the drain of The settings may be selected between the following two: Function Function number Setting value Setting description

the indoor unit. CAUTION Number or Setting Value. CAUTION 00 Enable

• Arrange the wires as illustrated below. Settings will not be changed if invalid numbers or setting values are 40

Take care to prevent infants from accidentally swallowing After turning off the power, wait 30 seconds or more before turning on it 01 Disable

selected. again. The FUNCTION SETTING doesn’t become effective if it doesn’t

batteries.

do so.

Grille hook

When not using the Remote Controller for an extended Operation method * Auto restart is an emergency function such as for power outage etc.

Do not attempt to use this function in normal operation. Be sure to

period, remove the batteries to avoid possible leakage and While pressing the “FAN” button and “SET TEMP. ( )” simultaneously,

damage to the unit. Function setting operate the unit by remote controller or external device.

press the “RESET” button to enter the function setting mode.

(2) Open the intake grille and remove. (7) Room temperature sensor switching

If leaking battery fluid comes in contact with your skin, STEP 1 • Function Details

eyes, or mouth, immediately wash with copious amounts (Only for Wired remote controller)

Remote controller custom code setting When using the Wired remote controller temperature sensor, change

of water, and consult your physician. (1) Filter sign the setting to “Both” (01).

Dead batteries should be removed immediately and dis- Use the following steps to select the custom code of the remote controller. Select appropriate intervals for displaying the filter sign on the indoor (... Factory setting)

posed of properly, either in a battery collection receptacle (Note that the air conditioner cannot receive a signal if the air conditioner unit according to the estimated amount of dust in the air of the room.

Function number Setting value Setting description

or to the appropriate authority. has not been set for the matching custom code.) If the indication is not required, select “No indication” (03).

00 Indoor unit

The custom codes that are set through this process (... Factory setting) 42

(3) Attach the connector cover. Do not attempt to recharge dry batteries. 01 Both

are applicable only to the signals in the FUNCTION Function number Setting value Setting description

SETTING. For details on how to set the custom 00 Standard (2,500 hours) 00: Sensor on the indoor unit is active.

Connector cover NOTES codes through the normal process, refer to 9.3. 01: Sensors on both indoor unit and wired remote controller are active.

Screw Remote controller custom code setting. 01 Long interval (4,400 hours) * Remote controller sensor must be turned on by using the remote con-

• Never mix new and used batteries, or batteries of different 11

02 Short interval (1,250 hours) troller

types. (1) Press the “SET TEMP. ( )( )” button to

03 No indication

• Batteries should last about one year under normal use. If the change the custom code between .

Remote Controller’s operating range becomes appreciably Match the code on the display to the air con- (2) Ceiling height

reduced, replace the batteries and press the RESET button ditioner custom code. (initially set to ) (If the

Setting record

Select the appropriate ceiling height according to the place of installation. Record any changes to the settings in the following table.

with the tip of a ballpoint pen or other small object. custom code does not need to be selected, (... Factory setting)

2. INSTALLING THE REMOTE CONTROLLER HOLDER press the “MODE” button and proceed to

Function number Setting value Setting description

STEP 2.) Setting Setting value

(2) Press the “TIMER MODE” button and check 00 Standard (2.7m)

20 (1) Filter sign

CAUTION that the indoor unit can receive signals at the 01 High ceiling (3.0m)

Check that the indoor unit correctly receives the signal displayed custom code. In case of Cassette type models: (2) Ceiling height

3. ATTACH THE INTAKE GRILLE from the remote controller, then install the remote control- (3) Press the “MODE” button to accept the cus- The ceiling height values are for the 4-way outlet. (3) Outlet directions

ler holder. tom code, and proceed to STEP 2. Do not change this setting in the 3-way outlet mode.

The installation is the reverse of “REMOVING THE INTAKE GRILLE”. (4) Room temperature

Select the remote controller holder selection site by paying 7000, 9000 Btu/h models cannot be installed in high ceilings. sensor control for cooling

The intake grille can be rotated and installed 4 ways to suit the user’s

careful attention to the following: The air conditioner custom code is factory-set to A.

Do not change this setting.

preference. (5) Room temperature

Avoid places in direct sunlight. sensor control for heating

Screw

Select a place that will not be affected by the heat from a (3) Outlet directions (6) Auto restart

CAUTION stove, etc. STEP 2 Select the appropriate number of outlet directions according to the installation conditions.

(... Factory setting) (7) Room temperature

The louver angle cannot be changed if the power is not on, Install the remote controller with a distance of 7 m between the remote Selecting the Function number and Setting value sensor switching

(If moved by hand, it may be damaged.) controller and the photocell as the criteria. However, when installing Function number Setting value Setting description

(1) Press the “SET TEMP. ( ) ( )” buttons to select the function number.

CAUTION the remote controller, check that it operates positively. (Press the “MODE” button to switch between the left and right digits.) 00 4-way After completing the FUNCTION SETTING, be sure to turn off the power

The grille assembly is directionally relative to the air con- 22 and turn it on again.

Install the remote controller holder to a wall, pillar, etc. with the tapping 01 3-way

Use only the supplied screws to install the cassette grille. ditioner body. (2) Press the “FAN” button to proceed to setting the value. (Press the

screw.

“FAN” button again to return to the function number selection.)

Install so that there is no gap between the grille assembly Insert (4) Room temperature sensor control for cooling

and the air conditioner body. (3) Press the “SET TEMP. ( ) ( )” buttons to select the setting value.

(Press the “MODE” button to switch between the left and right digits.) Depending on the installed environment, correction of the room tem-

Press in perature sensor may be required.

The cassette grille equips with an accessory to prevent the (4) Press the “TIMER MODE” button, and “START/STOP” button, in the Select the appropriate control setting according to the installed environ-

grill completely open. Be sure to read the INSTALLATION Screws order listed to confirm the settings. ment.

Indoor unit

SHEET included with the cassette grille before installation. (... Factory setting)

(5) Press the “RESET” button to cancel the function setting mode.

5~7

Ceiling Function number Setting value Setting description

Sealant (1) Mount the Holder. (2) Set the Remote Controller.

00 Standard

Slide up 01 Slightly lower control

Cassette grille 30

02 Lower control

03 Higher control

Pull out

No gap between ceiling and

cassette grille around entire

periphery (3) To remove the Remote Controller

(when use at hand).

9 REMOTE CONTROLLER

CUSTOM CODE SETTING Indoor unit

10 SPECIAL INSTALLATION

METHODS

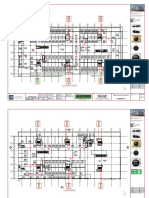

11 TEST RUN 13 ERROR CODES [Troubleshooting at the remote controller LCD]

This is possible only on the wired remote controller. (Option)

Printed circuit board Check items If you use a wireless remote controller, the lamp on the photo detector unit

[SELF-DIAGNOSIS]

When two or more air conditioners are installed in a room and the remote will output error codes by way of blinking patterns.

(1) Is operation of each button on the remote control unit normal?

controller is operating an air conditioner other than the one you wish to CAUTION If you use a wired type remote controller(option), error codes will appear on the remote If an error occurs, the following display will be shown.

(2) Does each lamp light normally?

set, change the custom code of the remote controller to operate only the controller display. See the lamp blinking patterns and error codes in the table below. (“EE” will appear in the set room temperature display.)

When setting DIP switches, do not touch any other parts on (3) Do airflow direction louvers operate normally?

air conditioner you wish to set (4 selections possible).

When two or more air conditioners are installed in a room, please contact the circuit board directly with your bare hands. (4) Is the drain normal? [Troubleshooting with the indoor display] R.C. address

(5) Do not have an abnormal noise and vibration during operation? Troubleshooting at the display is possible either on the wired or wireless

your retailer to set the individual air conditioner custom codes. Be sure to turn off the main power. Error code

remote controller.

Do not operate the air conditioner in test run for a long time.

Confirm the setting of the remote controller custom code and the FILTER LAMP TIMER LAMP OPERATION LAMP

printed circuit board setting.

1. GROUP CONTROL SYSTEM [Operation method] SU MO TU WE TH FR SA

If these are not confirmed, the remote controller cannot be Depending on your installation, choose from the following:

used to operate for the air conditioner. A number of indoor units can be operated at the same time using a single

remote controller. By the wireless remote controller (with “TEST RUN” button)

(1) Wiring method (indoor unit to remote controller) • To start test run, press the “START/STOP” button and the “TEST RUN” Ex. Self-diagnosis

Remote controller custom code setting button on the remote controller.

Indoor unit 1 Indoor unit 2 Indoor unit 3 Indoor unit 4 • To end test run, press the remote controller “START/STOP” button.

Use the following steps to select the custom code of the remote Error code Error contents

controller. (Note that the air conditioner cannot receive a signal if the air By the indoor unit or IR receiver unit

• To start test run, press the “MANUAL AUTO” button of the unit for 01

conditioner has not been set for the matching custom code.)

1 2 3 1 2 3 1 2 3 1 2 3 more than 10 seconds (forced cooling). 13 Indoor signal error

• To end test run, press the “MANUAL AUTO” button for more than 3 MANUAL AUTO 26

(1) Press the “START/STOP” button until only the clock is displayed on

seconds or press the remote controller “START/STOP” button. 27

the remote controller display. The OPERATION, TIMER and FILTER lamp operate as follows table according to the error contents.

(2) Press the “MODE” button for at least 5 seconds to display the cur- By the wired remote controller 00 Wired remote controller error

rent custom code (initially set to ). • For the operation method, refer to the installation manual and the OPERATION TIMER FILTER 02 Indoor room temperature sensor error

operating manual of the wired remote controller. lamp lamp Error contents

(3) Press the “SET TEMP. (▲) (▼)” button to change the custom code lamp

The Operation indicator lamp and Timer indicator lamp will 04 Indoor heat exchanger temperature sensor

between . Match the code on the display to the air con- Bus wire (2-7 times) Indoor signal error (middle) error

1 2 3 simultaneously flash during the test run mode.

Remote control- Wired remote controller error Indoor heat exchanger temperature sensor (inlet)

ditioner custom code. Heating test run will begin in a few minutes when HEAT is selected by (8 times)

ler wire 28

the remote controller [reverse cycle model only]. Indoor room temperature sensor error

error

(4) Press the “MODE” button again to return to the clock display. The Remote controller

(2 times) (2 times)

custom code will be changed. Indoor heat exchanger temperature 09 Float switch operated

When ground wire is necessary

(2 times) (3 times) sensor (middle) error 0C Outdoor discharge pipe temperature sensor error

Indoor heat exchanger temperature Outdoor heat exchanger temperature sensor

(2) R.C. address setting (DIP switch setting) (2 times) (4 times) sensor (inlet) error 06

(outlet) error

Set the R.C. address of each indoor unit using DIP switch on the indoor

unit circuit board. (see following table and figure.)

DIP switch is normally set to make R.C. address "00".

12 CUSTOMER GUIDANCE (2 times)

(3 times)

(6 times)

(2 times)

Float switch operated

Outdoor discharge pipe temperature

sensor error

0A

0E

Outdoor temperature sensor error

Heat sink thermistor (Inverter) error

Explain the following to the customer in accordance with the operating Outdoor heat exchanger temperature 15 Compressor temperature sensor error

manual: (3 times) (3 times) sensor (outlet) error

Indoor R.C. 1d 2-way valve temperature sensor error

unit address DIP SWITCH No.

(1) Starting and stopping method, operation switching, temperature (3 times) (4 times) Outdoor temperature sensor error 1E 3-way valve temperature sensor error

1 2 3 4 adjustment, timer, air flow switching, and other remote controller (3 times) (7 times) Heat sink thermistor (Inverter) error Outdoor heat exchanger temperature sensor

operations. 29 (middle) error

1 00 OFF OFF OFF OFF Compressor temperature sensor error

(2) Air filter removal and cleaning, and how to use the air louvers. (3 times) (8 times)

2 01 ON OFF OFF OFF (3) Give the operating and installation manuals to the customer. 20 Indoor MANUAL AUTO switch error

(3 times) (2 times) 2-way valve temperature sensor error

3 02 OFF ON OFF OFF (4) If the custom code is changed, explain to the customer how it changed 2A Power supply frequency detection error

(the system returns to custom code A when the batteries in the remote (3 times) (3 times) 3-way valve temperature sensor error

4 03 ON ON OFF OFF 17 IPM protection

• If no buttons are pressed within 30 seconds after the custom code controller are replaced). Outdoor heat exchanger temperature

04 OFF OFF ON OFF (3 times) (4 times) sensor (middle) error 18 CT error

is displayed, the system returns to the original clock display. In this 5 *(4) is applicable to using wireless remote controller.

case, start again from step 1. 6 05 ON OFF ON OFF (4 times) (2 times) Indoor MANUAL AUTO switch error 1A Compressor location error

• Depending on the remote controller, the custom code may return to

7 06 OFF ON ON OFF (4 times) (4 times) Power supply frequency detection error 1b Outdoor fan error

custom code A when the batteries are replaced. In this case, if you

use a code other than A, reset the code after replacing the batteries. 8 07 ON ON ON OFF (5 times) (2 times) IPM protection 1F Connected indoor unit error

If you do not know the air conditioner custom code setting, try each

9 08 OFF OFF OFF ON CT error 1C Outdoor unit computer communication error

code ( ) until you find the code which operates the air (5 times) (3 times)

09 ON OFF OFF ON 12 Indoor fan error

conditioner. 10 (5 times) (5 times) Compressor location error

11 10 OFF ON OFF ON 0F Discharge temperature error

(5 times) (6 times) Outdoor fan error

12 11 ON ON OFF ON 24 Excessive high pressure protection on cooling

(5 times) (7 times) Connected indoor unit error

2C 4-way valve error

Indoor unit setting 13 12 OFF OFF ON ON (5 times) (8 times) Outdoor unit computer communication error

16 Pressure switch abnormal, Pressure sensor error

14 13 ON OFF ON ON (6 times) (2 or 3 times) Indoor fan error

Jumper wire Remote control unit 2b Compressor temperature error

15 14 OFF ON ON ON Discharge temperature error

custom code (7 times) (2 times) 19 Active filter error

JM1 JM2 16 15 ON ON ON ON Excessive high pressure protection

(7 times) (3 times) 25 P.F.C. circuit error

Connect Connect A (Primary setting) on cooling

4-way valve error 11 Indoor unit EEPROM error

Disconnect Connect b Example : R.C. address 03 (7 times) (4 times)

Connect Disconnect c (7 times) (5 times) Pressure switch error, Pressure sensor error If “C0” appears in the R.C. address display, there is a remote controller

ON Compressor temperature error error.

Disconnect Disconnect d (7 times) (6 times)

(8 times) (2 or 3 times) Active filter error R.C. address Error code Content

Incompatible indoor unit is

(8 times) (4 times) P.F.C. circuit error C0 1d

connected

Indoor unit EEPROM error

Indoor unit remote con-

1 2 3 4 C0 1c

: OFF troller communication error

: Flashing (0.5s ON/0.5s OFF)

:Fast flashing PART No. 9374318261-04

9374318261-04_IM_EN.indb 2 2017/8/29 9:43:40

You might also like

- Structural Drawings 2Document9 pagesStructural Drawings 2Makenson MuscadinNo ratings yet

- Siemens TXR 320 Installation ManualDocument16 pagesSiemens TXR 320 Installation ManualRomel HufalarNo ratings yet

- EX1200-Electrical Circuit Diagram (Cummins Engine Specification)Document1 pageEX1200-Electrical Circuit Diagram (Cummins Engine Specification)Norman CoetzeeNo ratings yet

- Sap Open Text Imaging InstallationDocument8 pagesSap Open Text Imaging Installationkumudranjan100% (1)

- Information Sheet 3.1.2 Computer Specifications: 1.2 Obtain Correct Specifications From Relevant ResourcesDocument5 pagesInformation Sheet 3.1.2 Computer Specifications: 1.2 Obtain Correct Specifications From Relevant Resourcesapi-196541959100% (2)

- Ta 193114 001Document1 pageTa 193114 001Rene HebaNo ratings yet

- FJS 1923000149Document1 pageFJS 1923000149SHAHZAD LATIFNo ratings yet

- A29-K-HVA-VA-015028-001 - 01A Schematic Diagram For MOS-029 HVAC-Default-000Document1 pageA29-K-HVA-VA-015028-001 - 01A Schematic Diagram For MOS-029 HVAC-Default-000Muhammed ThanzeelNo ratings yet

- Lateral View (Left) : Detail ADocument14 pagesLateral View (Left) : Detail ARahul PatelNo ratings yet

- SCR 005075Document1 pageSCR 005075jeplgpbmcNo ratings yet

- Saudi Arabian Oil Company: 282 A BA-274759 006 0B2Document1 pageSaudi Arabian Oil Company: 282 A BA-274759 006 0B2Mohamed Wasim ShaikhNo ratings yet

- Mezzanine Level Fire AlarmDocument1 pageMezzanine Level Fire Alarmdanish0229No ratings yet

- PNG2023 Plumb 012 ADocument1 pagePNG2023 Plumb 012 ANoel MoronaNo ratings yet

- QGTL1 Pro 07 00002 001 - 10Document1 pageQGTL1 Pro 07 00002 001 - 10Muhammad Arham KhalilNo ratings yet

- ELEVATIONS (1:100) SECTION A-A (1:50) : NotesDocument2 pagesELEVATIONS (1:100) SECTION A-A (1:50) : NotesLubangakene BrianNo ratings yet

- B168082001P00 PDFDocument1 pageB168082001P00 PDFWaleed JaradatNo ratings yet

- P011-0002, Symbols & Legends (2,3)Document1 pageP011-0002, Symbols & Legends (2,3)Mubashir fareedNo ratings yet

- PB02-STG-001 Steam Turbine System (A10-P-2001)Document1 pagePB02-STG-001 Steam Turbine System (A10-P-2001)zhangNo ratings yet

- Ci PW 01 03 001Document1 pageCi PW 01 03 001harihfclNo ratings yet

- Saudi Arabian Oil Company: S61 S HA-004773 003 00Document1 pageSaudi Arabian Oil Company: S61 S HA-004773 003 00zarrar malikNo ratings yet

- Saudi Arabian Oil Company: S61 S HA-004773 003 00Document1 pageSaudi Arabian Oil Company: S61 S HA-004773 003 00zarrar malikNo ratings yet

- Issued For Construction: Hydrostatic Test ScheduleDocument1 pageIssued For Construction: Hydrostatic Test ScheduleMohamed HaleemNo ratings yet

- FINAL RAILWAY CROSSING PROPOSAL OF UER 2-ModelDocument1 pageFINAL RAILWAY CROSSING PROPOSAL OF UER 2-ModelSaurav KumarNo ratings yet

- B Block PitDocument1 pageB Block PitAPS DESIGN INFRA PVT.LTD.No ratings yet

- Attic Access - TguDocument5 pagesAttic Access - TgujhamiralexNo ratings yet

- DED-DIC-ARE&STR - CONCEPT DESIGN - 271023 - ModelDocument1 pageDED-DIC-ARE&STR - CONCEPT DESIGN - 271023 - ModelAnwar SalukiNo ratings yet

- Ven-002 - 1st Floor Plan Ventilation Layout (1) - Layout1Document1 pageVen-002 - 1st Floor Plan Ventilation Layout (1) - Layout1ᏗᎷᎥᏖᏕᎥᏁᎶᏂNo ratings yet

- LS Fence 1Document1 pageLS Fence 1jimNo ratings yet

- 03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrDocument1 page03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrD HOLNo ratings yet

- UNIT 11 - WORKING DRAWINGS - REV 1-Door & Window ScheduleDocument1 pageUNIT 11 - WORKING DRAWINGS - REV 1-Door & Window ScheduleD HOLNo ratings yet

- SIMON18012: Call Before You DigDocument1 pageSIMON18012: Call Before You DigBALAKRISHNANNo ratings yet

- 819-Tw-E-102 Electrical LT Block Diagram LT Block Diagram r1 (1) - OzoraDocument1 page819-Tw-E-102 Electrical LT Block Diagram LT Block Diagram r1 (1) - OzoraMichael NgoNo ratings yet

- SampleDocument1 pageSampleKYC BIM010No ratings yet

- Notes:: Saudi Arabian Oil CompanyDocument1 pageNotes:: Saudi Arabian Oil Companymohamed esmailNo ratings yet

- Captură de Ecran Din 2024-02-26 La 10.56.19Document1 pageCaptură de Ecran Din 2024-02-26 La 10.56.19samuelantonoviciNo ratings yet

- V A L L E Y: Saudi Arabian Oil CompanyDocument1 pageV A L L E Y: Saudi Arabian Oil CompanyThomas JohnNo ratings yet

- UWP 25418 001 Elevated Water Tank 5000L CR02 PDFDocument1 pageUWP 25418 001 Elevated Water Tank 5000L CR02 PDFer.praveenraj30No ratings yet

- 408 N.MAIN - FIRE SERVICE-Fire Service PlanDocument1 page408 N.MAIN - FIRE SERVICE-Fire Service PlanarielNo ratings yet

- Extracted Pages From PID BinderDocument15 pagesExtracted Pages From PID Bindermangesh patilNo ratings yet

- GDP - 2734 - Wakl - CD - 30-01-118 Diagramatic Section RWDP R0Document1 pageGDP - 2734 - Wakl - CD - 30-01-118 Diagramatic Section RWDP R0Mohd Khairul FitriNo ratings yet

- 522445-AUR901-DRG-BC-5600-CIVIL TYPICAL UNDERGROUND SERVICES DETAILS SHEET 1 OF 4油罐间Document1 page522445-AUR901-DRG-BC-5600-CIVIL TYPICAL UNDERGROUND SERVICES DETAILS SHEET 1 OF 4油罐间Gibson SitumorangNo ratings yet

- Notes:: Saudi Arabian Oil CompanyDocument1 pageNotes:: Saudi Arabian Oil Companymohamed esmailNo ratings yet

- A1700 Signage Location and DetailsDocument5 pagesA1700 Signage Location and DetailsJustMoveIt Trucking, OPCNo ratings yet

- TA2860 RHI SI ZZ DR N 3002 Temporary UtilitiesDocument1 pageTA2860 RHI SI ZZ DR N 3002 Temporary UtilitiesBack To SumateraNo ratings yet

- MOM Fortis, Kalyan 10.08.2022Document1 pageMOM Fortis, Kalyan 10.08.2022Mohd MustaqNo ratings yet

- SCHP53RD01 PDFDocument1 pageSCHP53RD01 PDFsnamprogNo ratings yet

- Mayfair LOTS 4 & 10 Buildings 4-6: Building 6 Roof PlanDocument1 pageMayfair LOTS 4 & 10 Buildings 4-6: Building 6 Roof PlanEric WilsonNo ratings yet

- Fire-Pump Room - Rev.cDocument1 pageFire-Pump Room - Rev.cwael72No ratings yet

- ODEC Ventilation Layout UKDocument1 pageODEC Ventilation Layout UKsondeepyadav4873No ratings yet

- 3Document1 page3tarique mohammedNo ratings yet

- Utilities Substation Ss-053: Saudi Arabian Oil CompanyDocument1 pageUtilities Substation Ss-053: Saudi Arabian Oil CompanyLino AbetoNo ratings yet

- Amphi TheatreDocument1 pageAmphi TheatreanzaniNo ratings yet

- 2084 CrawlspaceDocument7 pages2084 Crawlspacepatrick.estimatorsNo ratings yet

- 0415 RiserPoster 032315 Final.5cf68e0c62dee PDFDocument1 page0415 RiserPoster 032315 Final.5cf68e0c62dee PDFFernando Jimenez ChillonNo ratings yet

- Marked-Up P&ID For Hot Gas Bypass of J12-K-0613Document1 pageMarked-Up P&ID For Hot Gas Bypass of J12-K-0613nausheed123No ratings yet

- Meriton: Church AveDocument1 pageMeriton: Church AveIrfan SehovicNo ratings yet

- Binghati Powr Coordination DrawingDocument1 pageBinghati Powr Coordination Drawingzafrikhan875No ratings yet

- Cb-3 Mech'l Plans 05.06.22Document12 pagesCb-3 Mech'l Plans 05.06.22Mark Vincent MoraNo ratings yet

- DetailsDocument1 pageDetailstensiNo ratings yet

- Earthing Schematic Office R3 (04.01.2022) OUR ScopeDocument1 pageEarthing Schematic Office R3 (04.01.2022) OUR ScopeRZK AbbadonNo ratings yet

- 4355-Aa-Dc-22i10pr0900i - Checkprint For SquadDocument1 page4355-Aa-Dc-22i10pr0900i - Checkprint For Squadamit bagchiNo ratings yet

- Ta 680745 001Document1 pageTa 680745 001shahidNo ratings yet

- Mitsubishi PL-3GJB2.UK Service ManualDocument12 pagesMitsubishi PL-3GJB2.UK Service Manual陈唐伟No ratings yet

- 30RB B Series CatalogDocument16 pages30RB B Series Catalog陈唐伟No ratings yet

- Service Manual - Rav-Gp1101at8p-A Rav-Gp1401at8p-A Rav-Gp1601at8p-A-1632279104Document94 pagesService Manual - Rav-Gp1101at8p-A Rav-Gp1401at8p-A Rav-Gp1601at8p-A-1632279104陈唐伟No ratings yet

- Dynadr ConnectionDocument16 pagesDynadr Connection陈唐伟No ratings yet

- Master of Science (Engineering Geology) PDFDocument4 pagesMaster of Science (Engineering Geology) PDFMuhammad AzmanNo ratings yet

- Breaktor900 B4 - 0 Short Spec ENA Active Cooling - EB9DE-XX5BCDocument25 pagesBreaktor900 B4 - 0 Short Spec ENA Active Cooling - EB9DE-XX5BCHamza HammadiNo ratings yet

- Remplacement LVDT Valve 010310 (E)Document20 pagesRemplacement LVDT Valve 010310 (E)Arko RoosNo ratings yet

- Specification INPUT: 100-240V AC (50/60Hz)Document1 pageSpecification INPUT: 100-240V AC (50/60Hz)Federico UrquizaNo ratings yet

- Ta 062Document119 pagesTa 062ehj choNo ratings yet

- Axil FansDocument20 pagesAxil Fansjuberinamdar2465No ratings yet

- BMW Group Plant Debrecen Careers - 2Document2 pagesBMW Group Plant Debrecen Careers - 2Shivanshu PandeyNo ratings yet

- 5 Spark Kafka Cassandra Slides PDFDocument20 pages5 Spark Kafka Cassandra Slides PDFusernameusernaNo ratings yet

- Imad Khalfi CVDocument1 pageImad Khalfi CVImad KhalfiNo ratings yet

- DRX Influence - Compare Huawei DRX Parameter With Apple DRX ParameterDocument5 pagesDRX Influence - Compare Huawei DRX Parameter With Apple DRX ParameterAhmed GadNo ratings yet

- CH 16 Unix & Linux Operating SystemDocument36 pagesCH 16 Unix & Linux Operating SystemKumar HimanshuNo ratings yet

- Hybrid Cooler Project PresentationDocument13 pagesHybrid Cooler Project PresentationJK COTTONNo ratings yet

- Services As EmployeesDocument12 pagesServices As EmployeesCJ LNo ratings yet

- NDT One MarkDocument11 pagesNDT One MarkAnonymous 6SivdzjNo ratings yet

- Crimp Interchange: The Change in The Ratio of The Crimp of The Warp and Weft System Is Termed As Crimp InterchangeDocument12 pagesCrimp Interchange: The Change in The Ratio of The Crimp of The Warp and Weft System Is Termed As Crimp InterchangeAshutoshNo ratings yet

- 1974 Ski DooDocument292 pages1974 Ski DooVincent RoyNo ratings yet

- Bmo Beaconmedaes Psa Medical Oxygen Concentrator Plant SpecificationDocument13 pagesBmo Beaconmedaes Psa Medical Oxygen Concentrator Plant Specificationdiah131No ratings yet

- Fermi FET Technology Seminar ReportDocument21 pagesFermi FET Technology Seminar Reportimcoolsha999No ratings yet

- BS en 3452 3 Penetrant Testing Reference BlocksDocument15 pagesBS en 3452 3 Penetrant Testing Reference BlocksKresimir SimeonNo ratings yet

- Daag To Lirf b737Document76 pagesDaag To Lirf b737Abdel Hafid LahrecheNo ratings yet

- Sartorius Balance Cable Pinouts - TALtechDocument2 pagesSartorius Balance Cable Pinouts - TALtechWill CariasNo ratings yet

- Presentation Pavement Failures 1507355219 83810Document26 pagesPresentation Pavement Failures 1507355219 83810suraj shetNo ratings yet

- Seismic Design and Steel Connection DetailingDocument16 pagesSeismic Design and Steel Connection Detailingjose felix100% (1)

- Oracle9i Jdeveloper User's GuideDocument4,683 pagesOracle9i Jdeveloper User's Guidealvati85No ratings yet

- A Road AccidentDocument4 pagesA Road AccidentAiman FirdausNo ratings yet

- Electric Vehicle Machines and Drives - Design, Analysis and ApplicationDocument26 pagesElectric Vehicle Machines and Drives - Design, Analysis and Applicationmsssrinivas1No ratings yet