Professional Documents

Culture Documents

EN-GB8308 - TopLab Vertical Material Properties - 2.1

EN-GB8308 - TopLab Vertical Material Properties - 2.1

Uploaded by

OnebigunicornCopyright:

Available Formats

You might also like

- Saudi Aramco Painting Project APCSDocument104 pagesSaudi Aramco Painting Project APCSsmart_onyx1792% (13)

- S Se Errvviicce Eb Bu Ulllle Ettiin N T Trru UcckkssDocument50 pagesS Se Errvviicce Eb Bu Ulllle Ettiin N T Trru UcckkssAndy Chalifoux100% (2)

- R1200GS Maintenance SchedulesDocument0 pagesR1200GS Maintenance Schedulesstranger ninerNo ratings yet

- JK t1900 (Òîëüêî Èíñòðóêöèÿ)Document56 pagesJK t1900 (Òîëüêî Èíñòðóêöèÿ)jongaeck0% (1)

- Oxidation Number: Na, Be, K, PB, H, O, PDocument40 pagesOxidation Number: Na, Be, K, PB, H, O, Pjoe 45No ratings yet

- PURICOMPACT Eng Rev01Document2 pagesPURICOMPACT Eng Rev01FernandoSanfigNo ratings yet

- TDS - Compact Laminates - IsPACEDocument1 pageTDS - Compact Laminates - IsPACEomarfarooque0.3No ratings yet

- Tu Kompakt-plita Arpa (Yadro v Kolіr)Document2 pagesTu Kompakt-plita Arpa (Yadro v Kolіr)wasyl.dawydenkoNo ratings yet

- DataDocument1 pageDataStuxnetNo ratings yet

- H48-6 / TG-AH486: Thermal PadDocument1 pageH48-6 / TG-AH486: Thermal PadMalek Ellouz (Jay)No ratings yet

- KRONOSPANDocument1 pageKRONOSPANRely TokNo ratings yet

- Span Vs SPHTDocument1 pageSpan Vs SPHTNizar NazriNo ratings yet

- ARANDELA F436 DE 3-4 NEGRODocument1 pageARANDELA F436 DE 3-4 NEGROjhulyNo ratings yet

- Airvent - Dae - DC - DF - 1 - S11.1 - en - 10&4Document5 pagesAirvent - Dae - DC - DF - 1 - S11.1 - en - 10&4honghieutrNo ratings yet

- Elna (Radial Thru-Hole) RC3 SeriesDocument1 pageElna (Radial Thru-Hole) RC3 Seriesjghjkhgkh87No ratings yet

- Calculation MOLDocument2 pagesCalculation MOLIrsyad RosyidiNo ratings yet

- ASD Gama Lab TopDocument9 pagesASD Gama Lab Topdaniela ratuleaNo ratings yet

- 150w Core ZW42712TCDocument1 page150w Core ZW42712TCErkanNo ratings yet

- Tycoons - Specs of Carbon Steel Wire - 10B21, 10B38, 1010, 4140Document1 pageTycoons - Specs of Carbon Steel Wire - 10B21, 10B38, 1010, 4140Alexis BarolinNo ratings yet

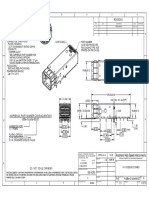

- Motiongoo Stepper Motor Drawing-17HT19S4168C1Document1 pageMotiongoo Stepper Motor Drawing-17HT19S4168C1Make RownNo ratings yet

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 pagesSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompNo ratings yet

- Din 17100Document1 pageDin 17100KhoirulAnwarNo ratings yet

- KEMET Part Number: T520V226M020ATE045: General InformationDocument1 pageKEMET Part Number: T520V226M020ATE045: General Informationvax1No ratings yet

- NIC Components NACV SeriesDocument3 pagesNIC Components NACV SeriesNICCompNo ratings yet

- Properties: Test Conditions Units Properties Test Conditions Units Typical ValuesDocument1 pageProperties: Test Conditions Units Properties Test Conditions Units Typical ValueszaherNo ratings yet

- MC-306 enDocument2 pagesMC-306 enminhhieuhanam93No ratings yet

- 07a. MR MDF TECHNICAL DATADocument2 pages07a. MR MDF TECHNICAL DATAsacdawoodNo ratings yet

- NIC Components NRE-L SeriesDocument5 pagesNIC Components NRE-L SeriesNICCompNo ratings yet

- CAR Abrasion Resistant AR Plus High Gloss Coloured Core Thin HPL StandardDocument1 pageCAR Abrasion Resistant AR Plus High Gloss Coloured Core Thin HPL StandardAnonymous FGzNDzIeJNo ratings yet

- Elna (SMD) RV SeriesDocument1 pageElna (SMD) RV Seriesjghjkhgkh87No ratings yet

- Motiongoo Stepper Motor Drawing-17HT13S6031Document1 pageMotiongoo Stepper Motor Drawing-17HT13S6031Make RownNo ratings yet

- GA-150-LL/ GA-150B-LL: FeaturesDocument5 pagesGA-150-LL/ GA-150B-LL: Featuresmccornejo1617No ratings yet

- NIC Components NRE-WY SeriesDocument7 pagesNIC Components NRE-WY SeriesNICCompNo ratings yet

- C NX2016SA eDocument1 pageC NX2016SA eadilNo ratings yet

- Elna (SMD) RV5 SeriesDocument2 pagesElna (SMD) RV5 Seriesjghjkhgkh87No ratings yet

- Electro140 ContactCleanerDocument1 pageElectro140 ContactCleanerRoberto Alfaro EspinozaNo ratings yet

- Polyester Limited: Properties Average ThicknessDocument1 pagePolyester Limited: Properties Average ThicknessPuneet SingalNo ratings yet

- NIC Components NRE-LS SeriesDocument5 pagesNIC Components NRE-LS SeriesNICCompNo ratings yet

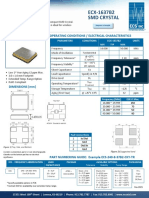

- ECX-1637 SMD Crystal: Operating Conditions / Electrical CharacteristicsDocument2 pagesECX-1637 SMD Crystal: Operating Conditions / Electrical CharacteristicsasdfasdfdfNo ratings yet

- ECX-1637B2 SMD Crystal: Operating Conditions / Electrical CharacteristicsDocument3 pagesECX-1637B2 SMD Crystal: Operating Conditions / Electrical CharacteristicsKiran PatelNo ratings yet

- Frenos Sauleda - ToP - 05Document1 pageFrenos Sauleda - ToP - 05Marcos LópezNo ratings yet

- Cem 1212cDocument3 pagesCem 1212cGabriel GranadoNo ratings yet

- Productdatasheet en m17 A4be473d03Document3 pagesProductdatasheet en m17 A4be473d03qcnsonglamNo ratings yet

- Especificacion-Tecnica ANTENA COMBADocument1 pageEspecificacion-Tecnica ANTENA COMBARosa FuentesNo ratings yet

- JRG CapacitorsDocument2 pagesJRG Capacitorsmarina anastasovaNo ratings yet

- Hpm24Cx: Piezo Sound GeneratorsDocument1 pageHpm24Cx: Piezo Sound Generatorsmsicoie1851No ratings yet

- Elna (SMD) RV3 SeriesDocument1 pageElna (SMD) RV3 Seriesjghjkhgkh87No ratings yet

- Dielectric Device KHB1890B01: Technical DataDocument2 pagesDielectric Device KHB1890B01: Technical DataJim LiebNo ratings yet

- QCL Series: General Specifi Cations Equivalent Series Resistance (ESR)Document2 pagesQCL Series: General Specifi Cations Equivalent Series Resistance (ESR)Alberto Fernández VázquezNo ratings yet

- CFCFree ElectroContactCleanerDocument1 pageCFCFree ElectroContactCleanerRoberto Alfaro EspinozaNo ratings yet

- MDF FR TDSDocument1 pageMDF FR TDSbahoxa3115No ratings yet

- Motiongoo Stepper Motor Drawing-17HF19S4168Document1 pageMotiongoo Stepper Motor Drawing-17HF19S4168Make RownNo ratings yet

- Electrical Data: (Basta)Document2 pagesElectrical Data: (Basta)Dwi KurniawanNo ratings yet

- MB8851 Spec Sheet - EngDocument1 pageMB8851 Spec Sheet - Engclinica celsocabralNo ratings yet

- 4600X Series - Thick Film Conformal Sips: FeaturesDocument2 pages4600X Series - Thick Film Conformal Sips: Featuresmohammad hosein nikbakhtNo ratings yet

- Wts - NIC NAYT SeriesDocument3 pagesWts - NIC NAYT SeriesKetan LohaniNo ratings yet

- OklahomaDocument21 pagesOklahomaYusuf ÜnlüsoyNo ratings yet

- Hi Temp 1Document1 pageHi Temp 1CADTDDNo ratings yet

- Revisions: Amphenol Part Number Confuguration UE86-G1636-00X3TDocument3 pagesRevisions: Amphenol Part Number Confuguration UE86-G1636-00X3Tkkk ghgfhgfNo ratings yet

- Ashoka Buildcon LTD.: Design Stipulation Code RefferedDocument1 pageAshoka Buildcon LTD.: Design Stipulation Code RefferedAnil UdaleNo ratings yet

- Elna (Non-Polar SMD) RVB SeriesDocument1 pageElna (Non-Polar SMD) RVB Seriesjghjkhgkh87No ratings yet

- 04020VA Data SheetDocument5 pages04020VA Data Sheetahmad16_ftua6999No ratings yet

- Series: Cp34-M Description: Peltier Module: FeaturesDocument5 pagesSeries: Cp34-M Description: Peltier Module: FeaturesDavid A Alemán QNo ratings yet

- Nylube X12F9Document3 pagesNylube X12F9OnebigunicornNo ratings yet

- Otis AC Resistance Controller SearchableDocument9 pagesOtis AC Resistance Controller SearchableOnebigunicornNo ratings yet

- Delco RGA Product Line 2023 FinalDocument5 pagesDelco RGA Product Line 2023 FinalOnebigunicornNo ratings yet

- Tac 32 ICON 32 ManualDocument220 pagesTac 32 ICON 32 ManualOnebigunicorn100% (1)

- Automatic Transmission CatalogDocument84 pagesAutomatic Transmission CatalogDmitriy TolochikNo ratings yet

- BS6622-BS7835 Single Core Armoured 33kV XLPE Stranded Copper ConductorDocument3 pagesBS6622-BS7835 Single Core Armoured 33kV XLPE Stranded Copper ConductorroyclhorNo ratings yet

- Gauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFDocument2 pagesGauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFArlen NurlanNo ratings yet

- 11-02-24r Glaverbel-SunergyDocument16 pages11-02-24r Glaverbel-SunergydatanotionNo ratings yet

- Strategies For Eliminating DecarburizationDocument3 pagesStrategies For Eliminating Decarburizationmp87_ingNo ratings yet

- Summer Training Presentation: ON Distillation Unit OF Mathura RefineryDocument14 pagesSummer Training Presentation: ON Distillation Unit OF Mathura RefineryGovindPatelNo ratings yet

- Guidelines On Dometic Gas Piping SystemDocument30 pagesGuidelines On Dometic Gas Piping Systemg00r100% (9)

- Blenders EnglDocument10 pagesBlenders EnglDaniel Tourón SaramellaNo ratings yet

- 2-Lubricants CharacteristcsDocument30 pages2-Lubricants CharacteristcsHariajahNo ratings yet

- Code G FanucDocument3 pagesCode G FanucSanchai Progaeew100% (1)

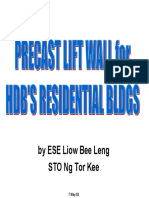

- Precast Lift WallDocument129 pagesPrecast Lift WallThandar MyintNo ratings yet

- GR-750XL-2: 75 Ton Capacity (68 Metric Tons) Hydraulic Rough Terrain CraneDocument16 pagesGR-750XL-2: 75 Ton Capacity (68 Metric Tons) Hydraulic Rough Terrain CraneJustin MorseNo ratings yet

- Environmental Engineering HS Peavy DR Rowe G TchobDocument4 pagesEnvironmental Engineering HS Peavy DR Rowe G TchobMalvika SafayaNo ratings yet

- QAP Format - QA 01 F 01Document1 pageQAP Format - QA 01 F 01Murukan PadmanabhanNo ratings yet

- Mailhem Ikos Environment Pvt. Ltd. Business Profile 2016Document16 pagesMailhem Ikos Environment Pvt. Ltd. Business Profile 2016SamsRsNo ratings yet

- JRC Jfe 582 - Install Transducer PDFDocument6 pagesJRC Jfe 582 - Install Transducer PDFleducthinh65No ratings yet

- Investigation Into The Wetting Phenomenon of Terry FabricsDocument5 pagesInvestigation Into The Wetting Phenomenon of Terry FabricsLatifNo ratings yet

- Pi 06Document1 pagePi 06Kapil DodiyaNo ratings yet

- Stainless Steel Wire MeshDocument8 pagesStainless Steel Wire MeshWinner Stainless Steel Wire Mesh FactoryNo ratings yet

- Decicoat T35 TDS 703ipDocument3 pagesDecicoat T35 TDS 703ipSaif KhanNo ratings yet

- Director Pharmaceuticals Manufacturing Supply Chain in NYC Resume Edward OestreicherDocument2 pagesDirector Pharmaceuticals Manufacturing Supply Chain in NYC Resume Edward OestreicherEdwardOestreicherNo ratings yet

- Litz Wire Termination GuideDocument5 pagesLitz Wire Termination GuidefdNo ratings yet

- ELEC3320 Lab ReportDocument16 pagesELEC3320 Lab ReportTameem MithaiwalaNo ratings yet

- MB Value in Sand PDFDocument6 pagesMB Value in Sand PDFVyankat ChateNo ratings yet

- Danfoss Pressure Switch KP34, KP35, KP36, KP37Document8 pagesDanfoss Pressure Switch KP34, KP35, KP36, KP37Parinpa Ketar100% (1)

- 243 IST ANTEA CONDENSING ERP GAR AEE EN CompressedDocument76 pages243 IST ANTEA CONDENSING ERP GAR AEE EN CompressedMarian GrecuNo ratings yet

EN-GB8308 - TopLab Vertical Material Properties - 2.1

EN-GB8308 - TopLab Vertical Material Properties - 2.1

Uploaded by

OnebigunicornOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EN-GB8308 - TopLab Vertical Material Properties - 2.1

EN-GB8308 - TopLab Vertical Material Properties - 2.1

Uploaded by

OnebigunicornCopyright:

Available Formats

MATERIAL PROPERTY DATASHEET

Decorative high-pressure compact laminates according to EN 438-4:2016 of thicknesses of 6 mm (±1/4 in) or greater for interior use. Sheets consisting of layers of natural fibres (paper and/or

wood) impregnated with thermosetting resins and surface layer(s) on one or both sides, having decorative colours or designs. A transparent topcoat is added to the surface layer(s) and cured by

Trespa’s unique in-house technology Electron Beam Curing (EBC), to enhance the surface properties. These components are bonded together with simultaneous application of heat and high

specific pressure to obtain a homogeneous closed material with increased density and integral decorative surface. They are available in the Standard grade (CGS) and in the Fire-Retardant grade

(CGF).

RESULTAB

GRADE: CGS (TOPLABVERTICAL) GRADE: CGF (TOPLABVERTICAL FR)

PROPERTIES TEST METHOD PROPERTY OR ATTRIBUTE UNIT

STANDARD: EN 438-4 STANDARD: EN 438-4

COLOUR/DECOR: ALLB COLOUR/DECOR: ALLB

SURFACE QUALITY

mm²/m² ≤1

Spots, dirt, similar surface defects

in²/ft² ≤ 0.0001

EN 438-2 : 4

mm/m² ≤ 10

Fibres, hairs & scratches

in/ft² ≤ 0.036

DIMENSIONAL TOLERANCES

6.0 ≤ t < 8.0: +/- 0.40

8.0 ≤ t < 12.0: +/- 0.50

mm

12.0 ≤ t < 16.0: +/- 0.60

16.0 ≤ t < 20.0: +/- 0.70

EN 438-2 : 5 Thickness

0.2362 ≤ t < 0.3150 : +/- 0.0157

0.3150 ≤ t < 0.4724 : +/- 0.0197

in

0.4724 ≤ t < 0.6299 : +/- 0.0236

0.6299 ≤ t < 0.7874 : +/- 0.0275

mm/m ≤2

EN 438-2 : 9 Flatness

in/ft ≤ 0.024

mm +5/-0

EN 438-2 : 6 Length & width

in + 0.1968 / - 0

mm/m ≤1

EN 438-2 : 7 Straightness of edges

in/ft ≤ 0.012

2550 x 1860 = max. difference between diagonals (x-y) = 4

3050 x 1530 = max. difference between diagonals (x-y) = 4

mm

3650 x 1860 = max. difference between diagonals (x-y) = 5

4270 x 2130 = max. difference between diagonals (x-y) = 6

Trespa Standard Squareness

100.39 x 73.23 = max. difference between diagonals (x-y) = 0.1575

120.08 x 60.24 = max. difference between diagonals (x-y) = 0.1575

in

143.70 x 73.23 = max. difference between diagonals (x-y) = 0.1969

168.11 x 83.86 = max. difference between diagonals (x-y) = 0.2362

PHYSICAL PROPERTIES

Wear resistance - Revolutions

Resistance to surface wear EN 438-2 : 10 Initial point ≥ 50

(min)

Indentation diameter - 6 ≤ t mm

Resistance to impact by large diameter ball EN 438-2 : 21 mm ≤ 10

with drop height 1.8 m

Resistance to scratching EN 438-2 : 25 Force Rating (min) ≥3

Resistance to dry heat (160° C / 320° F) EN 438-2 : 16 Appearance Rating (min) ≥4

Resistance to wet heat (100° C / 212° F) EN 438-2 : 18 Appearance Rating (min) ≥4

Mass increase (% max) t ≥ 6 mm ≤1

Resistance to immersion in boiling water EN 438-2 : 12 Thickness increase (% max) t ≥ 6 mm ≤1

Appearance Rating (min) ≥4

Longitudinal % ≤ 0.25

Dimensional stability at elevated temperature EN 438-2 : 17 Cumulative dimensional change

Transversal % ≤ 0.25

EN-GB8308 ■ Version 2.1 ■ Date 01-2023

Group 1 & 2 5

Resistance to staining EN 438-2 : 26 Appearance - Rating (min)

Group 3 5

Light fastness (xenon arc) EN 438-2 : 27 Contrast Grey scale ISO 105 A02 4-5

Resistance to water vapour EN 438-2 : 14 Appearance Rating (min) ≥4

Resistance to crazing EN 438-2 : 24 Appearance Rating (min) ≥4

Modulus of elasticity EN ISO 178 Stress MPa ≥ 9000

Flexural strength EN ISO 178 Stress MPa ≥ 120

Tensile strength EN ISO 527-2 Stress MPa ≥ 70

1 Please check www.trespa.info for the latest version of this document

RESULTAB

GRADE: CGS (TOPLAB

VERTICAL

) GRADE: CGF (TOPLABVERTICAL FR)

PROPERTIES TEST METHOD PROPERTY OR ATTRIBUTE UNIT

STANDARD: EN 438-4 STANDARD: EN 438-4

COLOUR/DECOR: ALLB COLOUR/DECOR: ALLB

Density EN ISO 1183 Density g/cm³ ≥ 1.35

PHYSICAL PROPERTIES

6 mm : ≥ 2000

8 mm : ≥ 3000

≥ 10 mm : ≥ 4000

Resistance to fixings ISO 13894-1 Pull out strength N

0.2362 in : ≥ 2000

0.3150 in : ≥ 3000

≥ 0.3937 in : ≥ 4000

FIRE PERFORMANCE

EUROPE

Classification t = 6 mm /

Euroclass B-s2, d0

0.2362 in

Reaction to Fire EN 13501-1 D-s2, d0

Classification t ≥ 8 mm /

Euroclass B-s1, d0

0.3150 in

NORTH AMERICA

Classification Class B A

ASTM E84/UL

Material Surface Burning CharacteristicsC Flame Spread Index FSI 26-75 0-25

723

Smoke Developed Index SDI 0-450 0-450

OTHER PROPERTIES

Realease of formaldehyde EN 717-2 Classification Class E1

A Due to conversion from metric values, the US values provided are approximate.

B All data are related to the products mentioned in the Trespa® TopLab® VERTICAL standard delivery programme.

C Laboratory test results are not intended to represent hazards that may be present under actual fire conditions.

EN-GB8308 ■ Version 2.1 ■ Date 01-2023

2 Please check www.trespa.info for the latest version of this document

You might also like

- Saudi Aramco Painting Project APCSDocument104 pagesSaudi Aramco Painting Project APCSsmart_onyx1792% (13)

- S Se Errvviicce Eb Bu Ulllle Ettiin N T Trru UcckkssDocument50 pagesS Se Errvviicce Eb Bu Ulllle Ettiin N T Trru UcckkssAndy Chalifoux100% (2)

- R1200GS Maintenance SchedulesDocument0 pagesR1200GS Maintenance Schedulesstranger ninerNo ratings yet

- JK t1900 (Òîëüêî Èíñòðóêöèÿ)Document56 pagesJK t1900 (Òîëüêî Èíñòðóêöèÿ)jongaeck0% (1)

- Oxidation Number: Na, Be, K, PB, H, O, PDocument40 pagesOxidation Number: Na, Be, K, PB, H, O, Pjoe 45No ratings yet

- PURICOMPACT Eng Rev01Document2 pagesPURICOMPACT Eng Rev01FernandoSanfigNo ratings yet

- TDS - Compact Laminates - IsPACEDocument1 pageTDS - Compact Laminates - IsPACEomarfarooque0.3No ratings yet

- Tu Kompakt-plita Arpa (Yadro v Kolіr)Document2 pagesTu Kompakt-plita Arpa (Yadro v Kolіr)wasyl.dawydenkoNo ratings yet

- DataDocument1 pageDataStuxnetNo ratings yet

- H48-6 / TG-AH486: Thermal PadDocument1 pageH48-6 / TG-AH486: Thermal PadMalek Ellouz (Jay)No ratings yet

- KRONOSPANDocument1 pageKRONOSPANRely TokNo ratings yet

- Span Vs SPHTDocument1 pageSpan Vs SPHTNizar NazriNo ratings yet

- ARANDELA F436 DE 3-4 NEGRODocument1 pageARANDELA F436 DE 3-4 NEGROjhulyNo ratings yet

- Airvent - Dae - DC - DF - 1 - S11.1 - en - 10&4Document5 pagesAirvent - Dae - DC - DF - 1 - S11.1 - en - 10&4honghieutrNo ratings yet

- Elna (Radial Thru-Hole) RC3 SeriesDocument1 pageElna (Radial Thru-Hole) RC3 Seriesjghjkhgkh87No ratings yet

- Calculation MOLDocument2 pagesCalculation MOLIrsyad RosyidiNo ratings yet

- ASD Gama Lab TopDocument9 pagesASD Gama Lab Topdaniela ratuleaNo ratings yet

- 150w Core ZW42712TCDocument1 page150w Core ZW42712TCErkanNo ratings yet

- Tycoons - Specs of Carbon Steel Wire - 10B21, 10B38, 1010, 4140Document1 pageTycoons - Specs of Carbon Steel Wire - 10B21, 10B38, 1010, 4140Alexis BarolinNo ratings yet

- Motiongoo Stepper Motor Drawing-17HT19S4168C1Document1 pageMotiongoo Stepper Motor Drawing-17HT19S4168C1Make RownNo ratings yet

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 pagesSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompNo ratings yet

- Din 17100Document1 pageDin 17100KhoirulAnwarNo ratings yet

- KEMET Part Number: T520V226M020ATE045: General InformationDocument1 pageKEMET Part Number: T520V226M020ATE045: General Informationvax1No ratings yet

- NIC Components NACV SeriesDocument3 pagesNIC Components NACV SeriesNICCompNo ratings yet

- Properties: Test Conditions Units Properties Test Conditions Units Typical ValuesDocument1 pageProperties: Test Conditions Units Properties Test Conditions Units Typical ValueszaherNo ratings yet

- MC-306 enDocument2 pagesMC-306 enminhhieuhanam93No ratings yet

- 07a. MR MDF TECHNICAL DATADocument2 pages07a. MR MDF TECHNICAL DATAsacdawoodNo ratings yet

- NIC Components NRE-L SeriesDocument5 pagesNIC Components NRE-L SeriesNICCompNo ratings yet

- CAR Abrasion Resistant AR Plus High Gloss Coloured Core Thin HPL StandardDocument1 pageCAR Abrasion Resistant AR Plus High Gloss Coloured Core Thin HPL StandardAnonymous FGzNDzIeJNo ratings yet

- Elna (SMD) RV SeriesDocument1 pageElna (SMD) RV Seriesjghjkhgkh87No ratings yet

- Motiongoo Stepper Motor Drawing-17HT13S6031Document1 pageMotiongoo Stepper Motor Drawing-17HT13S6031Make RownNo ratings yet

- GA-150-LL/ GA-150B-LL: FeaturesDocument5 pagesGA-150-LL/ GA-150B-LL: Featuresmccornejo1617No ratings yet

- NIC Components NRE-WY SeriesDocument7 pagesNIC Components NRE-WY SeriesNICCompNo ratings yet

- C NX2016SA eDocument1 pageC NX2016SA eadilNo ratings yet

- Elna (SMD) RV5 SeriesDocument2 pagesElna (SMD) RV5 Seriesjghjkhgkh87No ratings yet

- Electro140 ContactCleanerDocument1 pageElectro140 ContactCleanerRoberto Alfaro EspinozaNo ratings yet

- Polyester Limited: Properties Average ThicknessDocument1 pagePolyester Limited: Properties Average ThicknessPuneet SingalNo ratings yet

- NIC Components NRE-LS SeriesDocument5 pagesNIC Components NRE-LS SeriesNICCompNo ratings yet

- ECX-1637 SMD Crystal: Operating Conditions / Electrical CharacteristicsDocument2 pagesECX-1637 SMD Crystal: Operating Conditions / Electrical CharacteristicsasdfasdfdfNo ratings yet

- ECX-1637B2 SMD Crystal: Operating Conditions / Electrical CharacteristicsDocument3 pagesECX-1637B2 SMD Crystal: Operating Conditions / Electrical CharacteristicsKiran PatelNo ratings yet

- Frenos Sauleda - ToP - 05Document1 pageFrenos Sauleda - ToP - 05Marcos LópezNo ratings yet

- Cem 1212cDocument3 pagesCem 1212cGabriel GranadoNo ratings yet

- Productdatasheet en m17 A4be473d03Document3 pagesProductdatasheet en m17 A4be473d03qcnsonglamNo ratings yet

- Especificacion-Tecnica ANTENA COMBADocument1 pageEspecificacion-Tecnica ANTENA COMBARosa FuentesNo ratings yet

- JRG CapacitorsDocument2 pagesJRG Capacitorsmarina anastasovaNo ratings yet

- Hpm24Cx: Piezo Sound GeneratorsDocument1 pageHpm24Cx: Piezo Sound Generatorsmsicoie1851No ratings yet

- Elna (SMD) RV3 SeriesDocument1 pageElna (SMD) RV3 Seriesjghjkhgkh87No ratings yet

- Dielectric Device KHB1890B01: Technical DataDocument2 pagesDielectric Device KHB1890B01: Technical DataJim LiebNo ratings yet

- QCL Series: General Specifi Cations Equivalent Series Resistance (ESR)Document2 pagesQCL Series: General Specifi Cations Equivalent Series Resistance (ESR)Alberto Fernández VázquezNo ratings yet

- CFCFree ElectroContactCleanerDocument1 pageCFCFree ElectroContactCleanerRoberto Alfaro EspinozaNo ratings yet

- MDF FR TDSDocument1 pageMDF FR TDSbahoxa3115No ratings yet

- Motiongoo Stepper Motor Drawing-17HF19S4168Document1 pageMotiongoo Stepper Motor Drawing-17HF19S4168Make RownNo ratings yet

- Electrical Data: (Basta)Document2 pagesElectrical Data: (Basta)Dwi KurniawanNo ratings yet

- MB8851 Spec Sheet - EngDocument1 pageMB8851 Spec Sheet - Engclinica celsocabralNo ratings yet

- 4600X Series - Thick Film Conformal Sips: FeaturesDocument2 pages4600X Series - Thick Film Conformal Sips: Featuresmohammad hosein nikbakhtNo ratings yet

- Wts - NIC NAYT SeriesDocument3 pagesWts - NIC NAYT SeriesKetan LohaniNo ratings yet

- OklahomaDocument21 pagesOklahomaYusuf ÜnlüsoyNo ratings yet

- Hi Temp 1Document1 pageHi Temp 1CADTDDNo ratings yet

- Revisions: Amphenol Part Number Confuguration UE86-G1636-00X3TDocument3 pagesRevisions: Amphenol Part Number Confuguration UE86-G1636-00X3Tkkk ghgfhgfNo ratings yet

- Ashoka Buildcon LTD.: Design Stipulation Code RefferedDocument1 pageAshoka Buildcon LTD.: Design Stipulation Code RefferedAnil UdaleNo ratings yet

- Elna (Non-Polar SMD) RVB SeriesDocument1 pageElna (Non-Polar SMD) RVB Seriesjghjkhgkh87No ratings yet

- 04020VA Data SheetDocument5 pages04020VA Data Sheetahmad16_ftua6999No ratings yet

- Series: Cp34-M Description: Peltier Module: FeaturesDocument5 pagesSeries: Cp34-M Description: Peltier Module: FeaturesDavid A Alemán QNo ratings yet

- Nylube X12F9Document3 pagesNylube X12F9OnebigunicornNo ratings yet

- Otis AC Resistance Controller SearchableDocument9 pagesOtis AC Resistance Controller SearchableOnebigunicornNo ratings yet

- Delco RGA Product Line 2023 FinalDocument5 pagesDelco RGA Product Line 2023 FinalOnebigunicornNo ratings yet

- Tac 32 ICON 32 ManualDocument220 pagesTac 32 ICON 32 ManualOnebigunicorn100% (1)

- Automatic Transmission CatalogDocument84 pagesAutomatic Transmission CatalogDmitriy TolochikNo ratings yet

- BS6622-BS7835 Single Core Armoured 33kV XLPE Stranded Copper ConductorDocument3 pagesBS6622-BS7835 Single Core Armoured 33kV XLPE Stranded Copper ConductorroyclhorNo ratings yet

- Gauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFDocument2 pagesGauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFArlen NurlanNo ratings yet

- 11-02-24r Glaverbel-SunergyDocument16 pages11-02-24r Glaverbel-SunergydatanotionNo ratings yet

- Strategies For Eliminating DecarburizationDocument3 pagesStrategies For Eliminating Decarburizationmp87_ingNo ratings yet

- Summer Training Presentation: ON Distillation Unit OF Mathura RefineryDocument14 pagesSummer Training Presentation: ON Distillation Unit OF Mathura RefineryGovindPatelNo ratings yet

- Guidelines On Dometic Gas Piping SystemDocument30 pagesGuidelines On Dometic Gas Piping Systemg00r100% (9)

- Blenders EnglDocument10 pagesBlenders EnglDaniel Tourón SaramellaNo ratings yet

- 2-Lubricants CharacteristcsDocument30 pages2-Lubricants CharacteristcsHariajahNo ratings yet

- Code G FanucDocument3 pagesCode G FanucSanchai Progaeew100% (1)

- Precast Lift WallDocument129 pagesPrecast Lift WallThandar MyintNo ratings yet

- GR-750XL-2: 75 Ton Capacity (68 Metric Tons) Hydraulic Rough Terrain CraneDocument16 pagesGR-750XL-2: 75 Ton Capacity (68 Metric Tons) Hydraulic Rough Terrain CraneJustin MorseNo ratings yet

- Environmental Engineering HS Peavy DR Rowe G TchobDocument4 pagesEnvironmental Engineering HS Peavy DR Rowe G TchobMalvika SafayaNo ratings yet

- QAP Format - QA 01 F 01Document1 pageQAP Format - QA 01 F 01Murukan PadmanabhanNo ratings yet

- Mailhem Ikos Environment Pvt. Ltd. Business Profile 2016Document16 pagesMailhem Ikos Environment Pvt. Ltd. Business Profile 2016SamsRsNo ratings yet

- JRC Jfe 582 - Install Transducer PDFDocument6 pagesJRC Jfe 582 - Install Transducer PDFleducthinh65No ratings yet

- Investigation Into The Wetting Phenomenon of Terry FabricsDocument5 pagesInvestigation Into The Wetting Phenomenon of Terry FabricsLatifNo ratings yet

- Pi 06Document1 pagePi 06Kapil DodiyaNo ratings yet

- Stainless Steel Wire MeshDocument8 pagesStainless Steel Wire MeshWinner Stainless Steel Wire Mesh FactoryNo ratings yet

- Decicoat T35 TDS 703ipDocument3 pagesDecicoat T35 TDS 703ipSaif KhanNo ratings yet

- Director Pharmaceuticals Manufacturing Supply Chain in NYC Resume Edward OestreicherDocument2 pagesDirector Pharmaceuticals Manufacturing Supply Chain in NYC Resume Edward OestreicherEdwardOestreicherNo ratings yet

- Litz Wire Termination GuideDocument5 pagesLitz Wire Termination GuidefdNo ratings yet

- ELEC3320 Lab ReportDocument16 pagesELEC3320 Lab ReportTameem MithaiwalaNo ratings yet

- MB Value in Sand PDFDocument6 pagesMB Value in Sand PDFVyankat ChateNo ratings yet

- Danfoss Pressure Switch KP34, KP35, KP36, KP37Document8 pagesDanfoss Pressure Switch KP34, KP35, KP36, KP37Parinpa Ketar100% (1)

- 243 IST ANTEA CONDENSING ERP GAR AEE EN CompressedDocument76 pages243 IST ANTEA CONDENSING ERP GAR AEE EN CompressedMarian GrecuNo ratings yet