Professional Documents

Culture Documents

EZkontrol Users Manual

EZkontrol Users Manual

Uploaded by

Rubén de la RedCopyright:

Available Formats

You might also like

- User Manual: HDX Series Inverter / ChargerDocument17 pagesUser Manual: HDX Series Inverter / ChargerIbrahim DabaiNo ratings yet

- Product Information AC-S1 V1.0Document2 pagesProduct Information AC-S1 V1.0Paul CholewaNo ratings yet

- Sevcon Gen4 Size8 Data SheetDocument2 pagesSevcon Gen4 Size8 Data SheetJesse DavisNo ratings yet

- AC Superdrive (ACS) : DescriptionDocument2 pagesAC Superdrive (ACS) : DescriptionMamadou djibril BaNo ratings yet

- FireFinder XLS Advanced Fire Alarm Control Panel Data Sheet A6V10238846 Us enDocument12 pagesFireFinder XLS Advanced Fire Alarm Control Panel Data Sheet A6V10238846 Us enMarcio CardosoNo ratings yet

- 03 - Manual - Communication - ETR300-R & EVRC2A-NT - Ver1.12 - 201912Document97 pages03 - Manual - Communication - ETR300-R & EVRC2A-NT - Ver1.12 - 201912Anh0% (1)

- E700 Pocket Guide 2007-09Document2 pagesE700 Pocket Guide 2007-09TetsusaigaNo ratings yet

- ASI - Silcovert CDocument4 pagesASI - Silcovert ChohnzimhlnrftumftrNo ratings yet

- 124 Catalog Convertizoare de Frecventa IV5Document32 pages124 Catalog Convertizoare de Frecventa IV5bmonaandaNo ratings yet

- Mitsubishi E700 Variable Frequency Drive (VFD) - POCKET - GUIDEDocument2 pagesMitsubishi E700 Variable Frequency Drive (VFD) - POCKET - GUIDEMROstop.comNo ratings yet

- R7 Series Datasheet en 200607Document8 pagesR7 Series Datasheet en 200607Dany VallejoNo ratings yet

- Medium Voltage Soft Starters - SOLCON Product CatalogueDocument22 pagesMedium Voltage Soft Starters - SOLCON Product CatalogueCamilNo ratings yet

- V1000Document55 pagesV1000Aarón Romero GiraldoNo ratings yet

- Sigma-II Series Datasheet v0.99Document34 pagesSigma-II Series Datasheet v0.99Luciano Dos SantosNo ratings yet

- Amp Servo Products DatasheetDocument16 pagesAmp Servo Products DatasheetElectromateNo ratings yet

- E Bamocar d3Document46 pagesE Bamocar d3oscarhereNo ratings yet

- Assun Motor Catalogue-2020Document137 pagesAssun Motor Catalogue-2020MiguelNo ratings yet

- Variable Frequency DriveDocument2 pagesVariable Frequency Drivenksuthar5399100% (1)

- QS5 Servo Driver Manual PDFDocument88 pagesQS5 Servo Driver Manual PDFValentin ValoNo ratings yet

- C100 CatalogDocument20 pagesC100 CatalogMarcela RoneNo ratings yet

- Tolomatic ACS Drive Controller BrochureDocument12 pagesTolomatic ACS Drive Controller BrochureElectromateNo ratings yet

- WEG Soft StartersDocument36 pagesWEG Soft StartersgamasistemNo ratings yet

- 8200 MotecDocument3 pages8200 Motecyera1No ratings yet

- Yct Series Electromagnetic Speed Adjustable Motors: Eec Technology Corporation LimitedDocument4 pagesYct Series Electromagnetic Speed Adjustable Motors: Eec Technology Corporation LimitedGuillermo HernándezNo ratings yet

- WEG SSW Series Soft Starters 50019077 Brochure English PDFDocument36 pagesWEG SSW Series Soft Starters 50019077 Brochure English PDFJulian SteurerNo ratings yet

- BAMOCAR Motor ControllerDocument46 pagesBAMOCAR Motor ControllerShehzer100% (1)

- Sinus Penta Ac-DriveDocument13 pagesSinus Penta Ac-DriveMahesh Daxini ThakkerNo ratings yet

- Mid Presentation PLCDocument40 pagesMid Presentation PLCGOD oF DeAtHNo ratings yet

- Chapter 9 Technical Data: 9.1.1 CE MarkDocument24 pagesChapter 9 Technical Data: 9.1.1 CE MarkIngeniería AplicacionesNo ratings yet

- PDFDocument44 pagesPDFjalilemadiNo ratings yet

- Faldic Ryc 102c3-Vvt2Document20 pagesFaldic Ryc 102c3-Vvt2Seaman Kataki100% (1)

- SmartStep Servo-Drives R7D-APSRDocument10 pagesSmartStep Servo-Drives R7D-APSRLukasz TestoweNo ratings yet

- Geared Motors Power Distribution: V V V VDocument2 pagesGeared Motors Power Distribution: V V V VShamim Ahsan ParvezNo ratings yet

- Amp STAC5 DatasheetDocument7 pagesAmp STAC5 DatasheetElectromateNo ratings yet

- Ca VJ 01Document60 pagesCa VJ 01JoseNo ratings yet

- Medium Voltage IGBT Drives HIVECTOL - HVI - E: Hitachi MV Drives Manufactured in IndiaDocument8 pagesMedium Voltage IGBT Drives HIVECTOL - HVI - E: Hitachi MV Drives Manufactured in Indiaharshad_soni7912No ratings yet

- V1000 Drive ManualDocument26 pagesV1000 Drive ManualjitendrakumarmishraNo ratings yet

- WECON VD2 B Type Servo FlyerDocument5 pagesWECON VD2 B Type Servo FlyerZakaria ElhaouriNo ratings yet

- Vdrive Drives Plus v12Document4 pagesVdrive Drives Plus v12jorgel.infantezNo ratings yet

- Englilsh Manual of SoftstarterDocument39 pagesEnglilsh Manual of SoftstarterStefanLazarNo ratings yet

- Ae-Mae R: Contactorless (STO) Integrated Lift ControllerDocument8 pagesAe-Mae R: Contactorless (STO) Integrated Lift Controllerاحمد ابو جاسرNo ratings yet

- AC Inverter Drive: A1000 SeriesDocument8 pagesAC Inverter Drive: A1000 Seriesabhi_0302No ratings yet

- Rolling Controls: Electronic ControllerDocument2 pagesRolling Controls: Electronic ControllerMilad MNo ratings yet

- Gd350a Catalog v2.0Document2 pagesGd350a Catalog v2.0ZE RU ENGNo ratings yet

- Allen Bradley - PowerFlex 400Document28 pagesAllen Bradley - PowerFlex 400Marcos José Nuñez YsseleNo ratings yet

- ABB VFD CatalogesDocument25 pagesABB VFD CatalogesadehriyaNo ratings yet

- FVC800 FLUXVERTER DRIVES - BrochureDocument11 pagesFVC800 FLUXVERTER DRIVES - BrochureVenu BallaNo ratings yet

- 4420Document2 pages4420ABOUDHNo ratings yet

- Advanced Motion Controls Srst185Document4 pagesAdvanced Motion Controls Srst185ElectromateNo ratings yet

- Powertron ManualDocument24 pagesPowertron ManualJarek KlamannNo ratings yet

- CAT - 2013 - Industrial Controls Short FormDocument52 pagesCAT - 2013 - Industrial Controls Short FormKiliardt ScmidtNo ratings yet

- ACS - Danaher MotionDocument2 pagesACS - Danaher MotionMamadou Djibril BaNo ratings yet

- GS OverviewDocument51 pagesGS OverviewMuhammad AmjadNo ratings yet

- WEG CFW 09 VSDDocument8 pagesWEG CFW 09 VSDMpho MathubaNo ratings yet

- AMP Servo Products BrochureDocument16 pagesAMP Servo Products BrochureElectromateNo ratings yet

- NP225 450Document98 pagesNP225 450Traian SerbanNo ratings yet

- New Type RS Series Servo Driver User ManualDocument132 pagesNew Type RS Series Servo Driver User ManualmariusNo ratings yet

- Catalogue ELK MotorDocument28 pagesCatalogue ELK MotorToussaint100% (1)

- Agilent Models 6690A-6692A System DC Power Supply: Data SheetDocument5 pagesAgilent Models 6690A-6692A System DC Power Supply: Data Sheetdhavala2858No ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- DSSI - 3 - Simulation of DC Motor (2015)Document4 pagesDSSI - 3 - Simulation of DC Motor (2015)KenHuNo ratings yet

- Advance MemoryDocument56 pagesAdvance MemoryPratyush MishraNo ratings yet

- Samson Servo 120 - Power Amplifier ManualDocument13 pagesSamson Servo 120 - Power Amplifier ManualTiestoworld CrewNo ratings yet

- 20 KV Transmission LineDocument21 pages20 KV Transmission LineOctavianto ZakiNo ratings yet

- Daytona Lifestyle LP111 ProgrammersDocument2 pagesDaytona Lifestyle LP111 ProgrammersJohn WalesNo ratings yet

- Simple Low Power Inverter Circuit (12V DC To 230V or 110V AC) Using CD4047 and IRFZ44 Power MOSFETDocument3 pagesSimple Low Power Inverter Circuit (12V DC To 230V or 110V AC) Using CD4047 and IRFZ44 Power MOSFETsajid100% (2)

- Calculation For Short Circuit Current Calculation Using IEC / IEEE StandardDocument11 pagesCalculation For Short Circuit Current Calculation Using IEC / IEEE StandardibmmoizNo ratings yet

- Panou Solar FV Trina Solar 475 - 505 - Fisa Tehnica - Site TrinaDocument2 pagesPanou Solar FV Trina Solar 475 - 505 - Fisa Tehnica - Site TrinaBirshopulosNo ratings yet

- b4 PDFDocument156 pagesb4 PDFkeyerlinNo ratings yet

- Ib0300133l PDFDocument260 pagesIb0300133l PDFRamesh MahtoNo ratings yet

- Study of Gunn-Oscillator CharacteristicDocument10 pagesStudy of Gunn-Oscillator Characteristicsarkar salamNo ratings yet

- Test - Currrent ElectricityDocument2 pagesTest - Currrent Electricityopen webNo ratings yet

- Pump and Print Electronic Registration: Lectrocount Lcr-Ii Electronic RegisterDocument2 pagesPump and Print Electronic Registration: Lectrocount Lcr-Ii Electronic Registerhusan shahNo ratings yet

- As Electronics Coursework ExampleDocument5 pagesAs Electronics Coursework Exampleshvfihdjd100% (2)

- 4972b en MD2SDocument48 pages4972b en MD2SGiovanni RotondoNo ratings yet

- CHE 101 - Mock Questions and AnswersDocument5 pagesCHE 101 - Mock Questions and Answersbeulahhub0No ratings yet

- 1 Project OutlineDocument199 pages1 Project Outlinepaolo sangalangNo ratings yet

- Ultra Thin Fan Coil - Arctic Heat PumpsDocument9 pagesUltra Thin Fan Coil - Arctic Heat Pumpsjohnking5555No ratings yet

- Chapter 10 SuperconductivityDocument73 pagesChapter 10 SuperconductivityYasin ÖztürkNo ratings yet

- Altistart 46 VW3G46101 Display and Adjustment enDocument37 pagesAltistart 46 VW3G46101 Display and Adjustment enValentin AgacheNo ratings yet

- Liebert GXT3 10kVA Tower Model SLI 23442 REV3!05!12 ManualDocument44 pagesLiebert GXT3 10kVA Tower Model SLI 23442 REV3!05!12 ManualMianWaqarNo ratings yet

- EFCx610 ManualDocument94 pagesEFCx610 Manualmish bernsNo ratings yet

- Minimization of Power Losses On Selected 132kv Overhead Transmission Line in Hazara Division Pakistan To Improve The System EfficiencyDocument6 pagesMinimization of Power Losses On Selected 132kv Overhead Transmission Line in Hazara Division Pakistan To Improve The System EfficiencyEnpak ArsalanNo ratings yet

- Fabrication of Windmill Power Generator PDFDocument2 pagesFabrication of Windmill Power Generator PDFKellyNo ratings yet

- Tutorial 5Document2 pagesTutorial 5Afie Fahry AdzmiNo ratings yet

- MECT361 - Ch09 - Sensors (Stress and Strain) - SharedDocument38 pagesMECT361 - Ch09 - Sensors (Stress and Strain) - Sharedbossy kallyNo ratings yet

- Laboratory Manual For Ac Electrical CircuitsDocument75 pagesLaboratory Manual For Ac Electrical CircuitsArnulfo LavaresNo ratings yet

EZkontrol Users Manual

EZkontrol Users Manual

Uploaded by

Rubén de la RedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EZkontrol Users Manual

EZkontrol Users Manual

Uploaded by

Rubén de la RedCopyright:

Available Formats

EN | 1

Golden Motor Technology Co., Ltd.

2 | EN

The Product The Setup

The EZkontrol series permanent magnet Gone are the days of a dedicated

synchronous motor (PMSM) controllers programming device, old USB cables and

are built with ARM 32-bit Cortex-M4 core confusing interfaces. The EZkontrol’s

processor and features the latest Field Oriented simple and intuitive automatic self-learning

Control (FOC) vector control technology, calibration of motor parameters allows you to

enabling real time control of motor torque, get your motors up and running in no time…

field excitation, speed and power efficiently. … on your Mobile Phone!

Choice of voltage ranges between 24V to … via built-in Bluetooth!

240V and power from 1KW up to 30KW. … on a floating App!

Switch between Sinewave or Squarewave by … obtained via QR code!

downloading their respective firmwares over- Hundreds of programmable control parameters

the-air. for you to tweak and fine tune your drive

system to perfection! Get firmware updates

The Company online the same EZ way! It doesn’t get any EZ-

ier than this! It fully supports OTA (Over the

For over a decade, Goldenmotor has

Air) firmware upgrades via smart phones. You

roots deeply embedded in the field of new age

can even switch between Sinewave control or

electric propulsion, developing and crafting

Squarewave control in the same EZ controller

a new generation of electric motors and

by downloading the respective firmware OTA.

controllers for the ever-evolving EV market.

Every nook and cranny of our product design

reflects years of accumulated experience in All Aboard the CAN BUS

applications used in the electric vehicles, boats Want even more Kustomized Kontrol?

and various machines, understanding what EZkontrol supports multiple communication

the customer needs and delivering our core protocols and interfaces such as CAN-BUS,

technologies affordably with an extra touch RS485, UART etc. Sample source codes

of elegance. As your needs evolve, we evolve are available to jump start your CAN-BUS

with you. application development, find out more in our

CAN protocol manuals.

The Features

The EZkontrol series of BLDC motor Chill Out

FOC controllers are our latest addition to Every EZkontrol features an aluminum

your arsenal. With up to 30kWs of power in base heat sink that is Liquid-Cooling Ready

a variety of voltages and amperage (up to with 4 pre-drilled inlets/outlets which are

240V(DC) or 2000Amps) in our flagship E compatible with standard water tap threads

series, there is undoubtedly a model that suits fittings. Choose from any 2 of these 4 holes to

your requirements. Expect the EZkontrol to circulate your choice of cooling fluid via an

drive your (or our) BLDC motors smoothly external cooling pump.

and efficiently after a brief EZ & intuitive

installation. Decadent Display

Free Speedometer instruments Android

The Fast and The Wireless and iOS apps for you with fancy looking

Armed with powerful ARM 32-bit User Interfaces. Connect your smartphone

Cortex-M4 core processors, it will chew to EZkontrol via the built-in bluetooth

through vector control algorithms at lightning component. The app creates a very useful

speed, delivering Real-Time torque, excitation, log file to record your motor and controller

speed and power control as well as zero-delay status, running data (datetime, voltage, current,

monitoring functions via Bluetooth. rpm, motor temperature etc.) with date-time

stamp at each time interval (user definable in

seconds).

Golden Motor Technology Co., Ltd.

EN | 3

WeChat Host Softwares

Golden Motor Technology Co., Ltd.

4 | EN

Models

Max. Rated Max. Motor

Rated Max.

Phase Phase Bus Rated

Voltage Item No. Voltage

Current Current Current Power

(V) (V)

(A) (A) (A) (KW)

EZkontrol A48400 400 160 200 2-4

EZkontrol A48500 500 200 250 3-5

EZkontrol B48800 800 320 400 5-8

EZkontrol B481000 1000 400 500 6-10

48 EZkontrol C481200 75 1200 480 600 7-12

EZkontrol C481500 1500 600 750 9-14

EZkontrol D481600 1600 640 800 9-15

EZkontrol E482000 2000 800 1000 12-19

EZkontrol E482500 2500 1000 1250 14-24

EZkontrol A72400 400 160 200 3-6

EZkontrol A72500 500 200 250 4-7

EZkontrol B72800 800 320 400 7-12

EZkontrol B721000 1000 400 500 9-14

72 95

EZkontrol C721200 1200 480 600 10-17

EZkontrol C721500 1500 600 750 13-22

EZkontrol D722000 2000 800 1000 17-29

EZkontrol E722500 2500 1000 1250 22-36

EZkontrol A96300 300 120 150 3-6

EZkontrol A96400 400 160 200 5-8

EZkontrol B96600 600 240 300 7-12

EZkontrol B96800 800 320 400 9-15

96 120-130

EZkontrol C96900 900 360 450 10-17

EZkontrol C961200 1200 480 600 14-23

EZkontrol E961500 1500 600 750 17-29

EZkontrol E962000 2000 800 1000 23-38

EZkontrol A120300 300 120 150 4-7

EZkontrol B120600 600 240 300 9-14

120 EZkontrol C120900 145 900 360 450 13-22

EZkontrol D1201200 1200 480 600 17-29

EZkontrol E1201500 1500 600 750 22-36

Golden Motor Technology Co., Ltd.

EN | 5

EZkontrol A144200 200 80 100 3-6

EZkontrol B144400 400 160 200 7-12

144 EZkontrol C144600 190 600 240 300 10-17

EZkontrol D144800 800 320 400 14-23

EZkontrol E1441000 1000 400 500 17-29

EZkontrol A240100 100 40 50 3-5

EZkontrol B240200 200 80 100 6-10

240 EZkontrol C240300 290 300 120 150 9-14

EZkontrol D240400 400 160 200 12-19

EZkontrol E240500 500 200 250 14-24

Golden Motor Technology Co., Ltd.

6 | EN

Wiring Diagram with DC Contactor

Golden Motor Technology Co., Ltd.

EN | 7

Wiring Diagram without DC Contactor

Golden Motor Technology Co., Ltd.

8 | EN

Interface Definition

Wiring Function

Pin No. Function Description

Color Definition

CN1-1 Red KI Key Switch

CN1-13 Grey LCON DC Contactor Coil

CN1-2 Black GND Ground

CN1-14 Yellow BrakeH+ High Brake +

CN1-3 Black BrakeH- High Brake -

CN1-15 White BrakeL Low Brake

CN1-4 Green FWD Forward

CN1-16 Grey REV Reverse

CN1-5 Blue peedH High Speed

CN1-17 Brown peedL Low Speed

CN1-18 Orange Cruise Cruise

CN1-8 Red +12V Motor main position sensor power +12V

CN1-20 Yellow HA_A_M Motor main position sensor signal, Hall HA or encoder A

CN1-9 Green HB_B_M Motor main position sensor signal, Hall HB or encoder B

CN1-21 Blue HC_Z_M Motor main position sensor signal, Hall HC or encoder Z

CN1-22 White TEMP_M Motor Temperature Sensor

CN1-11 Black GND Motor position sensor power GND

CN1-23 Red +5V Main Throttle Power +5V

CN1-12 Green ThrottleM Main Throttle Signal

CN1-24 Black GND Main Throttle Power GND

CN2-5 Black PDO- Speed Pulse power supply -

CN2-16 Purple IF All-in-one Connection/Speed Pulse signal output

CN2-8 White R485_A R485 A

CN2-19 Purple R485_B R485 B

CN2-9 Brown R485_

R485 120Ω matching resistance

TERM

CN2-20 Black GND GND

CN2-10 Yellow CAN_H CAN H

CN2-21 Green CAN_L CAN L

CN2-11 Brown CAN_TERM CAN 120Ω matching resistance

CN2-22 Black CAN_GND CAN GND

Golden Motor Technology Co., Ltd.

EN | 9

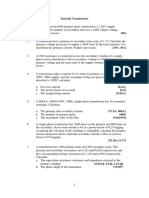

System Protection Characteristics

LED

Blinking Error Error Description Solution

Times

1 Overcurrent The current of phase wires Check if the phase wires are damaged or

are abnormal. there is any short circuit.

2 Overload The load exceeds the Change a controller with bigger power.

controller's capacity.

The bus voltage exceeds the Check if the bus voltage matches the

3 Overvoltage controller's default value. controller's default value,or check the

controller's default value.

The bus voltage is lower than Check the bus voltage and the battery

4 Undervoltage the controller's default value. capacity,or check the controller's default

value.

The temperature of the Improve the controller's heat dissipation,or

5 Controller controller is higher than 70 lower the controller's value of Max. phase

Overtemperature ℃. current, or change a controller with bigger

power.

Motor The temperature of the motor Improve the motor's heat dissipation,or lower

6 Overtemperature exceeds its default value. the controller's value of Max. phase current,

or change a motor with bigger power.

7 Motor Stall/Block Motor stall/Block time Check if there is stall/block condition on

exceeds default value. motor shaft.

Motor Phase Wire The phase wires are not Check the wire connections of the motor and

8 Disconnection connected correctly or controller.

disconnected.

9 Motor Main The throttle output signal is Check if the motor's main sensor is good.

Sensor valid when powered on.

10 Motor Auxiliary Motor Auxiliary Sensor Error Check if the motor's auxiliary sensor is good.

Sensor

11 Encoder Encoder Alignment Error Check if the motor's encoder alignment

Alignment signal is good.

12 The throttle output signal

Throttle Protection valid when powered on. is Check the throttle or the min. value of its

error parameters.

13 Main Throttle The output voltage of main Check the main throttle or the max. and min.

throttle is abnormal. values of its error parameters.

14 Auxiliary Throttle auxiliary throttle is abnormal. Check

The output voltage of the auxiliary throttle or the max. and

min. values of its error parameters.

15 Precharge Precharge Error Return to factory service.

16 DC Contactor DC Contactor Error Check if the DC Contactor is good or the

contact is good.

17 MOSFET The controller's MOS Return to factory service.

detection is abnormal.

18 Current Sensor The controller's current sensor Return to factory service.

detection is abnormal.

19 Self-learning Self-learning Failure Check the self -learning parameter settings

and if the self -learning method is correct.

Only the RS485 control mode is valid,check

20 RS485 RS485 Communication Error if the RS485 communication wire or VCU is

normal.

Only the CAN control mode is valid,check

21 CAN CAN Communication Error if the CAN communication wire or VCU is

normal.

22 Softwares System Softwares Error Return to factory service.

Golden Motor Technology Co., Ltd.

10 | EN

Dimensions

A Series Dimensions

Golden Motor Technology Co., Ltd.

EN | 11

B Series Dimensions

Golden Motor Technology Co., Ltd.

12 | EN

C Series Dimensions

Golden Motor Technology Co., Ltd.

EN | 13

D Series Dimensions

Golden Motor Technology Co., Ltd.

14 | EN

E Series Dimensions

Golden Motor Technology Co., Ltd.

EN | 15

Golden Motor Technology Co., Ltd.

You might also like

- User Manual: HDX Series Inverter / ChargerDocument17 pagesUser Manual: HDX Series Inverter / ChargerIbrahim DabaiNo ratings yet

- Product Information AC-S1 V1.0Document2 pagesProduct Information AC-S1 V1.0Paul CholewaNo ratings yet

- Sevcon Gen4 Size8 Data SheetDocument2 pagesSevcon Gen4 Size8 Data SheetJesse DavisNo ratings yet

- AC Superdrive (ACS) : DescriptionDocument2 pagesAC Superdrive (ACS) : DescriptionMamadou djibril BaNo ratings yet

- FireFinder XLS Advanced Fire Alarm Control Panel Data Sheet A6V10238846 Us enDocument12 pagesFireFinder XLS Advanced Fire Alarm Control Panel Data Sheet A6V10238846 Us enMarcio CardosoNo ratings yet

- 03 - Manual - Communication - ETR300-R & EVRC2A-NT - Ver1.12 - 201912Document97 pages03 - Manual - Communication - ETR300-R & EVRC2A-NT - Ver1.12 - 201912Anh0% (1)

- E700 Pocket Guide 2007-09Document2 pagesE700 Pocket Guide 2007-09TetsusaigaNo ratings yet

- ASI - Silcovert CDocument4 pagesASI - Silcovert ChohnzimhlnrftumftrNo ratings yet

- 124 Catalog Convertizoare de Frecventa IV5Document32 pages124 Catalog Convertizoare de Frecventa IV5bmonaandaNo ratings yet

- Mitsubishi E700 Variable Frequency Drive (VFD) - POCKET - GUIDEDocument2 pagesMitsubishi E700 Variable Frequency Drive (VFD) - POCKET - GUIDEMROstop.comNo ratings yet

- R7 Series Datasheet en 200607Document8 pagesR7 Series Datasheet en 200607Dany VallejoNo ratings yet

- Medium Voltage Soft Starters - SOLCON Product CatalogueDocument22 pagesMedium Voltage Soft Starters - SOLCON Product CatalogueCamilNo ratings yet

- V1000Document55 pagesV1000Aarón Romero GiraldoNo ratings yet

- Sigma-II Series Datasheet v0.99Document34 pagesSigma-II Series Datasheet v0.99Luciano Dos SantosNo ratings yet

- Amp Servo Products DatasheetDocument16 pagesAmp Servo Products DatasheetElectromateNo ratings yet

- E Bamocar d3Document46 pagesE Bamocar d3oscarhereNo ratings yet

- Assun Motor Catalogue-2020Document137 pagesAssun Motor Catalogue-2020MiguelNo ratings yet

- Variable Frequency DriveDocument2 pagesVariable Frequency Drivenksuthar5399100% (1)

- QS5 Servo Driver Manual PDFDocument88 pagesQS5 Servo Driver Manual PDFValentin ValoNo ratings yet

- C100 CatalogDocument20 pagesC100 CatalogMarcela RoneNo ratings yet

- Tolomatic ACS Drive Controller BrochureDocument12 pagesTolomatic ACS Drive Controller BrochureElectromateNo ratings yet

- WEG Soft StartersDocument36 pagesWEG Soft StartersgamasistemNo ratings yet

- 8200 MotecDocument3 pages8200 Motecyera1No ratings yet

- Yct Series Electromagnetic Speed Adjustable Motors: Eec Technology Corporation LimitedDocument4 pagesYct Series Electromagnetic Speed Adjustable Motors: Eec Technology Corporation LimitedGuillermo HernándezNo ratings yet

- WEG SSW Series Soft Starters 50019077 Brochure English PDFDocument36 pagesWEG SSW Series Soft Starters 50019077 Brochure English PDFJulian SteurerNo ratings yet

- BAMOCAR Motor ControllerDocument46 pagesBAMOCAR Motor ControllerShehzer100% (1)

- Sinus Penta Ac-DriveDocument13 pagesSinus Penta Ac-DriveMahesh Daxini ThakkerNo ratings yet

- Mid Presentation PLCDocument40 pagesMid Presentation PLCGOD oF DeAtHNo ratings yet

- Chapter 9 Technical Data: 9.1.1 CE MarkDocument24 pagesChapter 9 Technical Data: 9.1.1 CE MarkIngeniería AplicacionesNo ratings yet

- PDFDocument44 pagesPDFjalilemadiNo ratings yet

- Faldic Ryc 102c3-Vvt2Document20 pagesFaldic Ryc 102c3-Vvt2Seaman Kataki100% (1)

- SmartStep Servo-Drives R7D-APSRDocument10 pagesSmartStep Servo-Drives R7D-APSRLukasz TestoweNo ratings yet

- Geared Motors Power Distribution: V V V VDocument2 pagesGeared Motors Power Distribution: V V V VShamim Ahsan ParvezNo ratings yet

- Amp STAC5 DatasheetDocument7 pagesAmp STAC5 DatasheetElectromateNo ratings yet

- Ca VJ 01Document60 pagesCa VJ 01JoseNo ratings yet

- Medium Voltage IGBT Drives HIVECTOL - HVI - E: Hitachi MV Drives Manufactured in IndiaDocument8 pagesMedium Voltage IGBT Drives HIVECTOL - HVI - E: Hitachi MV Drives Manufactured in Indiaharshad_soni7912No ratings yet

- V1000 Drive ManualDocument26 pagesV1000 Drive ManualjitendrakumarmishraNo ratings yet

- WECON VD2 B Type Servo FlyerDocument5 pagesWECON VD2 B Type Servo FlyerZakaria ElhaouriNo ratings yet

- Vdrive Drives Plus v12Document4 pagesVdrive Drives Plus v12jorgel.infantezNo ratings yet

- Englilsh Manual of SoftstarterDocument39 pagesEnglilsh Manual of SoftstarterStefanLazarNo ratings yet

- Ae-Mae R: Contactorless (STO) Integrated Lift ControllerDocument8 pagesAe-Mae R: Contactorless (STO) Integrated Lift Controllerاحمد ابو جاسرNo ratings yet

- AC Inverter Drive: A1000 SeriesDocument8 pagesAC Inverter Drive: A1000 Seriesabhi_0302No ratings yet

- Rolling Controls: Electronic ControllerDocument2 pagesRolling Controls: Electronic ControllerMilad MNo ratings yet

- Gd350a Catalog v2.0Document2 pagesGd350a Catalog v2.0ZE RU ENGNo ratings yet

- Allen Bradley - PowerFlex 400Document28 pagesAllen Bradley - PowerFlex 400Marcos José Nuñez YsseleNo ratings yet

- ABB VFD CatalogesDocument25 pagesABB VFD CatalogesadehriyaNo ratings yet

- FVC800 FLUXVERTER DRIVES - BrochureDocument11 pagesFVC800 FLUXVERTER DRIVES - BrochureVenu BallaNo ratings yet

- 4420Document2 pages4420ABOUDHNo ratings yet

- Advanced Motion Controls Srst185Document4 pagesAdvanced Motion Controls Srst185ElectromateNo ratings yet

- Powertron ManualDocument24 pagesPowertron ManualJarek KlamannNo ratings yet

- CAT - 2013 - Industrial Controls Short FormDocument52 pagesCAT - 2013 - Industrial Controls Short FormKiliardt ScmidtNo ratings yet

- ACS - Danaher MotionDocument2 pagesACS - Danaher MotionMamadou Djibril BaNo ratings yet

- GS OverviewDocument51 pagesGS OverviewMuhammad AmjadNo ratings yet

- WEG CFW 09 VSDDocument8 pagesWEG CFW 09 VSDMpho MathubaNo ratings yet

- AMP Servo Products BrochureDocument16 pagesAMP Servo Products BrochureElectromateNo ratings yet

- NP225 450Document98 pagesNP225 450Traian SerbanNo ratings yet

- New Type RS Series Servo Driver User ManualDocument132 pagesNew Type RS Series Servo Driver User ManualmariusNo ratings yet

- Catalogue ELK MotorDocument28 pagesCatalogue ELK MotorToussaint100% (1)

- Agilent Models 6690A-6692A System DC Power Supply: Data SheetDocument5 pagesAgilent Models 6690A-6692A System DC Power Supply: Data Sheetdhavala2858No ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- DSSI - 3 - Simulation of DC Motor (2015)Document4 pagesDSSI - 3 - Simulation of DC Motor (2015)KenHuNo ratings yet

- Advance MemoryDocument56 pagesAdvance MemoryPratyush MishraNo ratings yet

- Samson Servo 120 - Power Amplifier ManualDocument13 pagesSamson Servo 120 - Power Amplifier ManualTiestoworld CrewNo ratings yet

- 20 KV Transmission LineDocument21 pages20 KV Transmission LineOctavianto ZakiNo ratings yet

- Daytona Lifestyle LP111 ProgrammersDocument2 pagesDaytona Lifestyle LP111 ProgrammersJohn WalesNo ratings yet

- Simple Low Power Inverter Circuit (12V DC To 230V or 110V AC) Using CD4047 and IRFZ44 Power MOSFETDocument3 pagesSimple Low Power Inverter Circuit (12V DC To 230V or 110V AC) Using CD4047 and IRFZ44 Power MOSFETsajid100% (2)

- Calculation For Short Circuit Current Calculation Using IEC / IEEE StandardDocument11 pagesCalculation For Short Circuit Current Calculation Using IEC / IEEE StandardibmmoizNo ratings yet

- Panou Solar FV Trina Solar 475 - 505 - Fisa Tehnica - Site TrinaDocument2 pagesPanou Solar FV Trina Solar 475 - 505 - Fisa Tehnica - Site TrinaBirshopulosNo ratings yet

- b4 PDFDocument156 pagesb4 PDFkeyerlinNo ratings yet

- Ib0300133l PDFDocument260 pagesIb0300133l PDFRamesh MahtoNo ratings yet

- Study of Gunn-Oscillator CharacteristicDocument10 pagesStudy of Gunn-Oscillator Characteristicsarkar salamNo ratings yet

- Test - Currrent ElectricityDocument2 pagesTest - Currrent Electricityopen webNo ratings yet

- Pump and Print Electronic Registration: Lectrocount Lcr-Ii Electronic RegisterDocument2 pagesPump and Print Electronic Registration: Lectrocount Lcr-Ii Electronic Registerhusan shahNo ratings yet

- As Electronics Coursework ExampleDocument5 pagesAs Electronics Coursework Exampleshvfihdjd100% (2)

- 4972b en MD2SDocument48 pages4972b en MD2SGiovanni RotondoNo ratings yet

- CHE 101 - Mock Questions and AnswersDocument5 pagesCHE 101 - Mock Questions and Answersbeulahhub0No ratings yet

- 1 Project OutlineDocument199 pages1 Project Outlinepaolo sangalangNo ratings yet

- Ultra Thin Fan Coil - Arctic Heat PumpsDocument9 pagesUltra Thin Fan Coil - Arctic Heat Pumpsjohnking5555No ratings yet

- Chapter 10 SuperconductivityDocument73 pagesChapter 10 SuperconductivityYasin ÖztürkNo ratings yet

- Altistart 46 VW3G46101 Display and Adjustment enDocument37 pagesAltistart 46 VW3G46101 Display and Adjustment enValentin AgacheNo ratings yet

- Liebert GXT3 10kVA Tower Model SLI 23442 REV3!05!12 ManualDocument44 pagesLiebert GXT3 10kVA Tower Model SLI 23442 REV3!05!12 ManualMianWaqarNo ratings yet

- EFCx610 ManualDocument94 pagesEFCx610 Manualmish bernsNo ratings yet

- Minimization of Power Losses On Selected 132kv Overhead Transmission Line in Hazara Division Pakistan To Improve The System EfficiencyDocument6 pagesMinimization of Power Losses On Selected 132kv Overhead Transmission Line in Hazara Division Pakistan To Improve The System EfficiencyEnpak ArsalanNo ratings yet

- Fabrication of Windmill Power Generator PDFDocument2 pagesFabrication of Windmill Power Generator PDFKellyNo ratings yet

- Tutorial 5Document2 pagesTutorial 5Afie Fahry AdzmiNo ratings yet

- MECT361 - Ch09 - Sensors (Stress and Strain) - SharedDocument38 pagesMECT361 - Ch09 - Sensors (Stress and Strain) - Sharedbossy kallyNo ratings yet

- Laboratory Manual For Ac Electrical CircuitsDocument75 pagesLaboratory Manual For Ac Electrical CircuitsArnulfo LavaresNo ratings yet