Professional Documents

Culture Documents

Hot Work Pre-Inspection Checklist

Hot Work Pre-Inspection Checklist

Uploaded by

ஹரிஹரசுதன்0 ratings0% found this document useful (0 votes)

141 views2 pages1) This document is a pre-inspection checklist for hot work being conducted as part of the Train 3 of WARA Pressure Maintenance Project.

2) It checks that the welder is qualified, fire protection measures are in place, proper PPE is being used, the work site supervisor is competent, and welding equipment meets requirements.

3) Upon inspection, the area was deemed safe to start work pending any noted improvements.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) This document is a pre-inspection checklist for hot work being conducted as part of the Train 3 of WARA Pressure Maintenance Project.

2) It checks that the welder is qualified, fire protection measures are in place, proper PPE is being used, the work site supervisor is competent, and welding equipment meets requirements.

3) Upon inspection, the area was deemed safe to start work pending any noted improvements.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

141 views2 pagesHot Work Pre-Inspection Checklist

Hot Work Pre-Inspection Checklist

Uploaded by

ஹரிஹரசுதன்1) This document is a pre-inspection checklist for hot work being conducted as part of the Train 3 of WARA Pressure Maintenance Project.

2) It checks that the welder is qualified, fire protection measures are in place, proper PPE is being used, the work site supervisor is competent, and welding equipment meets requirements.

3) Upon inspection, the area was deemed safe to start work pending any noted improvements.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

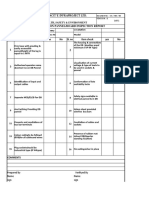

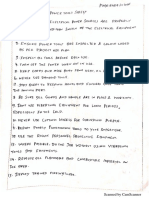

HOT WORK PRE-INSPECTION CHECKLIST

TRAIN 3 OF WARA PRESSURE MAINTENANCE PROJECT. EF- 1945,

CONTRACT NO : 17052048

Location: -------------------------------- Date: -----------------------------------

S.No Concerns Inspections YES NO N/A

Is the welder Qualified to Welder Qualification Checked

1.

the job

Awareness to KOC.SA.021 Checked training Records

2.

for welding and cutting

Fire Protection Enough fire Protection measures like

measures, PPE, work 1. Removal of flammable substances from site?

3.

location, Suitability to 2. Ventilation is provided?

work, workforce

3. PPE appropriate?

confession on safety of

the area to work, HSE & 4. SIMOPS which may lead to fire avoided?

Construction site 5. Is the welding booth safe enough for the task to be

Representative’s carried out?

inspection and 6. Enough safe measures for acetylene usage?

Confession on Suitability 7. Leak tests on torches done?

of the work location prior 8. Hoses were properly colour coded?

to start of the work 9. Flash back system Functional?

10. Correct torches and nozzles were selected as per

grade of work and manufacturer guidelines?

11. Oxygen is closed while torch was lit?

12. Welding / cutting torches handles as per 5.2.7 of KOC

SA.021?

PPE (as per KOC.SA.021 5.2.8)

1. Cotton cover all with approved aprons, sleeves,

leggings are available and worn?

2. Is PPE made up of non-ignitable material?

Work Site Supervisor

1. Is he competent to the job?

2. Has taken HOT PERMIT to carry job and available

onsite associated with JSA, TBT?

3. Fire extinguisher and gas monitors were available on

the area?

4. Is he remaining onsite throughout the job and stops it

when he needed to leave as per PTW

Procedure?

5. Trained Fire watcher is available and competent?

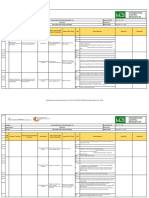

HOT WORK PRE-INSPECTION CHECKLIST

TRAIN 3 OF WARA PRESSURE MAINTENANCE PROJECT . EF 1945,

CONTRACT NO : 17052048

Location: -------------------------------- Date: -----------------------------------

Metal Arc Welding as Per 5.4 of KOC.SA.021

1. Convenient and quick electrical disconnection was

provided?

2. The insulation of cables, electrode holders, plugs and

sockets were in good condition ensuring adequate current

carrying capacity to conductor?

3. The welding Equipment is having KOC Clearance

certificate from controlling team and daily and

periodical?

4. The stationary transformer or generator is equipped

with a power switch for Power isolation in case of

emergency?

5. Polarity equilibrium maintained whenever multiple

welders using same welding machine?

6. Adequate Ventilation and suitable breathing apparatus

is providing while working in a confined space?

7. Presence of material that evolve toxic fumes or

flammable gases such as paints, thinners,

coatings,oils,grease,chemical,galvanized metals, zinc,

bronze and manganese steel etc.?

During our onsite JOB Safety Analysis we found that the area is safe to work. Yes / No

Needed following improvements before starts o the work.

Remarks:

NAME

Area HSE

Designation Work Site Supervisor Permit Applicant Representative

Company

The work environment to carry out the mentioned HOT Work is safe. Yes / No

No Needs Further Improvement:

Welder name & Signature

You might also like

- Mineral Oil Safety Regulations 1997Document34 pagesMineral Oil Safety Regulations 1997Otoloko OgheneroNo ratings yet

- JD 9965 PDFDocument625 pagesJD 9965 PDFJosé Roberto VircentsNo ratings yet

- Experiment 6 - Flow Lab Worksheet - With DataDocument2 pagesExperiment 6 - Flow Lab Worksheet - With DataMohsin MumtazNo ratings yet

- Management of Inert Confined Space EntryDocument4 pagesManagement of Inert Confined Space EntryLuqman OsmanNo ratings yet

- Plywood Material Safety Data Sheet For MR Plywood PDFDocument4 pagesPlywood Material Safety Data Sheet For MR Plywood PDFNirvana NircisNo ratings yet

- I Et 301000 1200 295 p4x 001 - 0 - PrelimDocument26 pagesI Et 301000 1200 295 p4x 001 - 0 - Prelimஹரிஹரசுதன்No ratings yet

- Fall Protection Program: Reviewed: May 2011Document20 pagesFall Protection Program: Reviewed: May 2011Marvin ReggieNo ratings yet

- CL #06 CPTW PDFDocument11 pagesCL #06 CPTW PDFmoNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- Toaz - Info Cold Work Permit PRDocument2 pagesToaz - Info Cold Work Permit PRYexiong YIALENGNo ratings yet

- Dellag La 3-36Document2 pagesDellag La 3-36FAIYAZ AHMEDNo ratings yet

- 3.1 - CR 9 (1) Risk AssessorDocument1 page3.1 - CR 9 (1) Risk AssessorSusan LouwNo ratings yet

- Earth Compactor Daily Check ListDocument2 pagesEarth Compactor Daily Check ListpjosesmNo ratings yet

- Management of Construction and DemolitionabudhabiDocument37 pagesManagement of Construction and DemolitionabudhabiMelete GashawNo ratings yet

- Risk Assessment of Manual HandlingDocument2 pagesRisk Assessment of Manual HandlingMAB AliNo ratings yet

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- TIPCO-HSE-OCP-046. PTW ProcedureDocument7 pagesTIPCO-HSE-OCP-046. PTW ProcedureibrahimNo ratings yet

- Drilling Machine Inspection ChecklistDocument1 pageDrilling Machine Inspection ChecklistKevin MichaelNo ratings yet

- Cold Work PermitDocument11 pagesCold Work PermitMuneeb Ur Rehman100% (1)

- 2 JHA On Shot Grit Blasting1Document3 pages2 JHA On Shot Grit Blasting1Akhilesh KumarNo ratings yet

- Noise MonitoringDocument7 pagesNoise Monitoringshahrul rollNo ratings yet

- 25 - Welding, Cutting and Hot WorkDocument16 pages25 - Welding, Cutting and Hot WorkRicardo DalisayNo ratings yet

- Jsa CompressorDocument9 pagesJsa CompressorRavi thokalNo ratings yet

- Fire Water TankDocument1 pageFire Water TankAnonymous yCpjZF1rF100% (1)

- CSHP Checklist 2011Document2 pagesCSHP Checklist 2011JenniferValle0% (1)

- HIRA - Copper Pipe Brazing WorkDocument2 pagesHIRA - Copper Pipe Brazing Workyogeshraut1910No ratings yet

- SOP For Work PermitDocument2 pagesSOP For Work PermitRaju YadavNo ratings yet

- Welding Procedure: PurposeDocument14 pagesWelding Procedure: Purposeinfos2magi856No ratings yet

- Job Safety Analysis: Air Compressor OperationDocument2 pagesJob Safety Analysis: Air Compressor OperationVi VekNo ratings yet

- Safety Data Sheet: ARDROX 907PB AerosolDocument11 pagesSafety Data Sheet: ARDROX 907PB Aerosolabdulbaset alselwi100% (1)

- SWMS Power FloatDocument10 pagesSWMS Power FloatSam LimNo ratings yet

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- MJ164 RIP SAW Operation ManualDocument36 pagesMJ164 RIP SAW Operation ManualEduardo Lopez CastilloNo ratings yet

- Equipment Machinery Safety Checklist-Pdf-EnDocument2 pagesEquipment Machinery Safety Checklist-Pdf-EnOliver Reazon RueloNo ratings yet

- JSEA-ICS-004 Cable Laying and PullingDocument13 pagesJSEA-ICS-004 Cable Laying and PullingJayson EscamillanNo ratings yet

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaNo ratings yet

- Removing (Cutting Off) A Safety Lockout Lock: (Must Be Completed Prior To Removing The Lock)Document1 pageRemoving (Cutting Off) A Safety Lockout Lock: (Must Be Completed Prior To Removing The Lock)El Saleh newcapitalNo ratings yet

- Index: Cv. Dira Utama SejahteraDocument12 pagesIndex: Cv. Dira Utama SejahteraFreshop SurabayaNo ratings yet

- EHS Approved Agency For Testing & Certification of Fire Fighting EquipmentDocument8 pagesEHS Approved Agency For Testing & Certification of Fire Fighting Equipmenttp101267No ratings yet

- Fall Protection Equipment Inspection Checklist - GL-HAL-HSE-0604Document2 pagesFall Protection Equipment Inspection Checklist - GL-HAL-HSE-0604Lijo JohnNo ratings yet

- Confined Space SapDocument2 pagesConfined Space SapfairusNo ratings yet

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Job Safety Analysis For Hydro Test: Indmax Prime-G, Ighds Unit, Iocl, BGRDocument5 pagesJob Safety Analysis For Hydro Test: Indmax Prime-G, Ighds Unit, Iocl, BGRAkash ShuklaNo ratings yet

- DM Code of Construction Safety 195-292 PDFDocument98 pagesDM Code of Construction Safety 195-292 PDFDANo ratings yet

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,No ratings yet

- MW-OPS-SP-3.6.13F1 Work Authorization Permit FormDocument3 pagesMW-OPS-SP-3.6.13F1 Work Authorization Permit FormGabriel Tan100% (1)

- Job Safety Analysis: How To Use This FormDocument4 pagesJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- Radiography Work Permit (OGF-HSE-23)Document3 pagesRadiography Work Permit (OGF-HSE-23)Mock ProjectNo ratings yet

- JSA PRE-TEST UploadDocument2 pagesJSA PRE-TEST UploadDenny Kurniawan PrawiraNo ratings yet

- Confined Space PlanDocument25 pagesConfined Space PlanPokiko MikotoNo ratings yet

- JSA-03 Shed DismantlingDocument3 pagesJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Gi-0006 011Document2 pagesGi-0006 011malika_00No ratings yet

- 142 Jsa Modify To 2 Inch MPW-2 To Reactor 2 Piping LineDocument6 pages142 Jsa Modify To 2 Inch MPW-2 To Reactor 2 Piping LineMohd KhaidirNo ratings yet

- Annexure 9 - Declaration by The Subcontractor For HSE ComplianceDocument1 pageAnnexure 9 - Declaration by The Subcontractor For HSE ComplianceShamim Mahmudur RahmanNo ratings yet

- Caretaker Risk Assessment - Working at HeightDocument8 pagesCaretaker Risk Assessment - Working at HeightLina MarcelaNo ratings yet

- Safe Work Method Statement - Part 1: Asbestos Removal (Bonded) Company DetailsDocument22 pagesSafe Work Method Statement - Part 1: Asbestos Removal (Bonded) Company DetailsNick Elliott-BondNo ratings yet

- PTW Tracking Log: Allied Engineering Construction Sdn. Bhd. Urc Engineering Sdn. BHDDocument1 pagePTW Tracking Log: Allied Engineering Construction Sdn. Bhd. Urc Engineering Sdn. BHDviniNo ratings yet

- Siemens LTD.: General Work Permit Serial No.Document3 pagesSiemens LTD.: General Work Permit Serial No.Dakshinamurthy PNo ratings yet

- Site Close Out ChecklistDocument1 pageSite Close Out Checklistஹரிஹரசுதன்No ratings yet

- K Srinath - Offer Letter - 000002Document1 pageK Srinath - Offer Letter - 000002ஹரிஹரசுதன்No ratings yet

- Evershine - Course Offerings-1Document6 pagesEvershine - Course Offerings-1ஹரிஹரசுதன்No ratings yet

- Srini Updated ResumeDocument3 pagesSrini Updated Resumeஹரிஹரசுதன்No ratings yet

- Piping IsoDocument1 pagePiping Isoஹரிஹரசுதன்100% (1)

- Warning Letter: Cpecc Wara ProjectDocument2 pagesWarning Letter: Cpecc Wara Projectஹரிஹரசுதன்No ratings yet

- Ra List ReportDocument208 pagesRa List Reportஹரிஹரசுதன்No ratings yet

- Ladder Safety 2002Document10 pagesLadder Safety 2002Enjel PutriNo ratings yet

- 04-08 2020Document21 pages04-08 2020ஹரிஹரசுதன்No ratings yet

- 18 08 2019Document1 page18 08 2019ஹரிஹரசுதன்No ratings yet

- MSDSDocument1 pageMSDSஹரிஹரசுதன்No ratings yet

- Mr. David WilliamsDocument1 pageMr. David Williamsஹரிஹரசுதன்No ratings yet

- Power Tools SafetyDocument1 pagePower Tools Safetyஹரிஹரசுதன்No ratings yet

- Introduction To Substations: Annotated Instructor's GuideDocument48 pagesIntroduction To Substations: Annotated Instructor's Guideஹரிஹரசுதன்No ratings yet

- UC Series: Fire Fighting Equipments Designed According ToDocument12 pagesUC Series: Fire Fighting Equipments Designed According ToJulio Acuña RNo ratings yet

- Heavy Goods Vehicle HGV Inspection Manual PDFDocument212 pagesHeavy Goods Vehicle HGV Inspection Manual PDFmunihireNo ratings yet

- Ips e in 120Document53 pagesIps e in 120ali1860No ratings yet

- Man 2258Document47 pagesMan 2258Eric PierceNo ratings yet

- Folleto Allen Regla NeumaticaDocument2 pagesFolleto Allen Regla Neumaticasubsecretaria obrasNo ratings yet

- WqrerDocument1 pageWqrerDan ErandioNo ratings yet

- Hydraulic Components and Systems (2012)Document203 pagesHydraulic Components and Systems (2012)bach.leconmeomapNo ratings yet

- Wear Sleeves 6403 - ENDocument44 pagesWear Sleeves 6403 - ENpaulpopNo ratings yet

- Reclaimer ChainDocument4 pagesReclaimer ChainAmeer Ahmad RazaNo ratings yet

- WORLD USG Multilingual Bike ManualDocument459 pagesWORLD USG Multilingual Bike ManualZé KonaNo ratings yet

- Data Sheet Classic k22 enDocument1 pageData Sheet Classic k22 enakshay tapkirNo ratings yet

- Practice Problems in ABSORPTION and HUMIDIFICATION - SolutionsDocument19 pagesPractice Problems in ABSORPTION and HUMIDIFICATION - SolutionsJenna Brasz100% (2)

- The Electric Potential: - The Potential Energy Per Unit Charge, U/q, Is The Electric Potential The Electric PotentialDocument29 pagesThe Electric Potential: - The Potential Energy Per Unit Charge, U/q, Is The Electric Potential The Electric PotentialMurtaza LokhandwalaNo ratings yet

- Chemical Do Sing Pots ManualDocument1 pageChemical Do Sing Pots ManualPaul KwongNo ratings yet

- Wind Load Section C - Hip RoofDocument6 pagesWind Load Section C - Hip Rooffred anthony UeraNo ratings yet

- Vitodens 222 Application GuideDocument52 pagesVitodens 222 Application GuideJulija RazmislavičienėNo ratings yet

- XH3-HE User'S Manual: Self-Contained, Single Pump Wellhead Control Panel For Harsh EnvironmentsDocument9 pagesXH3-HE User'S Manual: Self-Contained, Single Pump Wellhead Control Panel For Harsh EnvironmentsprabuNo ratings yet

- Kamiq Owners ManualDocument197 pagesKamiq Owners ManualhendyNo ratings yet

- Diagrama Eléctrico de Tablero Tornatech GPDDocument8 pagesDiagrama Eléctrico de Tablero Tornatech GPDJorge Calcaneo Martinez100% (1)

- Unified Development of Lateral Directional Departure CriteriaDocument5 pagesUnified Development of Lateral Directional Departure CriteriaVirginTebowNo ratings yet

- General Notes:: Checklist For Inspection of Electric ElevatorsDocument2 pagesGeneral Notes:: Checklist For Inspection of Electric ElevatorsAli IbrahimNo ratings yet

- A Review Study On Seismic Response of Steel Building Frames With Different Beam - Column ConnectionsDocument8 pagesA Review Study On Seismic Response of Steel Building Frames With Different Beam - Column ConnectionsIJRASETPublicationsNo ratings yet

- BOOST UsersGuideDocument330 pagesBOOST UsersGuideiturcic9No ratings yet

- Project NoteDocument89 pagesProject NoteشتشوتNo ratings yet

- Wavin PE Pressure Pipe Systems Technical ManualDocument60 pagesWavin PE Pressure Pipe Systems Technical ManualellichNo ratings yet

- P&ID May Nghien Malt 10t-hDocument1 pageP&ID May Nghien Malt 10t-halun nguyễnNo ratings yet

- Spare Parts CatalogueDocument484 pagesSpare Parts CatalogueAlexDorNo ratings yet

- P2002 JRDocument4 pagesP2002 JRturandotNo ratings yet