Professional Documents

Culture Documents

IONIQ

IONIQ

Uploaded by

Drikus OdendaalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IONIQ

IONIQ

Uploaded by

Drikus OdendaalCopyright:

Available Formats

IONIQ

Leak Detector

For High Volume Production

On the basis of its well- Main features

proven concept of production

line QC Testers, ATEQ has

2 possible configurations:

now developed a new leak

Tester, designed for the specific

requirements of high volume ■ Single channel ■ 1 to 6 channels

production of plastic parts. ■ Speed: ■ Speed:

up to 15 tests/s minimum cycle time: 0.7 s

■ Start by (optical) sensor ■ External test result box

This instrument is used for the Inputs

detection of localised moulding

faults, insufficient membrane

thickness, perforations, etc.... Common specifications:

The IONIQ is based on ■ Discharge current measurement ■ Reject levels as % of nominal

voltage

discharge current measurement ■ Integrated ionising high voltage

generator ■ Monitoring and protection of

and is able to detect defects in high voltage generator

■ I/O's for instrument control

the region of 10µm. and results ■ Output current limitation

0005

Measurement principle

Operation description of the ATEQ IONIQ

▼

The IONIQ measures the current flowing between a patented

charged probe and a ground plate placed under the part to be tested.

▼

The IONIQ uses the % of the nominal voltage (which reflects the

discharge current), measured on the part as PASS/FAIL level.

Part

▼

In a PASS situation.

No hole, no weak part, the IONIQ measures a high %.

The measured voltage and the nominal voltage are virtually equal.

The result is above the reject level, the part has passed the test.

▼

In a FAIL situation.

The IONIQ measures a low %. The measured voltage is significantly

below the nominal voltage. The result is below the reject level, the

part has failed the test.

▼

Test limitations: short probe-part-plate distance, electrical insulation

from environment.

Applications

This system is ideal for your high volume tests on bottle

caps for injection point defects, on plastic or insulating

membranes for thickness defects.

Technical Features

■ High voltage generator ■ Interfaces

Integrated and adjustable according to application. Programming on front panel.

8 inputs / 8 outputs for PLC controlled applications.

■ Temperature Isolated RS 232 / RS 485 for printer or MODBUS type

Operating: from + 5 to + 45°C network.

Storage: from 0 to + 60°C Inputs:

Specifications subject to modifications without notice

Optically isolated (3750 V RMS).

■ Dimensions 24 V - 10 mA maximum or dry contact.

H x W x D = 420 x 300 x 160 mm Outputs:

Weight: 6.5 kg Relay output

Rated 48 V / 500 mA maximum.

■ Power supply

Mains ~ 90 V à 260 V AC ■ Optional

Single phase ~ 50/60 Hz - 40 VA Pre-charge and discharge electrodes (ATEQ patent).

Note: It is vital that the instrument is connected to a

good quality earth.

Head Office:

15, rue des Dames - ZI des Dames - 78340 Les Clayes-Sous-Bois - France

( : + 33 1 30 80 10 20 - Fax : + 33 1 30 54 11 00

www.ateq.com - e-mail : info@ateq.com

You might also like

- 75 Gold Recovery MethodsDocument90 pages75 Gold Recovery MethodsAFLAC ............92% (38)

- LPI - Selftesttraining.202 450.v2019!02!20.by - Mark.65qDocument38 pagesLPI - Selftesttraining.202 450.v2019!02!20.by - Mark.65qgoatsoteNo ratings yet

- Arduino Uno ProjectDocument17 pagesArduino Uno ProjectDhairya Shah100% (1)

- Bill of Sale (English) - 2019Document1 pageBill of Sale (English) - 2019Brenda AvilaNo ratings yet

- CHROMA 19501-K-E Partial Discharge TesterDocument6 pagesCHROMA 19501-K-E Partial Discharge TesteraboofazilNo ratings yet

- APW7142Document22 pagesAPW7142gsmaster4141No ratings yet

- Current Transducer LXS Series 6, 15, 25 A: Ref: LXS 6-NPS, LXS 15-NPS, LXS 25-NPSDocument16 pagesCurrent Transducer LXS Series 6, 15, 25 A: Ref: LXS 6-NPS, LXS 15-NPS, LXS 25-NPSویرا محاسب پاسارگادNo ratings yet

- SY8201Document10 pagesSY8201relmasNo ratings yet

- Portable DC HipotsDocument4 pagesPortable DC Hipotsfelipe.aounNo ratings yet

- Voce e AquiloDocument13 pagesVoce e AquiloKelvin LeonNo ratings yet

- Technical Data SheetDocument12 pagesTechnical Data SheetYves KABWE LULUNo ratings yet

- Ec Rtu L: Controlsô L M v3.3 Certified Roof Top Unit ControllerDocument4 pagesEc Rtu L: Controlsô L M v3.3 Certified Roof Top Unit ControllerErdinc KlimaNo ratings yet

- 5A IntegratorDocument5 pages5A IntegratorWilsonNo ratings yet

- Art b22 DXXXXX SeriesDocument12 pagesArt b22 DXXXXX Seriesrica_alvesNo ratings yet

- Technical Sheet Room ControllerDocument2 pagesTechnical Sheet Room ControllerMyth SwordNo ratings yet

- AC Hipots 15-200kVDocument4 pagesAC Hipots 15-200kVfelipe.aounNo ratings yet

- UT525 UT526 English ManualDocument2 pagesUT525 UT526 English ManualKasun WeerasingheNo ratings yet

- Operation Manual: Leakage Alarm Unit Water Detector, Model 12 V or 24 V AC/DCDocument3 pagesOperation Manual: Leakage Alarm Unit Water Detector, Model 12 V or 24 V AC/DCmoocomNo ratings yet

- 1.0 Features 2.0 Description: Digital PWM Current-Mode Controller For Quasi-Resonant OperationDocument20 pages1.0 Features 2.0 Description: Digital PWM Current-Mode Controller For Quasi-Resonant OperationMisael GonzalezNo ratings yet

- Kikusui TOS5051 DatasheetDocument3 pagesKikusui TOS5051 Datasheetjalmeida88No ratings yet

- 1769IF8 13555 DatasheetDocument1 page1769IF8 13555 DatasheetAlvin Azhar IrfaniNo ratings yet

- Datasheet APW7142Document22 pagesDatasheet APW7142José Aparecido BarbosaNo ratings yet

- 10 Amp Digital Low Resistance: Dlro10HdDocument3 pages10 Amp Digital Low Resistance: Dlro10HdKrishna PardeshiNo ratings yet

- Lem Heme Iso 1000Document4 pagesLem Heme Iso 1000Ana Safranec VasicNo ratings yet

- Users Manual Phenix Technologies Inc.: PPD September 19, 2007Document31 pagesUsers Manual Phenix Technologies Inc.: PPD September 19, 2007Edinson Cardenas AlikhanNo ratings yet

- Charging OptionsDocument10 pagesCharging Optionsseshnag100No ratings yet

- Portable DC HipotsDocument4 pagesPortable DC HipotsFelipe M. AounNo ratings yet

- Sung Thu Tinh Dien - ONYX - 16Document8 pagesSung Thu Tinh Dien - ONYX - 16Toan TavanNo ratings yet

- Aeg DC 2000 enDocument2 pagesAeg DC 2000 enmauriceauNo ratings yet

- Ada4700 1 PDFDocument10 pagesAda4700 1 PDFKirlian KitzingerNo ratings yet

- Voltage Transducer DVL 1000 V 1000 VDocument8 pagesVoltage Transducer DVL 1000 V 1000 Vnaveen kumarNo ratings yet

- Manual Telurimetro Unila Geo XDocument3 pagesManual Telurimetro Unila Geo XGiovanni Torres100% (1)

- Current Transducer CKSR Series 6, 15, 25, 50 A: Ref: CKSR 6-NP, CKSR 15-NP, CKSR 25-NP, CKSR 50-NPDocument19 pagesCurrent Transducer CKSR Series 6, 15, 25, 50 A: Ref: CKSR 6-NP, CKSR 15-NP, CKSR 25-NP, CKSR 50-NPc.cesco8703No ratings yet

- Electrical Symbols 5. Tester's Structure (Front View) : Insulation Resistance MeasurementDocument2 pagesElectrical Symbols 5. Tester's Structure (Front View) : Insulation Resistance Measurementpepo123No ratings yet

- UT501B English ManualDocument2 pagesUT501B English ManualIniciar IniciarNo ratings yet

- HLSR-P SeriesDocument13 pagesHLSR-P SeriesGerson David Reto PeñaNo ratings yet

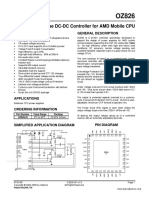

- Dual-Phase DC-DC Controller For AMD Mobile CPU: Features General DescriptionDocument7 pagesDual-Phase DC-DC Controller For AMD Mobile CPU: Features General Descriptionlordycarlos8588No ratings yet

- Voltage Regulator 6gc65 ProfileDocument2 pagesVoltage Regulator 6gc65 Profilenattapon.pNo ratings yet

- DP5000DP5000S (Low Voltage) V2.0Document3 pagesDP5000DP5000S (Low Voltage) V2.0khanhnd.hwNo ratings yet

- Ec Hpu L: Controlsô L M v3.3 Certified Heat Pump Unit ControllerDocument4 pagesEc Hpu L: Controlsô L M v3.3 Certified Heat Pump Unit ControllerErdinc KlimaNo ratings yet

- LAC74.1 Installation Guide V.2Document1 pageLAC74.1 Installation Guide V.2tarik tarikNo ratings yet

- ACS724LMC, ACS725LMC: High Accuracy Hall-Effect-Based Current Sensor with 265 µΩ Integrated ConductorDocument17 pagesACS724LMC, ACS725LMC: High Accuracy Hall-Effect-Based Current Sensor with 265 µΩ Integrated ConductorRicardo UrioNo ratings yet

- Visio3 8Document3 pagesVisio3 8hashim1980No ratings yet

- Hall Sensor - A700000006932794Document18 pagesHall Sensor - A700000006932794oier.eizmendiNo ratings yet

- Ipr-A GBBR 180315Document4 pagesIpr-A GBBR 180315Victor Hugo González BaezaNo ratings yet

- LC 103Document2 pagesLC 103serddsNo ratings yet

- Control PFDocument110 pagesControl PFMauro010461No ratings yet

- Vlf-Sinus-45kv Ds en v01Document2 pagesVlf-Sinus-45kv Ds en v01Hoku's NickNo ratings yet

- Olympus PSD-10 ESU - User Manual PDFDocument28 pagesOlympus PSD-10 ESU - User Manual PDFanhhp8xNo ratings yet

- APW7068Document23 pagesAPW7068Fərid SirafilzadəNo ratings yet

- D5048 DTS0286 enDocument2 pagesD5048 DTS0286 enmbidNo ratings yet

- Ho-Np SeriesDocument15 pagesHo-Np SeriespeterNo ratings yet

- Novus Controller n1200 FlyerDocument2 pagesNovus Controller n1200 FlyerAldrin HernandezNo ratings yet

- 10 Amp Digital Low Resistance: Dlro10HdxDocument4 pages10 Amp Digital Low Resistance: Dlro10HdxmuaadhNo ratings yet

- DPT R8-3W CatDocument2 pagesDPT R8-3W CatGovind RaoNo ratings yet

- Earth/Ground Resistance Clamp Testers: DET10C, DET20CDocument4 pagesEarth/Ground Resistance Clamp Testers: DET10C, DET20CMishel Salazar DefazNo ratings yet

- 6213AINDocument1 page6213AINJavier Montalvo BautistaNo ratings yet

- 12 KV Insulation Diagnostic System Megger Delta Adiradh Energy 1Document4 pages12 KV Insulation Diagnostic System Megger Delta Adiradh Energy 1raju singh shekhawatNo ratings yet

- Atten Catalogo 2Document14 pagesAtten Catalogo 2Carlos Gonzales PerezNo ratings yet

- Apollo Switch Monitor InputOutput ModuleDocument2 pagesApollo Switch Monitor InputOutput ModuleSooraj VsNo ratings yet

- Digital Multiple: Loop / PSC / Earth TesterDocument16 pagesDigital Multiple: Loop / PSC / Earth TestermlutfimaNo ratings yet

- ConnectorsDocument2 pagesConnectorsDrikus OdendaalNo ratings yet

- Leakjets UDocument2 pagesLeakjets UDrikus OdendaalNo ratings yet

- Series: Compact Leak Detector For Production TestingDocument2 pagesSeries: Compact Leak Detector For Production TestingDrikus OdendaalNo ratings yet

- Series: Compact Leak Detector For Production TestingDocument2 pagesSeries: Compact Leak Detector For Production TestingDrikus OdendaalNo ratings yet

- (Download PDF) Business Psychology and Organizational Behaviour 6Th Edition Eugene Mckenna Online Ebook All Chapter PDFDocument42 pages(Download PDF) Business Psychology and Organizational Behaviour 6Th Edition Eugene Mckenna Online Ebook All Chapter PDFkurt.holland582100% (13)

- GENG 3130 Sec 01 02 Syllabus Full 2022Document14 pagesGENG 3130 Sec 01 02 Syllabus Full 2022pass wordNo ratings yet

- Intermediate Accounting I - Cash and Cash EquivalentsDocument4 pagesIntermediate Accounting I - Cash and Cash EquivalentsJoovs JoovhoNo ratings yet

- Service DM Kalibrierung Tab Dienstleistungen enDocument2 pagesService DM Kalibrierung Tab Dienstleistungen enrcnexyNo ratings yet

- Nestle Waters Forecasting Improv Ment SlidesDocument37 pagesNestle Waters Forecasting Improv Ment Slidesamitwin1983No ratings yet

- Vacio REF-SVG001-EN EvacuationDocument16 pagesVacio REF-SVG001-EN EvacuationRuiz Caldera Eloy E.No ratings yet

- CALP Glossary 2023 ENDocument41 pagesCALP Glossary 2023 ENHendra WijayaNo ratings yet

- Geologist Board ExamDocument3 pagesGeologist Board ExamAdong FernandezNo ratings yet

- Design of A Vertical Thermosyphon ReboilerDocument6 pagesDesign of A Vertical Thermosyphon ReboilerhurrikenNo ratings yet

- Manual Tecnico Del Lpile PDFDocument246 pagesManual Tecnico Del Lpile PDFJose Smith CalisayaNo ratings yet

- Lab ManualDocument36 pagesLab ManualDhruv DalwadiNo ratings yet

- Education For Liberation - UmaDocument5 pagesEducation For Liberation - UmaREBECA ROMERONo ratings yet

- Software Processes: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 3 Slide 1Document49 pagesSoftware Processes: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 3 Slide 1suryadiNo ratings yet

- Applications of SolaviteDocument2 pagesApplications of SolaviteWorkshopNo ratings yet

- Hunter Color Lab UltraScan - PRO - ProspektusDocument4 pagesHunter Color Lab UltraScan - PRO - ProspektusSumeet KaurNo ratings yet

- Finnish Velo CarsDocument4 pagesFinnish Velo CarsThomas Wiesner100% (3)

- Mapper User ManualDocument66 pagesMapper User ManualHarsha KodaliNo ratings yet

- Kolb QuestionnaireDocument8 pagesKolb Questionnaireaandgand7cattosNo ratings yet

- Simple Circuit Design Tutorial For PoE ApplicationsDocument10 pagesSimple Circuit Design Tutorial For PoE ApplicationsTayyeb AliNo ratings yet

- Panasonic SC BT200Document60 pagesPanasonic SC BT200Mark CoatesNo ratings yet

- The Nepal Engineering Council ActDocument14 pagesThe Nepal Engineering Council ActRazn NhemaphukiNo ratings yet

- Plucka 1450909082Document83 pagesPlucka 1450909082AymeeenNo ratings yet

- Chapter 6. Infiltration and VentilationDocument1 pageChapter 6. Infiltration and VentilationKarthikeyan SankarrajanNo ratings yet

- Eu-R SAA ULDocument86 pagesEu-R SAA ULCarlos Alberto de Andrade Freitas JuniorNo ratings yet

- AmazonDocument2 pagesAmazongoldmine20233No ratings yet

- Recommended Books For RBI Grade B Exam With Bonus Online MaterialDocument15 pagesRecommended Books For RBI Grade B Exam With Bonus Online MaterialrahulNo ratings yet

- MSA CalculationDocument1 pageMSA Calculationshivshankar kushwahaNo ratings yet