Professional Documents

Culture Documents

BW Liberty Gas Form C

BW Liberty Gas Form C

Uploaded by

valter AssunçãoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BW Liberty Gas Form C

BW Liberty Gas Form C

Uploaded by

valter AssunçãoCopyright:

Available Formats

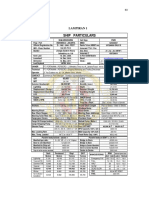

LPG/C BW LIBERTY

GAS FORM C

Main particulars

2.1 PREAMBLE

Ship's name BW LIBERTY

Owners BW Liberty Limited

Flag – Registry Norway (NIS) - Oslo

Builder Daewoo Shipbuilding & Marine Engineering Co. Ltd., Okpo, South Korea

Delivery 30th November 2007

Class Lloyd’s Register

Class notation +100A1, Liquefied Gas Carrier, Ship Type 2G, Butane, Propane, Anhydrous

ammonia, in Independent Tanks Type A Maximum SG 0.69, Maximum Vapour

Pressure 0.25 bar at sea(0.45 bar in harbour, Minimum Temperature -50° C,

*IWS, LMC, IGS,UMS, NAV1, RMC(LG), ShipRight(LG), LI

IMO No. 9350288

GRT / NRT

International 48,456 / 17,304

Suez 51,346.2 / 46,001.57

Panama N/A

2.2 HULL

Metres

LOA 226.00 mtrs

LBP 215.00 mtrs

Breadth 36.61 mtrs

Depth 22.20 mtrs

Keel to highest point 54.765 mtrs

KTM (lowered antenna) 52.365 mtrs

Max summer draft 11.822 mtrs Corresponding deadweight 54,975 mt

TPC fully loaded 70.87 mt

Mean draft with 95% full bunkers and full cargo

Specific Gravity Mean draft Corresponding DW

0.581 (C3 – 98%) 11.462 m 52,431

0.596 (C4 – 98%) 11.697 m 54,089

0.680 (NH3 – 87%)) 11.822 m 54,975

0.703 N/A N/A

REVISION DATE PREPARED BY APPROVED BY CHAPTER PAGE NO

00/SSU 01.07.2015 SSU - 02 2.1

LPG/C BW LIBERTY

Communication equipment

International call sign LAMM7

Radio station GMDSS

Satcom F-77

- Telephone +870 765 065 045 / 46

- Telefax 765 065 047 / 48

V Sat

- Telephone +47 85 23 07 03 / +65 31 58 09 71

Satcom C +870 425 907 110

Cell phone +47 97 56 69 28

MMSI 259 071 000

E-mail liberty@bwfleet.com

2.3 MACHINERY

Main Engine

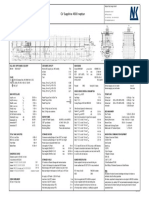

STX - MAN B & W 6S60 MC - C

Service power (90% MCR) 12,200 kW at 101.4 RPM

Grade fuel used HFO up to 600 cSt at 50C

Auxiliaries

Diesel 3 units

Make Yanmar 8N21AL-GV

kW/RPM (100%) 1,270 kW / 900 rpm

Grade fuel used HFO up to 600 cSt at 50C / MDO grade ISO-F-DMB-DMA

Speed/Consumption*

Guaranteed average loaded/ballast speed over 12 months

Average consumption on Main Engine guaranteed speed

Average consumption on auxiliaries

*) Above based on 50/50 propane/butane and max force 5 Beaufort

Slow speed/consumption figures as guidance only

Average loaded/ballast Consumption

13 Knots

14 Knots

15 Knots

Average consumption in port

Inert gas plant when operating

Boiler consumption

Permanent bunkers capacity (98% full)

(Incl. daily service and settling tanks)

HFO 3,390 mt

Diesel Oil 145 mt

Light Diesel Oil 95 mt

REVISION DATE PREPARED BY APPROVED BY CHAPTER PAGE NO

00/SSU 01.07.2015 SSU - 02 2.2

LPG/C BW LIBERTY

2.4 CARGO INSTALLATION

Transportable products and respective quantities

n-Butane Propane Ammonia

Tank 0.602 0.579 0.682

No. 100 % 98 % -0.08oC -42.12oC -33.6oC

m3 m3 mt mt mt

1 18,412.55 18,044.30 10,737 10,362 10,816

2 22,360.33 21,913.12 13,040 12,584 13,135

3 22,349.96 21,902.96 13,034 12,578 13,129

4 21,474.40 21,044.91 12,523 12,085 12,615

Total 84,597.24 82,905.29 49,334 47,609 49,695

Deck tank capacity N/A

Transportable products and respective quantities

Other transportable products:

Propane with max 5 mole % Ethane in liquid phase / Mixture of Propane and Butane in any proportion

Scantlings of the cargo tanks are based on a maximum density of cargo of 610 kg/m3. Cargo with

density up to 1,000 kg/m3 may be carried in the cargo tanks on the following conditions:

For density of 1,000 kg/m3 N/A

For densities between 610 and 1,000 87% by volume for cargo density of 690 kg/m3

kg/m3

Tank working pressure

Maximum pressure 0.450 barg (harbour) / 0.250 barg (sea)

Minimum pressure -0.050 bar

Minimum temperature acceptable in tanks -50 oC

Loading rate - tons/hour 2,500 mt on two manifolds

2.5 CARGO PUMPS

Number and type 8 x 600 m3/hr Hamworthy Svanehoj Centrifugal

Deepwell pumps

Location 2 x pumps in each cargo tank

Max permissible specific gravity 120 mLC, 690 kg/m3

Time for discharging full cargo using all pumps

against no backpressure 20 hrs

Cargo remaining onboard in cargo tanks after

completion pumping Total appr 60 m3 unpumpable liquid (all cargo tanks)

Total head when working in series with booster

pump 235 mLC

Booster pumps 2 x 600 m3/h Hamworthy Svanehoj Centrifugal,

115 mLC, 690 kg/m3

REVISION DATE PREPARED BY APPROVED BY CHAPTER PAGE NO

00/SSU 01.07.2015 SSU - 02 2.3

LPG/C BW LIBERTY

2.6 CARGO COMPRESSORS

Number and type 4 x Sulzer Burckhardt piston Compressor 3K 140-3A

Propane n-Butane Ammonia

Refrigeration Capacity 242 kW (5.0% Ethane) 345 kW 398 kW

Suction pressure 0.200 bar

2.7 INERT GAS SYSTEM

Does the vessel use inert gas? Yes

Utilization Inerting of Void spaces and Cargo tanks

Does the vessel produce inert gas? Yes

Type Hamworthy Moss Inert Gas Generator

Daily production 120,000 m³

Composition of inert gas

Carbon dioxide 14.0 %

Oxygen max. 1.0 %

Carbon monoxide max. 100 ppm by volume

Hydrogen max. Nil

Nitrogen Balance (84.9) %

Soot Bacharach 0

Sulphur oxides max. 1 ppm by volume

Dew point -45 oC at 760 mmHG

State if any shore supply of liquid nitrogen may be required No

What quantity? N/A

2.8 GAS FREEING

Can this operation be carried out at sea? Yes

State method incl. all details

For LPG Boil Off 18/24 hrs C3/C4

Inerting 30 hrs

Ventilating for Entry 30 hrs (IG blower)

For NH3 8 days down to 50 ppm

Advise time required and consumption of inert gas if any

From LPG approximately 30 hrs / 150,000 m3

From NH3 approximately N/A (venting with air)

Is the vessel equipped with inert gas blower? Yes

Capacity 5,000 m3/hr

Ventilation fan N/A (Inert gas blower to be used)

REVISION DATE PREPARED BY APPROVED BY CHAPTER PAGE NO

00/SSU 01.07.2015 SSU - 02 2.4

LPG/C BW LIBERTY

2.9 CHANGING GRADE

Can this operation be carried out at sea? Yes

State method used and time required for changing from NH3 to LPG and vice versa, to reach 50 ppm of

previous cargo in tanks atmosphere, the tanks being dry and free of moisture (dewpoint +10 degrees C)

From NH3 to LPG Boil off, Heating up, Venting with air and Inerting

Time required About 9.5 days

From LPG to NH3 Boil off, Heating up, Inerting and Venting with air

Time required About 4.5 days

Can vessel reduce in tank atmosphere and gas

installation concentration of previous cargo below Yes

50 ppm?

Method used, time required and extra shore supply

if any Boil off / heating / inerting / venting

How can it be checked that no liquid gas remain

onboard Level Gauge / Temperature sensors

2.10 CARGO HEATER

State discharging rate for propane with 2.5 mol % ethane to be brought from -42 oC to

0 oC at sea temperature of 15 oC 600 m3/hr

2.11 CARGO VAPORIZER

In case of need of vapour gas during discharge, can vessel produce its own if no shore

gas available? Yes

2.12 REFRIGERATING APPARATUS

Is it independent of cargo? Yes

2.13 MEASURING APPARATUS

What gauges onboard Level gauges

Location and type 2 for each cargo tank / Radar type

Number of temperature sensors/gauges pr tank 7 – (3 each side of tank and 1 in vapour dome)

Number of pressure sensors/gauges pr tank 1 in each tank

REVISION DATE PREPARED BY APPROVED BY CHAPTER PAGE NO

00/SSU 01.07.2015 SSU - 02 2.5

LPG/C BW LIBERTY

2.14 SAMPLES

Where can samples be taken? Vapour on dome / Liquid on dome using cargo pump

and manifold

Are sample bottles available onboard? No

2.15 CARGO LINES

(See also last page of this gas form C)

Is vessel fitted with midship manifolds Yes

Distance from cargo manifold to bow 114.21 mtrs

Distance from manifold to stern 111.79 mtrs

Height cargo manifold above main deck 1.564 mtrs

Height cargo manifold above waterline when in ballast 16.300 mtrs

Height cargo manifold above waterline when loaded 11.970 mtrs

Distance from shipside to manifold flange 3.000 mtrs

Distance between loading and vapour return connections 2.50 mtrs

Windage area in normal ballast condition 4,080.6 m2

Is vessel fitted with SPM chainstopper suitable for 76 mm chain. Yes

Is vessel fitted with cruciform bollards/fairleads/eye-pads in manifold area Yes

Dimension of lines

Diameter Flange size

Liquid System 1 400 mm / 16 inch ANSI 300

Liquid System 2 400 mm / 16 inch ANSI 300

Gas Line 250 mm / 10 inch ANSI 150

Booster Line 350 mm / 14 inch ANSI 300

What reducers onboard

Number Diameter Length Pressure rating

2 16” - 16” 50 cm ANSI 300 - ANSI 300

2 16” - 12” 50 cm ANSI 300 - ANSI 300

2 16” - 10” 50 cm ANSI 300 - ANSI 300

2 16” - 8” 50 cm ANSI 300 - ANSI 300

2 16” - 16” 50 cm ANSI 300 - ANSI 150

2 16” - 14” 50 cm ANSI 300 – ANSI 150

2 16” - 12” 50 cm ANSI 300 – ANSI 150

2 16” - 10” 50 cm ANSI 300 – ANSI 150

2 16” - 8” 50 cm ANSI 300 – ANSI 150

2 10” - 12” 50 cm ANSI 150 – ANSI 150

2 10” – 10” 50 cm ANSI 150 – ANSI 150

2 10” - 8” 50 cm ANSI 150 – ANSI 150

2 10” - 6” 50 cm ANSI 150 – ANSI 150

2.16 LIFTING DEVICE

Where situated Aft Amidship

Number and type 2 1

Lifting capacity 4 tons 5 tons

Max. distance from ship's side Port 4.0 mtrs 8.5 mtrs

of lifting hook Stb. 4.0 mtrs

REVISION DATE PREPARED BY APPROVED BY CHAPTER PAGE NO

00/SSU 01.07.2015 SSU - 02 2.6

LPG/C BW LIBERTY

2.17 HOSES

For what products are hoses suitable N/A

Number Length Diameter Working pressure Flange

0 N/A N/A N/A N/A

2.18 SPECIAL FACILITIES

How many grades can vessel segregate? 2

Indicate systems (Tks 1+3) and (Tks 2+4) or (Tks 1+3+4) and (Tk 2)

Is vessel able to load/discharge two or

more grades simultaneously? Yes

Can vessel sail with slack tanks? Yes

Is vessel fitted with purge tank? No

REVISION DATE PREPARED BY APPROVED BY CHAPTER PAGE NO

00/SSU 01.07.2015 SSU - 02 2.7

LPG/C BW LIBERTY

ARRANGEMENT OF CARGO MANIFOLD

DO FO L2(A) V2(A) V1 L1 L2(F) V2(F) FO

1.25 m 1.25 m

3.75 m

3.75 m

6.25 m 6.25 m

8.25 m 8.25 m

9.25 m

To Stern 111.79 m To Bow 114.21 m

d

c

g b a

e f

a) Height of manifold above deck 1.564 m

b) Height of manifold above tray 1.200 m

c) Distance manifold to Rail * 3.000 m Loaded

d) Distance manifold to ships side * 3.000 m

e) Dist. waterline loaded to manifold 11.970 m

f) Dist. waterline ballast to manifold 16.300 m

g) Dist. 1st stander to manifold 0.54 m

* without reducer

PARALLEL BODY LENGTH

LOADED CONDITION

Ballast

Stern 66.21 m 54.64 m Bow

50.10 m 46.01 m

BALLASTED CONDITION

REVISION DATE PREPARED BY APPROVED BY CHAPTER PAGE NO

00/SSU 01.07.2015 SSU - 02 2.8

You might also like

- Gas Form C Main Particulars: 2.1 PreambleDocument8 pagesGas Form C Main Particulars: 2.1 PreambleKeyur B ShrimaliNo ratings yet

- BW Messina Gasform C 1Document8 pagesBW Messina Gasform C 1sufiyan.madreNo ratings yet

- BW Kizoku Gas Form CDocument9 pagesBW Kizoku Gas Form CLifeatseaNo ratings yet

- Gas Madrid - Form CDocument10 pagesGas Madrid - Form CElchin AbishovNo ratings yet

- Gas Houston Form CDocument7 pagesGas Houston Form CElchin AbishovNo ratings yet

- Ship Particular MBDocument2 pagesShip Particular MBromi.arvNo ratings yet

- Epic Bali - Form-CDocument10 pagesEpic Bali - Form-Ccorobceanu.andrei900No ratings yet

- Eco ElysiumDocument10 pagesEco ElysiumPrem KumarNo ratings yet

- Fairchem Blueshark Vessel ParticularDocument4 pagesFairchem Blueshark Vessel Particularbhavana kholaNo ratings yet

- 20-Lampiran 1 Ship ParticularDocument1 page20-Lampiran 1 Ship ParticularAkun Gocar100% (1)

- Vessel CategorisationDocument12 pagesVessel CategorisationbenNo ratings yet

- Arr Stowage Plan Lome - Voy 117Document2 pagesArr Stowage Plan Lome - Voy 117nivasmarineNo ratings yet

- MV Spanaco Progress - TC DescriptionDocument1 pageMV Spanaco Progress - TC DescriptionSamrandNo ratings yet

- Bunker Confirmation Note: Product InformationDocument9 pagesBunker Confirmation Note: Product InformationAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Ship Particulars - PNS SerenaDocument1 pageShip Particulars - PNS SerenaID 29No ratings yet

- MCP HamburgDocument3 pagesMCP HamburgalbustamanteNo ratings yet

- PL 0035-Si-22 Simco 1x14 MVA 11112022Document1 pagePL 0035-Si-22 Simco 1x14 MVA 11112022Rivan rNo ratings yet

- KSL Santiago Ships ParticularDocument2 pagesKSL Santiago Ships Particularjeff100% (1)

- Night Shift 11-09-2022Document2 pagesNight Shift 11-09-2022fahadullahNo ratings yet

- Technical Offer: Pump Description Pump ModelDocument4 pagesTechnical Offer: Pump Description Pump ModelPraveen PrajapatiNo ratings yet

- I-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Document5 pagesI-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Martin DanzeNo ratings yet

- Eco NicalDocument13 pagesEco Nicalluizfellipe95No ratings yet

- Evening Shift 10-09-2022Document2 pagesEvening Shift 10-09-2022fahadullahNo ratings yet

- Night Shift 01-09-2022Document2 pagesNight Shift 01-09-2022fahadullahNo ratings yet

- Data Sheet CV-Sapphire PDFDocument1 pageData Sheet CV-Sapphire PDFthehoang12310No ratings yet

- Morning Shift 01-09-2022Document2 pagesMorning Shift 01-09-2022fahadullahNo ratings yet

- W8X62DF: CMCR and Engine Operating CurvesDocument24 pagesW8X62DF: CMCR and Engine Operating CurvesmanuNo ratings yet

- 2 Phase VerticalDocument4 pages2 Phase VerticalJAZEEL ALAVINo ratings yet

- BW Tokyo Gasform CDocument8 pagesBW Tokyo Gasform CAndi IrfanNo ratings yet

- CMCR and Engine Operating Curves: Rating FieldDocument26 pagesCMCR and Engine Operating Curves: Rating FieldFilipe SouzaNo ratings yet

- Separator SizingDocument9 pagesSeparator SizingTolstoy LeoNo ratings yet

- M.V. Arklow Rogue: Principal ParticularsDocument2 pagesM.V. Arklow Rogue: Principal ParticularsGökhan OğuzNo ratings yet

- Discharging SequenDocument1 pageDischarging SequenyajhairaNo ratings yet

- CMCR and Engine Operating Curves: Rating FieldDocument17 pagesCMCR and Engine Operating Curves: Rating FieldmanuNo ratings yet

- SHIPPARTICULLAR Gas-ElixirDocument12 pagesSHIPPARTICULLAR Gas-Elixirdharmawan100% (1)

- Night Shift 10-09-2022Document2 pagesNight Shift 10-09-2022fahadullahNo ratings yet

- Laporan Shift Malam 05 Maret 2019Document1 pageLaporan Shift Malam 05 Maret 2019Veeko RinaldoNo ratings yet

- LHSS OP P-1B TGL 03 September 2023 Day-1Document1 pageLHSS OP P-1B TGL 03 September 2023 Day-1kurniapusriNo ratings yet

- Technical Details - EHRW+SHRWDocument72 pagesTechnical Details - EHRW+SHRWprashant.jadhavNo ratings yet

- Evening Shift 01-09-2022Document2 pagesEvening Shift 01-09-2022fahadullahNo ratings yet

- CMCR and Engine Operating Curves: Rating FieldDocument24 pagesCMCR and Engine Operating Curves: Rating FieldmanuNo ratings yet

- MV Sunrise IMO 9590060Document2 pagesMV Sunrise IMO 9590060Егор ЛядовNo ratings yet

- Me Performance Jul - 2020Document1 pageMe Performance Jul - 2020Amit Raj AnandNo ratings yet

- D1 Technical Report: Appendix D - Semi-Submersible PlatformDocument6 pagesD1 Technical Report: Appendix D - Semi-Submersible PlatformIda Ayu Laksmi Kusuma WardhaniNo ratings yet

- Aldina Adriana - Kasus 5Document8 pagesAldina Adriana - Kasus 5Gyan PrameswaraNo ratings yet

- Pt. Carsurin Tanah Merah Coal Terminal Drafts Additional InformationDocument8 pagesPt. Carsurin Tanah Merah Coal Terminal Drafts Additional InformationMuhammad IsalNo ratings yet

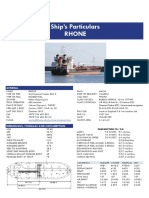

- Rhone 9327164 Oil Chemical - Tanker 71386Document2 pagesRhone 9327164 Oil Chemical - Tanker 71386ironiteNo ratings yet

- MV Musa Oba Ship ParticularDocument2 pagesMV Musa Oba Ship ParticularHectorNo ratings yet

- W8X62 21280kW 103rpm DELTADocument17 pagesW8X62 21280kW 103rpm DELTAmanuNo ratings yet

- 19.verification Letter Class NKDocument2 pages19.verification Letter Class NKST NakhimovetsNo ratings yet

- Calculation Note - Pump Rev 2Document4 pagesCalculation Note - Pump Rev 2Steve WanNo ratings yet

- Ship's ParticularsDocument1 pageShip's ParticularsStar BornNo ratings yet

- Morning Shift 10-09-2022Document2 pagesMorning Shift 10-09-2022fahadullahNo ratings yet

- A320 Essensial DataDocument1 pageA320 Essensial DataKrystal Yeoh100% (2)

- Ship'S Particulars: Draft (MLD.) Density DWT Displacement TPC FWA T. Fresh Fresh Tropical Summer WinterDocument2 pagesShip'S Particulars: Draft (MLD.) Density DWT Displacement TPC FWA T. Fresh Fresh Tropical Summer WinterBarış ÖzturkNo ratings yet

- LPG/C Gas Pasha (Updated 15/09/2020) : Vessel Particulars (Form C)Document10 pagesLPG/C Gas Pasha (Updated 15/09/2020) : Vessel Particulars (Form C)Akram HossainNo ratings yet

- 3612tale Jgd6 DesignDocument1 page3612tale Jgd6 DesignDenis JimenezNo ratings yet

- Basics of OIl RefineryDocument28 pagesBasics of OIl RefineryDebasis Kumar Saha50% (2)

- Form Pre Commisioning A2B (BD, PC, WA, GD)Document21 pagesForm Pre Commisioning A2B (BD, PC, WA, GD)JokoNo ratings yet

- CIRCUIT1 LAB07 RC and RL Transient Response 1Document6 pagesCIRCUIT1 LAB07 RC and RL Transient Response 1Christian JavierNo ratings yet

- Pau Fas FPS FSSDocument4 pagesPau Fas FPS FSSAntonio SerranoNo ratings yet

- 100DSV CatalogueDocument8 pages100DSV CatalogueMachani OmkarNo ratings yet

- En Unit 2 Hydrosphere AtmosphereDocument45 pagesEn Unit 2 Hydrosphere Atmospheremaytte.ahaNo ratings yet

- Megabras Tm25r ManualDocument21 pagesMegabras Tm25r ManualLucio ArrazolaNo ratings yet

- FFKM Simriz BrochureDocument5 pagesFFKM Simriz Brochureemperor_vamsiNo ratings yet

- Nic2 54a 940 CSDocument19 pagesNic2 54a 940 CSShiHong KuangNo ratings yet

- Marsha Math SBADocument13 pagesMarsha Math SBAantwone lewisNo ratings yet

- Injin DiselDocument119 pagesInjin DiselScalperNo ratings yet

- 10 Documented Operational and Maintenance (Preventive and Breakdown) Plan For Clinical and Support Service EquipmentDocument38 pages10 Documented Operational and Maintenance (Preventive and Breakdown) Plan For Clinical and Support Service EquipmentSanjay Kadam100% (1)

- First Solar: Student Name: Student IdDocument25 pagesFirst Solar: Student Name: Student IdUzma SiddiquiNo ratings yet

- Super CA Feb 2024 BilingualDocument25 pagesSuper CA Feb 2024 BilingualriyasharmastudiesNo ratings yet

- Raychem DS Eu1422 E150 enDocument2 pagesRaychem DS Eu1422 E150 enTrung Trinh BaoNo ratings yet

- 0 0 61110123312171c) DPRDocument97 pages0 0 61110123312171c) DPRGagan RamgarhiaNo ratings yet

- Ix35 FCEV ERG - EngDocument36 pagesIx35 FCEV ERG - Engranet tenarNo ratings yet

- T38 Beretta DepliantDocument8 pagesT38 Beretta DepliantJ RivkinNo ratings yet

- FAMCO Marelli Motori Explosion Proof Electric Motor CatalogDocument8 pagesFAMCO Marelli Motori Explosion Proof Electric Motor CatalogMustafaNo ratings yet

- Edfmt391770c FXFQ AvmDocument56 pagesEdfmt391770c FXFQ AvmArthur OliveiraNo ratings yet

- SI-SU-070123-2 New Screed GenerationDocument22 pagesSI-SU-070123-2 New Screed Generationjose luis juarezNo ratings yet

- Physics 2122 Week 1 10 by Kuya CharlesDocument15 pagesPhysics 2122 Week 1 10 by Kuya CharlesChoe Yoek SoekNo ratings yet

- Specification Sheet: Three-Speed Air HandlerDocument6 pagesSpecification Sheet: Three-Speed Air HandlerFernandoNo ratings yet

- EX550-5 Technical Manual (Operational Principle)Document151 pagesEX550-5 Technical Manual (Operational Principle)haimay118100% (1)

- Specifications: 2008 Ford Ranger 2008 Ford RangerDocument8 pagesSpecifications: 2008 Ford Ranger 2008 Ford RangerwawanNo ratings yet

- Basic ECEDocument2 pagesBasic ECEmarkvillaplazaNo ratings yet

- 17060v140y 3Document2 pages17060v140y 3Banupriya BalasubramanianNo ratings yet

- Basic Tec 2Document36 pagesBasic Tec 2TMTM MediaNo ratings yet

- Ns VM II 3.6kw Solar Hybrid InverterDocument2 pagesNs VM II 3.6kw Solar Hybrid InverterwaqargilllNo ratings yet

- EMICON Product Overview ENGDocument20 pagesEMICON Product Overview ENGanish SamsonNo ratings yet

- AstecDocument8 pagesAstecJuan PabloNo ratings yet