Professional Documents

Culture Documents

Concrete Manufacturer Case Study - Autoflame Service Support.

Concrete Manufacturer Case Study - Autoflame Service Support.

Uploaded by

Giovanni MontesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Manufacturer Case Study - Autoflame Service Support.

Concrete Manufacturer Case Study - Autoflame Service Support.

Uploaded by

Giovanni MontesCopyright:

Available Formats

Unit 1-2 Concorde Business Centre +44 (0)1959 578 822

Airport Industrial Estate savings@autoflame.com

Wireless Road www.autoflameservice.com

Biggin Hill, TN16 3YN Autoflame Service & Support

Concrete

Manufacturer

South East, England

• Upgrade of existing GP Unigas burners deemed

end of their life cycle to Limpsfield Gas Fired burners

complete with POD mounted Autoflame Mini Mk8

controls.

• Customer brief included syncing upgraded burners and

controls with on-site BMS system to control heat demand.

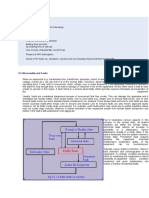

Problem Strategy

• Our team was initially called to site to provide • As a short-term solution, a temporary hire boiler was

emergency support as one of the client's burners installed in order to keep the site fully operational.

was in a state of disrepair. Therefore, with only This enabled our engineers to perform urgent works

2/3 boilers operating, the site load was not being on the existing boiler to bring all three boilers back to

fulfilled. full operation, without the need for downtime.

• Low reliability of current burners meant a longer-term • Following a site meeting, a boiler & burner upgrade

solution was required to ensure reduced downtime. was agreed as per our team's recommendations.

The old, non-operational burner, was replaced with a

Goals Limpsfield LCN123 burner with Autoflame controls &

panel. This allowed for new features including: water

level controls, TDS and bottom blowdown.

1. To get the faulty burner/boiler up to an operational

standard, whilst meeting efficiency goals as a lead • The job was predicted to take 4-weeks, however it

boiler (in line with BG01 arrangement 3). was completed ahead of schedule.

2. Reduce downtime of the plant. • Insurance inspection and NDT works were carried

out as part of the project upgrade.

Results • On-site training was given to operators to ensure a

comprehensive and safe handover.

No downtime: Hiring an emergency boiler whilst

upgrade works were undertaken meant the

plant was able to stay fully operational, which

Equipment

ensured site load was fulfilled. • 1 x Cochran boiler

Pre-Existing

Increased reliability: Existing equipment was • 1 x Cochran burner

modernised to improve reliability and therefore • 1 x Siemens controls panel

unscheduled downtime. • 2 x Cochran Thermax boiler

• 2 x Hamworthy Electrotec burner (1 operational)

Emissions monitoring & control: With the

installation of a Mk8 EGA Evo, emissions can

Newly Installed

1 x Limpsfield 1 x Autoflame

be monitored and adjustments can be made LCN123 Mk8 MM

via the Mk8 MMs' 3-parameter trim to ensure burner

efficient combustion. 1 x Autoflame

Mk8 EGA Evo

Increased safety: On-site training provided.

You might also like

- Wheel Loader 992KDocument24 pagesWheel Loader 992KRonald Mario Kupa AnticonaNo ratings yet

- Siemens Sgt-A45 Mobile Unit Data SheetDocument2 pagesSiemens Sgt-A45 Mobile Unit Data SheetThanapaet Rittirut100% (1)

- Beech King Air B-100 TPE331-10 ConversionDocument4 pagesBeech King Air B-100 TPE331-10 ConversionPlusaero100% (1)

- 993K Specalog Aehq5922 PDFDocument32 pages993K Specalog Aehq5922 PDFpercyNo ratings yet

- Brochure Gas Turbine SGT-400 For Power Generation PDFDocument4 pagesBrochure Gas Turbine SGT-400 For Power Generation PDFfrdnNo ratings yet

- Power Plant Review Lecture: By: Engr. Jermhel M. Solis, Ree, RmeDocument14 pagesPower Plant Review Lecture: By: Engr. Jermhel M. Solis, Ree, RmeAt Sa Wakas AyNo ratings yet

- ZWSC Major Overhaul of Three Elliott Gas Compressor Accomplishment ReportDocument2 pagesZWSC Major Overhaul of Three Elliott Gas Compressor Accomplishment ReportsyamsidiNo ratings yet

- Maritime Protection Igg Brochure PDFDocument4 pagesMaritime Protection Igg Brochure PDFPagan jatarNo ratings yet

- CS PP MRP Gsstorage Mar2018Document2 pagesCS PP MRP Gsstorage Mar2018ABCD123655No ratings yet

- Generator Circuit Breaker Brochure Retrofit Application Brochure GB FR FR PDFDocument8 pagesGenerator Circuit Breaker Brochure Retrofit Application Brochure GB FR FR PDFbobyNo ratings yet

- Welcome To Kushal Foods PVT LTD KANPUR Dehat, Uttar PradeshDocument31 pagesWelcome To Kushal Foods PVT LTD KANPUR Dehat, Uttar PradeshPrateek AgarwalNo ratings yet

- GE Power & Water LM6000-PFplus Gas Turbine Datasheet1xxx 1540752528Document2 pagesGE Power & Water LM6000-PFplus Gas Turbine Datasheet1xxx 1540752528anasabohashishNo ratings yet

- Lehe8967 00Document6 pagesLehe8967 00AM76No ratings yet

- Lehe2027-00 G20CM34Document4 pagesLehe2027-00 G20CM34mario_r3604466No ratings yet

- Control System CC3000Document2 pagesControl System CC3000Максим ПасичникNo ratings yet

- Steam Turbines Retrofitted in Record Time: ABB Review 3/1998Document6 pagesSteam Turbines Retrofitted in Record Time: ABB Review 3/1998Jin HernNo ratings yet

- Audit-And-Maintenance Reactive-Power-Compensation Brochure 2018-10 Doc314013i enDocument4 pagesAudit-And-Maintenance Reactive-Power-Compensation Brochure 2018-10 Doc314013i enARSAL 22231No ratings yet

- Power Requirements Warranty: Control Function SwitcherDocument2 pagesPower Requirements Warranty: Control Function SwitcherFouquetNo ratings yet

- Condition Monitoring Case StudiesDocument21 pagesCondition Monitoring Case StudiesGirish AralikattiNo ratings yet

- Steam Turbines en InteractiveDocument1 pageSteam Turbines en InteractiveSh.nasirpurNo ratings yet

- Ge Energy Opticomp Integrated Compressor Control SuiteDocument8 pagesGe Energy Opticomp Integrated Compressor Control SuitemessaoudmasterNo ratings yet

- Packaged Steam Generators: Vapor PowerDocument5 pagesPackaged Steam Generators: Vapor PowerEngels SalinasNo ratings yet

- Alfa Laval FCM One Gas: Fuel Conditioning System For ME-GI Dual-Fuel EnginesDocument2 pagesAlfa Laval FCM One Gas: Fuel Conditioning System For ME-GI Dual-Fuel EnginesSamo SpontanostNo ratings yet

- Case HistoryDocument1 pageCase HistoryJC MexguyNo ratings yet

- Excavator O&KDocument8 pagesExcavator O&Keknasius iwan sugoro100% (2)

- BIA AGL SystemDocument15 pagesBIA AGL SystemChathura JanakanthaNo ratings yet

- RTHB Tornillo - 130 A 150 TRDocument20 pagesRTHB Tornillo - 130 A 150 TRsarcitoNo ratings yet

- Key Issues For The Control of Refueling Outage Duration and Costs in PWR Nuclear Power PlantsDocument11 pagesKey Issues For The Control of Refueling Outage Duration and Costs in PWR Nuclear Power PlantsRajAnandNo ratings yet

- 2-SHEET - AGC Plant Management Data Sheet 4921240420 UKDocument24 pages2-SHEET - AGC Plant Management Data Sheet 4921240420 UKWasleyNo ratings yet

- S Inertgasgenerator DatasheetDocument4 pagesS Inertgasgenerator DatasheetVikram SinghNo ratings yet

- Dear Participants Welcome To A Discussion On FSSS/ Boiler Protection System Basic Concepts and StandardsDocument24 pagesDear Participants Welcome To A Discussion On FSSS/ Boiler Protection System Basic Concepts and StandardsRupesh AnandNo ratings yet

- Lehe0001 00Document6 pagesLehe0001 00AlfredoNo ratings yet

- 11.031 Rural Energy Service & Maintenance OfferingsDocument8 pages11.031 Rural Energy Service & Maintenance OfferingsUmar MajeedNo ratings yet

- Overhaul of Raw Material Mill Gearbox Saves More Than 300,000 EurosDocument5 pagesOverhaul of Raw Material Mill Gearbox Saves More Than 300,000 Eurosjesus rodriguezNo ratings yet

- CVGF Centrifugo - 400 A 1000 TRDocument16 pagesCVGF Centrifugo - 400 A 1000 TRsuperpuma86No ratings yet

- Boosters Guide Brochure PDFDocument8 pagesBoosters Guide Brochure PDFpowermanagerNo ratings yet

- Technical Spec GE Frame 9E'S - Rev1Document144 pagesTechnical Spec GE Frame 9E'S - Rev1Alaa Zora - OnlineNo ratings yet

- DTI Remote Monitoring Flyer - Autoflame Service SupportDocument2 pagesDTI Remote Monitoring Flyer - Autoflame Service SupportGiovanni MontesNo ratings yet

- Link de MegaDocument6 pagesLink de MegaAndres GutierrezNo ratings yet

- Mumtaz Abbas: ContactDocument5 pagesMumtaz Abbas: ContactMuhammad Hamza NaveedNo ratings yet

- Mechanism Retrofi Ts For High Voltage Circuit Breakers & Related SwitchgearDocument2 pagesMechanism Retrofi Ts For High Voltage Circuit Breakers & Related SwitchgearFakhri HakimNo ratings yet

- EagleBurgmann - RoTechBooster - For-Compressor Station - EN - 2107Document2 pagesEagleBurgmann - RoTechBooster - For-Compressor Station - EN - 2107edavidNo ratings yet

- Operation of Lime KlinDocument4 pagesOperation of Lime Klinhemendra499No ratings yet

- C PotDocument2 pagesC PotSoumya SagarNo ratings yet

- 27 1 15 L07 L22 RS Brochure GBDocument8 pages27 1 15 L07 L22 RS Brochure GBjennlin.changNo ratings yet

- Action Taken Report SOCDocument10 pagesAction Taken Report SOCSTPS ECRNo ratings yet

- Reliability & Efficiency Without Compromise: Rotary Screw CompressorsDocument8 pagesReliability & Efficiency Without Compromise: Rotary Screw CompressorsabdurohmanNo ratings yet

- Crawler Excavator Specifications: Service Weight 57.9 - 63.6 T Engine Output BucketsDocument14 pagesCrawler Excavator Specifications: Service Weight 57.9 - 63.6 T Engine Output Bucketsdamqn filipovNo ratings yet

- Turbine Pelton DesignDocument35 pagesTurbine Pelton DesignAD Lingga100% (3)

- CB AutoflameDocument10 pagesCB AutoflameWylbert ConsueloNo ratings yet

- 04 - SeAH Engineering - Torbo - EngDocument10 pages04 - SeAH Engineering - Torbo - Engвлад камр100% (1)

- OASC TDDocument8 pagesOASC TDFati ZoraNo ratings yet

- VBR LM2500 MetalSCAN Presentation AustraliaDocument18 pagesVBR LM2500 MetalSCAN Presentation AustraliaAbrahan BaezaNo ratings yet

- KrishnaKant 15EI832 IPIDocument36 pagesKrishnaKant 15EI832 IPITanviMaheshwariNo ratings yet

- Gantner Shaft Winch 2016 06Document3 pagesGantner Shaft Winch 2016 06freddyNo ratings yet

- CM20180308 58081 59847Document12 pagesCM20180308 58081 59847Daniel SolomonNo ratings yet

- Wheel LoaderDocument28 pagesWheel LoaderDejanNo ratings yet

- Carrier Paquetes de 75-150 TonDocument2 pagesCarrier Paquetes de 75-150 Tonhvac.mayoreoNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- VOLTAGE DROP AND FAULT CURRENT CALCULATIONS - IIEE PresentationDocument210 pagesVOLTAGE DROP AND FAULT CURRENT CALCULATIONS - IIEE PresentationEarl Jenn Abella100% (2)

- SMC1500-2U: Product Data SheetDocument3 pagesSMC1500-2U: Product Data SheetRedes ItcNo ratings yet

- References BI - Oil and Gas InstallationsDocument1 pageReferences BI - Oil and Gas InstallationsAmine Ben salemNo ratings yet

- Moeller Datasheet EMR4 W500 1 D 290183Document4 pagesMoeller Datasheet EMR4 W500 1 D 290183Marcio RangellNo ratings yet

- T.DANDA SIBUGAY Model2Document1 pageT.DANDA SIBUGAY Model2Bryan Lloyd PallegaNo ratings yet

- Performance Evaluation of On-Grid and Off-Grid Solar Photovoltaic SystemsDocument5 pagesPerformance Evaluation of On-Grid and Off-Grid Solar Photovoltaic SystemsSojol KumarNo ratings yet

- .Trashed-1673182817-GD100-PV Series Solar Pump VFD Manual - V1.0Document84 pages.Trashed-1673182817-GD100-PV Series Solar Pump VFD Manual - V1.0Anderson PiazziNo ratings yet

- Bill For JUly 2013parDocument2 pagesBill For JUly 2013parrpshvjuNo ratings yet

- Tutorial 9 - Brayton CycleDocument3 pagesTutorial 9 - Brayton CycleasdfsdjhNo ratings yet

- Hypersonic Hybrid VehicleDocument22 pagesHypersonic Hybrid Vehiclesearch1123No ratings yet

- Applications and Technological Development of Vertical Axis Wind Turbines of Hi-VAWT Technology CorpDocument10 pagesApplications and Technological Development of Vertical Axis Wind Turbines of Hi-VAWT Technology CorpGautham NNo ratings yet

- Open Circute Voltage (V) & Short Circute Current (A)Document9 pagesOpen Circute Voltage (V) & Short Circute Current (A)Thamotharan PirathapanNo ratings yet

- Literature AdDocument7 pagesLiterature AdSINDU ANUMALANo ratings yet

- If You Want To Save The Environment Imperatives Esl WorksheetDocument2 pagesIf You Want To Save The Environment Imperatives Esl WorksheetIya TemiNo ratings yet

- ENR 312: Wind Energy Technology: FALL 2021-2022 Lecture Notes Prepared by Asst. Prof. Dr. Neyre Tekbiyik ErsoyDocument25 pagesENR 312: Wind Energy Technology: FALL 2021-2022 Lecture Notes Prepared by Asst. Prof. Dr. Neyre Tekbiyik Ersoycılem cıuNo ratings yet

- Lecture Einstein Solid PDFDocument7 pagesLecture Einstein Solid PDFlantea1No ratings yet

- UNIT 10 - Lop 7Document6 pagesUNIT 10 - Lop 7Đặng Tiến DũngNo ratings yet

- Lab 4 Pacag Maryjoy G Bsabe4-1Document7 pagesLab 4 Pacag Maryjoy G Bsabe4-1Mary Joy Gonzales PacagNo ratings yet

- Refresher 3 PipeDocument11 pagesRefresher 3 PipeKira YagamiNo ratings yet

- GRD150 6F2S0842 0.8Document427 pagesGRD150 6F2S0842 0.8Nazi SweetNo ratings yet

- Ir Chong - SesbDocument26 pagesIr Chong - SesbNikhil Meshram50% (2)

- Marine Plate Heat ExchangerDocument6 pagesMarine Plate Heat ExchangerThet Aung Htay100% (1)

- CO2 Calculator EFNDocument17 pagesCO2 Calculator EFNyoppie arbhiNo ratings yet

- In This Lecture We Will Learn The Following:: GHJJJJ FSD KHJKMKFFJKHG ObjectivesDocument10 pagesIn This Lecture We Will Learn The Following:: GHJJJJ FSD KHJKMKFFJKHG ObjectivesDeborah RochaNo ratings yet

- IC Engines IntroductionDocument39 pagesIC Engines IntroductionalagurmNo ratings yet

- Nr17 GuidebookDocument20 pagesNr17 GuidebookIon ZabetNo ratings yet

- A0materials Science and EngineeringDocument58 pagesA0materials Science and EngineeringalfajNo ratings yet

- 5 EEA2010 - Ch-05 - Distribution and UtilizationDocument26 pages5 EEA2010 - Ch-05 - Distribution and UtilizationEffecure HealthcareNo ratings yet

- EE 158: Electrical System Design TDETWX Practice SetDocument2 pagesEE 158: Electrical System Design TDETWX Practice SetEmman Joshua BustoNo ratings yet