Professional Documents

Culture Documents

HL23

HL23

Uploaded by

Bogdan RusuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HL23

HL23

Uploaded by

Bogdan RusuCopyright:

Available Formats

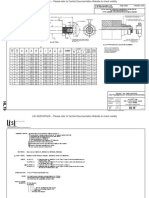

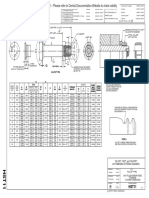

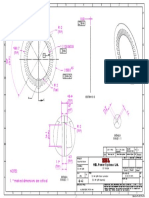

LISI AEROSPACE – Please refer to Central Documentation Website to check validity

S

HI-SHEAR Corporation, USA Design Holder CAGE No. 73197

AEROSPACE

a LISI AEROSPACE Company

23 For the current list of licensed manufacturers, please visit the

hi-shear corporation

LISI AEROSPACE website at:

2600 SKYPARK DRIVE, TORRANCE, CALIFORNIA 90509 U.S.A.

HTTP://WWW.LISI-AEROSPACE.COM/LICENSES

23

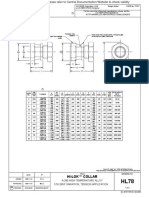

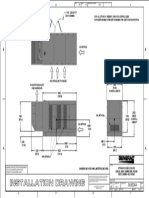

INDENTED HEAD MARKING .010 MAX DEPTH.

MANUFACTURER'S TRADEMARK "hs" PER REMAINING PORTION OF HI-LOK™

(MAX GRIP + B) ±.010 COLLAR AFTER ASSEMBLY

SPEC. 363. THE NUMBER(S) FOLLOWING

TRADEMARK INDICATES FIRST DASH. NO. 32

ARRANGEMENT OPTIONAL. W TYPICAL COLLARS:

MAX GRIP ± .005

HL77, HL182, HL277

T S CHAMFER

R RAD

23

HL

101° A Y 100°

23

99° DIA DIA 90°

8

hs

D TD

Z 8 DIA

DIA THREAD ROLLED PER AS8879

H COLLAR WRENCHING

(MODIFIED). MAJOR DIA SHALL DEVICE AUTOMATICALLY

BE PER "TD" SHEARS OFF

HI-LOK™ PIN

HI-LOK™ PIN AND COLLAR AFTER ASSEMBLY

1 8 23 SEE COLLAR STANDARDS

FOR COLLAR STRENGTHS.

SOCKET DOUBLE LOWER STRENGTH (PIN OR

FIRST PIN S SHEAR TENSION COLLAR) DETERMINES

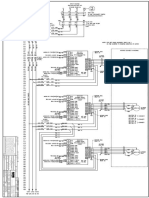

A B D TD R Z THREAD

DASH NOM F H CHAMFER W T Y POUNDS POUNDS SYSTEM STRENGTH

DIA REF DIA DIA RAD MAX MODIFIED

NO. DIA REF HEX DEPTH DIA MINIMUM MINIMUM

.2922 .1635 .1595 .0540 .025 .1640-32 .0645 .135 .090

5 5/32 .312 .004 .010 1/32 x 45° UNJC-3A 1,760 860

.2874 .1625 .1570 .0520 .015 .0635 .115 .075

.3536 .1895 .1840 .0688 .030 .1900-32 .0806 .135 .119

6 3/16 .325 .005 .015 1/32 x 45° UNJF-3A 2,550 1,150

.3486 .1885 .1810 .0667 .020 .0791 .115 .104

.4732 .2495 .2440 .0939 .030 .2500-28 .0967 .150 .142

8 1/4 .395 .006 .015 1/32 x 45° UNJF-3A 4,420 2,000

.4682 .2485 .2410 .0918 .020 .0947 .130 .122

.5619 .3120 .3060 .1048 .040 .3125-24 .1295 .170 .180

10 5/16 .500 .007 .015 3/64 x 45° UNJF-3A 6,900 2,800

.5569 .3110 .3020 .1027 .030 .1270 .150 .160

.6912 .3745 .3680 .1329 .040 .3750-24 .1617 .200 .217

12 3/8 .545 .008 .015 3/64 x 45° UNJF-3A 9,940 3,900

.6862 .3735 .3640 .1308 .030 .1582 .180 .197

.8041 .4370 .4310 .1540 .050 .4375-20 .1930 .230 .253

14 7/16 .635 .009 .022 3/64 x 45° UNJF-3A 13,800 6,000

.7969 .4360 .4260 .1510 .040 .1895 .210 .233

.9166 .4995 .4930 .1750 .050 .5000-20 .2242 .260 .289

16 1/2 .685 .010 .022 3/64 x 45° UNJF-3A 18,000 7,600

.9095 .4985 .4880 .1720 .040 .2207 .240 .269

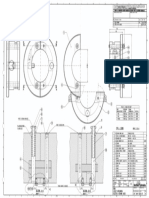

GENERAL NOTES: 1 Head edge out of roundness shall not exceed "F". SPECIFICATION: HI-LOK™ Product Specification 342 .

2. Concentricity: Conical surface of head to "D" diameter within .005 FIM.

3. "H" is dimensioned from maximum "D" diameter. CODE: First dash number indicates nominal diameter in 1/32nds.

23 4. Dimensions are in inches and to be met after finish. Second dash number indicates maximum grip in 1/16ths.

See Finish note for explanation of code letters.

23 5. Surface texture per ASME B46.1.

6. Hole preparation per NAS618.

7. Use HL123 for oversize replacement. HOW TO ORDER

23 EXAMPLE: Pin Part Number

8 Curved or flat edge manufacturer's option. HL23TT8-8

MATERIAL: 7075 aluminum alloy per AMS-QQ-A-225/9 or QQ-A-430.

8/16 or 1/2 Maximum Grip Length

HEAT TREAT: Age to T6 condition per AMS2770. 8/32 or 1/4 Nominal Diameter Pin

Finish Code

FINISH: HL23-( )-( ) = Anodize per MIL-A-8625, dye color natural and cetyl Pin Basic Part Number "HI-LOK", "HL", AND "HI-KOTE",

alcohol lube per Hi-Shear Spec. 305. ARE TRADEMARKS OF HI-SHEAR CORPORATION

HL23D( )-( ) = Anodize per MIL-A-8625, and solid film lube per

AS5272, Type I. DRAWN BY DATE TITLE

HL23TT( )-( ) = Anodize per MIL-A-8625, dye color natural and translube. R.K.L. 1962-05-08 HI-LOK™ PIN

100° FLUSH MS20426 SHEAR HEAD

HL23

APPROVED DATE

ALUMINUM ALLOY

CESSNA 1962-05-08

1/16 GRIP VARIATION

REVISION DATE DRAWING NUMBER

M.BEARD

23 2017-08-01

HL23 1 OF 1

C 2017 Hi-Shear Corporation

You might also like

- Micro Econ 6 Principles of Microeconomics 6Th Edition William A Mceachern Full ChapterDocument67 pagesMicro Econ 6 Principles of Microeconomics 6Th Edition William A Mceachern Full Chapterchristine.parsons231100% (6)

- Nas464 PDFDocument4 pagesNas464 PDFGlenn CHOU100% (1)

- John Deere 790 DLDocument211 pagesJohn Deere 790 DLCarlosFlores100% (1)

- Instagram Creators Handbook - IGTV PDFDocument48 pagesInstagram Creators Handbook - IGTV PDFAndrei Neațu100% (1)

- InterSchool Activity ScriptDocument7 pagesInterSchool Activity ScriptJessica Loren Leyco87% (15)

- Parcor CompuDocument14 pagesParcor CompuErika delos Santos100% (3)

- HL18 1Document2 pagesHL18 1FlorinNo ratings yet

- HL19Document2 pagesHL19Bogdan RusuNo ratings yet

- HL21Document2 pagesHL21Bogdan RusuNo ratings yet

- HST11Document2 pagesHST11何少杰No ratings yet

- HL22Document1 pageHL22Bogdan RusuNo ratings yet

- HL379Document1 pageHL379Renato WatanabeNo ratings yet

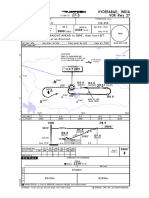

- Vor Rwy 27Document1 pageVor Rwy 27Hardeep KumarNo ratings yet

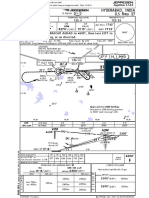

- Vohy Ils 27-PlainDocument1 pageVohy Ils 27-PlainRajeshNo ratings yet

- HL78Document2 pagesHL78Renato WatanabeNo ratings yet

- PDFDocument53 pagesPDFPhuc LeNo ratings yet

- Nas354 PDFDocument1 pageNas354 PDFGlenn CHOU100% (1)

- ,5 (-J - $438 DBGFC 631-44AJ: I Customer Part No., Y51 q955Document2 pages,5 (-J - $438 DBGFC 631-44AJ: I Customer Part No., Y51 q955dieselmotorsbogotasasNo ratings yet

- MODELDCGFC 629-15&G: Customer Part No. 4025676Document2 pagesMODELDCGFC 629-15&G: Customer Part No. 4025676dieselmotorsbogotasasNo ratings yet

- ArchDocument4 pagesArchCarlos Torres OliverosNo ratings yet

- MMBTDocument11 pagesMMBTCap Pa RamírezNo ratings yet

- Boeing FastenersDocument40 pagesBoeing FastenersnajibNo ratings yet

- National Aerospace Standard: Inactive For New Design After July 30, 1993. SEE NAS1003 THRU 1020. /9Document4 pagesNational Aerospace Standard: Inactive For New Design After July 30, 1993. SEE NAS1003 THRU 1020. /9Glenn CHOU100% (1)

- SRSC23Document2 pagesSRSC23ajsniffNo ratings yet

- Stinson SR-10 Reliant Specs For L940 Aircraft Specifications 1201Document11 pagesStinson SR-10 Reliant Specs For L940 Aircraft Specifications 1201wellingtonNo ratings yet

- Nas1921 AiaDocument4 pagesNas1921 AiaGrandiosNo ratings yet

- AN3054 - REV-8 Nut, Coupling, Electrical ConduitDocument1 pageAN3054 - REV-8 Nut, Coupling, Electrical ConduitMark JuhrigNo ratings yet

- Faor - Ils y Rwy 03l - Ils-02Document1 pageFaor - Ils y Rwy 03l - Ils-02prakashcapt46No ratings yet

- NBL Rear Axle 5300024 IDocument32 pagesNBL Rear Axle 5300024 Ialberto pedrozaNo ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- ROC-MSE-SPC-00157 - 01-Standard Pipe Support PDFDocument136 pagesROC-MSE-SPC-00157 - 01-Standard Pipe Support PDFAob AprilNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 10.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 10.DwgsartajNo ratings yet

- Model: Pump Injection SpecificationDocument2 pagesModel: Pump Injection SpecificationdieselmotorsbogotasasNo ratings yet

- Hood For DarrenDocument1 pageHood For Darrenryanbuchan36No ratings yet

- 3 J 4 DBGFCC631-2AE: Customer Part No. 79885Document2 pages3 J 4 DBGFCC631-2AE: Customer Part No. 79885Miguel RojasNo ratings yet

- Drawing Created From Pro/Engineer 3D File. Eco Modification To Be Applied To Solid Model OnlyDocument1 pageDrawing Created From Pro/Engineer 3D File. Eco Modification To Be Applied To Solid Model OnlyJuly E. Maldonado M.No ratings yet

- Fall Arrester DrawingDocument1 pageFall Arrester DrawingthomsonNo ratings yet

- VAC LRPW Rev2Document1 pageVAC LRPW Rev2Demostene NeacsiuNo ratings yet

- 12610D1SC JDocument33 pages12610D1SC JAngel AndinoNo ratings yet

- GE Lighting Systems and PolesDocument2 pagesGE Lighting Systems and PolesCel NimapNo ratings yet

- Slow Rpm.Document1 pageSlow Rpm.DTNgoNo ratings yet

- ARV-HII-ELECT-038 - XA - 28VDC Aux PWRDocument2 pagesARV-HII-ELECT-038 - XA - 28VDC Aux PWRArmando CastellanosNo ratings yet

- Aerospace Allloy 356AT-6, 4th Axis CNC Machined Top and Bottom! .062 Wall 6061T6 Seamless TubeDocument1 pageAerospace Allloy 356AT-6, 4th Axis CNC Machined Top and Bottom! .062 Wall 6061T6 Seamless Tubeниколай дехтярNo ratings yet

- HL77Document1 pageHL77Renato WatanabeNo ratings yet

- Sie Ban Rbo CNR Iml: Madrid, Spain Lemd/Mad Ilszorlocrwy18LDocument1 pageSie Ban Rbo CNR Iml: Madrid, Spain Lemd/Mad Ilszorlocrwy18LLuther Suerte III50% (2)

- Produced by An Autodesk Student Version: Al-Suki ArchitectsDocument1 pageProduced by An Autodesk Student Version: Al-Suki Architectsshady masoodNo ratings yet

- D PRXDocument1 pageD PRXDiana ArredondoNo ratings yet

- Item 1 - Ficha Tecnica IBOP Upper Canrig 1250 ACDocument6 pagesItem 1 - Ficha Tecnica IBOP Upper Canrig 1250 ACanghelo marquezNo ratings yet

- Operating ParametersDocument1 pageOperating Parameters陆军No ratings yet

- StairsDocument1 pageStairsALANA PACHECONo ratings yet

- SX-43 PF Sep1948Document8 pagesSX-43 PF Sep1948Eduardo Areco0% (1)

- Ils Dme Rwy17 Las AmericasDocument1 pageIls Dme Rwy17 Las Americasmoises baezNo ratings yet

- 70088-R-BJ101-XD-1333021 DDM - Ibop Mechanism Sleeve & Crank Assembly - 012922Document1 page70088-R-BJ101-XD-1333021 DDM - Ibop Mechanism Sleeve & Crank Assembly - 012922abdi rachmanNo ratings yet

- PrintDocument1 pagePrintRachid OugouadfelNo ratings yet

- Bg2082 Rev AaDocument2 pagesBg2082 Rev AaycwbycwbNo ratings yet

- Werna 162-164Document1 pageWerna 162-164YANdalfNo ratings yet

- Notes:: Drawing For Information Only Not For ConstructionDocument1 pageNotes:: Drawing For Information Only Not For ConstructionPandi KokoyNo ratings yet

- 27 JAN 22 Ad 2 Ltai Iac - 5 Turkey AIP Instrument Rwy 36C Catiorlocy Ils Y AntalyaDocument1 page27 JAN 22 Ad 2 Ltai Iac - 5 Turkey AIP Instrument Rwy 36C Catiorlocy Ils Y Antalyafhesap439No ratings yet

- ChartAccessServlet 2Document1 pageChartAccessServlet 2Alma BravoNo ratings yet

- Ds-pp-0010 - Mechanical Data Sheet Basket Strainers (Rev. 1)Document2 pagesDs-pp-0010 - Mechanical Data Sheet Basket Strainers (Rev. 1)Panisa BanimaNo ratings yet

- Rail and Wheels: Guide ChannelDocument1 pageRail and Wheels: Guide ChannelnarumenonNo ratings yet

- MV Dubai Knight - Bunker TablesDocument26 pagesMV Dubai Knight - Bunker Tablesfernandosirgo1No ratings yet

- Model: Catalog Page No: 50 0 - DBGFC63741AJ Customer Part NoDocument2 pagesModel: Catalog Page No: 50 0 - DBGFC63741AJ Customer Part NodieselmotorsbogotasasNo ratings yet

- AnalogI PDFDocument48 pagesAnalogI PDFJerc ZajNo ratings yet

- Sprui 03 BDocument329 pagesSprui 03 BHou BouNo ratings yet

- Budget Choux EkondjeDocument4 pagesBudget Choux EkondjePikol WeladjiNo ratings yet

- Directory of Old Age Homes in India 2009Document478 pagesDirectory of Old Age Homes in India 2009sonyadavid86% (7)

- Research Methods in Biomechanics: Second Edition (Ebook) : November 2013Document14 pagesResearch Methods in Biomechanics: Second Edition (Ebook) : November 2013Jun KimNo ratings yet

- Alogrithm 02Document69 pagesAlogrithm 02Nebiyu Tefera ShiteNo ratings yet

- Food Handlers Risk AssessmentDocument1 pageFood Handlers Risk AssessmentNidheesh K KNo ratings yet

- Boracay Foundation v. Province of AklanDocument3 pagesBoracay Foundation v. Province of AklanGabrielle Adine Santos100% (1)

- NX Nastran Error ListDocument224 pagesNX Nastran Error ListAdriana Livadariu100% (3)

- 5.5 KW SyRM Stator Lamination - 8 02 67 0015 - R00Document1 page5.5 KW SyRM Stator Lamination - 8 02 67 0015 - R00rakesh bardepurNo ratings yet

- A To Z: Social Media MarketingDocument89 pagesA To Z: Social Media MarketingJordan Kasteler100% (1)

- 2020.11.05 Taylor v. Doe ComplaintDocument62 pages2020.11.05 Taylor v. Doe ComplaintseahorsieNo ratings yet

- 2010-2016: Formation and Pre-Debut Activities: The X FactorDocument1 page2010-2016: Formation and Pre-Debut Activities: The X FactorHQNo ratings yet

- 416F SpecalogDocument9 pages416F Specalogagegnehutamirat100% (1)

- PMIT Admission Brochure - Spring 2021Document3 pagesPMIT Admission Brochure - Spring 2021Shayekh Mohiuddin Ahmed NavidNo ratings yet

- Data Bulletin Variable Frequency Drives and Short-Circuit Current RatingsDocument12 pagesData Bulletin Variable Frequency Drives and Short-Circuit Current Ratingsrenzo_aspa_orgNo ratings yet

- Using MySQL With LabVIEWDocument49 pagesUsing MySQL With LabVIEWsion2010363650% (2)

- Module 4Document3 pagesModule 4Queenie ValleNo ratings yet

- Fluke Bangladesh 368 FC Leakage Current Clamp MeterDocument4 pagesFluke Bangladesh 368 FC Leakage Current Clamp MeterFluke BangladeshNo ratings yet

- Learning Agreement Student Mobility For StudiesDocument6 pagesLearning Agreement Student Mobility For StudiesEmin FerhatovicNo ratings yet

- WB9CYY HW8 Mods 20240403Document27 pagesWB9CYY HW8 Mods 20240403bcpsr7sc86No ratings yet

- Activity Work ScheduleDocument7 pagesActivity Work ScheduleAndre JingNo ratings yet

- Account Statement From 27 Mar 2022 To 5 Apr 2022: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument2 pagesAccount Statement From 27 Mar 2022 To 5 Apr 2022: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalancePiyush AgarwalNo ratings yet

- Management of Information Systems in The Digital AgeDocument8 pagesManagement of Information Systems in The Digital Ageinescoste4No ratings yet

- Laboratory Exercise 1Document23 pagesLaboratory Exercise 1Paterson SoroñoNo ratings yet

- Isihskipper January 2010Document25 pagesIsihskipper January 2010enelcharcoNo ratings yet