Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

6 viewsLab P06 - Boron Ion Implantation and Annealing

Lab P06 - Boron Ion Implantation and Annealing

Uploaded by

Anh LuuThe document describes the process steps for boron ion implantation and annealing on a semiconductor wafer. The steps include: 1) implanting boron ions at 50 keV and a dose of 8×1014 #/cm2 at 7 degrees tilt, 2) annealing at 900C for 30 minutes to activate the implanted boron followed by a drive-in and oxidation process at 1000C, and 3) measuring the resulting oxide thickness.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- EE432/EE532 Microelectronic Fabrication Techniques: Final Lab ReportDocument28 pagesEE432/EE532 Microelectronic Fabrication Techniques: Final Lab Reportapi-546410997No ratings yet

- Metal Dusting Corrosion Initiation in Conversion of Natural Gas To Synthesis GasDocument24 pagesMetal Dusting Corrosion Initiation in Conversion of Natural Gas To Synthesis GasPrasanna RajaNo ratings yet

- Presentation On Semi Conductors and P-N Junction Diode FabricationDocument18 pagesPresentation On Semi Conductors and P-N Junction Diode FabricationPrudhvi BadeNo ratings yet

- MAE 536 Micro/Nano Electromechanical Systems: Yong Zhu Lecture 10 - Surface MicromachiningDocument48 pagesMAE 536 Micro/Nano Electromechanical Systems: Yong Zhu Lecture 10 - Surface MicromachiningAnonymous 8kdwhwUNo ratings yet

- EE-611 Lab Report Fabrication and Characterization of Organic Solar CellDocument6 pagesEE-611 Lab Report Fabrication and Characterization of Organic Solar Cellpeeyush_tapadiyaNo ratings yet

- Fabrication of 5 % Zn doped BaCe0.7Zr0.1Y0.15Zn0.05O3-δ electrolyteDocument19 pagesFabrication of 5 % Zn doped BaCe0.7Zr0.1Y0.15Zn0.05O3-δ electrolyteafif03.m21No ratings yet

- Reaction Analysis of Initial Oxidation of Silicon by Uv-Light-Excited Ozone and The Application To Rapid and Uniform Sio2 Film GrowthDocument8 pagesReaction Analysis of Initial Oxidation of Silicon by Uv-Light-Excited Ozone and The Application To Rapid and Uniform Sio2 Film GrowthAmitNo ratings yet

- Aashul Heda (BT10MME042) Akashy Toradmal (BT10MME021) Hetasha Vaidya (BT10MME043) Varun Pande (BT10MME065)Document7 pagesAashul Heda (BT10MME042) Akashy Toradmal (BT10MME021) Hetasha Vaidya (BT10MME043) Varun Pande (BT10MME065)Prashant ParshivnikarNo ratings yet

- Jeon 2017Document22 pagesJeon 2017Erdi Sofyandra AdikriNo ratings yet

- Raynaud 2002Document8 pagesRaynaud 2002MaximimilianoNo ratings yet

- Nitromet Liquid Ferritic NitrocarburizingDocument11 pagesNitromet Liquid Ferritic NitrocarburizingDoez AryanaNo ratings yet

- Hasmizam 2008Document6 pagesHasmizam 2008Ananda Vallezi PaladinoNo ratings yet

- EgunlaeandKutelu2008Anodizingcell 4thFORUM2008Document6 pagesEgunlaeandKutelu2008Anodizingcell 4thFORUM2008tseeree1 palam1No ratings yet

- Journal of The Taiwan Institute of Chemical Engineers: Tawfik A. Saleh, Gaddafi I. DanmalikiDocument9 pagesJournal of The Taiwan Institute of Chemical Engineers: Tawfik A. Saleh, Gaddafi I. DanmalikiPrativa BeheraNo ratings yet

- 1 s2.0 S096014819900097X MainDocument11 pages1 s2.0 S096014819900097X MaincimavNo ratings yet

- Fabrication of Pressure SensorDocument14 pagesFabrication of Pressure SensorTuan Anh NguyenNo ratings yet

- Bokov Et Al. - 2021 - Interplay Between Decarburization, Oxide Segregation, and DensificationDocument12 pagesBokov Et Al. - 2021 - Interplay Between Decarburization, Oxide Segregation, and DensificationAnna ShelyugNo ratings yet

- 1 s2.0 S0272884206002276 MainDocument5 pages1 s2.0 S0272884206002276 MainirmamendoNo ratings yet

- Chemical Mechanical Planarization of Patterned InP in Shallow TrenchDocument5 pagesChemical Mechanical Planarization of Patterned InP in Shallow TrenchitaloxyyNo ratings yet

- Chem 509Document13 pagesChem 509ezzaabrar44No ratings yet

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaDocument6 pagesCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôNo ratings yet

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaDocument6 pagesCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôNo ratings yet

- Fadillah 2021 J. Phys. - Conf. Ser. 1816 012019Document8 pagesFadillah 2021 J. Phys. - Conf. Ser. 1816 012019Ari Sulistyo RIniNo ratings yet

- Optimization of Mechanical Behavior of Ni-P Nanocomposite Coatings Using Taguchi ApproachDocument12 pagesOptimization of Mechanical Behavior of Ni-P Nanocomposite Coatings Using Taguchi ApproachTJPRC PublicationsNo ratings yet

- Synergetic Effect Between Copper Oxide and Ceria For Soot Catalytic OxidationDocument22 pagesSynergetic Effect Between Copper Oxide and Ceria For Soot Catalytic OxidationMaterials Research InstituteNo ratings yet

- Effects of Ba Loading and Calcination Temperature On Baal O Formation For Bao/Al O No Storage and Reduction CatalystsDocument8 pagesEffects of Ba Loading and Calcination Temperature On Baal O Formation For Bao/Al O No Storage and Reduction CatalystsRia DevitasariNo ratings yet

- Co Adsorption On Clean and Atomic-Layer-Cu-Covered Zno (1010) SurfacesDocument5 pagesCo Adsorption On Clean and Atomic-Layer-Cu-Covered Zno (1010) Surfacesleminhlan19214565No ratings yet

- Cathode Properties of Na - 3MPO - 4CO - 3Document6 pagesCathode Properties of Na - 3MPO - 4CO - 3Dinar IstiyantoNo ratings yet

- Poll Res-61 - Published Paper - Priyanka WaditakeDocument6 pagesPoll Res-61 - Published Paper - Priyanka WaditakePrashantNo ratings yet

- Synthesis of GrapheneDocument7 pagesSynthesis of GrapheneMostafa DadashbabaNo ratings yet

- Metallurgical FurnacesDocument6 pagesMetallurgical FurnacesJuan Ignacio Gonzalez CabreraNo ratings yet

- 2010 - Preparation of Nanocrystalline Lithium Niobate Powders at Low TemperatureDocument6 pages2010 - Preparation of Nanocrystalline Lithium Niobate Powders at Low Temperature13408169705No ratings yet

- Unit - IDocument69 pagesUnit - IsaravananNo ratings yet

- VLSI Process Technology (ECE 5124)Document2 pagesVLSI Process Technology (ECE 5124)meenakshimani996No ratings yet

- Thin Solid Films: Atif Mossad Ali, Adel A. Ismail, Rasha Najmy, Ali Al-HajryDocument7 pagesThin Solid Films: Atif Mossad Ali, Adel A. Ismail, Rasha Najmy, Ali Al-HajryHamada Shoukry MohammedNo ratings yet

- Novel Synthesis of SrBi2Nb2O9 Powders From Hydroxide PrecursorsDocument4 pagesNovel Synthesis of SrBi2Nb2O9 Powders From Hydroxide PrecursorsMuthu RajanNo ratings yet

- Tan 2020 Mater. Res. Express 7 015059Document9 pagesTan 2020 Mater. Res. Express 7 015059Jeisson PerezNo ratings yet

- Summer Project 2019: S N Bose National Centre For Basic ScienceDocument19 pagesSummer Project 2019: S N Bose National Centre For Basic ScienceNopu BhutiaNo ratings yet

- RAPDDocument4 pagesRAPD123vidyaNo ratings yet

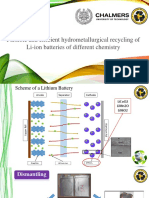

- Flexible and Efficient Hydrometallurgical Recycling of Li-Ion Batteries of Different ChemistryDocument46 pagesFlexible and Efficient Hydrometallurgical Recycling of Li-Ion Batteries of Different Chemistrytaufiq_hidayat_1982No ratings yet

- Facile Synthesis of Bcno Yellow-Emitting Phosphors Applications For White Leds by Microwave HeatingDocument7 pagesFacile Synthesis of Bcno Yellow-Emitting Phosphors Applications For White Leds by Microwave HeatingRiriNo ratings yet

- Ball Milling Effect On The Structure of Single-Wall Carbon NanotubesDocument7 pagesBall Milling Effect On The Structure of Single-Wall Carbon NanotubesLondon BridgeNo ratings yet

- Chapter 2: CMOS Technology: Instructor: Dr. Po-Wen Chiu (EE/NTHU)Document35 pagesChapter 2: CMOS Technology: Instructor: Dr. Po-Wen Chiu (EE/NTHU)王靖堯No ratings yet

- IR Study of PB-SR Titanate Borosilicate GlassesDocument4 pagesIR Study of PB-SR Titanate Borosilicate GlassesMiranti PuspitasariNo ratings yet

- Research Article Effect of Ce Addition On Adsorption and Oxidation of No Over Mno /al ODocument8 pagesResearch Article Effect of Ce Addition On Adsorption and Oxidation of No Over Mno /al OIka Ria Indriani 2110246987No ratings yet

- Kci Fi001467849Document5 pagesKci Fi001467849Valeria ChacónNo ratings yet

- Application of Tio2-Mounted Activated Carbon To The Removal of Phenol From WaterDocument8 pagesApplication of Tio2-Mounted Activated Carbon To The Removal of Phenol From WaterA. M. SHAREQUENo ratings yet

- Zhu 2014 Fabrication of ZnO and TiO2 Combined Activated Carbon NanocompositeDocument4 pagesZhu 2014 Fabrication of ZnO and TiO2 Combined Activated Carbon Nanocompositeluke nguNo ratings yet

- EP0619600A2Document5 pagesEP0619600A2JBertrandNo ratings yet

- Research Article: The Improved Photocatalytic Properties of Methylene Blue For V O /Cnt/Tio Composite Under Visible LightDocument5 pagesResearch Article: The Improved Photocatalytic Properties of Methylene Blue For V O /Cnt/Tio Composite Under Visible LightguleruyarNo ratings yet

- Best Paper For ResearchDocument7 pagesBest Paper For ResearchHumaira KhalilNo ratings yet

- 1 s2.0 S0008622303006389 Main PDFDocument5 pages1 s2.0 S0008622303006389 Main PDFŞebnem Gül İlarslanNo ratings yet

- 2015 XPS Investigation of Impurities Containing Boron Films Affected by Energetic Deuterium Implantation and Thermal DesorptionDocument6 pages2015 XPS Investigation of Impurities Containing Boron Films Affected by Energetic Deuterium Implantation and Thermal DesorptionyouamareNo ratings yet

- MARBN SteelDocument16 pagesMARBN SteelTibor KeményNo ratings yet

- Amru Daulay, Andriayani, Marpongahtun, Saharman Gea, TamrinDocument8 pagesAmru Daulay, Andriayani, Marpongahtun, Saharman Gea, TamrinAmru DaulayNo ratings yet

- Flow Cytometer ReportDocument3 pagesFlow Cytometer ReportikechiNo ratings yet

- Ensc 851 PDFDocument13 pagesEnsc 851 PDFMubina SarwarNo ratings yet

- CMOS Processing Technology Silicon: A Semiconductor With Resistance Between That of Conductor and AnDocument18 pagesCMOS Processing Technology Silicon: A Semiconductor With Resistance Between That of Conductor and AntmdmurthyNo ratings yet

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- HWK 4 Spring 2023Document1 pageHWK 4 Spring 2023Anh LuuNo ratings yet

- Bell States and Quantum TeleportationDocument11 pagesBell States and Quantum TeleportationAnh LuuNo ratings yet

- AlgorithmDocument2 pagesAlgorithmAnh LuuNo ratings yet

- Grover Algorithm Spring 2023Document25 pagesGrover Algorithm Spring 2023Anh LuuNo ratings yet

- Lab P12 - Sheet Resistance MeasurementDocument2 pagesLab P12 - Sheet Resistance MeasurementAnh LuuNo ratings yet

- Lab P10-P11 - 4th Lithography (Aluminum Metal-Line)Document1 pageLab P10-P11 - 4th Lithography (Aluminum Metal-Line)Anh LuuNo ratings yet

- 1-EECE 6041 IntroductionDocument18 pages1-EECE 6041 IntroductionAnh LuuNo ratings yet

- Lab P09 - Aluminum Deposition and SinteringDocument1 pageLab P09 - Aluminum Deposition and SinteringAnh LuuNo ratings yet

- 2-EECE 6041 OxidationDocument10 pages2-EECE 6041 OxidationAnh LuuNo ratings yet

- 8-EECE 6041 Piezoresistive Pressure Sensor - Part2Document14 pages8-EECE 6041 Piezoresistive Pressure Sensor - Part2Anh LuuNo ratings yet

Lab P06 - Boron Ion Implantation and Annealing

Lab P06 - Boron Ion Implantation and Annealing

Uploaded by

Anh Luu0 ratings0% found this document useful (0 votes)

6 views1 pageThe document describes the process steps for boron ion implantation and annealing on a semiconductor wafer. The steps include: 1) implanting boron ions at 50 keV and a dose of 8×1014 #/cm2 at 7 degrees tilt, 2) annealing at 900C for 30 minutes to activate the implanted boron followed by a drive-in and oxidation process at 1000C, and 3) measuring the resulting oxide thickness.

Original Description:

Microfabrication

Original Title

Lab P06 - Boron Ion Implantation and annealing

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes the process steps for boron ion implantation and annealing on a semiconductor wafer. The steps include: 1) implanting boron ions at 50 keV and a dose of 8×1014 #/cm2 at 7 degrees tilt, 2) annealing at 900C for 30 minutes to activate the implanted boron followed by a drive-in and oxidation process at 1000C, and 3) measuring the resulting oxide thickness.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

6 views1 pageLab P06 - Boron Ion Implantation and Annealing

Lab P06 - Boron Ion Implantation and Annealing

Uploaded by

Anh LuuThe document describes the process steps for boron ion implantation and annealing on a semiconductor wafer. The steps include: 1) implanting boron ions at 50 keV and a dose of 8×1014 #/cm2 at 7 degrees tilt, 2) annealing at 900C for 30 minutes to activate the implanted boron followed by a drive-in and oxidation process at 1000C, and 3) measuring the resulting oxide thickness.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

UNIVERSITY OF CINCINNATI

EECE 5141/6041: Microfabrication Lab for Semiconductor Devices and MEMS

Lab P06: Boron Ion Implantation and Annealing/Drive-in

Procedures

1. Boron Ion Implantation

(a). The ion implantation parameters for satisfying the conditions are as follows.

Energy: 50 keV

Dose: 8×1014 #/cm2

Species: Boron

Offset (tilt): 7 degrees

Rp (projected range): 1,566 Å

ΔRp (projected range): 504 Å

(b). Remove PR with AZ NMP Rinse (Positive PR Stripper) at 80-90°C for about 1 hour.

(c). Perform Baker Clean process

2. Annealing/Drive-in and oxidation

Annealing is carried out at 900°C for 30 minutes in nitrogen gas to heal the damaged tracks in

the semiconductor crystal lattice due to high-energy implantation and also to activate the

implanted boron. After this, the drive-in and oxidation processes are carried out at 1000 °C.

The process conditions for this step are as follows.

Dry O2 10 min Si + O2 → SiO2

Wet O2 40 min Si + 2H2O → SiO2 + 2H2

Dry O2 10 min Si + O2 → SiO2

Unload wafer in N2 (idle gas)

3. Measure the oxide thickness.

4. Protect the front side of the wafer with PR coating. [Recipe 28 in Lab P02]

HMDS coating → PR coating → Hard bake

5. Dip the PR coated wafer in BOE solution to remove the oxide on the back side of the wafer to

prepare for anodic bonding. Calculate the time for BOE according to the oxide thickness.

6. Remove PR with AZ NMP Rinse. Clean wafer with acetone, IPA and DI water to make sure

PR residue is fully removed.

You might also like

- EE432/EE532 Microelectronic Fabrication Techniques: Final Lab ReportDocument28 pagesEE432/EE532 Microelectronic Fabrication Techniques: Final Lab Reportapi-546410997No ratings yet

- Metal Dusting Corrosion Initiation in Conversion of Natural Gas To Synthesis GasDocument24 pagesMetal Dusting Corrosion Initiation in Conversion of Natural Gas To Synthesis GasPrasanna RajaNo ratings yet

- Presentation On Semi Conductors and P-N Junction Diode FabricationDocument18 pagesPresentation On Semi Conductors and P-N Junction Diode FabricationPrudhvi BadeNo ratings yet

- MAE 536 Micro/Nano Electromechanical Systems: Yong Zhu Lecture 10 - Surface MicromachiningDocument48 pagesMAE 536 Micro/Nano Electromechanical Systems: Yong Zhu Lecture 10 - Surface MicromachiningAnonymous 8kdwhwUNo ratings yet

- EE-611 Lab Report Fabrication and Characterization of Organic Solar CellDocument6 pagesEE-611 Lab Report Fabrication and Characterization of Organic Solar Cellpeeyush_tapadiyaNo ratings yet

- Fabrication of 5 % Zn doped BaCe0.7Zr0.1Y0.15Zn0.05O3-δ electrolyteDocument19 pagesFabrication of 5 % Zn doped BaCe0.7Zr0.1Y0.15Zn0.05O3-δ electrolyteafif03.m21No ratings yet

- Reaction Analysis of Initial Oxidation of Silicon by Uv-Light-Excited Ozone and The Application To Rapid and Uniform Sio2 Film GrowthDocument8 pagesReaction Analysis of Initial Oxidation of Silicon by Uv-Light-Excited Ozone and The Application To Rapid and Uniform Sio2 Film GrowthAmitNo ratings yet

- Aashul Heda (BT10MME042) Akashy Toradmal (BT10MME021) Hetasha Vaidya (BT10MME043) Varun Pande (BT10MME065)Document7 pagesAashul Heda (BT10MME042) Akashy Toradmal (BT10MME021) Hetasha Vaidya (BT10MME043) Varun Pande (BT10MME065)Prashant ParshivnikarNo ratings yet

- Jeon 2017Document22 pagesJeon 2017Erdi Sofyandra AdikriNo ratings yet

- Raynaud 2002Document8 pagesRaynaud 2002MaximimilianoNo ratings yet

- Nitromet Liquid Ferritic NitrocarburizingDocument11 pagesNitromet Liquid Ferritic NitrocarburizingDoez AryanaNo ratings yet

- Hasmizam 2008Document6 pagesHasmizam 2008Ananda Vallezi PaladinoNo ratings yet

- EgunlaeandKutelu2008Anodizingcell 4thFORUM2008Document6 pagesEgunlaeandKutelu2008Anodizingcell 4thFORUM2008tseeree1 palam1No ratings yet

- Journal of The Taiwan Institute of Chemical Engineers: Tawfik A. Saleh, Gaddafi I. DanmalikiDocument9 pagesJournal of The Taiwan Institute of Chemical Engineers: Tawfik A. Saleh, Gaddafi I. DanmalikiPrativa BeheraNo ratings yet

- 1 s2.0 S096014819900097X MainDocument11 pages1 s2.0 S096014819900097X MaincimavNo ratings yet

- Fabrication of Pressure SensorDocument14 pagesFabrication of Pressure SensorTuan Anh NguyenNo ratings yet

- Bokov Et Al. - 2021 - Interplay Between Decarburization, Oxide Segregation, and DensificationDocument12 pagesBokov Et Al. - 2021 - Interplay Between Decarburization, Oxide Segregation, and DensificationAnna ShelyugNo ratings yet

- 1 s2.0 S0272884206002276 MainDocument5 pages1 s2.0 S0272884206002276 MainirmamendoNo ratings yet

- Chemical Mechanical Planarization of Patterned InP in Shallow TrenchDocument5 pagesChemical Mechanical Planarization of Patterned InP in Shallow TrenchitaloxyyNo ratings yet

- Chem 509Document13 pagesChem 509ezzaabrar44No ratings yet

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaDocument6 pagesCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôNo ratings yet

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaDocument6 pagesCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôNo ratings yet

- Fadillah 2021 J. Phys. - Conf. Ser. 1816 012019Document8 pagesFadillah 2021 J. Phys. - Conf. Ser. 1816 012019Ari Sulistyo RIniNo ratings yet

- Optimization of Mechanical Behavior of Ni-P Nanocomposite Coatings Using Taguchi ApproachDocument12 pagesOptimization of Mechanical Behavior of Ni-P Nanocomposite Coatings Using Taguchi ApproachTJPRC PublicationsNo ratings yet

- Synergetic Effect Between Copper Oxide and Ceria For Soot Catalytic OxidationDocument22 pagesSynergetic Effect Between Copper Oxide and Ceria For Soot Catalytic OxidationMaterials Research InstituteNo ratings yet

- Effects of Ba Loading and Calcination Temperature On Baal O Formation For Bao/Al O No Storage and Reduction CatalystsDocument8 pagesEffects of Ba Loading and Calcination Temperature On Baal O Formation For Bao/Al O No Storage and Reduction CatalystsRia DevitasariNo ratings yet

- Co Adsorption On Clean and Atomic-Layer-Cu-Covered Zno (1010) SurfacesDocument5 pagesCo Adsorption On Clean and Atomic-Layer-Cu-Covered Zno (1010) Surfacesleminhlan19214565No ratings yet

- Cathode Properties of Na - 3MPO - 4CO - 3Document6 pagesCathode Properties of Na - 3MPO - 4CO - 3Dinar IstiyantoNo ratings yet

- Poll Res-61 - Published Paper - Priyanka WaditakeDocument6 pagesPoll Res-61 - Published Paper - Priyanka WaditakePrashantNo ratings yet

- Synthesis of GrapheneDocument7 pagesSynthesis of GrapheneMostafa DadashbabaNo ratings yet

- Metallurgical FurnacesDocument6 pagesMetallurgical FurnacesJuan Ignacio Gonzalez CabreraNo ratings yet

- 2010 - Preparation of Nanocrystalline Lithium Niobate Powders at Low TemperatureDocument6 pages2010 - Preparation of Nanocrystalline Lithium Niobate Powders at Low Temperature13408169705No ratings yet

- Unit - IDocument69 pagesUnit - IsaravananNo ratings yet

- VLSI Process Technology (ECE 5124)Document2 pagesVLSI Process Technology (ECE 5124)meenakshimani996No ratings yet

- Thin Solid Films: Atif Mossad Ali, Adel A. Ismail, Rasha Najmy, Ali Al-HajryDocument7 pagesThin Solid Films: Atif Mossad Ali, Adel A. Ismail, Rasha Najmy, Ali Al-HajryHamada Shoukry MohammedNo ratings yet

- Novel Synthesis of SrBi2Nb2O9 Powders From Hydroxide PrecursorsDocument4 pagesNovel Synthesis of SrBi2Nb2O9 Powders From Hydroxide PrecursorsMuthu RajanNo ratings yet

- Tan 2020 Mater. Res. Express 7 015059Document9 pagesTan 2020 Mater. Res. Express 7 015059Jeisson PerezNo ratings yet

- Summer Project 2019: S N Bose National Centre For Basic ScienceDocument19 pagesSummer Project 2019: S N Bose National Centre For Basic ScienceNopu BhutiaNo ratings yet

- RAPDDocument4 pagesRAPD123vidyaNo ratings yet

- Flexible and Efficient Hydrometallurgical Recycling of Li-Ion Batteries of Different ChemistryDocument46 pagesFlexible and Efficient Hydrometallurgical Recycling of Li-Ion Batteries of Different Chemistrytaufiq_hidayat_1982No ratings yet

- Facile Synthesis of Bcno Yellow-Emitting Phosphors Applications For White Leds by Microwave HeatingDocument7 pagesFacile Synthesis of Bcno Yellow-Emitting Phosphors Applications For White Leds by Microwave HeatingRiriNo ratings yet

- Ball Milling Effect On The Structure of Single-Wall Carbon NanotubesDocument7 pagesBall Milling Effect On The Structure of Single-Wall Carbon NanotubesLondon BridgeNo ratings yet

- Chapter 2: CMOS Technology: Instructor: Dr. Po-Wen Chiu (EE/NTHU)Document35 pagesChapter 2: CMOS Technology: Instructor: Dr. Po-Wen Chiu (EE/NTHU)王靖堯No ratings yet

- IR Study of PB-SR Titanate Borosilicate GlassesDocument4 pagesIR Study of PB-SR Titanate Borosilicate GlassesMiranti PuspitasariNo ratings yet

- Research Article Effect of Ce Addition On Adsorption and Oxidation of No Over Mno /al ODocument8 pagesResearch Article Effect of Ce Addition On Adsorption and Oxidation of No Over Mno /al OIka Ria Indriani 2110246987No ratings yet

- Kci Fi001467849Document5 pagesKci Fi001467849Valeria ChacónNo ratings yet

- Application of Tio2-Mounted Activated Carbon To The Removal of Phenol From WaterDocument8 pagesApplication of Tio2-Mounted Activated Carbon To The Removal of Phenol From WaterA. M. SHAREQUENo ratings yet

- Zhu 2014 Fabrication of ZnO and TiO2 Combined Activated Carbon NanocompositeDocument4 pagesZhu 2014 Fabrication of ZnO and TiO2 Combined Activated Carbon Nanocompositeluke nguNo ratings yet

- EP0619600A2Document5 pagesEP0619600A2JBertrandNo ratings yet

- Research Article: The Improved Photocatalytic Properties of Methylene Blue For V O /Cnt/Tio Composite Under Visible LightDocument5 pagesResearch Article: The Improved Photocatalytic Properties of Methylene Blue For V O /Cnt/Tio Composite Under Visible LightguleruyarNo ratings yet

- Best Paper For ResearchDocument7 pagesBest Paper For ResearchHumaira KhalilNo ratings yet

- 1 s2.0 S0008622303006389 Main PDFDocument5 pages1 s2.0 S0008622303006389 Main PDFŞebnem Gül İlarslanNo ratings yet

- 2015 XPS Investigation of Impurities Containing Boron Films Affected by Energetic Deuterium Implantation and Thermal DesorptionDocument6 pages2015 XPS Investigation of Impurities Containing Boron Films Affected by Energetic Deuterium Implantation and Thermal DesorptionyouamareNo ratings yet

- MARBN SteelDocument16 pagesMARBN SteelTibor KeményNo ratings yet

- Amru Daulay, Andriayani, Marpongahtun, Saharman Gea, TamrinDocument8 pagesAmru Daulay, Andriayani, Marpongahtun, Saharman Gea, TamrinAmru DaulayNo ratings yet

- Flow Cytometer ReportDocument3 pagesFlow Cytometer ReportikechiNo ratings yet

- Ensc 851 PDFDocument13 pagesEnsc 851 PDFMubina SarwarNo ratings yet

- CMOS Processing Technology Silicon: A Semiconductor With Resistance Between That of Conductor and AnDocument18 pagesCMOS Processing Technology Silicon: A Semiconductor With Resistance Between That of Conductor and AntmdmurthyNo ratings yet

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- HWK 4 Spring 2023Document1 pageHWK 4 Spring 2023Anh LuuNo ratings yet

- Bell States and Quantum TeleportationDocument11 pagesBell States and Quantum TeleportationAnh LuuNo ratings yet

- AlgorithmDocument2 pagesAlgorithmAnh LuuNo ratings yet

- Grover Algorithm Spring 2023Document25 pagesGrover Algorithm Spring 2023Anh LuuNo ratings yet

- Lab P12 - Sheet Resistance MeasurementDocument2 pagesLab P12 - Sheet Resistance MeasurementAnh LuuNo ratings yet

- Lab P10-P11 - 4th Lithography (Aluminum Metal-Line)Document1 pageLab P10-P11 - 4th Lithography (Aluminum Metal-Line)Anh LuuNo ratings yet

- 1-EECE 6041 IntroductionDocument18 pages1-EECE 6041 IntroductionAnh LuuNo ratings yet

- Lab P09 - Aluminum Deposition and SinteringDocument1 pageLab P09 - Aluminum Deposition and SinteringAnh LuuNo ratings yet

- 2-EECE 6041 OxidationDocument10 pages2-EECE 6041 OxidationAnh LuuNo ratings yet

- 8-EECE 6041 Piezoresistive Pressure Sensor - Part2Document14 pages8-EECE 6041 Piezoresistive Pressure Sensor - Part2Anh LuuNo ratings yet