Professional Documents

Culture Documents

MIP17 - HSE - PP - 032 Four Week Look Ahead HIP August 2023 Rev 0

MIP17 - HSE - PP - 032 Four Week Look Ahead HIP August 2023 Rev 0

Uploaded by

AmeerHamzaWarraichCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MIP17 - HSE - PP - 032 Four Week Look Ahead HIP August 2023 Rev 0

MIP17 - HSE - PP - 032 Four Week Look Ahead HIP August 2023 Rev 0

Uploaded by

AmeerHamzaWarraichCopyright:

Available Formats

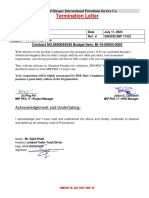

Branch of Sinopec International Petroleum Services Corp.

MIP PKG 17 Ras Tanura Area Pipelines

CONTRACT No.: 6600044545 BI No.: BI-10-09004-0003

Hazard Identification Plan (HIP)

(Based on ‘’Four” Week Look Ahead Schedule)

August – 2023.

DOCUMENT No.: MIP17 – HSE – PP – 032 REVISION: 0

MIP17 – HSE – PP – 032 REV 0 Page 1 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines

BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) AUG- 2023

MIP PKG 17 Ras Tanura Area Pipelines

CONTRACT No.: 6600044545

BI-10-09004-0003

Julius G.

Xu Pingfei

Carbonell

HSSE

0 18/07/2023 First Issue for Review & Approval HSSE Manager Project Manager

Department

Prepared Reviewed Approved

Rev. No. Date Reason for Issue

By By By

Document Title:

Four Week Look Ahead Hazard Identification Plan (HIP) August- 2023

Document No.: Rev. No.: Issue/Rev. Date:

MIP17 – HSE – PP – 032 0 18/07/2023

Submitted by:

MIP17 – HSE – PP – 032 REV 0 Page 2 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines

BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) AUG- 2023

Table of Contents

1.0 INTRODUCTION ................................................................................................................................................................. 4

2.0 HAZARD CLASSIFICATION ............................................................................................................................................. 4

3.0 AUDIENCE ............................................................................................................................................................................ 5

4.0 EMERGENCY CONTACT LIST ........................................................................................................................................ 6

5.0 ROLES & RESPONSIBILITES........................................................................................................................................... 7

MIP17 – HSE – PP – 032 REV 0 Page 3 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) AUG- 2023

1.0 INTRODUCTION

This Hazard Identification Plan is not intended to replace and/or repeat the content of the Project Hazard Identification Plan but only to focus on the

hazards, controls, barriers, and safeguards relating to the upcoming ‘Four Week Construction Look Ahead’.

These hazards, controls, barriers, and safeguards are triggered by the construction activities to be undertaken, environmental factors, current issues,

recent incidents, or assessments.

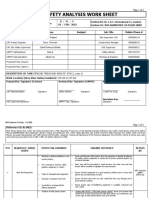

2.0 HAZARD CLASSIFICATION

When identifying hazards associated with the listed activity first determine what the realistic consequence is, then identify what the probability of that

consequence occurring is. By plotting these two in the A3 worksheet you will come up with Higher and Medium risk activities.

DEFINITION Severity Consequence

SAFETY / HEALTH ENVIRONMENTAL IMPACT DEFINITION

IMPACT 1 2 3 4 5

1 No injury or damage to No or slight effect 1 Very Low - Never heard of in the industry 5

health

CONSEQUENCE CATEGORY

PROBABILITY CATEGORY

2 Treatment beyond First Minor contamination 2 Low - Some instances in the industry 4 1,2,3,4,5,6,7,8,9,

Aid

10,11,12,13,14,15,

16,17,18,19

Probability

3 Lost time or restricted Localized event 3 Medium - Incident has happened in the company 3 20,21,

work

22,23,24,25,26,27

4 Single fatality or No significant lasting 4 High - Happens several times a year in the company 2

permanent disability consequence

5 Multiple fatalities Lasting consequence 5 Very High - Happens several times a year in the facility 1

MIP17 – HSE – PP – 032 REV 0 Page 4 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) AUG- 2023

3.0 AUDIENCE

This Hazard Identification Plan is developed by the contractor and the intended audience are the Contractor Leads/Supervisors & Safety Officers. SAPMT

should also be made aware of the hazards involved and the controls that should be put in place to ensure an incident free workplace, SAPMT will use this

Hazard Identification Plan as reference for Safety Walks and Site Visits.

1,2,3,4,5,6,7,8,9,

4 10,11,12,1314,15,

16,17,18,19

LIKELIHOOD

20,21,

3 22,23,24,25,26,27

1 2 3 4 5

CONSEQUENCES

MIP17 – HSE – PP – 032 REV 0 Page 5 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) AUG- 2023

4.0 EMERGENCY CONTACT LIST

MIP17 – HSE – PP – 032 REV 0 Page 6 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) AUG- 2023

5.0 ROLES & RESPONSIBILITES

The Roles & Responsibilities involved in executing this Hazard Identification Plan are detailed in the RACI Chart below:

Contractor

Contractor Contractor HSE Contractor Contractor SAPMT SAPMT

Discipline

Const. Mgr. Team HSE DC SPE Engineer

Lead

Develop Hazard Identification Plan

based on the Four Week Look ahead A R - - -

Schedule

Determine activities for each craft A C&R - - -

Identify potential hazards

A C&R I C

Assess the level of risk (consequence

C&R C

x probability)

Identify controls barriers & safeguards

to eliminate/reduce C&R C

consequence/severity of an incident

Disseminate to Craft Supervisors C&R

Transmit to SAPMT A R I

Assign to SAPMT Engineer to verify

that controls barriers & safeguards R I

listed have been implemented

SAPMT Engineer to verify that

controls barriers & safeguards listed A R

have been implemented

Communicate any gaps to the

I A R

Contractor WHO?

R = Responsible, A = Accountable, C = Consult, I = Informed

MIP17 – HSE – PP – 033 REV 0 Page 7 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

Pre-Mitigated Risk Controls / Barriers / Safeguards

Category/

No

Activity

Location Scenario Potential Hazards Consequenc Probabilit Responsible

e y

Rating List all required

ENGINEERING CONTROL:-

a. Uncertified welder a. Obtain the valid work permit from Saudi

Aramco or Internal work permit system

b. Fire/explosion b. Approved HIP, Method Statement and JSA Construction

c. Damage to new must be in place. Sinopec PM

instruments / c. Permit issuer and Permit receiver shall conduct Sinopec CM

cables, etc. joint inspection prior to start the welding activity

d. Only an approved welder shall be allowed to Sinopec Supv.

d. Electrocution perform welding job HSE Manager

All Active e. Prior to commencing open flame work, all

Pipeline e. Hand injury HSE Supv.

combustible materials should be removed from

Location Welding,

Welding and f. Eye injury the working area. HSE officer

1 (If

Grinding (Hot Cutting, f. Install proper welding booth with approved fire

applicabl g. Lack of work permit Work permit

works) Grinding Brazing blanket.

e) a related document. g. Watering of work area at completion of work to receiver/issuer

and Tie-in

High

4 4 ensure no smoldering occurs.

h. Fire, injury to h. Ensure Proper housekeeping

i. Trained fire watch must stay a minimum of 30

personnel Client:

minutes at the end-of-shift for inspection of the

i. Damage to area to detect possible smoldering fires / Abdullah

ensure area is in safe condition after work shift. Muhawish

equipment

j. Construction supervisor Task-specific JSA

j. Burn / eye irritation should be discussed and explained to the work Fahad Al-

force. Almokhlies

k. Pinch point when

k. Adequate proper handling of lifting equipment Michael labios

installing / removing

to be use and proper inspection shall be

fit-up clamps Omar Malki

conducted prior to start the activity

l. Ensure to maintain adequate welding habitat Ali Alaradi

l. Struck by Vehicles OE&CG

(box up) using fire blanket

& H. E

m. Ensure the surrounding working area shall be

free of combustible materials

m. Caught in between

MIP17 – HSE – PP – 032 REV 0 Page 8 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

n. Provide adequate UL fire extinguishers

n. Striking the existing o. Pay welding machine shall in good working

facilities condition

p. Only qualified operator shall operate the pay

o. Defective equipment welding tractor

q. Make sure that the Pay welder with Lifting

Capacity is rated with the equipment being lift.

r. Daily checklists of the pay welding tractor shall

be conducted prior the start of the job

s. Make sure that the 3rd party inspection sticker

of pay welding tractor are conducted and valid

t. Electrical equipment shall be regularly checked

for defects.

u. All electrical cable, distribution panel box on

the pay welding tractor is properly arranged

and protected from the contact of employees at

the working area.

v. Danger electrical hazard Warning signages

shall be posted on the power engine and

distribution panel box.

w. Proper bonding and grounding techniques shall

be used for any operation where static

electricity could become an ignition source.

x. All employees should be stay away from pay

welding tractor while operating.

y. Compressed gas cylinders shall not be placed

in a confined space.

z. Compressed gas cylinders shall be properly

marked or labeled, including their contents,

with lettering in Arabic and English

aa. Cylinders shall be inspected for damage,

severe corrosion, valve leakage and current

hydro test date prior to each use.

MIP17 – HSE – PP – 032 REV 0 Page 9 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

bb. All cylinders shall have an approved pressure-

reducing regulator with check valve connected

to the cylinder valve.

cc. Continuous monitoring of gas present in the

working area.

dd. Tools constructed of good quality materials

shall be used. Use of “homemade” tools is

prohibited.

ee. Hand and power tools shall be always kept

clean. Tools shall be inspected before and

after use, as well as before storage.

ff. Personnel shall not operate power tools unless

they are appropriately trained in their selection,

use, inspection, and storage. Training records

shall be made available upon request.

ADMINISTRATIVE CONTROLS:-

a. Familiarize workers with tool operation.

b. Tools and equipment used should be color-cod

ed and shall be inspected by authorized compe

tent person.

c. Power tools and hand tools usage shall comply

with the CSM I-11 Hand Tools and Power

Tools.

d. The workers involved in this activity should be

aware of pinch points.

e. Adequate ergonomics training.

f. Awareness on welding activities.

g. Only approved well-maintained equipment shall

be used.

h. All personnel working around electrical equipm

ent have completed electrical safety training.

i. Regular housekeeping shall be done to prevent

slips, trips and fall.

PERSONAL PROTECTIVE EQUIPMENT:-

a. Wear eye protection when using hand/power to

MIP17 – HSE – PP – 032 REV 0 Page 10 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

ols, which cause flying debris.

b. Wear appropriate hand protection; observe goo

d work practices in ensuring that work gloves a

re in good condition.

c. Wear safety goggles/glasses at all times & prop

er protective gloves

d. Face shields over safety glasses

e. Approved hearing protection (e.g., earplugs) sh

all be provided at the job site and shall be worn

in high noise areas (i.e., 85 decibel [dBA] or hi

gher).

f. Fire retardant clothing / apron gloves for welder

s

g. Proper welding hoods for welding, respiratory

and eye protections for welding crew.

h.

REFERENCES: -

a. All relevant controls in Saudi Aramco CSM.

ENGINEERING CONTROL: - Construction

a) Gas release a. Obtain the valid work permit from Saudi

(i.e.H2S or any Sinopec PM

Aramco or Internal work permit system

Toxic gas) b. Approved HIP, Method Statement and JSA Sinopec CM

Civil Works All Active b) Fire, Explosion must be in place.

Working Near Sinopec Supv.

Location c) Struck by moving c. Permit issuer and Permit receiver shall

Hydrocarbon conduct joint inspection prior to start the HSE Manager

Right of way (If equipment

High

2 Area/Restricted d) Stuck in desert activity

(Man applicabl 4 4 HSE Supv.

Area e) Struck by heavy d. Continuous monitoring of gas present in the

Machine e) HSE officer

equipment the working area.

Interface) e. Give awareness to workforce regarding Work permit

existing facilities.

H2S safety. receiver/issuer

f. Fire Extinguisher that are UL/FM approved

shall be made available when working near

hydrocarbon area.

MIP17 – HSE – PP – 032 REV 0 Page 11 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

g. Do not allow any naked flame in live Client:

hydrocarbon area. Abdullah

h. Evacuate the area in case of gas release. Muhawish

i. Designated assembly area shall be at safe

distance from live area. Fahad Al-

j. Mechanical excavators shall not be used Almokhlies

within 3 m (10 ft.) of underground utilities or Michael labios

installations. Omar Malki

k. Excavations are not permitted under an Ali Alaradi

existing foundation. Excavations are not OE&CG

allowed to intersect a forty- five-degree

(45°) plane extending downward from the

bottom edge of an existing foundation,

unless a properly engineered support

system is installed prior to start of work or

the excavation is in stable rock.

l. Existing underground piping, manholes,

electrical cables, duct banks, sidewalks,

etc., that could be undermined by an

excavation shall be properly braced or

shored.

ADMINISTRATIVE CONTROLS: -

a. If any utility found during excavation worker

shall stop the work and inform to work

supervisor. Work supervisor then shall inform

to company.

b. SA certified operator shall be utilized to

operate heavy equipment

c. Operator shall have valid SAG license and

experience in operating the equipment

d. Spotter assigned for monitoring equipment

operation

MIP17 – HSE – PP – 032 REV 0 Page 12 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

e. Isolate equipment swing areas

f. Make eye contact with operators before

approaching equipment

g. Restrict work area entry to authorized

personnel only during construction activities

h. Safe access should be clearly marked

i. Access shall be kept clear from any obstruction

j. Spray water/ dust control.

k. Barricading all work place, equipment and plant

at work site

l. No one shall be under a suspended load or the

swing radius of the excavator/backhoe bucket.

m. Operator must have sufficient experience to

operate the equipment

PERSONAL PROTECTIVE EQUIPMENT:-

a. Use appropriate PPE.

REFERENCES:-

b. Refer to GI 1021.000 Street and Road Closure,

Excavation Reinstatement and Traffic Controls.

c. Saudi Aramco Engineering Standard:SAES-A-

111 Borrow Pit Requirements ,OSHA Safety

And Health Standards:29 CFR 1926 Subpart P

Excavations

Construction

ENGINEERING CONTROL:-

Working close to

Sinopec PM

Overhead Power a. Obtain the valid work permit from Saudi

All Active Sinopec CM

Location lines and Aramco or Internal work permit system

Civil Works

High

Underground Electrocution b. Approved HIP, Method Statement and JSA Sinopec Supv.

3 s (If

Applicabl Cables must be in place. HSE Manager

e) c. Permit issuer and Permit receiver shall

conduct joint inspection prior to start the HSE Supv.

activity HSE officer

MIP17 – HSE – PP – 032 REV 0 Page 13 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

d. Ensure that goal posts of corresponding Work permit

height as per CSM III-2 Table 2.1 shall be receiver/issuer

installed.at a minimum of 25 meters

horizontal distance from power line.

e. Movement of drilling rigs, cranes, or heavy

equipment near or under overhead power Client:

lines shall be coordinated with the SA Power Abdullah

Operation Department as per GI 2.702. Muhawish

4 4

f. Access below overhead power lines shall be

restricted by barriers where the “goal posts” Fahad Al-

are located. Almokhlies

g. Continuous monitoring of gas present in the Michael labios

working area. Omar Malki

Ali Alaradi

OE&CG

ADMINISTRATIVE CONTROLS:-

a. Overhead power lines shall be protected per

GI 2.702 by barriers and/or timber/wire “goal

posts” to maintain required clearances.

b. Overhead power lines shall be rerouted away

from construction work or placed

underground, if possible.

c. Only inspected and color coded hand tools

must be used

PERSONAL PROTECTIVE EQUIPMENT:-

d. Use appropriate PPE.

REFERENCES:-

MIP17 – HSE – PP – 032 REV 0 Page 14 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

e. Refer to GI 1021.000 Street and Road Closure,

Excavation Reinstatement and Traffic Controls.

Saudi Aramco Engineering Standard:SAES-A-

111 Borrow Pit Requirements ,OSHA Safety And

Health Standards:29 CFR 1926 Subpart P

Excavations

ENGINEERING CONTROL:-

Construction

a. Lack of necessary a. Obtain the valid work permit from Saudi Sinopec PM

permits & Aramco or Internal work permit system

Sinopec CM

documents b. Approved HIP, Method Statement and JSA

must be in place. Sinopec Supv.

b. Falling of

load/unsafe rigging c. Permit issuer and Permit receiver shall HSE Manager

& lifting conduct joint inspection prior to start the

activity HSE Supv.

c. Side boom

failure/tipped over d. If critical lift required, lifting plan shall be HSE officer

Lifting Operation prepared by approved rigger 1 as per

d. Caught in between Work permit

All Active Unloading and e. Pinch point WMS/JSA and GI 7.028, Crane Lifts: Types

and Procedures receiver/issuer

Location Stringing of f. Struck by load or

Cranes and

High

4 s (If equipment e. The Critical Lift Plan form shall be properly

Lifting Pipes on the 4 4

Applicabl g. Human injury. completed, signed, and approved prior to

Operations Right of Way

h. Man, or materials the lift. It shall first be signed by the

e using Side Client:

Fall from height. originator; then signed by the crane

Boom. operator, rigger, and USER supervisor. It

i. Material and Abdullah

property damage. shall then be reviewed and approved by a Muhawish

j. High Speed wind Saudi Aramco certified Rigger-I.

Fahad Al-

k. Lack of proper f. Cranes shall have a minimum tail swing

communication Almokhlies

clearance of 0.6 m (2 ft). Barricades shall be

between operator provided at the crane's working radius when Michael labios

and rigger working around personnel. Omar Malki

g. All chains, hooks, slings, shackles, wire Ali Alaradi

ropes, and other equipment used with lifting OE&CG

equipment shall meet Saudi Aramco

MIP17 – HSE – PP – 032 REV 0 Page 15 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

standards. In addition, a record shall be kept

on site. Saudi Aramco G.I. 7.029 shall be

followed

h. Maintain safe working distances based

upon the voltage of the line for any part of

the equipment, including booms, buckets,

articulating arms, masts, etc. (Reference:

SACSM Vol.2 , Part III, Crane & Lifting

Equipment, Paragraph 7.3.23, table 7.1)

i. Lifting equipment working in an operating

area must display a current inspection

sticker. Operators must have a valid SAG

license, and Saudi Aramco certificate for the

type of lifting equipment they are operating.

j. Ensure that the soil is compacted and

stable.

k. Provision of steel matting. Fully extended

outriggers with wood matting prior to lifting.

l. The outrigger should be fully extended with

150% outrigger pad.

m. Cranes working near trenches and

excavations shall be a minimum distance

equal to the depth of the trench or

excavation for Class A soils and twice

the distance for Class B and C soils

n. Lifting activity must be stopped when wind

speed exceeds 32 KPH or manufacturer

specification (Whatever is less).

ADMINISTRATIVE CONTROLS:-

a. Crane operator should undergo competency

training and certification before operating as

per GI 7.025

MIP17 – HSE – PP – 032 REV 0 Page 16 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

b. All equipment will be inspected and shall have

the inspection certificate/sticker provided by SA

approve 3rd party inspection company for

elevating/lifting equipment.

c. Loads noted in approved Critical Lift Plans

shall be rigged by a rigger certified for that load

category (Rigger-I, II, or III).

d. The Critical Lift Plan form shall be properly

completed, signed, and approved prior to the lift.

It shall first be signed by the originator; then

signed by the crane operator, rigger, and USER

supervisor. It shall then be reviewed and

approved by a Saudi Aramco certified Rigger-I.

e. Well maintained equipment must be used with

the 3rd party certification and sticker.

f. Operators must have a valid license from

government of SA and must be Saudi Aramco

Certified.

g. Fill-up / complete pre-use inspection checklist

prior to equipment operation.

h. Checklist for the crane used and other rigging

activities to be filled out before any lifting

activities.

PERSONAL PROTECTIVE EQUIPMENT:-

a. Wear reflective hi-visibility vest when exposed

to vehicular traffic.

b. Proper PPE to be worn at all times.

REFERENCES:-

Refer to the Saudi Aramco Safety Handbook ,

Refer to GI 7.025 for crane operator certification

requirements, G.I. 07.026 Cranes and Heavy

MIP17 – HSE – PP – 032 REV 0 Page 17 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

Equipment Accident Reporting Procedures G.I.

07.028 Refer to G.I. 07.029 Rigging Hardware

Requirements, Crane Lifts Types and Procedures

and G.I. 07.030 Crane Inspection and Testing

Requirements,

• Injury to people ENGINEERING CONTROL: -

a. Obtain the valid work permit from Saudi Construction

caused by over Aramco or Internal work permit system.

Sinopec PM

pressure or b. Approved HIP, Method Statement and JSA

must be in place. Sinopec CM

equipment failure.

c. Permit issuer and Permit receiver shall conduct Sinopec Supv.

• Flooding joint inspection before starting the activity.

HSE Manager

• Damage to the d. Pressure testing and associated work shall be

performed in accordance with GI 2.102 and the HSE Supv.

welded pipe. approved pressure test procedure. HSE officer

• Pressure relief valve e. Only personnel involved with the pressure test Work permit

shall be allowed near the system at any time

All Active failure. receiver/issuer

Valve Seat Leak during the test.

HIGH

Locations

5

Mechanical work (If Testing (Hydro • Pipe fitting, Safety 4 4 f. All mechanical equipment used in hydro testing

Applicable) Test) pins, whip check, must have been inspected prior to use.

g. Lock out and tag out procedure shall be Client:

Hoses connections. obtained. If required.

Abdullah

• Blinds failure h. All required checklists shall be available &

verified prior to start of the activity. Muhawish

• The Applying wrong i. Checklist for pressure testing based on G.I. Fahad Al-

test pressure. 2.102 must be follow and checked before Almokhlies

starting the work.

• Damaged and Michael labios

j. Ensure that the pressure relief valve to be used

unsuitable hose. Omar Malki

is calibrated and set to relieve at 5% above the

Ali Alaradi

• Use of contaminated test pressure.

OE&CG

k. Valve data sheet, approved procedure and

water or test reference standard shall be available prior to

MIP17 – HSE – PP – 032 REV 0 Page 18 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

medium. start in order to cross check the correct test

a. Unauthorized entry pressure to be used.

l. All vents shall be open during filling so that all

trapped air is vented prior to applying of test

pressure.

m. Check the proper range of pressure to be

applied as per data sheet.

n. Apply the pressure and load it gradually for

10%, 25%, 50%, 75% and 100%

o. Material certification shall be obtained for all

components including joining materials and

valves test limits prior to start.

p. Inspect Hoses, Couplings, Safety pins, prior to

use, discard damaged items immediately.

q. Ensure that quick couplings are properly locked

together and pinned. All air hoses shall be

provided with whip arrestor.

r. Experienced crew shall be available to tight the

flanges during filling. The system shall be

depressurized and drained in case of any leaks

from joints.

s. Ensure that pressure holding time is being

followed as per data sheet.

t. Welding joints shall be checked visually if there

is any leakage.

u. Inspect the test system during gradually

loading of pressure for 10%.25%,75% & 100%

v. Working area shall be adequately illuminated,

(300 lux) sufficient lights shall be installed.

ADMINISTRATIVE CONTROLS: -

MIP17 – HSE – PP – 032 REV 0 Page 19 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

a. Trained workers shall be deployed under

continuous supervision by a competent

supervisor.

b. All routes of access and egress to the testing

area shall be restricted by barriers and clearly

marked with warning signs.

c. Barricades and warning signs shall be installed

and posted to keep unauthorized personnel

away from the hydro testing activities.

d. All personnel to be made aware of

pressurization prior to start the activity. Gradual

pressurizing, no person shall be allowed near

valve.

e. No repair or tightening of connections is

allowed when pressure is not in zero.

f. Competent person should release the pressure

by opening the vent and drain value.

PERSONAL PROTECTIVE EQUIPMENT: -

a. Wear eye protection when using hand/power

tools, which cause flying debris.

b. Wear appropriate hand protection; observe

good work practices in ensuring that work

gloves are in good condition.

c. Wear safety goggles/glasses always.

d. Face shields over safety glasses.

Approved hearing protection (e.g., earplugs) shall

be worn in high noise areas (85 decibel [dBA] or

higher).

MIP17 – HSE – PP – 032 REV 0 Page 20 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

a. Discuss the JSA & leak testing procedure with

the working crew before the start of work.

b. Only skilled & trained personnel are allowed to

perform the job. Construction

c. Equipment/tools must be inspected before

Sinopec PM

using.

d. Provide calibrated relief pressure valves to Sinopec CM

avoid overpressure. Sinopec Supv.

e. Ensure proper tightening of flanges before HSE Manager

pressurizing the line.

f. Ensure the area should be properly barricaded HSE Supv.

and installed warning signs. HSE officer

g. Ensure proper means of communication during Work permit

All Active pressure testing. receiver/issuer

Location

Leak Testing of • Overpressure h. Keep continuous monitoring of all connection

High

6 Mechanical s (If • Falling & Release of 4 4 joints/flanges.

Anchor Sleeve

work Applicabl high-pressure gas i. Competent supervision must be available

e throughout the completion of the job. Client:

j. Take rest after specific intervals to avoid mental

Abdullah

stress/fatigue.

k. The cylinder valve shall always be opened Muhawish

slowly to prevent damage to the regulator. Fahad Al-

l. Cylinders shall be chained or otherwise Almokhlies

secured in an upright position; use Michael labios

bottle/cylinder racks wherever possible.

Omar Malki

m. A protective cap shall remain on the valve when

Ali Alaradi

the cylinder is not in use.

OE&CG

n. Unless a trolley or special carrier is used,

regulators and hoses shall be detached, and

cylinder valve caps put back in place before

moving.

MIP17 – HSE – PP – 032 REV 0 Page 21 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

o. Material Safety Data Sheet (MSDS) or

Chemical Hazard Bulletin (CHB), shall be used

when working with chemicals or hazardous

substances.

p. Keep away from the pressurized segment

being tested.

q. Monitor the pressure gauge from a safe

distance away from a potential source of high-

pressure jetting (such as flange joint, spade,

and coupling etc.)

r. Barricades shall be provided as per set

maximum distance considering the test

pressure level.

s.

ENGINEERING CONTROL:-

a. Untrained & Construction

a. Issuer and receiver shall conduct joint site

uncertified inspection and secure work permit from Saudi Sinopec PM

equipment operator

Aramco operations within according to GI. Sinopec CM

b. Uninspected &

2.100 work permit system”

Uncertified work Sinopec Supv.

equipment b. Use only SA-certified work permit receivers

All Active HSE Manager

Manual Excavation c. Work around heavy when work will be conducted in SA restricted

Location

equipment areas or where required by the SAPO. HSE Supv.

High

7 s (If Exposing existing

Excavation d. Work equipment 4 4 c. Approved HIP, JSA And Method Statement

Applicabl utilities (cables, HSE officer

can fall into should be available at job site.

e pipelines, Work permit

excavation d. Comply with SA G.I. 6.030 (traffic and vehicle

structures Etc.) e. Cave in/ collapse. safety), & GI 1021.000, Street and Road receiver/issuer

f. Lack of necessary Closure, Excavation secure the area by

permits & installing barricades, sign boards, blinking

documents lights. Warning signs must be kept at suitable

g. Caught in between distance to warn the approaching vehicle to Client:

work area. All workers must be worn with

MIP17 – HSE – PP – 032 REV 0 Page 22 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

h. Gas release reflective jackets for good visibility. No one Abdullah

(i.e.H2S or any shall be allowed to sit beneath the right of way. Muhawish

Toxic gas) e. A Pre-Excavation Checklist shall be properly

Fahad Al-

i. Fire, Explosion completed and made available upon request.

f. A daily-Excavation Checklist shall be properly Almokhlies

j. Damage to

underground utilities completed and made available upon request. Michael labios

g. Adequate and suitable protective systems (i.e., Omar Malki

k. Workers hit by

benching, sloping or shoring) shall be planned Ali Alaradi

heavy equipment

for if the excavation will be at a depth of 1.2 m

l. Incomplete detour (4 ft) or more in soil other than stable rock, as OE&CG

causing vehicle per Section 1.7. Excavations less than 1.2 m (4

accident ft) deep may also require protective systems if

m. Improper road sidewall cave-in hazards exist.

closer h. An excavation plan shall be prepared and

n. Detour lighting available upon request.

failure while night i. For excavations greater than 2.4 m (8 ft) deep

causing vehicle in Type B or C soil, an excavation plan (e.g.,

accident shoring design calculations and drawings) that

o. Untrained & meets the requirements of this chapter shall be

uncertified developed by a degreed civil/structural

equipment operator engineer.

p. Excavation collapse j. For excavations greater than 6 m (20 ft) deep,

(Cave-in) regardless of soil type, an excavation plan

q. Presence or (e.g., shoring design calculations and

accumulation of drawings) that meets the requirements of this

toxic gases. chapter shall be developed by a degreed

r. Improper signaling civil/structural engineer and reviewed by the

while lifting SA Consulting Services Department (CSD).

operation k. A properly completed Confined Space Entry

s. Equipment (side Permit shall be obtained to enter excavations

boom) turning over equal to or greater than 1.2 m (4 ft) deep.

t. Multiple injuries l. Before excavation activities begin, the SAPO

u. Tripping hazard (e.g., engineering/technical) shall confirm and

v. Slipping hazard mark (e.g., by flags or chalk) the location of

any known or suspected underground pipes,

MIP17 – HSE – PP – 032 REV 0 Page 23 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

w. Accident & Injury cables, vessels, structures, etc., that are in the

area of the proposed excavation.

m. Mechanical excavators shall not be used until

all underground utilities and installations have

been exposed by hand digging.

n. Mechanical excavators shall not be used within

3 m (10 ft) of underground utilities or

installations. Pneumatic breakers shall only be

used where necessary to break concrete or

other hard materials.

o. Existing underground piping, manholes,

electrical cables, duct banks, sidewalks, etc.,

that could be undermined by an excavation

shall be properly braced or shored.

p. Suitable shoring shall be installed, or the sides

benched or sloped back to a safe angle, for all

excavations 1.2 m (4 ft) deep or greater, or for

soil piles over 1.5 m (5 ft) high.

q. Stairways, ladders, ramps and/or other safe

means of egress shall be located in

excavations that are 1.2 m (4 ft) or more in

depth so as to require no more than 7.5 m (25

ft) of lateral travel distance for personnel (i.e.,

ladders shall be spaced at least every 15 m [50

ft] along a trench).

r. Ladders shall rest on the bottom of the

excavation and shall extend at least 1 m (3 ft)

above the top landing point.

s. Personnel shall not be in an excavation where

they could be exposed to a possible cave-in,

such as could be caused by equipment

operating or passing nearby. Personnel shall

not be within a distance less than the depth of

the excavation from the edge where equipment

is located.

MIP17 – HSE – PP – 032 REV 0 Page 24 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

t. Gas tests shall be performed per GI 2.709

when there is reason to suspect oxygen

deficiency or the presence of a flammable/toxic

atmosphere in an excavation.

u. Appropriate emergency rescue equipment

(e.g., breathing apparatus, full body harness

and lifeline, basket stretcher) shall be readily

available during work.

v. Only excavating and backfilling equipment

(track hoes, rock breakers, backhoes, front

loaders, etc.) are permitted within 2 m (6.5 ft)

of the edge of an excavation.

condition at all times.

ADMINISTRATIVE CONTROLS:-

a. Before excavation activities begin, the following

factors shall be evaluated by an excavation

competent person who has the proper training

and/or experience.

b. Hard barricades (e.g., concrete or water-filled

plastic “jersey” barriers, metal fencing) shall be

used to keep motor vehicles, cranes and heavy

equipment at the proper distance away from

the excavation.

c. Pedestrian barricades shall be placed no less

than 1 m (3 ft) from the edge of the

excavation.

d. Fire extinguishers (UL Listed) shall be placed

at strategic points.

e. A safe means of access and egress shall be

provided and maintained.

f. Cranes, side booms and other elevating/lifting

equipment shall be SA certified.

g. Pick and shovel shafts shall be free of cracks,

splinters and other defects or damage

MIP17 – HSE – PP – 032 REV 0 Page 25 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

h. Hand excavation tools (e.g., picks and shovels)

shall be maintained in good

i. If any utility found during excavation worker

shall stop the work and inform to work

supervisor. Work supervisor then shall inform

to company.

j. SA certified operator shall be utilized to

operate heavy equipment

k. Operator shall have valid SAG license and

experience in operating the equipment

l. Spotter assigned for monitoring equipment

operation

m. Isolate equipment swing areas

n. Make eye contact with operators before

approaching equipment

o. Restrict work area entry to authorized

personnel only during construction activities

p. Safe access should be clearly marked

q. Access shall be kept clear from any obstruction

r. Spray water/ dust control.

s. Barricading all work place, equipment and plant

at work site

t. No one shall be under a suspended load or the

swing radius of the excavator/backhoe bucket.

u. Operator must have sufficient experience to

operate the equipment

PERSONAL PROTECTIVE EQUIPMENT:-

a. Use appropriate PPE.

REFERENCES:-

a. Refer to GI 1021.000 Street and Road Closure,

Excavation Reinstatement and Traffic Controls

(See Appendix D),

b. Saudi Aramco Engineering Standard:SAES-A-1

MIP17 – HSE – PP – 032 REV 0 Page 26 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

11 Borrow Pit Requirements ,OSHA Safety And

Health Standards:29 CFR 1926 Subpart P Exc

avations

ENGINEERING CONTROL:-

a. Gas test shall be conducted for Oxygen, LEL, Construction

H2S and CO. prior to entry and regular interval

during the activity and test result shall be Sinopec PM

recorded. Sinopec CM

b. Gas test shall be conducted by trained and Sinopec Supv.

authorized gas tester (AGT).

c. Only calibrated gas testing device shall be HSE Manager

used for gas testing. HSE Supv.

d. Proper ventilation shall be provided inside

confined space. HSE officer

a. Presence or e. Upon reaching 1.2 meters (4 feet) or more in Work permit

All Active Pipelines Crossing

accumulation of depth, proper means of access and egress receiver/issuer

Location Asphalt Roads

toxic gases. (Ladder or stairway with handrail) shall be

High

8. Confined s (If with Open Cut and b. No standby man 4 4 provided and located at Intervals of 7.5 meters

Spaced Entry Applicabl excavation c. Improper access (25 feet) or less lateral travel.

e d. Fire f. Access shall be controlled by designated and

Client:

e. Oxygen deficiency trained standby man who shall maintain entry

log for entrants. Abdullah

g. Proper shoring/Sloping/benching as per soil Muhawish

condition to be provided. Fahad Al-

h. Keep all heavy equipment minimum 2 meters

Almokhlies

away from the edge of excavation

i. Excavated soil shall be placed at least 1 meter Michael labios

away from the edge of excavation. Omar Malki

j. No material storage along the edge of Ali Alaradi

excavation OE&CG

k. A safe and adequate access to the site shall be

maintained at all time by demarking and

MIP17 – HSE – PP – 032 REV 0 Page 27 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

barricading with relevant warning signs and

hazard warning lights

l. Vehicles not to operate within 2 meters of edge

of excavation unless cleared by geological

report, provide extra support.

m. If depth of excavation is more than 2 meter

then min. distance for vehicle movement from

edge is depth of excavation.

n. Hard barricading shall be installed at least one

meter from the excavation edge.

o. Follow the manual handling procedure and

techniques.

p. Worker shall be trained in manual handling and

adopt good body posture while doing manual

handling.

q. Avoid water accumulation inside the trenches

and provide dewatering.

r. Ensure the availability of first aider

,ambulance with driver as per SA

CSM requirement

s. Rescue plan has to be prepared

and implemented. rescue

equipment need to be made

available at all time

t. Adequate emergency rescue equipment shall

be made available.

u. Using still plate of min. thickness of 10 mm. for

making shim.

v. Sufficient no. of shim to withstand the manhole

cover load.

w. Keeping height of shim to minimum. (It shall not

exceed than 150 mm)

x. Controlling load precisely by tagline for correct

alignment.

MIP17 – HSE – PP – 032 REV 0 Page 28 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

y. Do not hold, push or pull the load directly by

hand to align it.

z. Keep all body parts away from load while lifting

and placing it.

ADMINISTRATIVE CONTROLS:-

a. All employees involved in confined space exca

vation or need to work inside must be trained in

confined space.

b. SA approved operators shall be assigned as pe

r equipment they operating.

c. All entrants shall be trained and qualified to ent

er the confined space.

d. Entrants must be provided with the personal m

ulti gas detector.

e. Log in and log out must be followed by the auth

orized standby man

f. Standby man shall be provided with the Flash li

ght to monitor the entrants.

g. Entrant must be provided with the Head light an

d in addition man-cart also fitted with the lightin

g system.

h. Harness should be worn by the entrant and clip

ped to the man cart, and a rope must be tied to

the cart for emergency and fast pull out.

i. Only workers who have completed confined sp

ace entry training shall be allowed to enter into

confined space.

j. Excavation plan shall be required if the excavat

ion is greater than 6 metres (20 feet) deep rega

rdless the type of soil or 2.4 meters (8 feet) dee

p type B or C soil.

k. All equipment shall be equipped with reverse al

arm and revolving warning light.

l. All equipment / vehicles shall be inspected by 3

MIP17 – HSE – PP – 032 REV 0 Page 29 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

rd party or equipment inspector and provide wit

h sticker.

m. PWAS shall be installed with equipment as per

GI 7.031.

n. Emergency contact numbers shall be posted o

n the entrance of confined space.

o. Work area, access and welfare facilities will be

properly illuminated.

p. Cables shall be raised at least 7 ft. height from

ground or dug into the ground

q. All electrical circuits shall be protected with GF

CI for lighting. Cables shall be safeguarded for

m sharp edges while routing.

r. Check cables and connectors for damage and i

nsulation. Avoid over loading by providing suffic

ient junction boxes.

s. Ensure monthly inspection and color coded for

all power tools and electrical equipment, panel

and generator.

t. The retrieval lifeline (Rope) will be connected to

the Man cart to pull out manually in case of fail

ure. Entrants must be kept attached/ secure hi

mself with the man-cart to

u. pull out safely.

v. Air horn/whistle as a mean of call is recommen

ded for entry attendant.

w. Use proper access ladder

x. Welfare facilities (Drinking water/ Rest shelter/

Toilet etc..) must be provided nearby within 100

meters.

y. Good quality sockets and pins are only used. P

rovided Fire extinguisher

z. Ensure all persons on site understand the actio

ns required during emergency situation.

aa. Emergency assembly areas shall be identified

MIP17 – HSE – PP – 032 REV 0 Page 30 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

and all workers trained for evacuation procedur

es.

bb. PPE must be worn as specified in the MSDS (s

ee attached MSDS)

cc. Copies of MSDS for all the chemicals must be

kept on site and provide all crew members with

appropriate safety information and training (saf

e handling) related to the specific chemical they

may be expected to deal with.

dd. Assigning Trained and skilled craftsman in che

mical handling.

ee. Exclusion of all ignition sources.

ff. Using correct hand tools for applying adhesive.

PERSONAL PROTECTIVE EQUIPMENT:-

a. Utilize proper personal protective equipment

(PPEs)

b. Wear appropriate PPE such as rubber gloves,

full sleeve coverall, respirator, safety goggle etc.

c. Utilize SCBA, Rescue structure, Tripod

REFERENCES:-

Refer to General Instruction 1780.001,

“Atmosphere Supplying Respirators” General

Instruction 2.708 “Gas Testing Procedures”,

ANSI Z117.1-1989, “Safety Requirements for

Confined Spaces” U.S. OSHA 29 CFR

1910.146, “Permit-required Confined Spaces”

Km 0-106 a. Lack of necessary ENGINEERING CONTROL:- Construction

pipe 12” & 30” Pipeline

High

9 Pipe bending permits & a. Issuer and receiver shall conduct joint site Sinopec PM

4 4

laydown bending work documents inspection and secure work permit from Saudi

(Hot work) Sinopec CM

yard b. Human injury. Aramco operations or internal work permit

MIP17 – HSE – PP – 032 REV 0 Page 31 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

c. Struck by vehicles within according to GI. 2.100 work permit Sinopec Supv.

d. Pipe damaged by system” HSE Manager

over-bending b. Use only SA-certified work permit receivers

e. Foot injury from when work will be conducted in SA restricted HSE Supv.

dropping material areas or where required by the SAPO. HSE officer

f. Abnormal noise c. Approved HIP, JSA And Method Statement

g. Pinch/crushing point should be available at job site. Work permit

h. Equipment turn over d. Comply with SA G.I. 7.028 & 7.029, (Crane receiver/issuer

on personnel Lifts, Types and Procedure lifting) & (Rigging

i. Inadequate Hardware Requirements), equipment must be

inspection of certified by Saudi Aramco with valid inspection

rigging equipment / sticker. All lifting tackles must be inspected and Client:

Fall of suspended color coded.

Abdullah

load Administrative Controls:-

a. Equipment Operator and rigger must be Muhawish

j. Pipe coating

damaged by debris experienced and certified from Saudi Aramco Fahad Al-

on the machine having a specific and valid certificate. Crane Almokhlies

k. Injury to personnel operator will complete the crane daily

Michael labios

l. Slip., Trip and Fall inspection /pre-operation checklist. The lifting

area will be barricaded with warning tap and Omar Malki

sign boards will be placed to stop unauthorized Ali Alaradi

entrants. OE&CG

b. Protect slings from sharp edges and abrasions;

avoid sharp bends.

c. Preventive maintenance by machine will be

observed.

d. Ensure that periodic maintenance of the all

heavy equipment vehicles is applied and

recorded.

e. Sleeping or resting under any heavy equipment

is sickly prohibited.

f. All material properly arranged and segregated.

g. Exclusion zone to be established manned and

barricaded off with proper warning notices

MIP17 – HSE – PP – 032 REV 0 Page 32 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

“Caution, Pipe bending & lifting In Progress”

posted throughout the activity.

h. All frequent and periodic sling inspections shall

be performed by a Saudi Aramco certified

rigger

i. Damaged slings shall be reported & removed

from service, especially those with visible

chemical & damaged tags/rated capacity

j. The roller/pipe cradle cradles, which may be

used during bending, shall be padded to

prevent the damage.

k. Ensure all shackles and other connecting

devices are completely closed or bolted.

l. Make sure the rope is not knotted when the

winch is retracting.

m. Make sure there is no one in the direction of

the winch rope.

n. The winch should be operated slowly. Abrupt

strain on the rope is strictly prohibited

o. Tools constructed of good quality materials

shall be used. Use of “homemade” tools is

prohibited

p. Personnel shall not place any part of their body

between moving parts of bending machine.

q. Chains, gears, revolving shafts and other

moving parts shall be properly guarded

r. Ensure that trash and debris is properly

collected and disposed of daily.

s. Ensure that trash and debris is properly

collected and disposed of daily.

t. Install barricades and warning signboards at a

reasonable distance.

PERSONAL PROTECTIVE EQUIPMENT:-

a. Use appropriate PPE.

MIP17 – HSE – PP – 032 REV 0 Page 33 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

ENGINEERING CONTROL:-

a. Obtain the valid work permit from Saudi

Aramco or Internal work permit system

according to GI 2.100 and Approved

Contractor Work permit procedure. Construction

a. Lack of necessary b. Permits Issuer and receiver shall conduct joint Sinopec PM

permits & site inspection and secure work permit from

Saudi Aramco operations within according to Sinopec CM

documents

b. Human injury. GI. 2.100 work permit system” Sinopec Supv.

c. Struck by vehicles c. Approved HIP, Method Statement, and JSA HSE Manager

d. Pipe damaged by procedure must be in place.

HSE Supv.

over-bending d. All utilities (along the proposed bore path)

e. Foot injury from identified and marked, shall be exposed and HSE officer

dropping material confirmed. Work permit

All Active 12” & 30” Dia f. Abnormal noise e. Ensure that the transmitter tracking system is

receiver/issuer

Location Pipeline Road g. Pinch/crushing point calibrated with good working condition.

High

10 Mechanical s (If crossing by h. Equipment turn over 4 4 f. Drill head must be properly fitted in front of the

work Applicabl Trenchless on personnel first drill pipe and aligned properly to the drill

e) Construction-HDD i. Inadequate line.

inspection of g. Positive two-way communication between the Client:

rigging equipment / drill operator and exit side personnel is Abdullah

Fall of suspended essential to ensure safe distance is Muhawish

load maintained away from rotating drill pipe and

j. Pipe coating tooling. Fahad Al-

damaged by debris h. Ensure Close Supervision of the activity up to Almokhlies

on the machine the completion. Michael labios

k. Injury to personnel i. Excavation work on or near roads, streets and Omar Malki

Slip., Trip and Fall sidewalks shall meet the requirements of GI

Ali Alaradi

1021.000 and shall not be performed without

prior approval of the relevant authorities. OE&CG

j. A Pre-Excavation Checklist shall be properly

completed before start the work.

k. A daily-Excavation Checklist shall be properly

completed and made available upon request

MIP17 – HSE – PP – 032 REV 0 Page 34 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

l. Ensure to acquire the underground facilities

drawing and communicated to supervisor and

equipment operators

m. A plan shall be submitted by the contractor

showing the required clearance from the

proposed bore.

Administrative Controls:-

n. The HDD operator shall position the drilling

equipment at the appropriate drilling entry

point as per the Bore Plan.

o. Ensure that the operator of the machine follow

the JSA and the method of statements and the

proper operation for drilling

p. A copy of MSDS for the entire chemical

(Pileman-BH-Bentonite, Caustic Soda Flakes

and Soda Ash etc.) must be readily available

at the work location all the times.

q. He chemical handler should be properly

trained.

r. Only qualified and competent personnel shall

perform the work.

s. Installed safety warning signboards on the

affected area.

t. All equipment / vehicles shall be inspected by

3rd party or equipment inspector and provide

with sticker.

PERSONAL PROTECTIVE EQUIPMENT:-

a. Utilize proper personal protective equipment

(PPEs)

b. Wear appropriate PPE such as rubber gloves,

full sleeve coverall, respirator, safety goggle etc.

MIP17 – HSE – PP – 032 REV 0 Page 35 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

ENGINEERING CONTROL:-

a. Obtain the valid work permit from Saudi

Aramco or the Internal work permit system.

a. Lack of necessary b. Issuer and receiver shall conduct a joint site

permits & inspection and secure work permits from Saudi Construction

documents Aramco Operations within accordance to GI. Sinopec PM

b. Miss 2.100 “Work Permit System” and Sinopec

Sinopec CM

communication/ internal work permit system.

understanding c. Hazard Analysis: An assessment of work Sinopec Supv.

c. Insufficient light activity conducted during the joint site HSE Manager

d. Human injury. inspection before the work is started. It is

e. Foot injury from performed by the work permit issuer (or his HSE Supv.

f. Working without designated representative) and the receiver. HSE officer

authority, d. If necessary obtain countersign on work permit

Installation Of Work permit

All Active Unauthorized entry. from the concern department /personnel such

Overhead g. Working near as POD (Power, Electrical), communication (IT) receiver/issuer

Location

High

11 Electrical s (If Powerlines Existing Overhead 4 4 etc.

work Power Line e. Obtain the work permit before starting work, all

Applicabl Drilling Of Hole

h. Falling of Load the necessary documents shall be present and

e) For electrical Pole during Lifting secured at site. Client:

i. Electrical hazards f. Contractor shall obtained work permit from Abdullah

Metal in eyes & other agency/government or department like:

Muhawish

cuts POD, STC, MOBILY, MOT, MARFIQ, ROYAL

j. Fire COMMISSION if required. Fahad Al-

k. Electric Shock / g. If necessary, obtain countersign on work permit Almokhlies

Electrocution from the concern department /personnel such

Michael labios

l. Noise and Vibration as POD (Power, Electrical), communication

m. Manual Handling (IT) etc. Omar Malki

Hazard Administrative Controls:- Ali Alaradi

n. Defective equipment a. Overhead power lines shall be protected by OE&CG

o. Slip and trip hazards barriers and/or timber/wire “goal posts” to

maintain required clearances.

b. Heavy equipment shall maintain the safe

distance of 10 Ft from overhead power line.

MIP17 – HSE – PP – 032 REV 0 Page 36 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

c. All heavy equipment/vehicles shall be

grounded as soon as they are positioned near

overhead power lines for any type of work.

d. Have a signaler stationed in full view of the

operator to warn the operator each time the

equipment may approach the minimum

distance

e. Always stay and maintain a safe distance from

moving & working equipment. No one will be

allowed to stay in excavation while pipe

lowering. Make sure excavation is ready for

lowering and no one remains inside.

f. Allow only properly trained employees to

operate and maintain Cable Puller Equipment.

g. All pulleys, rollers, gears and pinch points shall

be guarded.

h. prevent contact between personnel and the

lines being pulled

i. Ensure surrounding equipment and materials

will not interfere with body movement

j. Suitably maintained drum roller frames, jacks,

rollers and operatives controlled to ensure

hands are clear when cable is moving.

k. Comply with SA G.I. 6.012 (Isolation, Lockout

and use of Hold Tag), Ensure work related

power sources properly isolated. Use Hot Stick

to discharge the electricity after isolation.

l. Only properly certified personnel (e.g., SA

Electrical System Operator) shall perform work

on energized electrical equipment.

m. Auger Drilling shall be leveled in accordance

with manufacturer’s specifications and shall be

located on a properly compacted foundation

prior to performing any lift.

MIP17 – HSE – PP – 032 REV 0 Page 37 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

n. Keep a safe distance to avoid flying debris

came from the soil cutting materials

o. Do not leave the hole unattended, install

barricade signage’s and cover the hole with

hard wood to avoid falling of people, animals

etc.

PERSONAL PROTECTIVE EQUIPMENT:-

a. Electrical workers shall wear an arc rated face

shield or arc flash hood as required by GI

2.721.

b. Utilize proper personal protective equipment

(PPEs)

c. Wear appropriate PPE such as rubber gloves,

full sleeve coverall, respirator, safety goggle

etc.

d. Approved hearing protection (e.g., earplugs)

shall be provided at the job site and shall be

worn in high noise areas (i.e., 85 decibel [dBA]

or higher).

a. Lack of necessary ENGINEERING CONTROL:- Construction

permits & a. Obtain the valid work permit from Saudi Sinopec PM

documents Aramco or Internal work permit system

Sinopec CM

b. Insufficient light according to GI 2.100 and Approved Contractor

All Active c. Human injury. Work permit procedure. Sinopec Supv.

Night Work & b. Permits Issuer and receiver shall conduct joint

Location d. Foot injury from HSE Manager

Extended Extended Hour

High

12 s (If dropping material site inspection and secure work permit from

Hours & 4 4 HSE Supv.

activities of the e. Unskilled workforce Saudi Aramco operations within according to

Applicabl Work permit

Night Work construction work f. Fire or explosion GI. 2.100 work permit system”

e) receiver/issuer

g. Vehicle accident c. Approved HIP, Method Statement, JSA and

h. Low visibility Extended hours & night work procedure must

i. Equipment turn over be in place.

on personnel d. Ensure to provide adequate lighting for the

j. Restlessness night activities, tower lights shall be fixed at the Client:

MIP17 – HSE – PP – 032 REV 0 Page 38 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

k. sleepiness on the desired location as per the requirement of Abdullah

job work. Muhawish

l. Weather conditions e. Work area shall be adequately illuminated at a

Fahad Al-

and Poor Visibility minimum of 85 lux which includes access

ways, actual work area, excavations, welfare Almokhlies

m. Fatigue

n. Multiple injuries facilities, etc. Michael labios

o. Tripping hazard f. Backup tower lights shall be available in case OE&CG

p. Slipping hazard of any damage or failure to the existing lights. OE&CG

g. Sufficient illumination arrangements shall be

ensured throughout the working zone

h. Full time electrician shall be assigned to look

after the lighting arrangements.

i. Workers and work equipment movement will be

limited only up to authorized working area. No

one will be allowed to enter or work in restricted

area, which not under scope of work.

j. All existing utilities plant, piping and equipment

will be protected in safe manner to avoid any

damage. Do not interfere with existing

equipment.

Administrative Controls:-

a. Appropriate number of First Aid Kits and

personnel trained and certified on First Aid and

BLS must be available on site.

b. Food must be arranged and provided

accordingly taking into consideration the timing

and number of workers

c. Safety Staffs (Safety Officer and Safety

Supervisor) must be deployed according to the

actual number of personnel working on site as

per SA CSM 5th Edition, Section 4.5, Table

4.1-Contractor Site Safety Staff Requirements.

d. Appropriate means of communication must be

provided to support safe execution of activity,

MIP17 – HSE – PP – 032 REV 0 Page 39 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

as well as in responding to emergency

situations.

e. It is mandatory that all workers wear clear

glass, working clothes with reflective strips for

enhanced visibility during the night.

f. Follow safe speed limit will be strictly followed.

Vehicle and equipment will be parked only at

safe location away from right of way.

g. Do not perform any job in poor lighting or in dark

areas to avoid accident and personal injuries.

h. Sitting or sleeping in dark places shall be

strictly prohibited.

i. While moving around the working area, watch

your step to avoid slipping or tripping. Do not

lay cables or keep work tools in walking areas.

Always ensure proper housekeeping.

j. Emergency rescue equipment and team shall

be available during extended/ night work.

k. Emergency arrangements shall be ensure to

encounter any emergency and ER procedure

shall be established and followed for

immediate rescue and medical assistance.

l. During any night work there shall be a

competent Supervisor at the Job Site and he

shall have suitable means of communication

should an emergency occur (Radio or Mobile

Telephone).

m. The responsible persons at site (Supervisor,

Foremen, and Safety Officers) shall be aware

of Emergency Contact Numbers in case of

incident.

PERSONAL PROTECTIVE EQUIPMENT:-

a. Utilize proper personal protective equipment

(PPEs)

MIP17 – HSE – PP – 032 REV 0 Page 40 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

b. Wear appropriate PPE such as rubber gloves,

full sleeve coverall, respirator, safety goggle etc.

ENGINEERING CONTROL: -

a. Comply with SA G.I. 6.012 (Isolation, Lockout Construction

and use of Hold Tag), Ensure work related

power sources properly isolated. Use Hot Stick Sinopec PM

a. Electrocution to discharge the electricity after isolation. Sinopec CM

Hazard caused b. Isolation shall be considered complete only Sinopec Supv.

serious electric burn when no associated control device is capable

of energizing the equipment. HSE Manager

injuries or death

c. All necessary isolation and blinding HSE Supv.

b. Danger to existing equipment/devices (locks, tags, properly rated

A/G &U/G facilities blinds, etc.) shall be made ready and inspected HSE officer

c. Defective Electrical before commencing work. Work permit

Tools/Equipment d. Each organization issuing locks shall have a receiver/issuer

All Active Shifting & erection d. Caught in system of uniquely identified locks.

High

13 Electrical Location of existing light between/Personnel 4 4 e. Barricade the work location and deploy

work s pole minor/serious standby man to prevent unauthorized entrants

injures into work location.

Client:

e. Electric Shock / f. Conduct pre-job meeting with all concerned

Electrocution parties to clearly know the role and Abdullah

f. Noise and Vibration responsibilities at all levels. Muhawish

g. Manual Handling g. The type, size and quantity of arc flash PPE Fahad Al-

Hazard and FRC per GI 2.721 shall be provided to

Almokhlies

h. Defective equipment electrical workers by their employer and shall

i. Slip and trip hazards be properly used. Michael labios

h. Grounding for electrical tools and wiring Omar Malki

installations shall be in accordance with SAES- Ali Alaradi

P-111 OE&CG

i. Contractor shall comply with the National Fire

Protection Association, NFPA 70, National

MIP17 – HSE – PP – 032 REV 0 Page 41 of 70

LSTK CONTRACTOR:

COMPANY Branch of Sinopec

Saudi Arabian Oil Company International Petroleum

Services Corp

Project: CONTRACT No# 6600044545

MIP PKG 17 Ras Tanura Area Pipelines BI No. 10-09004-0003

Document title: Four Week Look Ahead Hazard Identification Plan (HIP) Aug - 2023

Electrical Code (NEC), and SA’s electrical

safety requirements.

Administrative Controls:-

a. The responsible persons at site (Supervisor,

Foremen, and Safety Officers) shall be aware

of Emergency Contact Numbers in case of

incident.