Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

105 viewsPaver Blocks Fixing

Paver Blocks Fixing

Uploaded by

Bharathraj RajThis checklist summarizes the steps for fixing paver blocks at a project site. It includes 14 check points to ensure the paver blocks are properly laid out according to approved drawings, the correct materials are used, proper preparation of the sub-base and sand layers is completed, the paver blocks are laid in the right pattern and alignment, cuts are made cleanly where needed, compaction is performed, and joints are filled with sand. The checklist is to be signed off by the sub-contractor, quality engineer, and customer once all steps have been satisfactorily completed.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You might also like

- Final Checklist-SLABDocument2 pagesFinal Checklist-SLABAh Rashed100% (1)

- Doc27 - Checklist For Aluminium WindowsDocument2 pagesDoc27 - Checklist For Aluminium Windowshkshyla89100% (1)

- Surveying & Setting Out ChecklistDocument1 pageSurveying & Setting Out ChecklistBudoy Smith100% (2)

- Plastering ChecklistDocument1 pagePlastering ChecklistBudoy Smith100% (1)

- Quality Checklist For Site Works: External & Partition Wall/ RR MasonryDocument1 pageQuality Checklist For Site Works: External & Partition Wall/ RR MasonryBudoy Smith100% (1)

- Dasarathi Naik and Engineers PVT - Ltd. Check List For ReinforcementDocument1 pageDasarathi Naik and Engineers PVT - Ltd. Check List For ReinforcementTusarranjan BhuyanNo ratings yet

- Pour CardDocument1 pagePour CardJohn DoeNo ratings yet

- Tile Work ChecklistDocument2 pagesTile Work ChecklistMohdali416100% (1)

- Islamic Garden in SpainDocument46 pagesIslamic Garden in SpainJoudi SKNo ratings yet

- Installation of Granite CounterDocument1 pageInstallation of Granite CounterBharathraj RajNo ratings yet

- PlumbingDocument1 pagePlumbingGabriel GabeNo ratings yet

- FRP Gratings FixingDocument1 pageFRP Gratings FixingBharathraj RajNo ratings yet

- Electrical ConduitingDocument1 pageElectrical ConduitingGabriel GabeNo ratings yet

- Sanitary Fixtures Installation & TestingDocument1 pageSanitary Fixtures Installation & TestingGabriel GabeNo ratings yet

- Water Supply ChecklistDocument1 pageWater Supply ChecklistBudoy Smith100% (1)

- Check List For BlockworkDocument2 pagesCheck List For BlockworkVipin Kumar ParasharNo ratings yet

- Check List Handover Rev.0Document1 pageCheck List Handover Rev.0Ali Mari BalochNo ratings yet

- Concrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17Document1 pageConcrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17mahesh naikNo ratings yet

- Check List For Final Coat Painting (External) : Company NameDocument1 pageCheck List For Final Coat Painting (External) : Company NameSayed WafiNo ratings yet

- Quality Control - Works Inspection: Glazed DoorsDocument1 pageQuality Control - Works Inspection: Glazed DoorsParasNo ratings yet

- Checklist For ShutteringDocument4 pagesChecklist For ShutteringMir Masood Shah0% (1)

- 6-Interior (FalseCeiling) QCDocument1 page6-Interior (FalseCeiling) QCConstruction UpdatePHNo ratings yet

- HPS QA ChecklistsDocument24 pagesHPS QA ChecklistsparthNo ratings yet

- Checklist For Tiles FlooringDocument2 pagesChecklist For Tiles FlooringKishoreNo ratings yet

- Brickandblockworkqualitycontrolchecklist 161202070038 PDFDocument2 pagesBrickandblockworkqualitycontrolchecklist 161202070038 PDFLikopo Matiea100% (1)

- Checklist For Gypsum Plaster WorksDocument1 pageChecklist For Gypsum Plaster WorksSantosh YadavNo ratings yet

- QC Checklist For Block WorksDocument1 pageQC Checklist For Block WorksRsjBugtongNo ratings yet

- Check List For Block Brick WorkDocument4 pagesCheck List For Block Brick Workvenugopal mvvNo ratings yet

- Check List For Plastering: Company NameDocument1 pageCheck List For Plastering: Company NameSayed Wafi100% (1)

- IPS Screed ChecklistDocument2 pagesIPS Screed ChecklistArc FortiusNo ratings yet

- Quality Checklist For Site Works: Water ProofingDocument1 pageQuality Checklist For Site Works: Water ProofingLordgie AgtucaNo ratings yet

- Quality Checklist For Site Works: FlooringDocument1 pageQuality Checklist For Site Works: FlooringLordgie AgtucaNo ratings yet

- C4M Dado Wall Tiling Work ChecklistDocument2 pagesC4M Dado Wall Tiling Work ChecklistKishoreNo ratings yet

- Quality Checklist For Site Works: Flooring/ DadoingDocument1 pageQuality Checklist For Site Works: Flooring/ DadoingBudoy Smith100% (2)

- Project Title:: Checklist For Block WorkDocument2 pagesProject Title:: Checklist For Block Workalfie100% (1)

- Checklist For PCCDocument4 pagesChecklist For PCCVishnuhari DevarajNo ratings yet

- Block Work CHK ListDocument1 pageBlock Work CHK Listhafis100% (1)

- C4M Aluminium Sliding WorksDocument1 pageC4M Aluminium Sliding WorksKishoreNo ratings yet

- Check List For ReinforcementDocument1 pageCheck List For Reinforcementmanish100% (3)

- Checklist For Block Work Lay Out: Project: Client: Consultant: Contractor: Trojan & NPC (J.V.)Document1 pageChecklist For Block Work Lay Out: Project: Client: Consultant: Contractor: Trojan & NPC (J.V.)Mani AppaNo ratings yet

- Check List For Floor Screed WorksDocument1 pageCheck List For Floor Screed WorksYash SharmaNo ratings yet

- Quality Checklist For Site WorksDocument2 pagesQuality Checklist For Site WorksLordgie AgtucaNo ratings yet

- Concrete Checklist: Structural and Design CheckDocument8 pagesConcrete Checklist: Structural and Design CheckStephen AgyinNo ratings yet

- Quality Control - Works Inspection: AAC Block WallDocument1 pageQuality Control - Works Inspection: AAC Block WallParas100% (1)

- Checklist - Fire FightingDocument1 pageChecklist - Fire FightingAarnav SinghNo ratings yet

- 3 Checklist For Structural Work (Post-Pour)Document2 pages3 Checklist For Structural Work (Post-Pour)alfieNo ratings yet

- Form 07 (Brick Wall)Document1 pageForm 07 (Brick Wall)HongducBuiNo ratings yet

- Quality Checklist For Site Works: Concrete Pour CardDocument1 pageQuality Checklist For Site Works: Concrete Pour CardLordgie AgtucaNo ratings yet

- ITP-ALU Doors & Windows & Glazing WorksDocument2 pagesITP-ALU Doors & Windows & Glazing WorksYash Sharma100% (1)

- Checklist For External Painting R1Document1 pageChecklist For External Painting R1hkshyla89No ratings yet

- Fire Fighting PipesDocument1 pageFire Fighting PipesMIDHUN RAJNo ratings yet

- Checklist For PlasteringDocument1 pageChecklist For PlasteringGururaj TavildarNo ratings yet

- Checklist For Pre ConcretingDocument4 pagesChecklist For Pre ConcretingIfeanyi IwuallaNo ratings yet

- Inspection ChecklistDocument2 pagesInspection Checklistgilbert cruzNo ratings yet

- Tata Consulting Engineers Limited: Concrete Pour C ArdDocument4 pagesTata Consulting Engineers Limited: Concrete Pour C ArdGuna Sekaran100% (1)

- Checklist For ShutteringDocument2 pagesChecklist For ShutteringPravin Bote50% (2)

- Checklist For Concrete Works: Name of Work: Employer: Contract No.: ContractorDocument1 pageChecklist For Concrete Works: Name of Work: Employer: Contract No.: Contractormallikarjuna ketheNo ratings yet

- Checklist For Anti Termite TreatmentDocument4 pagesChecklist For Anti Termite TreatmentMd.Naimur rahaman juelNo ratings yet

- Installation of Granite CounterDocument1 pageInstallation of Granite CounterGabriel GabeNo ratings yet

- Checklist For Marble Dry Cladding WorkDocument1 pageChecklist For Marble Dry Cladding WorkGabriel GabeNo ratings yet

- ACP Cladding InstallationDocument1 pageACP Cladding InstallationGabriel GabeNo ratings yet

- Community Based SanitationDocument4 pagesCommunity Based SanitationAnwar RosyidNo ratings yet

- Saptec PaperDocument3 pagesSaptec PaperAbdul QadirNo ratings yet

- Shearband SystemDocument5 pagesShearband SystemSameer SawantNo ratings yet

- CPM Rectification Ramp Crack at KPJ Maharani Rev1Document1 pageCPM Rectification Ramp Crack at KPJ Maharani Rev1Matt CerosNo ratings yet

- Heading Data InterfacesDocument9 pagesHeading Data InterfacesArie DinataNo ratings yet

- D Lca 1specsDocument83 pagesD Lca 1specsFaten Hamamah MohamedNo ratings yet

- Form 1.7 CBLM COC 2-LO1Document86 pagesForm 1.7 CBLM COC 2-LO1Jon Snow100% (1)

- Joint DesignDocument44 pagesJoint DesignMuhammad ImranNo ratings yet

- Appointment SRSDocument6 pagesAppointment SRSSonu SharmaNo ratings yet

- Securify Identity LogsDocument4 pagesSecurify Identity Logsyakuptakir9No ratings yet

- P 25Document113 pagesP 25gokedaNo ratings yet

- National Institute of Technology, Silchar: Presentation ON Turnkey ConstructionDocument18 pagesNational Institute of Technology, Silchar: Presentation ON Turnkey ConstructionShashank MishraNo ratings yet

- An Improvement of A Hydraulic Selfclimbing Formwork2019archive of Mechanical EngineeringOpen AccessDocument13 pagesAn Improvement of A Hydraulic Selfclimbing Formwork2019archive of Mechanical EngineeringOpen AccessPatricio Díaz ArbeNo ratings yet

- Peter Eisenman Bibliography PDFDocument24 pagesPeter Eisenman Bibliography PDFNancy Al-AssafNo ratings yet

- Impala and BigQueryDocument47 pagesImpala and BigQuerydurdurkNo ratings yet

- Philips Lighting 1Document45 pagesPhilips Lighting 1Manisankar DhabalNo ratings yet

- 20.0 M Span & 12.00 M Clear Carriageway High Level Bridge Shruti-Layout2Document1 page20.0 M Span & 12.00 M Clear Carriageway High Level Bridge Shruti-Layout2samir bendreNo ratings yet

- Web-Based Real-Time Information Dashboard: Vincent Andersson Martin HesslundDocument64 pagesWeb-Based Real-Time Information Dashboard: Vincent Andersson Martin Hesslundgeldartz fairyNo ratings yet

- Irc Code ListDocument6 pagesIrc Code Listmoondonoo7No ratings yet

- Huawei S5700 Series Switches Tech-Level Main SlidesDocument90 pagesHuawei S5700 Series Switches Tech-Level Main Slidesk2wojciechowskiNo ratings yet

- ACE Hammer CatalogueDocument8 pagesACE Hammer CatalogueAgung NgurahNo ratings yet

- 2 LPS - Part 3 (Edited)Document46 pages2 LPS - Part 3 (Edited)bdaminda6701No ratings yet

- Brick Construction GuideDocument13 pagesBrick Construction Guidecmms88100% (2)

- Avaya Aura Session Manager - Fact SheetDocument8 pagesAvaya Aura Session Manager - Fact SheetaliceiswonderfulNo ratings yet

- M 1 HWDocument68 pagesM 1 HWHamza_yakan967No ratings yet

- Collarjoints Masonry PDFDocument2 pagesCollarjoints Masonry PDFDipin Nediya ParambathNo ratings yet

- Manual P250AF, P265F Gas Powered Burners EnglishDocument46 pagesManual P250AF, P265F Gas Powered Burners EnglishCARLOS RAMOSNo ratings yet

- Microsoft Modern Data EstateDocument48 pagesMicrosoft Modern Data EstateShyam SharmaNo ratings yet

- Nan Mudhalvan Project Report Batch 8Document46 pagesNan Mudhalvan Project Report Batch 8Visa Meena2351No ratings yet

Paver Blocks Fixing

Paver Blocks Fixing

Uploaded by

Bharathraj Raj0 ratings0% found this document useful (0 votes)

105 views1 pageThis checklist summarizes the steps for fixing paver blocks at a project site. It includes 14 check points to ensure the paver blocks are properly laid out according to approved drawings, the correct materials are used, proper preparation of the sub-base and sand layers is completed, the paver blocks are laid in the right pattern and alignment, cuts are made cleanly where needed, compaction is performed, and joints are filled with sand. The checklist is to be signed off by the sub-contractor, quality engineer, and customer once all steps have been satisfactorily completed.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis checklist summarizes the steps for fixing paver blocks at a project site. It includes 14 check points to ensure the paver blocks are properly laid out according to approved drawings, the correct materials are used, proper preparation of the sub-base and sand layers is completed, the paver blocks are laid in the right pattern and alignment, cuts are made cleanly where needed, compaction is performed, and joints are filled with sand. The checklist is to be signed off by the sub-contractor, quality engineer, and customer once all steps have been satisfactorily completed.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

105 views1 pagePaver Blocks Fixing

Paver Blocks Fixing

Uploaded by

Bharathraj RajThis checklist summarizes the steps for fixing paver blocks at a project site. It includes 14 check points to ensure the paver blocks are properly laid out according to approved drawings, the correct materials are used, proper preparation of the sub-base and sand layers is completed, the paver blocks are laid in the right pattern and alignment, cuts are made cleanly where needed, compaction is performed, and joints are filled with sand. The checklist is to be signed off by the sub-contractor, quality engineer, and customer once all steps have been satisfactorily completed.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 1

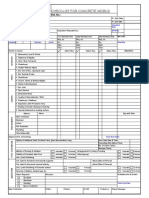

PAVER BLOCKS FIXING Report No:

CHECKLIST Date:

Customer : Project : Project Code:

Sub- Contractor : WO No & Amndt, If any.:

Manufacturer : PO No & Amndt, If any.:

Item Description: Identification No.

Location : Sub Location:

Package: Drg No & Rev No :

FQP No. & Rev No. RFIC No.

Make: Grid No & Level:

Qty:

Checked

Sl.No. Description of Check Points Remarks

Yes No NA

1 Approved layout drawing is available.

2 Method Statement is approved by client

Make, sizes, shapes, colour and shade of paver blocks is

3

approved by client

4 Third party test reports are available as applicable

All required tools like spade, rake, trowel, measuring tape, spirit

5 level, paving mallet, paver block cutting machine, wheel barrow

are available.

6 Interface with utilities drawing is checked before starting of work

7 Soil surface is leveled as per the approved drawing

Spreading, leveling and compaction of sub-base material of

8

minimum 100 mm thick layer or as per drawing is done

9 Spreading & leveling of sand to correct level is done

Laying of paver blocks done from corner or as per approved layout

10

drawing

11 Periodically checked for line & alignment

Masonry saw or splitter tool used to make good & clean cuts in

12

pavers.

Plate compactor used to ensure pavers blocks are snuggly

13

pressed

14 Joints between pavers are filled with fine dry sand.

Remarks :

Signature of Sub - Contractor & Date Signature of TPL-FQE & Date Signature of Customer / Inspection Authority & Date

You might also like

- Final Checklist-SLABDocument2 pagesFinal Checklist-SLABAh Rashed100% (1)

- Doc27 - Checklist For Aluminium WindowsDocument2 pagesDoc27 - Checklist For Aluminium Windowshkshyla89100% (1)

- Surveying & Setting Out ChecklistDocument1 pageSurveying & Setting Out ChecklistBudoy Smith100% (2)

- Plastering ChecklistDocument1 pagePlastering ChecklistBudoy Smith100% (1)

- Quality Checklist For Site Works: External & Partition Wall/ RR MasonryDocument1 pageQuality Checklist For Site Works: External & Partition Wall/ RR MasonryBudoy Smith100% (1)

- Dasarathi Naik and Engineers PVT - Ltd. Check List For ReinforcementDocument1 pageDasarathi Naik and Engineers PVT - Ltd. Check List For ReinforcementTusarranjan BhuyanNo ratings yet

- Pour CardDocument1 pagePour CardJohn DoeNo ratings yet

- Tile Work ChecklistDocument2 pagesTile Work ChecklistMohdali416100% (1)

- Islamic Garden in SpainDocument46 pagesIslamic Garden in SpainJoudi SKNo ratings yet

- Installation of Granite CounterDocument1 pageInstallation of Granite CounterBharathraj RajNo ratings yet

- PlumbingDocument1 pagePlumbingGabriel GabeNo ratings yet

- FRP Gratings FixingDocument1 pageFRP Gratings FixingBharathraj RajNo ratings yet

- Electrical ConduitingDocument1 pageElectrical ConduitingGabriel GabeNo ratings yet

- Sanitary Fixtures Installation & TestingDocument1 pageSanitary Fixtures Installation & TestingGabriel GabeNo ratings yet

- Water Supply ChecklistDocument1 pageWater Supply ChecklistBudoy Smith100% (1)

- Check List For BlockworkDocument2 pagesCheck List For BlockworkVipin Kumar ParasharNo ratings yet

- Check List Handover Rev.0Document1 pageCheck List Handover Rev.0Ali Mari BalochNo ratings yet

- Concrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17Document1 pageConcrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17mahesh naikNo ratings yet

- Check List For Final Coat Painting (External) : Company NameDocument1 pageCheck List For Final Coat Painting (External) : Company NameSayed WafiNo ratings yet

- Quality Control - Works Inspection: Glazed DoorsDocument1 pageQuality Control - Works Inspection: Glazed DoorsParasNo ratings yet

- Checklist For ShutteringDocument4 pagesChecklist For ShutteringMir Masood Shah0% (1)

- 6-Interior (FalseCeiling) QCDocument1 page6-Interior (FalseCeiling) QCConstruction UpdatePHNo ratings yet

- HPS QA ChecklistsDocument24 pagesHPS QA ChecklistsparthNo ratings yet

- Checklist For Tiles FlooringDocument2 pagesChecklist For Tiles FlooringKishoreNo ratings yet

- Brickandblockworkqualitycontrolchecklist 161202070038 PDFDocument2 pagesBrickandblockworkqualitycontrolchecklist 161202070038 PDFLikopo Matiea100% (1)

- Checklist For Gypsum Plaster WorksDocument1 pageChecklist For Gypsum Plaster WorksSantosh YadavNo ratings yet

- QC Checklist For Block WorksDocument1 pageQC Checklist For Block WorksRsjBugtongNo ratings yet

- Check List For Block Brick WorkDocument4 pagesCheck List For Block Brick Workvenugopal mvvNo ratings yet

- Check List For Plastering: Company NameDocument1 pageCheck List For Plastering: Company NameSayed Wafi100% (1)

- IPS Screed ChecklistDocument2 pagesIPS Screed ChecklistArc FortiusNo ratings yet

- Quality Checklist For Site Works: Water ProofingDocument1 pageQuality Checklist For Site Works: Water ProofingLordgie AgtucaNo ratings yet

- Quality Checklist For Site Works: FlooringDocument1 pageQuality Checklist For Site Works: FlooringLordgie AgtucaNo ratings yet

- C4M Dado Wall Tiling Work ChecklistDocument2 pagesC4M Dado Wall Tiling Work ChecklistKishoreNo ratings yet

- Quality Checklist For Site Works: Flooring/ DadoingDocument1 pageQuality Checklist For Site Works: Flooring/ DadoingBudoy Smith100% (2)

- Project Title:: Checklist For Block WorkDocument2 pagesProject Title:: Checklist For Block Workalfie100% (1)

- Checklist For PCCDocument4 pagesChecklist For PCCVishnuhari DevarajNo ratings yet

- Block Work CHK ListDocument1 pageBlock Work CHK Listhafis100% (1)

- C4M Aluminium Sliding WorksDocument1 pageC4M Aluminium Sliding WorksKishoreNo ratings yet

- Check List For ReinforcementDocument1 pageCheck List For Reinforcementmanish100% (3)

- Checklist For Block Work Lay Out: Project: Client: Consultant: Contractor: Trojan & NPC (J.V.)Document1 pageChecklist For Block Work Lay Out: Project: Client: Consultant: Contractor: Trojan & NPC (J.V.)Mani AppaNo ratings yet

- Check List For Floor Screed WorksDocument1 pageCheck List For Floor Screed WorksYash SharmaNo ratings yet

- Quality Checklist For Site WorksDocument2 pagesQuality Checklist For Site WorksLordgie AgtucaNo ratings yet

- Concrete Checklist: Structural and Design CheckDocument8 pagesConcrete Checklist: Structural and Design CheckStephen AgyinNo ratings yet

- Quality Control - Works Inspection: AAC Block WallDocument1 pageQuality Control - Works Inspection: AAC Block WallParas100% (1)

- Checklist - Fire FightingDocument1 pageChecklist - Fire FightingAarnav SinghNo ratings yet

- 3 Checklist For Structural Work (Post-Pour)Document2 pages3 Checklist For Structural Work (Post-Pour)alfieNo ratings yet

- Form 07 (Brick Wall)Document1 pageForm 07 (Brick Wall)HongducBuiNo ratings yet

- Quality Checklist For Site Works: Concrete Pour CardDocument1 pageQuality Checklist For Site Works: Concrete Pour CardLordgie AgtucaNo ratings yet

- ITP-ALU Doors & Windows & Glazing WorksDocument2 pagesITP-ALU Doors & Windows & Glazing WorksYash Sharma100% (1)

- Checklist For External Painting R1Document1 pageChecklist For External Painting R1hkshyla89No ratings yet

- Fire Fighting PipesDocument1 pageFire Fighting PipesMIDHUN RAJNo ratings yet

- Checklist For PlasteringDocument1 pageChecklist For PlasteringGururaj TavildarNo ratings yet

- Checklist For Pre ConcretingDocument4 pagesChecklist For Pre ConcretingIfeanyi IwuallaNo ratings yet

- Inspection ChecklistDocument2 pagesInspection Checklistgilbert cruzNo ratings yet

- Tata Consulting Engineers Limited: Concrete Pour C ArdDocument4 pagesTata Consulting Engineers Limited: Concrete Pour C ArdGuna Sekaran100% (1)

- Checklist For ShutteringDocument2 pagesChecklist For ShutteringPravin Bote50% (2)

- Checklist For Concrete Works: Name of Work: Employer: Contract No.: ContractorDocument1 pageChecklist For Concrete Works: Name of Work: Employer: Contract No.: Contractormallikarjuna ketheNo ratings yet

- Checklist For Anti Termite TreatmentDocument4 pagesChecklist For Anti Termite TreatmentMd.Naimur rahaman juelNo ratings yet

- Installation of Granite CounterDocument1 pageInstallation of Granite CounterGabriel GabeNo ratings yet

- Checklist For Marble Dry Cladding WorkDocument1 pageChecklist For Marble Dry Cladding WorkGabriel GabeNo ratings yet

- ACP Cladding InstallationDocument1 pageACP Cladding InstallationGabriel GabeNo ratings yet

- Community Based SanitationDocument4 pagesCommunity Based SanitationAnwar RosyidNo ratings yet

- Saptec PaperDocument3 pagesSaptec PaperAbdul QadirNo ratings yet

- Shearband SystemDocument5 pagesShearband SystemSameer SawantNo ratings yet

- CPM Rectification Ramp Crack at KPJ Maharani Rev1Document1 pageCPM Rectification Ramp Crack at KPJ Maharani Rev1Matt CerosNo ratings yet

- Heading Data InterfacesDocument9 pagesHeading Data InterfacesArie DinataNo ratings yet

- D Lca 1specsDocument83 pagesD Lca 1specsFaten Hamamah MohamedNo ratings yet

- Form 1.7 CBLM COC 2-LO1Document86 pagesForm 1.7 CBLM COC 2-LO1Jon Snow100% (1)

- Joint DesignDocument44 pagesJoint DesignMuhammad ImranNo ratings yet

- Appointment SRSDocument6 pagesAppointment SRSSonu SharmaNo ratings yet

- Securify Identity LogsDocument4 pagesSecurify Identity Logsyakuptakir9No ratings yet

- P 25Document113 pagesP 25gokedaNo ratings yet

- National Institute of Technology, Silchar: Presentation ON Turnkey ConstructionDocument18 pagesNational Institute of Technology, Silchar: Presentation ON Turnkey ConstructionShashank MishraNo ratings yet

- An Improvement of A Hydraulic Selfclimbing Formwork2019archive of Mechanical EngineeringOpen AccessDocument13 pagesAn Improvement of A Hydraulic Selfclimbing Formwork2019archive of Mechanical EngineeringOpen AccessPatricio Díaz ArbeNo ratings yet

- Peter Eisenman Bibliography PDFDocument24 pagesPeter Eisenman Bibliography PDFNancy Al-AssafNo ratings yet

- Impala and BigQueryDocument47 pagesImpala and BigQuerydurdurkNo ratings yet

- Philips Lighting 1Document45 pagesPhilips Lighting 1Manisankar DhabalNo ratings yet

- 20.0 M Span & 12.00 M Clear Carriageway High Level Bridge Shruti-Layout2Document1 page20.0 M Span & 12.00 M Clear Carriageway High Level Bridge Shruti-Layout2samir bendreNo ratings yet

- Web-Based Real-Time Information Dashboard: Vincent Andersson Martin HesslundDocument64 pagesWeb-Based Real-Time Information Dashboard: Vincent Andersson Martin Hesslundgeldartz fairyNo ratings yet

- Irc Code ListDocument6 pagesIrc Code Listmoondonoo7No ratings yet

- Huawei S5700 Series Switches Tech-Level Main SlidesDocument90 pagesHuawei S5700 Series Switches Tech-Level Main Slidesk2wojciechowskiNo ratings yet

- ACE Hammer CatalogueDocument8 pagesACE Hammer CatalogueAgung NgurahNo ratings yet

- 2 LPS - Part 3 (Edited)Document46 pages2 LPS - Part 3 (Edited)bdaminda6701No ratings yet

- Brick Construction GuideDocument13 pagesBrick Construction Guidecmms88100% (2)

- Avaya Aura Session Manager - Fact SheetDocument8 pagesAvaya Aura Session Manager - Fact SheetaliceiswonderfulNo ratings yet

- M 1 HWDocument68 pagesM 1 HWHamza_yakan967No ratings yet

- Collarjoints Masonry PDFDocument2 pagesCollarjoints Masonry PDFDipin Nediya ParambathNo ratings yet

- Manual P250AF, P265F Gas Powered Burners EnglishDocument46 pagesManual P250AF, P265F Gas Powered Burners EnglishCARLOS RAMOSNo ratings yet

- Microsoft Modern Data EstateDocument48 pagesMicrosoft Modern Data EstateShyam SharmaNo ratings yet

- Nan Mudhalvan Project Report Batch 8Document46 pagesNan Mudhalvan Project Report Batch 8Visa Meena2351No ratings yet