Professional Documents

Culture Documents

CutpointBlog Measuring Mud Lost With Cuttings

CutpointBlog Measuring Mud Lost With Cuttings

Uploaded by

Saeed AraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CutpointBlog Measuring Mud Lost With Cuttings

CutpointBlog Measuring Mud Lost With Cuttings

Uploaded by

Saeed AraCopyright:

Available Formats

Mud to Cuttings Ratio: Measuring Mud Lost with Cuttings Discarded by SCE

Controlling fluid related drilling costs depends on The term “wet cuttings discard” means the

having accurate data about the volume of drilling mixture of dry cuttings and drilling fluid discarded

fluid that “floods over” or is “retained on” or by a shale shaker or other processing equipment.

“piggy backs with” drill cuttings sent to disposal In all cases, the “wet cuttings discard” will be

from solids control process equipment (SCE). The heavier than the mud pumped downhole. This

Mud to Cuttings Ratio (MCR) is based on wet difference in density means a “weight-up

cuttings density. It is also quickest, easiest, and formula” can be used to determine MCR.

most cost-effective way to collect mud loss data. Cutpoint Inc has developed phone apps to

simplify the calculations and the apps are readily

What is Mud to Cuttings Ratio?

available on Android and Apple app stores.

MCR is a ratio that quantifies the volume of

drilling fluid lost when drill cuttings are discarded Only a single field measurement of wet cuttings

by shale shakers. The ratio is determined by density needs to be made to calculate the MCR

measuring the density difference between once a discard sample is collected. This is because

suction pit mud and the wet cuttings discard. The suction pit mud weight is always known. Accurate

test is based on density, but MCR data is reported measurement of the density of wet cuttings is

as a volumetric ratio. best accomplished with an indirect measurement

of cuttings volume. Since most cuttings are not

An MCR of “2:1” means the sample is a mixture liquid enough to be self-leveling, direct volume

of 2 parts mud and 1 part “dry cuttings”. For measurements can be difficult to do accurately. A

example, mixing 28 gallons of drill mud with 14 cuttings volume measurement is best performed

gallons of dry drill cuttings creates a volume of by adding cuttings to a graduated cylinder that

one barrel with an MCR of 2:1. has been partially filled with liquid. The

displacement of the pre-filled liquid enables

cuttings volume to be determined “indirectly”.

28 gallons The Cutpoint MCR Kit™ is designed to simplify

Suction Pit Mud

measurement of cuttings density under field

conditions.

MCR Advantages

The MCR method works equally well for water-

14 gallons

Dry Drill Solids base and oil-base fluids. Compared to retort

methods, MCR data offers significant time and

labor savings. MCR data is more accurate because

a large sample volume is used. An MCR analysis

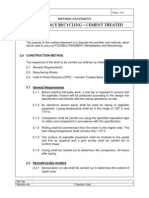

Fig. 1: Oilfield Barrel illustrating MCR of 2:1 takes less than 10 minutes giving solids control

technicians real-time data that can be used to

How is MCR calculated?

optimize equipment and verify cost savings from

The term “dry cuttings” means drill cuttings with

cuttings drying equipment. Additionally, MCR

no drilling fluid in contact with them. Imagine

data can be used to quantify the savings when the

cuttings that have been chipped from the

mud discarded from shale shakers and other

downhole formation while drilling with dry air.

processing equipment is reduced.

CPB22067r0 Copyright 2022 Cutpoint Inc Page 1 of 1

You might also like

- Ebook Ebook PDF Planning Local Economic Development Theory and Practice 6th Edition PDFDocument41 pagesEbook Ebook PDF Planning Local Economic Development Theory and Practice 6th Edition PDFsteven.cornell545100% (41)

- Nelson Physics 11 SolutionsDocument14 pagesNelson Physics 11 SolutionsRhea100% (1)

- BS 1377part4 90 PDFDocument49 pagesBS 1377part4 90 PDFkranthi13100% (2)

- Old Mitsubishi Cars - MMC ManualsDocument25 pagesOld Mitsubishi Cars - MMC ManualsJOVEO MANONGSONG50% (2)

- Method Statement For Cold In-Place Recycling - CementDocument6 pagesMethod Statement For Cold In-Place Recycling - CementNordin Yunus100% (2)

- Kill Sheet Calculation Steps, Formulas & Calculators - Drilling ManualDocument7 pagesKill Sheet Calculation Steps, Formulas & Calculators - Drilling ManualGourav RanaNo ratings yet

- CBR To Cu PDFDocument16 pagesCBR To Cu PDFDaniel AdrianNo ratings yet

- Dynamic Cone Penetrometer (DCP)Document2 pagesDynamic Cone Penetrometer (DCP)Harcana AdriantaraNo ratings yet

- Steven Schick Learning Brian Ferneyhough's Bone Alphabet PDFDocument23 pagesSteven Schick Learning Brian Ferneyhough's Bone Alphabet PDFRokitMan_No ratings yet

- EMERY SJ 1988 The Prediction of Moisture Content in Untreated Pavement Layers CSIR Research Report 644Document109 pagesEMERY SJ 1988 The Prediction of Moisture Content in Untreated Pavement Layers CSIR Research Report 644Karien BesterNo ratings yet

- Cabillarity & Permeability (Lec7)Document11 pagesCabillarity & Permeability (Lec7)ahmed alhajNo ratings yet

- Balu 2Document1 pageBalu 2Vishnu ChNo ratings yet

- Materials and RCC Quality RequirementsDocument27 pagesMaterials and RCC Quality RequirementsMarcelo Galli LopesNo ratings yet

- Cep 224 Lecture 4Document84 pagesCep 224 Lecture 4Ervin Jhon BogaNo ratings yet

- Validation of Nuclear Gauge Density-Meter Readings Against Sand Replacement MethodDocument6 pagesValidation of Nuclear Gauge Density-Meter Readings Against Sand Replacement MethodGerald MaregesiNo ratings yet

- Improve Near-Wellbore Reservoir CharacterizationDocument2 pagesImprove Near-Wellbore Reservoir CharacterizationariosabzNo ratings yet

- CBR Test ManualDocument6 pagesCBR Test ManualmmNo ratings yet

- CBR Test ManualDocument6 pagesCBR Test ManualHarsh HarkhaniNo ratings yet

- Inaccuracies in Draught SurveysDocument6 pagesInaccuracies in Draught SurveysVladimir KuzmichNo ratings yet

- JCB Model 2DX Bucket Capacity 0.32 Dumper Capacity 12 Quantity To Excavate 100 Bank Qty Common Earth Soft Murrum Soft Rock Angle of SwingDocument4 pagesJCB Model 2DX Bucket Capacity 0.32 Dumper Capacity 12 Quantity To Excavate 100 Bank Qty Common Earth Soft Murrum Soft Rock Angle of SwingKeshav VarpeNo ratings yet

- MCQ Quetionaries From HarshalghaseDocument15 pagesMCQ Quetionaries From Harshalghasemezgebu biresawNo ratings yet

- CFD Analysis of Supersonic Flow Through CD Nozzle: ObjectiveDocument1 pageCFD Analysis of Supersonic Flow Through CD Nozzle: ObjectiveChristiano ElondoNo ratings yet

- Offshore Drilling & CompletionDocument19 pagesOffshore Drilling & CompletionmmkhbNo ratings yet

- Mathematical Modeling of Solids-Drilling Fluid Separation in Shale Shakers in Oil Fields - A State of Art ReviewDocument20 pagesMathematical Modeling of Solids-Drilling Fluid Separation in Shale Shakers in Oil Fields - A State of Art ReviewLuiz Augusto Da Cruz MeleiroNo ratings yet

- Analysis of Main Parameters Affecting Substrate Mor 2015 Journal of ColloidDocument8 pagesAnalysis of Main Parameters Affecting Substrate Mor 2015 Journal of ColloidIara CardealNo ratings yet

- Innovations in 3D Concrete Printing Material Development 1706184607Document3 pagesInnovations in 3D Concrete Printing Material Development 1706184607ziphajlNo ratings yet

- CONCRETEDocument26 pagesCONCRETEsweety shresthaNo ratings yet

- Maccagno Spreadsheet ModelIing of Grain Size Evolution During Rod RollingDocument9 pagesMaccagno Spreadsheet ModelIing of Grain Size Evolution During Rod RollingGaurav BhargavaNo ratings yet

- Inter-U 2018 - Case Study - Presentation - DDLSCorp PDFDocument39 pagesInter-U 2018 - Case Study - Presentation - DDLSCorp PDFJM Flores De SilvaNo ratings yet

- Aggregate Crushing Value and Ten Percent Fines ValueDocument3 pagesAggregate Crushing Value and Ten Percent Fines ValueShuvro ChakravortyNo ratings yet

- Hamid2018 Article AssessingTheEffectOfDensityAndDocument10 pagesHamid2018 Article AssessingTheEffectOfDensityAndFrimini Mng'anyaNo ratings yet

- Topic: Standard Proctor Compaction TestDocument11 pagesTopic: Standard Proctor Compaction TestHaider ShahNo ratings yet

- Rotan Presentation 04Document23 pagesRotan Presentation 04Chris JosephNo ratings yet

- Project Report On Tank PrefianlDocument50 pagesProject Report On Tank PrefianlK GIRISH KUMAR100% (3)

- Geotechnical Module #2Document3 pagesGeotechnical Module #2jitlcompanyNo ratings yet

- 10.6. Liquid-Liquid Separation: 10.6.1. Decanters (Settlers)Document6 pages10.6. Liquid-Liquid Separation: 10.6.1. Decanters (Settlers)ashishkapoorsrmNo ratings yet

- Final of Final Draft Corected After Defence 2Document116 pagesFinal of Final Draft Corected After Defence 2getachew asefaNo ratings yet

- Measurement of Overflow Density in Spiral Classifiers Using A Vibrating Fork Densitometer With Accuracy EvaluationDocument8 pagesMeasurement of Overflow Density in Spiral Classifiers Using A Vibrating Fork Densitometer With Accuracy EvaluationClyde SuerteNo ratings yet

- Design of Flexible Pavement by Various MethodDocument3 pagesDesign of Flexible Pavement by Various MethodAmul KotharkarNo ratings yet

- Particle Size Measurement of Cement by Laser Diffraction Using Microtrac S3500Document5 pagesParticle Size Measurement of Cement by Laser Diffraction Using Microtrac S3500kirdipNo ratings yet

- Chapter 4. Shaker Screens: Separation PerformanceDocument10 pagesChapter 4. Shaker Screens: Separation Performancekaleem ullah janNo ratings yet

- BMC Lab ManualDocument112 pagesBMC Lab ManualUaj AvhaNo ratings yet

- SPE/IADC 67818 Tortuosity Versus Micro-Tortuosity - Why Little Things Mean A LotDocument12 pagesSPE/IADC 67818 Tortuosity Versus Micro-Tortuosity - Why Little Things Mean A LotsnnsnnsnnNo ratings yet

- Density Determination of The Water Produced at CenDocument6 pagesDensity Determination of The Water Produced at Cenplascar.vencimentoNo ratings yet

- BS 1377part4 90 PDFDocument49 pagesBS 1377part4 90 PDFADENIYI DAPONo ratings yet

- University of Gondar: Institutes of Technology Department of Civil EngineeringDocument56 pagesUniversity of Gondar: Institutes of Technology Department of Civil EngineeringnahomNo ratings yet

- Grinding and Milling in Cement Manufacturing: 1.2 Fineness RequirementsDocument6 pagesGrinding and Milling in Cement Manufacturing: 1.2 Fineness RequirementsJosé UrdayNo ratings yet

- 2 - Prediction of In-Situ CBR From DCPDocument5 pages2 - Prediction of In-Situ CBR From DCPHugo VilemaNo ratings yet

- MR Scanner BRDocument6 pagesMR Scanner BRlaskireNo ratings yet

- Experimental Study of Micro Ultrasonic Machining ProcessDocument4 pagesExperimental Study of Micro Ultrasonic Machining ProcessPrashantNo ratings yet

- Assignment Sbeq2632 Engineering SurveyDocument5 pagesAssignment Sbeq2632 Engineering Surveysyaira zukiNo ratings yet

- C.5 Reservoir Saturation ToolDocument29 pagesC.5 Reservoir Saturation ToolTamer KoksalanNo ratings yet

- Ehnes Estimation of Design Flows For PDFDocument35 pagesEhnes Estimation of Design Flows For PDFDylan PowellNo ratings yet

- Carbon BrushDocument39 pagesCarbon BrushBrion Bara Indonesia100% (1)

- Calibration of Vessel Tanks With The Use of 3D Laser ScanningDocument2 pagesCalibration of Vessel Tanks With The Use of 3D Laser ScanningshivamNo ratings yet

- Geosphere 360 TT PsDocument1 pageGeosphere 360 TT PsRohith PgNo ratings yet

- Correlation of Drop Size With Shear Tip Speed: September 2012Document7 pagesCorrelation of Drop Size With Shear Tip Speed: September 2012Soufiane El AoumarieNo ratings yet

- CBR Predicted by Index Properties For AlDocument4 pagesCBR Predicted by Index Properties For AlSUNIL JHILMILNo ratings yet

- DensityDocument2 pagesDensityEngineeri TadiyosNo ratings yet

- March 11,2006 MattDocument3 pagesMarch 11,2006 MattStephen John ClementeNo ratings yet

- Clear: Hole Cleaning and Wellbore Risk Reduction ServiceDocument12 pagesClear: Hole Cleaning and Wellbore Risk Reduction ServiceWaleed Barakat MariaNo ratings yet

- Field Moisture and Density Testing With Nuclear GaugeDocument30 pagesField Moisture and Density Testing With Nuclear GaugeAnonymous 59kjvq4OLB100% (1)

- The Ringelmann Effect: Studies of Group Size and Group Performance1Document14 pagesThe Ringelmann Effect: Studies of Group Size and Group Performance1Saeed AraNo ratings yet

- Well AbondonmentDocument10 pagesWell AbondonmentSaeed AraNo ratings yet

- Final Report BodyDocument87 pagesFinal Report BodySaeed AraNo ratings yet

- 1 s2.0 S2666546820300318 MainDocument11 pages1 s2.0 S2666546820300318 MainSaeed AraNo ratings yet

- The Most Accurate Whipstock OrientationDocument2 pagesThe Most Accurate Whipstock OrientationSaeed AraNo ratings yet

- Coil Tubing TelemetryDocument2 pagesCoil Tubing TelemetrySaeed AraNo ratings yet

- Chemical Reactions at HomeDocument20 pagesChemical Reactions at Home201911371No ratings yet

- Fluid Phase Equilibria: Andr Es F. Martínez, Cesar A. Sanchez, Alvaro Orjuela, Gerardo RodríguezDocument9 pagesFluid Phase Equilibria: Andr Es F. Martínez, Cesar A. Sanchez, Alvaro Orjuela, Gerardo RodríguezJuan Camilo Rodriguez SandovalNo ratings yet

- Actinomyces OdontolyticusDocument4 pagesActinomyces OdontolyticusLiviu Athos TamasNo ratings yet

- Therapeutic Exercise: Foundation & Techniques: Resource Person: Dr. Rahat Ayub PT SHS.326.Lec.15Document31 pagesTherapeutic Exercise: Foundation & Techniques: Resource Person: Dr. Rahat Ayub PT SHS.326.Lec.15Fatima YasirNo ratings yet

- C O / C - S,, Y V: /Itdversions/19.3.0.1/Itdstart - Aspx?Svc 3F50C3C0-1874-400E-Af3A-5036E 79Dec9FDocument201 pagesC O / C - S,, Y V: /Itdversions/19.3.0.1/Itdstart - Aspx?Svc 3F50C3C0-1874-400E-Af3A-5036E 79Dec9FharshiniNo ratings yet

- Data Sheets: For Hfc/Hfo/Hcfc Refrigerants Standard and Ecoinside SeriesDocument3 pagesData Sheets: For Hfc/Hfo/Hcfc Refrigerants Standard and Ecoinside Seriessilverblade123192No ratings yet

- Fire-Lite B200SR-LF Data SheetDocument2 pagesFire-Lite B200SR-LF Data SheetJMAC SupplyNo ratings yet

- The Chemistry of CarbohydratesDocument2 pagesThe Chemistry of CarbohydratesANGELA DENISSE AMAT100% (1)

- 1992 - Pavese - Modern Gas-Based Temperature and Pressure Measurements PDFDocument518 pages1992 - Pavese - Modern Gas-Based Temperature and Pressure Measurements PDFAlexanderNo ratings yet

- Unit I and IIDocument46 pagesUnit I and IIYg SonuNo ratings yet

- Industrial Plastics Theory and Applications 6th Edition Lokensgard Test Bank DownloadDocument5 pagesIndustrial Plastics Theory and Applications 6th Edition Lokensgard Test Bank DownloadMary Galindo100% (30)

- JAC - Hfc4da12cDocument104 pagesJAC - Hfc4da12cLaibern JppdNo ratings yet

- Optical Fiber Fabricated From 3D Printed Silica PreformsDocument8 pagesOptical Fiber Fabricated From 3D Printed Silica PreformsMahmudur Rahman RashaNo ratings yet

- 2 Lane Widening With Paved ShouldersDocument147 pages2 Lane Widening With Paved ShouldersyedidiNo ratings yet

- B S T Year 5Document9 pagesB S T Year 5INCREASE & ABUNDANT SCHOOLSNo ratings yet

- TD 2106 4PG BW Oct2015Document4 pagesTD 2106 4PG BW Oct2015Patrick BrilhanteNo ratings yet

- Top-Down Calculus Workbook: Derivatives Intuition PracticeDocument145 pagesTop-Down Calculus Workbook: Derivatives Intuition PracticeAnderson AlfredNo ratings yet

- Archaeology: Spatial Analysis in Archaeology. Ian Hodder and Clive OrtonDocument3 pagesArchaeology: Spatial Analysis in Archaeology. Ian Hodder and Clive OrtonjackNo ratings yet

- Solicitation GardenDocument15 pagesSolicitation GardenRhoy Mamanao DalafuNo ratings yet

- The Heychris DramaDocument14 pagesThe Heychris DramaAnnNo ratings yet

- BeachDocument18 pagesBeachkarem754100% (3)

- Stative: Special Verbs - They Can Be Used As Stative and As DynamicDocument3 pagesStative: Special Verbs - They Can Be Used As Stative and As DynamicAnonymous Q21YDaSfNo ratings yet

- Filmu Nyan2Document61 pagesFilmu Nyan2Nike B. Lavenia BZNo ratings yet

- Hour To Hour Window Shutdown TOX 2018 RevDocument125 pagesHour To Hour Window Shutdown TOX 2018 Revccr gundihNo ratings yet

- ASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFDocument7 pagesASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFJA KNo ratings yet

- Anti Area StudiesDocument15 pagesAnti Area StudiesGeorge GageleaNo ratings yet