Professional Documents

Culture Documents

THK - SHS-R-LR (En - A01 - 100)

THK - SHS-R-LR (En - A01 - 100)

Uploaded by

Miguel tovarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

THK - SHS-R-LR (En - A01 - 100)

THK - SHS-R-LR (En - A01 - 100)

Uploaded by

Miguel tovarCopyright:

Available Formats

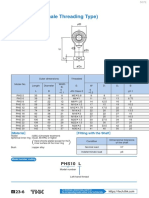

513-1E

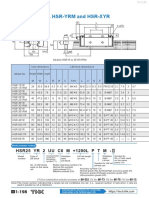

Models SHS-R, SHS-RM, SHS-LR and SHS-LRM

W

4-S×ℓ

B

(K)

M

(H3)

W2 W1

Outer dimensions LM block dimensions Pilot hole for side nipple

Height Width Length

Model No. Grease

nipple

M W L B C S×ℓ L1 T K N E e0 f0 D0

SHS 15R

28 34 64.4 26 26 M4×5 48 5.9 25 9.5 5.5 PB1021B 4 8 3

SHS 15RM

SHS 25R

40 48 92 35 35 M6×8 71 8 34.2 11.5 12 B-M6F 6 9.5 3

SHS 25RM

SHS 25LR

40 48 109 35 50 M6×8 88 8 34.2 11.5 12 B-M6F 6 9.5 3

SHS 25LRM

SHS 30R 106 40 80

45 60 40 M8×10 8 38 11 12 B-M6F 5.8 9 5.2

SHS 30LR 131 60 105

SHS 35R 122 50 93

55 70 50 M8×12 14.7 47.5 15 12 B-M6F 6.5 12.5 5.2

SHS 35LR 152 72 123

SHS 45R 140 60 106

70 86 60 M10×17 14.9 61.1 20.5 16 B-PT1/8 8 18 5.2

SHS 45LR 174 80 140

SHS 55R 171 75 131

80 100 75 M12×18 19.4 67.3 21 16 B-PT1/8 10 18 5.2

SHS 55LR 213 95 173

Model number coding

SHS25 LR 2 QZ KKHH C0 M +1240L P T M -Ⅱ

Model Type of With QZ Contamination Stainless LM rail length (in mm) Stainless steel

number LM block Lubricator protection steel Accuracy symbol (*3) LM rail Symbol for

accessory symbol (*1) LM block Normal grade (No Symbol)

No. of LM blocks Symbol for No. of rails used

used on the same rail Radial clearance symbol (*2) High accuracy grade (H) LM rail on the same

Normal (No symbol) Precision grade (P) jointed use plane (*4)

Light preload (C1) Super precision grade (SP)

Medium preload (C0) Ultra precision grade (UP)

(*1) See contamination protection accessory on A1-516. (*2) See A1-71. (*3) See A1-77. (*4) See A1-13.

Note) This model number indicates that a single-rail unit constitutes one set. (i.e., required number of sets when 2 rails are

used in parallel is 2 at a minimum.)

Those models equipped with QZ Lubricator cannot have a grease nipple. When desiring a grease nipple for a model attached with QZ, contact THK.

Download data by searching for the corresponding

A1-100 model number on the Technical Support site. https://tech.thk.com

513-1E

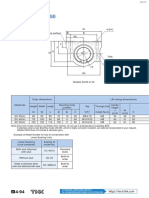

SHS

(E) L

**

4- φ D0

L1 e0

C

φ d2 N f0

LM Guide

h

M1

φ d1

F

Unit: mm

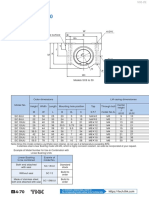

LM rail dimensions Basic load rating Static permissible moment kN•m* Mass

MA MB MC

LM LM

Width Height Pitch Length* C C0

block rail

W1

1 Double 1 Double 1

H3 0 W2 M1 F d1×d2×h Max kN kN kg kg/m

-0.05 block blocks block blocks block

3000

3 15 9.5 13 60 4.5×7.5×5.3 14.2 24.2 0.175 0.898 0.175 0.898 0.16 0.22 1.3

(1240)

3000

5.8 23 12.5 20 60 7×11×9 31.7 52.4 0.566 2.75 0.566 2.75 0.563 0.66 3.2

(2020)

3000

5.8 23 12.5 20 60 7×11×9 36.8 64.7 0.848 3.98 0.848 3.98 0.696 0.8 3.2

(2020)

44.8 66.6 0.786 4.08 0.786 4.08 0.865 1.04

7 28 16 23 80 9×14×12 3000 4.5

54.2 88.8 1.36 6.6 1.36 6.6 1.15 1.36

62.3 96.6 1.38 6.76 1.38 6.76 1.53 1.8

7.5 34 18 26 80 9×14×12 3000 6.2

72.9 127 2.34 10.9 2.34 10.9 2.01 2.34

82.8 126 2.05 10.1 2.05 10.1 2.68 3.24

8.9 45 20.5 32 105 14×20×17 3090 10.4

100 166 3.46 16.3 3.46 16.3 3.53 4.19

128 197 3.96 19.3 3.96 19.3 4.9 5.05

12.7 53 23.5 38 120 16×23×20 3060 14.5

161 259 6.68 31.1 6.68 31.1 6.44 6.57

Note) The maximum length under “Length*” indicates the standard maximum length of an LM rail. (See A1-102.)

Static permissible moment* 1 block: the static permissible moment with one LM block

Double blocks: static permissible moment when two LM blocks are in close contact with each other

Total block length L : The total block length L shown in the table is the length with the dust proof parts, code UU or SS.

If other contamination protection accessories or lubricant equipment are installed, the

total block length will increase.

(See A1-491 or A1-512)

**

A pilot hole for side nipples, when a grease nipple for a model equipped with LaCS or QZ Lubricator is needed.

Pilot holes for side nipples are not drilled through for models other than those stated above.

For grease nipple mount machining, contact THK.

Options⇒A1-477 A1-101

You might also like

- Trio 44x32 Twin FMW Operating ManualDocument33 pagesTrio 44x32 Twin FMW Operating ManualOrlando Melipillan100% (2)

- Pioneer Ts Wx400daDocument12 pagesPioneer Ts Wx400daboroda2410100% (3)

- 51C1 (1H51C450E1) AT115C Nouvo ZDocument54 pages51C1 (1H51C450E1) AT115C Nouvo ZRenNo ratings yet

- DRS PDFDocument460 pagesDRS PDFCao Lan100% (3)

- Models HSR-YR, HSR-YRM and HSR-XYR: Hsr25 Yr 2 Uu C0 M +1200L P T MDocument2 pagesModels HSR-YR, HSR-YRM and HSR-XYR: Hsr25 Yr 2 Uu C0 M +1200L P T MHenryNo ratings yet

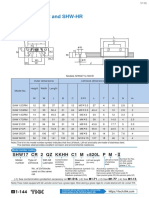

- Models SHW-CR and SHW-HRDocument2 pagesModels SHW-CR and SHW-HRjose DsNo ratings yet

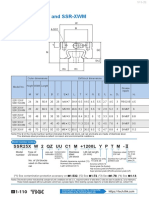

- Models SSR-XW and SSR-XWM: Ssr25X W 2 QZ Uu C1 M +1200L Y P T MDocument2 pagesModels SSR-XW and SSR-XWM: Ssr25X W 2 QZ Uu C1 M +1200L Y P T Mjombo123No ratings yet

- HSR C LC PDFDocument2 pagesHSR C LC PDFLio SnNo ratings yet

- Models HSR-C, HSR-CM, HSR-LC, HSR-LCM, HSR-XC and HSR-XLC: Hsr25 C 2 QZ Uu C0 M +1200L P T MDocument2 pagesModels HSR-C, HSR-CM, HSR-LC, HSR-LCM, HSR-XC and HSR-XLC: Hsr25 C 2 QZ Uu C0 M +1200L P T MVN MÁY TỰ ĐỘNGNo ratings yet

- Models SHS-C and SHS-LCDocument2 pagesModels SHS-C and SHS-LCbennyfergusonNo ratings yet

- GSR-R: LM Guide Separate Type (Radial) Model GSR-RDocument12 pagesGSR-R: LM Guide Separate Type (Radial) Model GSR-RVu Dinh VanNo ratings yet

- Series: Male Connector: KJHDocument9 pagesSeries: Male Connector: KJHSorin IordacheNo ratings yet

- Models SC6 To 30: To Download A Desired Data, Search For The Corresponding Model Number in The Technical SiteDocument2 pagesModels SC6 To 30: To Download A Desired Data, Search For The Corresponding Model Number in The Technical SiteMihai-Sergiu MateiNo ratings yet

- Models HSR-B, HSR-BM, HSR-LB and HSR-LBM: Hsr25 B 2 QZ Uu C0 M +1200L P T MDocument2 pagesModels HSR-B, HSR-BM, HSR-LB and HSR-LBM: Hsr25 B 2 QZ Uu C0 M +1200L P T Msiunatsu8985No ratings yet

- Date:16.07 Project Name: Zelco-SL TYPE - TOWER - 3M LEG EXTENSION Revision. 0Document10 pagesDate:16.07 Project Name: Zelco-SL TYPE - TOWER - 3M LEG EXTENSION Revision. 0alifbaharunNo ratings yet

- PHS Bearing DetailsDocument9 pagesPHS Bearing DetailsNandan DesignNo ratings yet

- Linear Guide Rail 1683713889306 1683768944613Document16 pagesLinear Guide Rail 1683713889306 1683768944613cameronrogNo ratings yet

- Models SHS-C and SHS-LCDocument2 pagesModels SHS-C and SHS-LCCosmin AdrianNo ratings yet

- POS 10 End Bearing DimensionDocument2 pagesPOS 10 End Bearing DimensionherrysugarNo ratings yet

- SFH S: TypesDocument8 pagesSFH S: Typeshoward bitasNo ratings yet

- En A01 184 PDFDocument2 pagesEn A01 184 PDFsiunatsu8985No ratings yet

- PMI Linear Guide MSA-56-57Document2 pagesPMI Linear Guide MSA-56-57Tahar TaharNo ratings yet

- Head ClearancesDocument2 pagesHead ClearancesMohan Rao0% (2)

- THK LM Guide en - A01 - 102Document2 pagesTHK LM Guide en - A01 - 102ajaykrishnaaNo ratings yet

- Models SC35 To 50: To Download A Desired Data, Search For The Corresponding Model Number in The Technical SiteDocument2 pagesModels SC35 To 50: To Download A Desired Data, Search For The Corresponding Model Number in The Technical SiteDonizetti ManutençãoNo ratings yet

- Sprocket Series M0800-En-UsDocument3 pagesSprocket Series M0800-En-UsMounir EchineNo ratings yet

- Poutrelles Américaines Standard: Dimensions: ASTM A6 - 05 Tolérances: ASTM A6 - 05 Inclinaison Des Ailes: 1/6Document4 pagesPoutrelles Américaines Standard: Dimensions: ASTM A6 - 05 Tolérances: ASTM A6 - 05 Inclinaison Des Ailes: 1/6Nazar Abdul KareemNo ratings yet

- Global Standard Type LM Guide Model SHS: Structure and FeaturesDocument16 pagesGlobal Standard Type LM Guide Model SHS: Structure and Featuresmiguel angelNo ratings yet

- Linear Rail SBIDocument28 pagesLinear Rail SBIbách hàNo ratings yet

- WH Me 062008Document1 pageWH Me 062008abdul.shukur4uNo ratings yet

- Taper LockDocument10 pagesTaper LockdjenanNo ratings yet

- Packing List SST 32m Hl-dhj-1Document13 pagesPacking List SST 32m Hl-dhj-1Imam SyarifudinNo ratings yet

- FlowCon SH 50 150 Data Sheet EngDocument8 pagesFlowCon SH 50 150 Data Sheet EngJerry FebriansyahNo ratings yet

- CounterboreDocument3 pagesCounterborejonNo ratings yet

- GSX-S150L8: Parts CatalogueDocument92 pagesGSX-S150L8: Parts Cataloguecash lessNo ratings yet

- B 67 FceecDocument64 pagesB 67 FceecMubashir SubhaniNo ratings yet

- MZ45 MZ45GDocument2 pagesMZ45 MZ45GSalpa AdenugrahaNo ratings yet

- Models HSR-CB, HSR-CBM, HSR-HB and HSR-HBM: Hsr35 CB 2 QZ ZZHH C0 M +1400L P T MDocument2 pagesModels HSR-CB, HSR-CBM, HSR-HB and HSR-HBM: Hsr35 CB 2 QZ ZZHH C0 M +1400L P T Msiunatsu8985No ratings yet

- EOS00684Document1 pageEOS00684VEERAMANINo ratings yet

- Catalogo Dr200sel5 (2014-5 E24)Document72 pagesCatalogo Dr200sel5 (2014-5 E24)Javier Llumpo100% (1)

- TransferSystemTS5v3 0 PDFDocument174 pagesTransferSystemTS5v3 0 PDFAlex DincaNo ratings yet

- Kyocera 1737 Plus Parts ManualDocument37 pagesKyocera 1737 Plus Parts ManualPhạm Công ThứNo ratings yet

- Starline: Pump DimensionsDocument20 pagesStarline: Pump DimensionslilikNo ratings yet

- Catalogo GZ150Document71 pagesCatalogo GZ150Javier LlumpoNo ratings yet

- Directions For Use of Parts Catalogue: 1. Applicable Model of MachinesDocument16 pagesDirections For Use of Parts Catalogue: 1. Applicable Model of MachinesMari Angeles Martinez MelladoNo ratings yet

- Ev FH M678 3403Document1 pageEv FH M678 3403Jose Lopez100% (1)

- LUKAS Compact CylindersDocument5 pagesLUKAS Compact CylindersMilan BanovicNo ratings yet

- 51b2 (1j51b450ea) T115lse Vega Disk)Document54 pages51b2 (1j51b450ea) T115lse Vega Disk)RenNo ratings yet

- Linear Rail Plug DatasheetDocument1 pageLinear Rail Plug DatasheetstephenhNo ratings yet

- Grundfos InstructionDocument22 pagesGrundfos InstructionSajeev NerurkarNo ratings yet

- SJ700B NDocument46 pagesSJ700B NJorjNo ratings yet

- Umeta Grease Fittings ACCORDING TO SAE J-534Document9 pagesUmeta Grease Fittings ACCORDING TO SAE J-534Alan TsaiNo ratings yet

- K01 Type - 40°C +85°C 15000H: ApplicationsDocument11 pagesK01 Type - 40°C +85°C 15000H: ApplicationsBrunophb2012No ratings yet

- K04 TypeDocument6 pagesK04 TypeSami-marika TkNo ratings yet

- gsx250rlm0 p10Document82 pagesgsx250rlm0 p10Fabio NieraNo ratings yet

- Parts Catalog t135hc YamahaDocument65 pagesParts Catalog t135hc YamahaRomi Iswandi100% (1)

- Philippines: 2016/4/8 News No. Date Comment PE0-MC-160025 Apr.,1,2016 COR:FIG.32 FLASHER LIGHT LIST CORRECTIONDocument53 pagesPhilippines: 2016/4/8 News No. Date Comment PE0-MC-160025 Apr.,1,2016 COR:FIG.32 FLASHER LIGHT LIST CORRECTIONLK JoaquinNo ratings yet

- Scorpio-Z 2009-5BP9 (1h5bp460e1)Document64 pagesScorpio-Z 2009-5BP9 (1h5bp460e1)PuncxNo ratings yet

- "L3" Drive End: Operation - Assembly Instructions and Parts List ForDocument7 pages"L3" Drive End: Operation - Assembly Instructions and Parts List ForACCA PumpsNo ratings yet

- Blind Flange-ISO 6164Document1 pageBlind Flange-ISO 6164nemi90No ratings yet

- Hypex - Katalog - 02 - Linear Guides2021-30-37Document8 pagesHypex - Katalog - 02 - Linear Guides2021-30-37Pedro MenaNo ratings yet

- Amalie GreasesDocument2 pagesAmalie GreasesDavid PomaNo ratings yet

- SKF Cage MaterialsDocument2 pagesSKF Cage MaterialsKamolwan WeerachatsakulNo ratings yet

- Lubexpert: User ManualDocument47 pagesLubexpert: User Manualali hamadNo ratings yet

- All Pum 010enDocument24 pagesAll Pum 010encachorrexNo ratings yet

- Piaggio Beverly Cruiser 500 I.E. (EN)Document364 pagesPiaggio Beverly Cruiser 500 I.E. (EN)ManuallesNo ratings yet

- SB6205 Snow Blades - Generic ManualDocument44 pagesSB6205 Snow Blades - Generic ManualEd DugganNo ratings yet

- How To Use This ManualDocument3 pagesHow To Use This ManualjimNo ratings yet

- Single-Line Automatic Lubrication Systems: Product Catalogue 2023Document208 pagesSingle-Line Automatic Lubrication Systems: Product Catalogue 2023ANo ratings yet

- SKF Lgwa-2-Data SheetDocument2 pagesSKF Lgwa-2-Data SheetRahul SharmaNo ratings yet

- Robinson R44 IPC 4/10Document4 pagesRobinson R44 IPC 4/10Sergio Daniel Jimenez RomeroNo ratings yet

- 02 - Manual OI Bomba Peristáltica - DFBa016Document16 pages02 - Manual OI Bomba Peristáltica - DFBa016Andrés RodríguezNo ratings yet

- Cosmo SnaDocument4 pagesCosmo SnaNang DapiNo ratings yet

- PIUSI Brochure Agricoltura Web enDocument32 pagesPIUSI Brochure Agricoltura Web enManuel.suarezgmail ComNo ratings yet

- STRONG-LP 10 SILVER - STRONG - Do You Want To Be Best With Silver - ManualDocument27 pagesSTRONG-LP 10 SILVER - STRONG - Do You Want To Be Best With Silver - Manualapi-3695814No ratings yet

- BCA Clutch BearingsDocument6 pagesBCA Clutch BearingsOscar ValderramaNo ratings yet

- Staburags Nbu 12/300 KP: Long-Term Grease For Rolling and Plain BearingsDocument1 pageStaburags Nbu 12/300 KP: Long-Term Grease For Rolling and Plain BearingsJa AkNo ratings yet

- L565 L566 Series ADocument83 pagesL565 L566 Series AArief Wahyudi100% (1)

- (Gantry Crane) - Operation and Maintenance ManualDocument179 pages(Gantry Crane) - Operation and Maintenance Manualasri elektronikNo ratings yet

- Electric Motor Problems & Diagnostic TechniquesDocument12 pagesElectric Motor Problems & Diagnostic Techniquesjuanca249No ratings yet

- Mobilith SHC Series Performance ProfileDocument2 pagesMobilith SHC Series Performance ProfileAhmed Mohamed HassanNo ratings yet

- Belarus Tractor Operators Manual Be o 5 8 9 SerDocument12 pagesBelarus Tractor Operators Manual Be o 5 8 9 SerJoséNo ratings yet

- 1 Equipment CatalogueDocument66 pages1 Equipment CataloguesupljinaNo ratings yet

- Aeroshell Grease 22: Versatile Multi-Purpose GreaseDocument2 pagesAeroshell Grease 22: Versatile Multi-Purpose GreaseNICKYNo ratings yet

- Catalogo de Retenedores TimkenDocument40 pagesCatalogo de Retenedores TimkenJuan Carlos FuentesNo ratings yet

- Technical Manual MSI Manually Adjustable ChokeDocument27 pagesTechnical Manual MSI Manually Adjustable ChokeralphNo ratings yet

- Instruction Manual Cardan ShaftsDocument4 pagesInstruction Manual Cardan ShaftsMarinkons SrbicicNo ratings yet

- Nissan 2000 Xterra Clutch Service ManualDocument14 pagesNissan 2000 Xterra Clutch Service ManualOnceUponAThingNo ratings yet

- Piaggio MP3 400 I.E. (EN)Document399 pagesPiaggio MP3 400 I.E. (EN)ManuallesNo ratings yet