Professional Documents

Culture Documents

Mud Density Introduction

Mud Density Introduction

Uploaded by

Ahmed SalahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mud Density Introduction

Mud Density Introduction

Uploaded by

Ahmed SalahCopyright:

Available Formats

Introduction

Theory :

The pressure exerted by a static mud column depends on both the

density and the depth. by the equation :

Hp=0.052*ρ*depth

The density of the drilling fluid must be controlled to provide

adequate hydrostatic head to prevent inflow of formation fluids, but

not so high as to cause loss of circulation or adversely affect the

drilling rate and damaging the formation.

The hydrostatic pressure gradient of formation fluids varies from

0,43 psi/ft to over 0.52 psi/ft (0.1 to 0.12 kg/cm2/m), depending on

the salinity of the water.

In order to prevent the inflow of formation fluids and to lay down a

thin, low permeability filter cake on the walls of the hole, the

pressure of the mud column must exceed _the pore pressure_ the

pressure exerted by the fluids in the pores of the formation by at

least 200 psi (14 kg/cm2). The pore pressure depends on the depth

of the porous formation, the density of the formation fluids, and the

geological conditions.

There is two types of geological conditions affect pore pressure:

1) normally pressured formations, which have a self-supporting

structure of solid particles (so the pore pressure depends only on

the weight of the overlying pore fluids) and,

2) abnormally pressured or( geopressured) formations, which are

not fully compacted into a self-supporting structure (so the pore

fluids must bear the weight of some or all of the overlying

sediments as well as the weight of the overlying fluids).

The bulk density of partially compacted sediments increases with

depth, but an average Sp.g of 2.3 is usually accepted, so that the

overburden (or geostatic or litholostatic) pressure gradient is about

1 psi/ft (0.23 kg/cm2/m), and the pore pressure of geopressured

formations is somewhere between the normal and the overburden

pressure gradients, depending on the degree of compaction.

Besides controlling pore fluids, the pressure of the mud column on

the walls of the hole helps maintain borehole stability.

In the interest of well safety, there is a natural tendency to carry a

mud density well above that actually needed to control the

formation fluids, but this policy has several major disadvantages. In

the first place, excessive mud density may increase the pressure on

the borehole walls so much that the hole fails in tension. This failure

is known as induced fracturing.

The problem, is how to maintaining mud density high enough to

control formation fluids, but not so high as to induce a fracture,

becomes acute when normally pressured and

geopressured formations are exposed at the same time.

From mud density test in laboratory we can studying the density, and how

we can control it as the drilling process need

Material gram/ Ib/gal lb/ft3 Ib/bbl kg/m3

Unit cm3

Water 1.0 8.33 62.4 350 1000

Oil 0.8 6.66 50 280 800

Barite 4.3 35.8 268 1500 4300

Clay 2.5 20.8 156 874 2500

Salt 2.2 18.3 137 770 2200

Down hole pressure analysis:-

The hydrostatic pressure is the weight of water from the bottom of the well

to the surface.

Hydrostatic pressure increase with increase mud density, for example

figure1 shown below: -

mud weight Lap Test procedures :-

1- clean the mud balance & let it to dry

2- start with mud balance calibration:-

Fill the mud balance cup with water , close the

cup tightly until water expelled from the hole in the cap

( to free the trapped air ), place the beam on the

support and balance it by moving the rider along the

graduated scale. The beam is horizontal when the

.bubble is on center line. (Calibration point)

3- Read the values at each side of the rider.

4- Empty the cup & repeat step2 but refill the cup with the new

mud

5- Read the values again including calibration.

6- Add 10gm of Barite to the mud.

7- Repeat step4 & step5.

8- add 20 gm of Barite to the mud.

9- Repeat steps 4,5

10- Add 30gm of Barite to the mud

11- Finally Clean all equipments & tools.

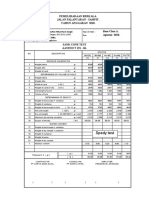

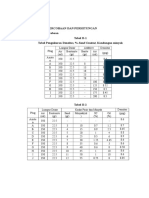

3-Lab test results :-

In this test we run 5 tests to evaluate increase mud density by

adding barite , we use 10gm,20gm,and30gm of barite to increase

mud weight as shown at table 1:-

Table 1,Lap test results:-

Mud type Sp.gr PPG Ib/ft^3 Psi/1000ft

Premix mud 1.02 8.6 64.5 445

Mud+20gm barite 1.065 8.9 66.5 461

Mud+30gm barite 1.09 9.1 67.8 468

Mud+40gm barite 1.1 9.13 68.9 473

psi/1000ft

473 475

468 470

465

461 460

pressure gradiant

455

450

445 445

440

435

430

mud + mud + baraite mud + baraite premix mud

baraite40gm 30gm 20gm

Axis Title

PPG

9.2

9.1

9

8.9

8.8

8.7

9.13 9.1 8.6

8.9 8.5

8.6 8.4

8.3

mud + mud + baraite mud + baraite premix mud

baraite40gm 30gm 20gm

lb/ft^3

69

68

67

66

65

64

63

62

mud + mud + baraite mud + baraite premix mud

baraite40gm 30gm 20gm

Types of mud weighting Materials

Description:

The Mud Balance as shown below is used to determine density of

the drilling fluid. The instrument consists of a constant volume cup

with a lever arm and rider calibrated to read directly the density of

the fluid in ppg (water 8.33), pcf (water 62.4), specific gravity

(water = 1.0) and pressure gradient in psi/1000 ft. (water 433

psi/1000 ft.)

Calculation

Q1#

W1=9.5 ppg

W2=12 ppg

1490(w 2−w 1)

X= ( 35.5−w 2) x= 158.5 pound

158.5∗50 3602.2

X= 2.20 x=3602.2 kg x= 1000

=3.60tons

Q2#

W1=8.5 ppg

W2=11 ppg

1490(w 2−w 1)

X= ( 35.5−w 2) x=152.04 pounds

152.04∗50 3455.47

x= 2.20 x=3455.47kg x= 1000

=3.45tons

You might also like

- The PATHFINDER Training ProgramDocument5 pagesThe PATHFINDER Training ProgramLyell E. Petersen100% (1)

- Max Lifting Height 16.35mDocument4 pagesMax Lifting Height 16.35mJan HendriksNo ratings yet

- Effect of Barite On Density of Drilling MudDocument3 pagesEffect of Barite On Density of Drilling MudAtif MalikNo ratings yet

- Thermapac: Steam-Resistant GravelDocument4 pagesThermapac: Steam-Resistant Gravelatilio martinezNo ratings yet

- Dragline Range 8200Document2 pagesDragline Range 8200IonNo ratings yet

- Experiment Ii Examination of Cements Suspension RheologyDocument7 pagesExperiment Ii Examination of Cements Suspension RheologyronaldsdqNo ratings yet

- Sand Content in MudDocument10 pagesSand Content in MudAhmed SalahNo ratings yet

- PAL3915FCDocument66 pagesPAL3915FCmarco.ivaniNo ratings yet

- Gear Pump For Polymer ProcessingDocument6 pagesGear Pump For Polymer ProcessingRodolfo Manuel Alarcón TroncosoNo ratings yet

- Pump Calculation - Rev 0Document6 pagesPump Calculation - Rev 0m khaeron100% (1)

- SAND CONTENTabdoDocument8 pagesSAND CONTENTabdoTaha ShalabiNo ratings yet

- Procedure For Formate Base MudDocument5 pagesProcedure For Formate Base MudVikas kumar singhNo ratings yet

- CBR Laboratorium PB - 0113 - 76 AASHTO T - 193 - 74Document2 pagesCBR Laboratorium PB - 0113 - 76 AASHTO T - 193 - 74Gung SuryaNo ratings yet

- Ocean Container DimensionsDocument3 pagesOcean Container DimensionsicyNo ratings yet

- Brosur Savior ABCDocument2 pagesBrosur Savior ABCRizky RahmanNo ratings yet

- Item DIM QTYDocument5 pagesItem DIM QTYZeleke TaimuNo ratings yet

- Reservoir EngineeringDocument13 pagesReservoir EngineeringFaridz HimawanNo ratings yet

- 9 5/8'' 7/8 M/L 4.8 Stage (HEMIDRIL) : A B C D EDocument1 page9 5/8'' 7/8 M/L 4.8 Stage (HEMIDRIL) : A B C D EfinNo ratings yet

- Concrete Trial Mix: Jabbar Al Ahmad Causeway Project MPW Hyundai E &CDocument2 pagesConcrete Trial Mix: Jabbar Al Ahmad Causeway Project MPW Hyundai E &Craja qammarNo ratings yet

- SlabDocument96 pagesSlabSHEK VEN TEONo ratings yet

- Light Dripline With Continuous Labyrinth With Inlet Continuous Double FilterDocument2 pagesLight Dripline With Continuous Labyrinth With Inlet Continuous Double FilterDaniel Alejandro GuerreroNo ratings yet

- 313F L GC: Hydraulic ExcavatorDocument10 pages313F L GC: Hydraulic ExcavatorAntónio Pedro TavaresNo ratings yet

- HiDocument7 pagesHiCarjez LoveNo ratings yet

- Thermo-Dynamic Steam Trap TD52, TDS52Document2 pagesThermo-Dynamic Steam Trap TD52, TDS52member1000No ratings yet

- Experiment 2Document17 pagesExperiment 2Anusha AnuNo ratings yet

- PAL1318 BisDocument32 pagesPAL1318 Bismarco.ivaniNo ratings yet

- Swell Packer UpdateDocument26 pagesSwell Packer UpdateLinNo ratings yet

- 93 .SG, CBR, MDD, PI, SP - GRDocument11 pages93 .SG, CBR, MDD, PI, SP - GRChandra Prakash KarkiNo ratings yet

- Instruction Manual Api Mud BalanceDocument6 pagesInstruction Manual Api Mud BalanceSherif MohammedNo ratings yet

- Specifications Guide Electric Range ENDocument2 pagesSpecifications Guide Electric Range ENmanoNo ratings yet

- Settling Plug Mixing ProcedureDocument8 pagesSettling Plug Mixing ProcedureKamel TouahriaNo ratings yet

- Max Lifting Height 12.52mDocument4 pagesMax Lifting Height 12.52mEUROPARTSNo ratings yet

- Ashirvad - HDPEDocument4 pagesAshirvad - HDPERathan Gadiya Rathan GadiyaNo ratings yet

- Carbon Dioxide Co2 Fire ExtinguisherDocument1 pageCarbon Dioxide Co2 Fire ExtinguisherBinod KumarNo ratings yet

- Piping BOM - GI PipeDocument3 pagesPiping BOM - GI PipeIshwar AltNo ratings yet

- Data Sheet: Karrasch & Eckert Karrasch & Eckert Karrasch & Eckert Karrasch & EckertDocument1 pageData Sheet: Karrasch & Eckert Karrasch & Eckert Karrasch & Eckert Karrasch & EckertTS WongNo ratings yet

- Amstrong Auto DrainDocument2 pagesAmstrong Auto Drainbudi utomoNo ratings yet

- Drilling Report DENSITY CONTROL ADDITIVES AND SOLID CONTROLDocument14 pagesDrilling Report DENSITY CONTROL ADDITIVES AND SOLID CONTROLsarah alsNo ratings yet

- PETE 4059 Fall 2012 - IncompleteDocument7 pagesPETE 4059 Fall 2012 - IncompleteMuStafaAbbasNo ratings yet

- RheologyDocument10 pagesRheologyTaha ShalabiNo ratings yet

- Front End LoadersDocument18 pagesFront End LoadersDiegoNo ratings yet

- Algas-SDI H Series 160-800Document2 pagesAlgas-SDI H Series 160-800ALEX CRISTOBALNo ratings yet

- Pemeliharaan Berkala. Jalan Palantaran - Sampit. Tahun Anggaran 2010Document25 pagesPemeliharaan Berkala. Jalan Palantaran - Sampit. Tahun Anggaran 2010harry apriyantoNo ratings yet

- Test Report Sieve Analysis of Extracted Mineral Aggregates (ASTM D5444 & C136 / AASHTO T 27)Document6 pagesTest Report Sieve Analysis of Extracted Mineral Aggregates (ASTM D5444 & C136 / AASHTO T 27)Shafiqullah GowharyNo ratings yet

- Project - 011Document26 pagesProject - 011nileshmakwana8176No ratings yet

- Item No. Description QTY Unit: A. EarthworksDocument25 pagesItem No. Description QTY Unit: A. EarthworksJeorge Michael FortoNo ratings yet

- Dry Powder Extinguisher APRDDocument1 pageDry Powder Extinguisher APRDAltayyeb AlfaryjatNo ratings yet

- Vapour HoseDocument2 pagesVapour HoseMEHDINo ratings yet

- ABC & Co2 MS Standard - SRI - Fire ExtinguisherDocument1 pageABC & Co2 MS Standard - SRI - Fire ExtinguisherEve MdhrNo ratings yet

- Abc Dry Chemical Fire ExtinguisherDocument1 pageAbc Dry Chemical Fire ExtinguisherMohammed RayanNo ratings yet

- CAT Primary PulveriserDocument2 pagesCAT Primary PulverisertwrwtrtrNo ratings yet

- Lab Manual Polytechnic Sul 2022Document32 pagesLab Manual Polytechnic Sul 2022AramNo ratings yet

- BXR SeriesDocument2 pagesBXR Seriesaaron mufukNo ratings yet

- Alfa Laval GJ 4 - Product Leaflet - Ese03004 PDFDocument5 pagesAlfa Laval GJ 4 - Product Leaflet - Ese03004 PDFVils ArabadzhievaNo ratings yet

- Mud ThinnerDocument12 pagesMud Thinnerabdilrhman sulimanNo ratings yet

- Compressive Strength: Date Client Site Grade Plant Code Slump 1-d 3-d 7-d 28-dDocument9 pagesCompressive Strength: Date Client Site Grade Plant Code Slump 1-d 3-d 7-d 28-dQuality ControlNo ratings yet

- K A B L C D: Linear Measure Area Measure Volume Measure Weight Energy - Work PressureDocument1 pageK A B L C D: Linear Measure Area Measure Volume Measure Weight Energy - Work Pressurejose amorimNo ratings yet

- Bab 2 FinalDocument7 pagesBab 2 FinalDhika PradanaNo ratings yet

- Rectangular BeamsDocument1 pageRectangular BeamsMarcus SouzaNo ratings yet

- Mech PDFDocument9 pagesMech PDFgurusamyNo ratings yet

- Pradeep Kumar Singh: Mob - No.+91-9350532171Document2 pagesPradeep Kumar Singh: Mob - No.+91-9350532171Puspendra Singh YadavNo ratings yet

- 1-MEPs-ELECT-LTG-B4&7-0001 (SH 1-1) - R-2 (FND Reviewed) - LTG-B4-0001Document1 page1-MEPs-ELECT-LTG-B4&7-0001 (SH 1-1) - R-2 (FND Reviewed) - LTG-B4-0001muzeek306No ratings yet

- WWI 29th Infantry DivisionDocument89 pagesWWI 29th Infantry DivisionCAP History LibraryNo ratings yet

- Cross FluteDocument6 pagesCross FluteAvicena AlbiruniNo ratings yet

- River VolgaDocument11 pagesRiver Volgaapi-317411236No ratings yet

- DILO SF6 Catalogue 2021 ENDocument214 pagesDILO SF6 Catalogue 2021 ENBadraa BatorgilNo ratings yet

- Selection Circuit: Current Sources: Elektronika 1 Pak SuryaDocument13 pagesSelection Circuit: Current Sources: Elektronika 1 Pak SuryaAfif JuniharNo ratings yet

- Operating Instructions Mechanical Temperature Switches ML1H, MT1H, L2H, T2H, L1X/L1X-EX, T1X/T1X-EX, T2X/T2X-EXDocument8 pagesOperating Instructions Mechanical Temperature Switches ML1H, MT1H, L2H, T2H, L1X/L1X-EX, T1X/T1X-EX, T2X/T2X-EXمحمد فرحاتNo ratings yet

- Industrialised Building SystemDocument20 pagesIndustrialised Building SystemreenaNo ratings yet

- An Outline of The Life and Works of Col Paul Revere (1901)Document164 pagesAn Outline of The Life and Works of Col Paul Revere (1901)liketoreadNo ratings yet

- Veeam Top 10 Reasons Choose Veeam 9 5Document2 pagesVeeam Top 10 Reasons Choose Veeam 9 5Anonymous xKgV3e6XLNo ratings yet

- About The MasnaviDocument23 pagesAbout The MasnaviDr. Mustafa Yasin BaşçetinNo ratings yet

- Final Report of LPG Gas StoveDocument69 pagesFinal Report of LPG Gas StoveUdit SharmaNo ratings yet

- Welcoming The VighnahartaDocument2 pagesWelcoming The VighnahartaDeepa HNo ratings yet

- Waste Collectors in Sri LankaDocument32 pagesWaste Collectors in Sri Lankasameera jayalathNo ratings yet

- Shining The Light I ... by Robert Shapiro Tom... (Z-Lib - orDocument1,016 pagesShining The Light I ... by Robert Shapiro Tom... (Z-Lib - orbatiyeNo ratings yet

- Hydroscand Catalogue PDFDocument382 pagesHydroscand Catalogue PDFemaus100% (1)

- Meth QuPPe PO V11 PDFDocument86 pagesMeth QuPPe PO V11 PDFDasharath OulkarNo ratings yet

- How To Grow Tomatoes: Cold Spring Harbor Protocols November 2008Document19 pagesHow To Grow Tomatoes: Cold Spring Harbor Protocols November 2008SethNo ratings yet

- Royal Enfield Price ListDocument126 pagesRoyal Enfield Price Listmaniamson50% (20)

- PumpsDocument27 pagesPumpsumar100% (2)

- Question Pack 1 - UnlockedDocument18 pagesQuestion Pack 1 - UnlockedShadowneek123No ratings yet

- Energy Utilization and Audit: Chemical Engineering Dept. Wolkite UniversityDocument14 pagesEnergy Utilization and Audit: Chemical Engineering Dept. Wolkite UniversityGetasew TesfaNo ratings yet

- Hampton Inn 5.20 2021 Public PacketDocument49 pagesHampton Inn 5.20 2021 Public PacketArielle BreenNo ratings yet

- Module 4: Short Questions: K G X T T TDocument2 pagesModule 4: Short Questions: K G X T T TRohan KulkarniNo ratings yet

- Turbine Presentation, NGDocument46 pagesTurbine Presentation, NGNitesh GargNo ratings yet

- Scientific ResearchDocument136 pagesScientific ResearchTEWODROS ASFAWNo ratings yet

- Greyhound Free Patt.Document14 pagesGreyhound Free Patt.claire_garland100% (2)